MARKET OVERVIEW

The Global Wet Wire Drawing Lubricants market represents the specialty segment of the industry dealing with industrial lubricants that work specifically to optimize the process of wet wire drawing. Wet wire drawing is used widely in manufacturing, when drawing metal wires. At that time, a lubricant is used to minimize the friction, regulate heat creation, and enhance the surface finish as part of the drawing. It services various industries such as automotive, construction, and telecommunications and electronics industries which use wires made from the materials steel, copper, and aluminum. This is a market that develops supply of advanced lubricants meeting the specific needs for overcoming difficulties in wet wire drawing.

Such lubricants are used as emulsions, oils, or even as a synthetic solution which engineers specifically to increase production rate and tooling life and even deliver wires of uniform quality; some factors affecting them would include viscosity, stability over the thermal range and suitability in various wire stocks. Companies in this industry continue to innovate to meet the exacting demands of modern manufacturing processes while addressing environmental issues by developing biodegradable and non-toxic lubricants. The Global Wet Wire Drawing Lubricants market is extensive in terms of stakeholders who will include lubricant producers, wire drawing machinery vendors, and end-users coming from various industries.

Manufacturers are investing heavily in research and development to design products that align with industry trends, including the need for higher-speed production, precision engineering, and reduced operational costs. Regional variations in demand, shaped by industrialization levels and wire consumption patterns, also influence the dynamics of this market. For example, regions with robust automotive and electronics sectors tend to generate higher demand for these specialized lubricants. The Global Wet Wire Drawing Lubricants market will grow with technological advancements in wire drawing machinery and industry requirements. Manufacturers will be forced to produce lubricants that can function under stricter conditions due to the increasing adoption of automation and smart monitoring systems in the manufacturing process. Sustainability will also remain a key aspect, and the pressure to develop green formulations will continue to build, adhering to the regulatory standards without compromising on performance.

Globalization and trade dynamics also shape this market. The interdependence of automotive and telecommunication industries fosters global wire material exchanges, thereby influencing lubricant demand across regions. On the other hand, rivalry among manufacturers encourages innovation, because companies are competing to find a niche in terms of quality and cost efficiency.

The technical aspect is complemented by collaborations and partnerships that underpin the market’s functioning. Suppliers and manufacturers often closely work with end-users in developing customized solutions tailored to specific production needs. The trajectory of the Global Wet Wire Drawing Lubricants market will be determined by such relationships, ensuring that it stays relevant in a competitive industrial landscape.

The global wet wire drawing lubricants market is a dynamic, vital sector to the metal wire-dependent industries. Advances in technology, sustainability practices, and constant pursuit for efficiency and reliability in performing wire drawing operations will feature its development. This will be an important part of industrial manufacturing and will serve as a response to customers’ evolving needs.

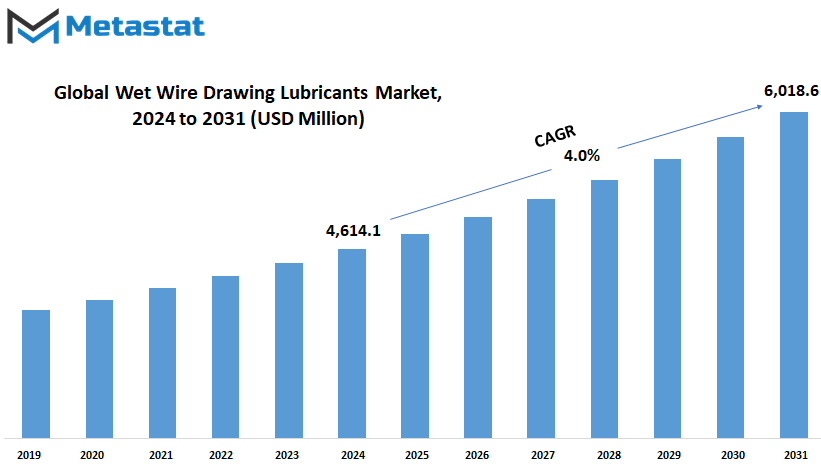

Global Wet Wire Drawing Lubricants market is estimated to reach $6,018.6 Million by 2031; growing at a CAGR of 4.0% from 2024 to 2031.

