MARKET OVERVIEW

This includes the global metal processing machines market, playing an important role in the manufacturing and industrial industries to meet the requirements of the machinery applied for shaping, cutting, or forming metal parts. This market, in particular, holds a significant position in these industries: automotive, aerospace, construction, and heavy machinery manufacturing, where besides durability, precision is important. Metal processing machines lay the foundation for everything from small metal parts to large constructions that need to be created. Consequently, the industries that rely on metal-based materials are using this equipment in huge amounts. This kind of equipment market has several industries; as a result, it manifests significant power on international industrial activities.

The global market of metal processing machines includes various kinds of machines, which are developed to meet specific demands of different industries. Some of these include lathes, milling machines, grinding machines, and presses, among many others. Each machine has a specific purpose in metal fabrication. Generally, these machines alter the shape and dimensions of metals and their surface properties as per the required end product. Ever-increasing innovative and technological developments in industries will bring forth the need for high levels of advanced and efficient metal processing machines.

Among all the key characteristics of the Global Metal Processing Machines market, technology sophistication plays a very crucial role. Fully integrated automation, robotics, and digital control systems have significantly altered the landscape. For example, use of CNC machines has revolutionized the processings of metals as increased accuracy, exclusion of human errors, and faster production rate have been facilitated. Demand in areas like high-volume production but quality stringent has been fueled, and technology will continue to rule the market as well as depict its future course.

Geographically, the Global Metal Processing Machines market covers major industrial regions in the world, consisting of North America, Europe, and Asia-Pacific. The demand herein varies by region due to the specific reasons engaging the local industrial activities and general economic realities in each of the regions. For example, in the Asia-Pacific, the rapid industrialization and urbanization in the region are going to stir up the requirement for these machines, particularly in countries like China, Japan, and India. Demand from Europe and North America would remain stable, as both are countries that possess an established automotive and aerospace industries. This is because their natural distribution is diversified and dynamic, varies locally according to local needs and trends.

The Global Metal Processing Machines market is very flexible as it has the capability to operate on different types of metals and application equipment. These machines process different kinds of metals, for instance steel, aluminum, copper, and titanium, where every metal has its own strong demand in terms of hardness, malleability, and corrosion resistance. It makes the market versatile enough to take aboard a vast array of industries that have associated certain demands for its metal components. As materials science continues to evolve, there is an increasing probability that the metal processing machines will be changed for newer alloys and composite materials, further strengthening the scope of the market.

In a nutshell, this Global Metal Processing Machines market is in the heart of global manufacturing and tends to spur processes in various industries. The continuous advancement of technology as well as rising demands from growth economies will continue to shape this market by fueling further growth. While metal-based materials and components have become one element in most industries, the ensuing demand for precise and efficient metal processing machines will remain strong, shaping the future of worldwide manufacturing, across all industry lines.

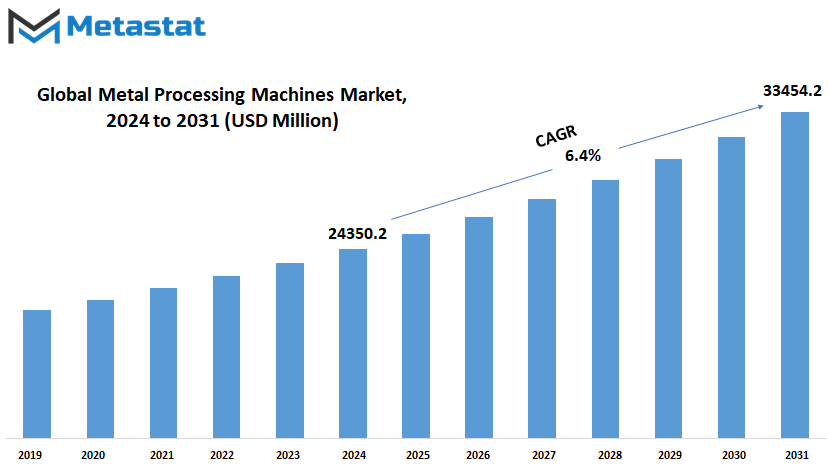

Global Metal Processing Machines market is estimated to reach $33454.2 Million by 2031; growing at a CAGR of 4.6% from 2024 to 2031.

