MARKET OVERVIEW

The global stainless steel foil market, including its industry, basically is the process of developing, marketing, and utilization of high-precision ultra-thin sheets made out of stainless steel. Such Stainless Steel Foils usually in microns are said to display an unmatched combination of flexibility, strength, as well as anti-corrosion properties that make them utterly invaluable for industrial applications ranging from electronics and automotive to aerospace, as well as even medical equipment. Technological advancements, driving demand for miniaturization and enhanced performance, make stainless steel foil increasingly important as a material meeting stringent operational and environmental requirements.

This market covers different geographies and serves a range of industrial processes. The companies that produce this product boast of advanced manufacturing methods such as cold rolling and annealing. This means that the product is finished with high precision and quality thickness. Competition is determined by the capacity to deliver customized foil suited for specific applications and suppliers try to meet the tough specifications set by these clients in technology-based industries.

In the context of Global Stainless Steel Foil, importance lies in its ability to provide a base for innovation. It finds a huge application in manufacturing shielding and conductive parts by virtue of its strength and thermal stability. This material is used in the automotive industry through catalytic converters and battery parts, which improves its performance and longevity. Aerospace industries value its light yet strong properties, and the medical industry uses its biocompatibility in implants and surgical instruments. This diversity ensures that the global stainless steel foil market will continue to be a support for high-tech and precision-oriented industries for the next few years.

The future of the global stainless steel foil market would reflect improvements in manufacturing technology and increased emphasis on sustainability. Industry players would probably invest heavily in the research and development of more thinly foiled but tougher and stronger foils with more resistance to external stressors. Tightening environmental regulations in most parts of the world will most probably make manufacturers take up greener modes of production, saving more energy and waste in the process. This would be an advantage in the position taken by the industry as one which could successfully balance innovation with the environmental imperative.