GROWTH FACTORS

The Global Wet Wire Drawing Lubricants Market is likely to face changes and opportunities in the near future through shifting demands and advancements. This market plays a significant role in industries such as automotive, construction, and electronics, which require high-quality drawn wire. The growing demand for high-quality wires has spurred innovations in lubricant formulations, which play a crucial role in optimizing wire drawing efficiency and, ultimately, product quality. These innovations not only streamline production processes but also meet the stringent requirements of industries that seek precision and durability in their products.

The most significant growth factor in this market is the growing demand for high-performance wires withstanding heavy industrial use. The demand is especially critical in the automotive industry where high-strength wires play a vital role in ensuring safety and functionality. For the construction industry, they ensure structural stability, while for the electronics industry, they form intricate and reliable electrical connections. The high standards are met by optimized wet wire drawing lubricants ensuring that the wires produced do not have friction, but are smooth and have very minimal breakage during drawing.

On the other hand, there are some limitations in the growth of the global wet wire drawing lubricants market. Strict environmental regulations that limit the use of some chemicals, which were formerly used in lubricant formulation, can be seen. These regulations aim to decrease ecological damage but tend to make the development of compliant lubricants more complicated and expensive. Maintenance costs related to lubricant systems in industrial settings also might scare smaller businesses away from the use of advanced technologies. Such factors may slow down growth in specific market segments.

The future of the market appears to be promising due to increasing attention towards sustainability. Eco-friendly, biodegradable lubricants are a potential new area of solutions, ensuring all environmental considerations are kept within the solution without affecting, or in many cases enhancing, performance. Increased new opportunities for these environmentally friendly options should be anticipated as businesses commit to international sustainability agreements. Companies with a strategic R&D commitment to producing lubricants should expect this as a potential source of future competitive advantage and as part of further market innovations.

The global wet wire drawing lubricants market will evolve in a future where efficiency and quality meet environmental concerns. With sustainability in mind, this market will unlock new growth channels and remain crucial to world-wide critical industries.

MARKET SEGMENTATION

By Type

Wet wire drawing lubricants are an essential part of the global wet wire drawing lubricants market that is going to witness massive changes in the near future. The industries worldwide are increasingly focusing on the efficient process of manufacturing, and lubricants play a crucial role in improving the quality of wire drawing operations by minimizing friction, smooth surface finish, and long equipment life. The lubricant market includes calcium-based, sodium-based, polymer-based, synthetic, and hybrid lubricants. As industrial practices are transformed by technological advancements and sustainability considerations, the market for these lubricants is expected to grow as demand increases from sectors such as construction, automotive, and electronics.

Calcium-based lubricants will be in demand because they possess excellent thermal stability and provide high-pressure performance. Such lubricants are particularly required in drawing processes that call for heavy-duty performance. Sodium-based lubricants can be beneficial in terms of water solubility and cost-effectiveness. For specific applications, these lubricants have been preferred due to these advantages. These types have been used for a long time by industries as their dependable alternatives, but growing trends indicate that innovative products will be more widely accepted.

Polymer-based lubricants are at a more advanced stage of solutions and are specially used in high-precision wire drawing operations where uniformity is essential and there is significant wear. Growing focus on lightweight and strong materials, especially in automobile and aircraft industries, may create future opportunities for the adoption of polymer-based lubricants. Synthetic lubricants with good chemical stability and a smaller environment footprint are well suited with current global efforts at green manufacturing. These lubricants are increasingly preferred in eco-friendly solutions without compromising efficiency. Hybrid lubricants combine multiple benefits of various formulations with more flexibility and enhanced performance. Their ability to adjust with diverse operational needs gives it a promising choice for the future advancements in the Global Wet Wire Drawing Lubricants market.

Future developments in lubricant technologies are likely to overcome challenges such as rising environmental regulations and demands for energy efficiency. Manufacturers are expected to invest in research and development to create formulations that improve productivity but meet ecological standards. Moreover, automation in wire drawing processes will further influence the choice and application of lubricants.