GROWTH FACTORS

The Global Metal Processing Machines market has seen significant potential for growth over the next few years, with a couple of factors that would dominate its future landscape. One key growth factor is the increased need in many sectors for metal processing. With expansion in sectors like automobile and aerospace industries, along with construction projects, an increasing demand for high-value added metal processing machines is very likely. Manufacturers will always try to look for ways of making things more efficient and cheaper to produce. The market is bound to introduce the integration of improved technology, and this is not any different from the type of technology being encouraged in this market. Technology advancement, particularly the automation and robotics technologies, are poised to further propel growth for the market. Such innovation will assist manufacturers in improving precision, and speed with more flexibility in the processing of metal, which translates to higher output and quality.

The ever-growing demand for sustainability is another critical driver of the Global Metal Processing Machines market. Increasing concerns of environmental issues compel business undertakings to search for machinery that, instead of merely boosting productivity, also decreases waste and energy consumption. More manufacturers will look at green technologies like energy-efficient machines and processes so that they may be aligned with the commitment towards sustainability. This trend towards sustainable practices is likely to increase new machinery investment and, therefore, increase growth in the market.

However, some constraints are likely to hinder the growth of the market. Since investment for new machinery related to advanced metal processing requires a high investment cost, it is relatively limited for smaller-sized concerns and even for medium-sized ones. They cannot afford these new technologies at these heights and so may limit the growth of the market. Change in raw material cost will also affect production, causing uncertainty among manufacturers, thus limiting their investment in new machines.

Emerging markets have vast growth potential in the Global Metal Processing Machines market. As their economies are progressing with rapid industrialization, the demand for metal processing machinery will experience a sharp upward trend in these regions. The regions will establish infrastructure and manufacturing platforms and would look for sophisticated metal processing solutions. Furthermore, this market is witnessing rapid relocation of production lines to these markets, thus increasing the demand for efficient metal processing machines.

It states that this market will boom considerably with this increase in demand, technological advancement, and a significant drift towards sustainability. Despite some impediments seemingly standing in their way, growth prospects in emerging markets appear quite exciting for manufacturers as well as investors. Once this industry adjusts to such changes, it will really boost the future of metal processing worldwide.

MARKET SEGMENTATION

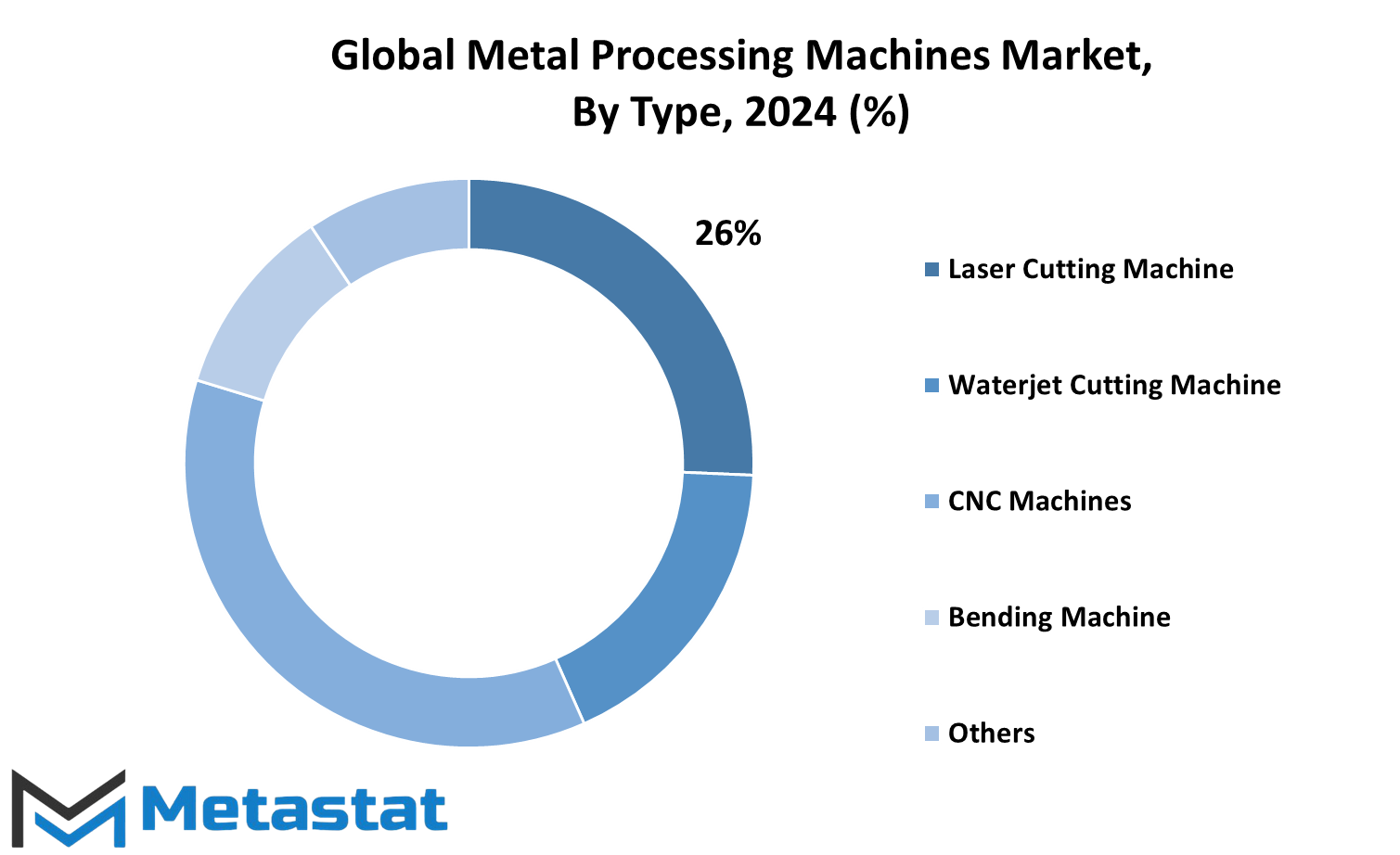

By Type

Industry growth and change with new technologies will shape the Global Metal Processing Machines market. Critical in manufacturing and production processes across automobile, aerospace, and construction sectors, this market of many machines used in processing metals will grow further as industries change and new technologies are invented. There is increasing use of precision and efficiency in processing of metal, and thus changes in the design and functioning capabilities will be much in demand for the machine.

Perceived to be one of the market segments most prominent in the Laser Cutting Machine market, essentially the machine uses focused laser beams to cut materials. With high precision and speed, the industries are striving to reduce waste and enhance their quality products, hence increasing the favorability toward laser cutting machines. Such machines are also preferred by many manufacturers as they do not require further finishing to achieve intricate designs and smooth edges. The automation features will be highly improved in laser cutting technology in the near future, and better software will be developed for much better control and efficiency.

The second very important segment is Waterjet Cutting Machine. This technology allows high-pressure water mixed with an abrasive material to make a cut through metal as well as other materials. The technique is very effective for heavy metals as well as materials that can’t tolerate high temperatures. Also, the market for waterjet cutting will improve with greater interest in green manufacturing practices, as this process generates minimal waste and no bad fumes. However, improvements may be focused on gaining higher speeds and efficiency out of the machine; therefore, it may be a potentially attractive business opportunity for manufacturers.

Another key innovation area of Global Metal Processing Machines is Computer Numerical Control Machines, short for CNC Machines. The machine can be programmed for a wide variety of milling and turning machining tasks with tolerance. As need for customization and flexibility in production evolves, CNC technology will move towards more complicated systems capable of solving a wide range of changing production needs. Incorporating artificial intelligence into CNC machines is going to create an increased trend in which the efficiency and effectiveness of operations will be enhanced and adjusted in real time.

Improved bending machines will play an important role in bending metals into all shapes and sizes. These machines will be designed with capabilities such that they can manage more intensive bending tasks, including larger materials, to meet the growing requirements of industries like construction and manufacturing. Easy operating software and more automation make these machines simple to set up in less time and quicken production output.