Overall, the market for Global Wet Wire Drawing Lubricants is promising steady growth as industries keep up with technological progress and evolving requirements. Tailor-made, sustainable lubricant development will probably continue, hence shaping the future environment into one that offers the promise of both economic and environmental benefits.

By Application

The Global Wet Wire Drawing Lubricants market is expected to experience considerable changes in the near future as industries continue to embrace advanced technologies to improve efficiency and reduce operational costs. These lubricants play a critical role in wire drawing processes by minimizing friction, enhancing tool life, and ensuring the smooth production of wires. They are especially designed for wet wire drawing, where a lubrication system directly meets with the wires to not break them and ensure excellent quality. With an expansion in industrial base, its demand will be steadily raised.

The market can further be bifurcated in two main applications, namely ferrous wire drawing and non-ferrous wire drawing. Ferrous wire drawing involves products made from iron-based materials, such as steel, most commonly used in constructional, automotive, and manufacture industries. Because of a need for more precision or durability in such industries, the demand for a lubrication that will be able to ensure the manufacturing of really strong, high-quality wires boosts. Non-ferrous wire drawing is about all metal, such as copper and aluminum, alloys, primarily used in electrical and electronic industries. Increased use of renewable energy technologies and electric vehicles is likely to boost demand for non-ferrous wires, thereby indirectly fueling the requirement for specialized lubricants.

Future trends in the Global Wet Wire Drawing Lubricants market will be impressive, with newer product developments focused on improving formulations towards the changing demands of industry. Manufacturers have been seen to focus more on ecologically friendly and biodegradable lubricants. This type not only ensures compliance with environmental legislations but also attracts organizations, which are highly concerned with sustainable practices. Synthetic lubricants and hybrid lubricants have also made their entrance with improved performance, applicable for high-speed and highly stressed wire drawing applications.

Technological integration is another factor that might influence this market. The addition of smart monitoring systems in order to optimize the use of lubricants can have a great cost-saving potential for industries, which makes them opt for advanced products. In addition, with fast-paced global infrastructure projects and technological development, the demand for high-performance wires is also expected to rise, further emphasizing the importance of wet wire drawing lubricants.

The Global Wet Wire Drawing Lubricants market stands to benefit from industrial improvements, sustainable trends, and the increased demand for better quality wires in various application areas. This dynamic sector will dictate the future direction of wire production in sectors across the globe.

By End-Use

The Global Wet Wire Drawing Lubricants market has a significant position in the support of multiple industries in terms of its efficiency and precision in performing wire drawing processes. Demand for such lubricants in industries will continue to increase as these industries grow in size and adapt to change with the times. These special lubricants are necessary for friction and heat reduction in the wire drawing process, which eventually results in higher quality of products, longer tool life, and improved operational performance. The needs of several end-use industries directly affect this market, shaping its growth and innovation path.

The automotive industry is among the major contributors to the growth of the Global Wet Wire Drawing Lubricants market. The need for excellent wires and cables grows dramatically with increasingly electric vehicles and technologically advanced automobiles. These lubricants ensure that wiring systems of high durability and reliability come out in mass production and are vital to the processes of modern automotive manufacturing. Moreover, further innovations of this segment can be estimated with the rising trend in smart vehicle systems and movement toward sustainability.

The importance of wet wire drawing lubricants lies in the production of structural components and wiring used for residential, commercial, and infrastructure projects in the construction sector. With global trends in urbanization accelerating at a rapid pace, there is an increased demand by the construction industry for more robust and efficient wire production. These lubricants have to do with the creation of materials that meet the highest standards required for safety and durability.

The electrical and electronics industry also strongly supports the Global Wet Wire Drawing Lubricants market in producing finer, complex components that constitute its appliances and machinery. Continued developments in technology demand highly integrated, high-performing electronic devices, making wet wire drawing lubricant demands a significant contributor. Of equal importance is the way telecommunication companies greatly help sustain the growth in expansion and development of Internet usage and data transfer operations around the world.

These lubricants are in demand due to the specific needs of industrial manufacturing and aerospace for precision wires in machinery, tools, and advanced engineering solutions. The increasing complexity of manufacturing processes and the push for lightweight, high-performance materials in aerospace applications make wet wire drawing lubricants critical.