The Global Metal Processing Machines market is thus ready to experience a tremendous transformation, with the developments in technology offering ample scopes and changes for the style and design of manufacturing systems. Each segment-power laser cutting machines, bending machines, etc.—will contribute to meeting modern industries’ demands, rendering the market dynamic and responsive to ever-changing demand patterns among manufacturers in each other’s countries.

By Application

The Global Metal Processing Machines market is a key subcomponent of the larger manufacturing industry that emphasizes equipment used in metal shaping, cutting, and finishing. The market functions through applications with each providing unique contribution towards the development of the future. The main industries using these machines include the automotive, aerospace, construction, electronics, energy, and industrial machinery, along with others. Each of the aforementioned applications lends uniquely to the overall demand for metal processing machinery.

An example is the auto manufacturing sector that is continually undergoing an increase in precision and efficiency. More frequently, advances in vehicle technology will raise higher demands for manufacturers to produce parts meeting even tighter quality requirements through more efficient metal processing machines. Probably, it will spur them to much more investment in automated solutions that enhance production rates with accuracy. Innovation in this field will most probably lead to the application of lighter materials, hence improving efficiency in fuel consumption as well as efficiency in the general performance of a vehicle.

The aerospace industry is going to derive much benefit also concerning metals processing technology innovations. This industry tends to emphasize on having reduced weight with retained strength and safety, thus the machines utilized will have to be strong enough for working with advanced alloys and composite material. Such demands would necessitate innovation in machining and forming technologies. Lighter, more efficient aircraft will require the employability of those technologies to meet such a demand. Digital technologies, as applied to production procedures, including artificial intelligence and the Internet of Things, will further enhance the optimization of production procedures in this field.

The need for strong and economical materials will still be the backbone of the construction sector, thus working in favor of metal processing machinery. It will demand more rugged infrastructure as this world continues to urbanize. Therefore, there will be an increased demand for advanced machinery with the ability to process a huge volume of metals at a fast speed.

Further miniaturization of parts in the electronics industry necessitates rapid transformation. In this regard, the manufacturing of machines for metal processing should incorporate the capability of producing significantly smaller, more complex pieces with heightened accuracy. As technology progresses, it would most likely be in the best interest of manufacturers to produce more advanced machines, such as higher speeds and the ability to create a wide variety of products.

New processing machines in metals will come with the emergence of renewable sources in the energy industry. Equipment that efficiently produces components for wind turbines as well as solar panels will be in big demand.

The Global Metal Processing Machines market, therefore, will evolve as different industries learn to adapt to changing demands. Manufacturers will have to keep abreast of technology and market trends to remain competitive and viable to their customers. The future will be promising, but challenges will emerge in this market, and a case for innovation and growth will be established along multiple applications.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$24350.2 million |

|

Market Size by 2031 |

$33454.2 Million |

|

Growth Rate from 2024 to 2031 |

4.6% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The Global Metal Processing Machines market, therefore, is a very dynamic sector influenced by all kinds of regional characteristics and trends. Understanding the respective regional divisions is crucial for any business aiming to thrive in such a competitive environment. The five key regions are North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each of these areas has developed somewhat different market drivers, challenges, and opportunities that influence the landscape of metal processing technology.

North America encompasses the U.S., Canada, and Mexico; characterized by advanced technology and high manufacturing standards, it supports a healthy market. Strong automotive and aerospace industries bring robust demand for efficient metal processing machinery, from which the market is expected to experience stable growth in light of manufacturers continually seeking innovative ways in which to improve their manufacturing productivity and reduce waste. A major concern area of future development is anticipated to be sustainability and the use of environmental friendliness in manufacturing processes.

The Global Metal Processing Machines market is also affected by Europe, with the UK, Germany, France, and Italy among many countries. The region emphasizes precision engineering and high-quality manufacturing. In fact, countries like Germany are actually leaders of metalworking technologies and, therefore, bring about huge advancements in machine tools and processing techniques. Those businesses that can use those technologies to their advantage in automation and smart manufacturing will excel over others. The trend in newer, greener technologies will be in methodologies in production all over the continent.