In the future, the Global Wet Wire Drawing Lubricants market is poised to grow further, supported by advancements in materials and sustainable practices. With industries increasingly seeking eco-friendly solutions, the market is expected to adapt and innovate, ensuring its continued relevance in global manufacturing.

By Distribution Channel

The Global Wet Wire Drawing Lubricants market has a significant position in the support of multiple industries in terms of its efficiency and precision in performing wire drawing processes. Demand for such lubricants in industries will continue to increase as these industries grow in size and adapt to change with the times. These special lubricants are necessary for friction and heat reduction in the wire drawing process, which eventually results in higher quality of products, longer tool life, and improved operational performance. The needs of several end-use industries directly affect this market, shaping its growth and innovation path.

The automotive industry is among the major contributors to the growth of the Global Wet Wire Drawing Lubricants market. The need for excellent wires and cables grows dramatically with increasingly electric vehicles and technologically advanced automobiles. These lubricants ensure that wiring systems of high durability and reliability come out in mass production and are vital to the processes of modern automotive manufacturing. Moreover, further innovations of this segment can be estimated with the rising trend in smart vehicle systems and movement toward sustainability.

The importance of wet wire drawing lubricants lies in the production of structural components and wiring used for residential, commercial, and infrastructure projects in the construction sector. With global trends in urbanization accelerating at a rapid pace, there is an increased demand by the construction industry for more robust and efficient wire production. These lubricants have to do with the creation of materials that meet the highest standards required for safety and durability.

The electrical and electronics industry also strongly supports the Global Wet Wire Drawing Lubricants market in producing finer, complex components that constitute its appliances and machinery. Continued developments in technology demand highly integrated, high-performing electronic devices, making wet wire drawing lubricant demands a significant contributor. Of equal importance is the way telecommunication companies greatly help sustain the growth in expansion and development of Internet usage and data transfer operations around the world.

These lubricants are in demand due to the specific needs of industrial manufacturing and aerospace for precision wires in machinery, tools, and advanced engineering solutions. The increasing complexity of manufacturing processes and the push for lightweight, high-performance materials in aerospace applications make wet wire drawing lubricants critical.

In the future, the Global Wet Wire Drawing Lubricants market is poised to grow further, supported by advancements in materials and sustainable practices. With industries increasingly seeking eco-friendly solutions, the market is expected to adapt and innovate, ensuring its continued relevance in global manufacturing.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$4,614.1 million |

|

Market Size by 2031 |

$6,018.6 Million |

|

Growth Rate from 2024 to 2031 |

4.0% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The regional dynamics of its growth and demand shape the global Wet Wire Drawing Lubricants market. Geographical segmentation of the report covers regions such as North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. With the maturing process of the industry, innovation, adaptation towards local demands, and meeting the constantly evolving requirements of the industry across the geographic locations will unfold. NORTH AMERICA Market Break-up: The countries under North America include: United States Canada Mexico. The U.S. is one of the global leaders in both wire drawing lubricants production and use due to its well developed manufacturing sector and high-technology industries. The markets for high-performance lubricants, therefore, will continue going up as the level of automation and energy efficiency among industries increases in the country. Canada and Mexico are also expected to provide steady demand; but the overall pattern in the two markets would generally follow the trend of demand that will prevail in the U.S.

Europe which includes UK, Germany, France, Italy, etc. is another region important for Wet Wire Drawing Lubricants market. Germany and Italy are strong manufacturing countries, mainly in the automobile and machine building industries and will require high-quality lubricants as well. Stricter environmental regulation and an increasing emphasis on sustainability will also propel this market toward green lubricants in Europe. Growth will also come from France and the UK as industry in these countries look to reduce their environmental footprint.

Asia-Pacific, including China, India, Japan, and South Korea, will grow in the next years. China, being a manufacturing hub, will have a high demand for wire drawing lubricants as its industries continue to expand. The growth of infrastructure and industrial sectors in India will increase demand for these lubricants, especially as manufacturing practices modernize. Japan and South Korea will also contribute, especially in the electronics and automotive sectors, where high-performance lubricants are used. With the focus on innovation by these countries, advanced lubricant solutions will demand increase.

South America, primarily in Brazil and Argentina, will have a moderate increase. Industrialization in those countries will increasingly push up demand for wire drawing lubricants. More importantly, Brazil will play an important role since it boasts of the large industrial base.

The Middle East & Africa, including the GCC countries, Egypt, South Africa, and the rest of the region, will grow differently. However, the GCC countries will make intensive investments in upgrading their industrial sectors. Industrial upgradation would enhance demand for wire drawing lubricants. South Africa would increase markets due to manufacturing expansion.

COMPETITIVE PLAYERS

The global Wet Wire Drawing Lubricants market has shown consistent growth in recent years and is expected to continue expanding due to the increasing demand for advanced wire production techniques across various industries. Wet wire drawing lubricants are essential in the wire drawing process as they help reduce friction, heat, and wear, making the process more efficient and ensuring the durability and quality of the final product. These lubricants are used in industries such as automotive, telecommunications, and electrical components, where high-quality wire products are critical.

Looking into the future, the market for Wet Wire Drawing Lubricants will likely see significant advancements in both product formulations and applications. Technological innovations are expected to drive demand for more efficient and environmentally friendly lubricants. Players in this market are continuously working to improve their product offerings by focusing on new materials that provide better performance and reduce the environmental impact. The shift towards more sustainable and eco-friendly solutions will play a crucial role in shaping the market's direction in the coming years.

Key players in the global Wet Wire Drawing Lubricants market include well-established companies like Blachford Corporation, TRAXIT International GmbH, and CONDAT Group, who have a significant presence due to their strong product portfolios and innovative solutions. These companies, alongside others such as Zeller+Gmelin GmbH & Co. KG, RichardsApex Inc., and Petrofer Chemie, are constantly enhancing their lubricant formulations to meet the evolving needs of the wire drawing industry. Their expertise in manufacturing and extensive distribution networks make them highly competitive players in the market.

As the demand for wire products continues to rise, especially with the expansion of the telecommunications and electronics sectors, these key players will need to focus on research and development to stay ahead of the competition. The shift towards automation and increased precision in wire production processes is likely to increase the demand for lubricants that offer improved performance under high-speed conditions. Companies like Fuchs Lubricants, Pan Chemicals S.p.A., and ChemPoint are well-positioned to capitalize on these trends by providing cutting-edge solutions.

Furthermore, new entrants like Kyoeisha Chemical Co., Ltd., Sunbelt Lubricants, and J.M. Lube Chemicals Private Limited are expected to challenge the market leaders by offering innovative and cost-effective products. Lubrimetal S.p.A., Peddington Group, and others will continue to compete by diversifying their offerings to cater to the growing and diverse needs of the Wet Wire Drawing Lubricants market. As competition intensifies, the future of the market will be shaped by both established and emerging players working to meet the demands of a rapidly changing industrial landscape.

Wet Wire Drawing Lubricants Market Key Segments:

By Type

- Calcium-Based Lubricants

- Sodium-Based Lubricants

- Polymer-Based Lubricants

- Synthetic Lubricants

- Hybrid Lubricants

By Application

- Ferrous Wire Drawing

- Non-Ferrous Wire Drawing

By End-Use Industry

- Automotive

- Construction

- Electrical and Electronics

- Telecommunication

- Industrial Manufacturing

- Aerospace

By Distribution Channel

- Direct Sales

- Distributors and Dealers

- Online Retail

Key Global Wet Wire Drawing Lubricants Industry Players

- Blachford Corporation

- TRAXIT International GmbH

- CONDAT Group

- Zeller+Gmelin GmbH & Co. KG

- RichardsApex Inc.

- Petrofer Chemie

- Carl Bechem GmbH

- Fuchs Lubricants

- Pan Chemicals S.p.A.

- ChemPoint

- Kyoeisha Chemical Co., Ltd.

- Sunbelt Lubricants

- J.M. Lube Chemicals Private Limited

- Lubrimetal S.p.A.

- Peddington Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252