Industrialization and urbanization in the Asia-Pacific, that encompasses big markets like India, China, Japan, and South Korea, increases the demand for metal processing machines. China is one of the world's manufacturing superpowers in itself and is therefore a significant driver of demand for metalworking machinery worldwide apart from both countries' concentration on infrastructure development and rising investments in their manufacturing capabilities.

Asia Pacific manufacturers will continue adopting new technologies to enhance productivity. The current situation is encouraging for the metal processing industry of South America, particularly in Brazil and Argentina, where industrial activities are gaining momentum. Plenty of Challenges remain in the Middle East & Africa region for the GCC countries, Egypt, and South Africa but opportunities do exist. In the next year, when these markets are tided up for modernization and huge projects of infrastructure, the demand for advanced metal processing machines will increase. In a nutshell, the global metal processing machines market is likely to grow up and various opportunities and challenges have been noticed in each region which have to be traversed for different businesses to ultimately succeed in this vibrant industry.

COMPETITIVE PLAYERS

The Global Metal Processing Machines market promises colossal growth and transformation in the near future with the advancement of technology and higher demand on these machines. With more refinement in the manufacturing lines, there will always be a critical need for high-quality and efficient machines for metal processing. It is a part of very integral sectors such as automotive, aerospace, construction, and electronics where accuracy is compromised with speed. Automation and other digital technologies that will integrate with metal processing are likely to change the face of it. With this integration, there would be more efficiency and reduced costs on production.

Among the key players in the metal processing sector, one can probably experience innovative steps concerning further enhancement of their competitive edge. Such companies include Trumpf SE + Co. KG and DMG Mori is known for its advanced technology and is presumed to be one of the forerunners in introducing advanced machinery that makes use of artificial intelligence and machine learning. It will help manufacturers optimize their activities and reduce the likelihood of downtimes by great margins. Apart from this, companies like Haas Automation, Inc., and Yamazaki Mazak Corporation would expand their product lines and provide quality customer services in order to meet the various demands of the clients.

Moving ahead, sustainability would be another factor of concern in the Global Metal Processing Machines market. Due to growing environmental concerns, manufacturers would focus more on energy-efficient machinery and less on the waste-producing processes. This is why companies such as FANUC Corporation and Emag GmbH & Co. KG are set to lead in coming up with some form of eco-friendly solutions which, apart from being under regulatory compliance, open to consumer new avenues into achieving environmental-friendliness. This will make the world gain and, hopefully, after some time, so will innovation and growth.

Besides cooperation and other technological collaboration between the players in the industry, there will also be progress due to technological collaboration. Some of the companies that include Mitsubishi Electric Corporation and Hurco Companies, Inc. are expected to partner with institutions of research and other firms of technology so as to take new opportunities for the design and manufacture of machines. Such an approach will strengthen their capabilities and bring forth next-generation processing machines for metals.

The Global Metal Processing Machines industry is bound to undergo drastic changes forced by technological advancement, ecological approach, and competitive approach. Innovation may have already made Andritz AG, Okuma, and JTEKT Corporation the top dogs in metal processing. On the other hand, if the future is to shine brighter, then technology and manufacturing would be that combination which would simplify things while letting industries finally meet the requirements of expanding markets everywhere.

Metal Processing Machines Market Key Segments:

By Type

- Laser Cutting Machine

- Waterjet Cutting Machine

- CNC Machines

- Bending Machine

- Others

By Application

- Automotive

- Aerospace

- Construction

- Electronics

- Energy

- Industrial Machinery

- Others

Key Global Metal Processing Machines Industry Players

- Trumpf SE + Co. KG

- DMG Mori

- Haas Automation, Inc.

- Yamazaki Mazak Corporation

- AMADA MACHINERY CO., LTD.

- FANUC Corporation

- Emag GmbH & Co. KG

- Mitsubishi Electric Corporation

- Hurco Companies, Inc.

- Andritz AG

- Okuma

- JTEKT Corporation

- Bystronic Group

- Breton S.p.A.

- PRIMA INDUSTRIE S.P.A.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383