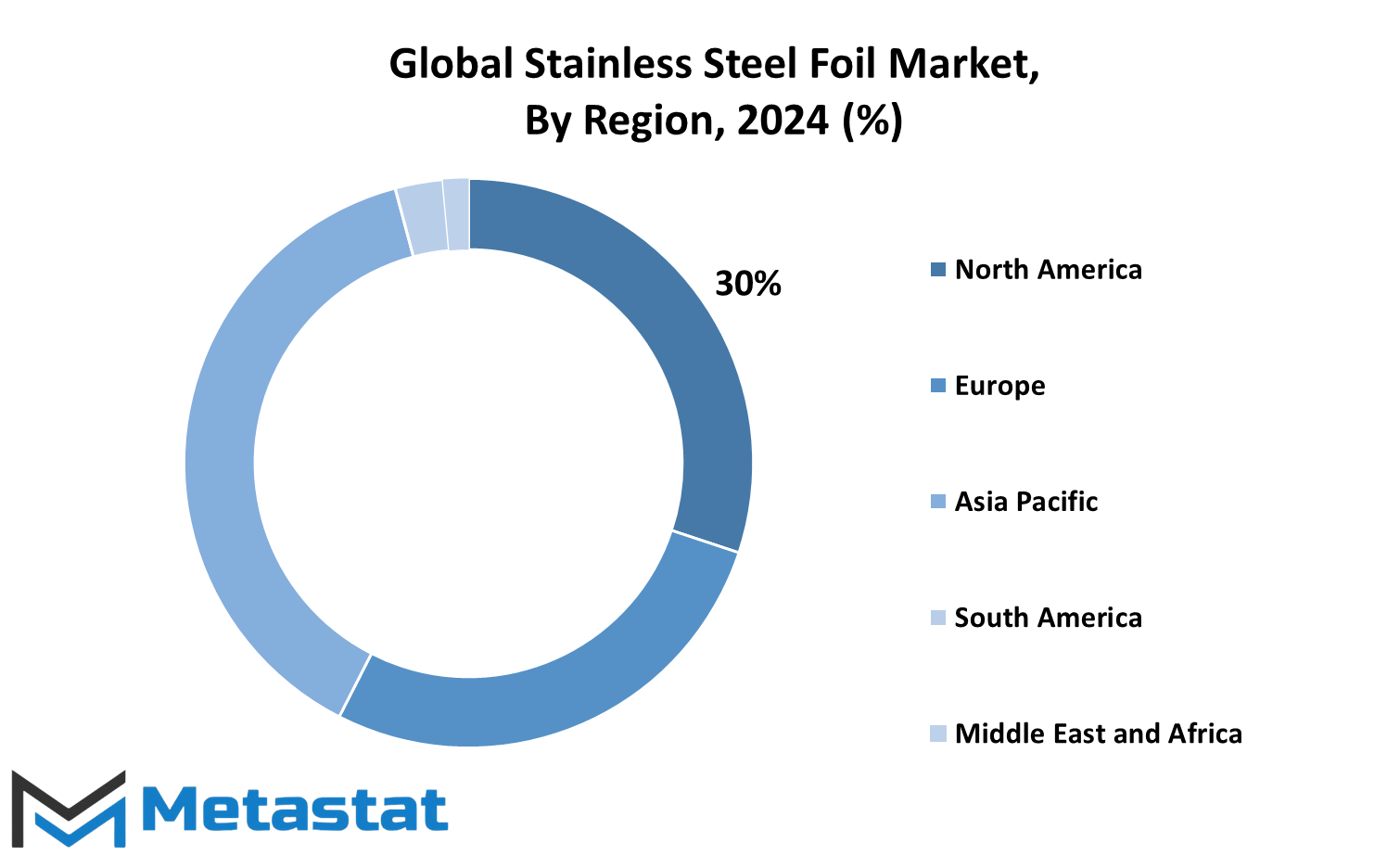

Regional dynamics in the global stainless steel foil market will also change, as emerging economies will play a greater role in both production and consumption. Accelerated industrialization in regions such as Asia-Pacific will increase demand for stainless steel foil in local automotive and electronics industries, thus creating new opportunities for growth in the market. North America and Europe will be focused on the high-end applications, which will have advanced technologies meeting the changing needs of customers.

This global stainless steel foil market is part of many high-tech industries in terms of its function. As the world advances in terms of precision, efficiency, and sustainability, the market will remain dynamic and continues to innovate, adapt, and expand its influence in this world scale. Due to the unique properties of this material along with its critical role in advanced manufacturing, it will always stay relevant within the modern industrial landscape in meeting all the complex demands.

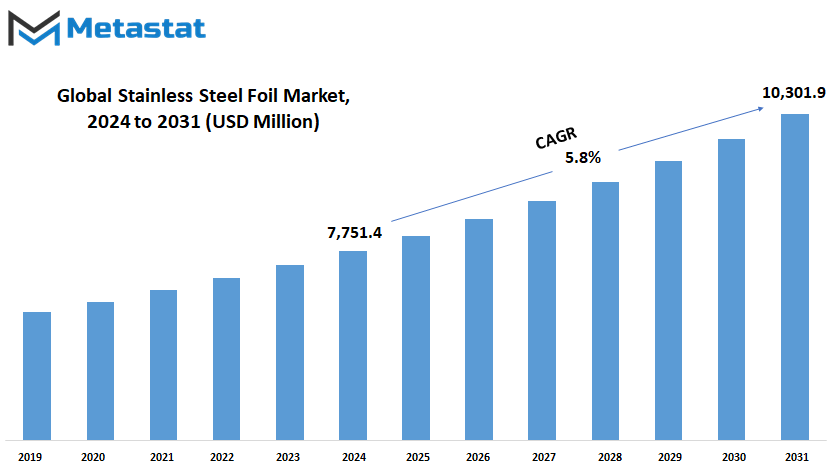

Global stainless steel foil market is estimated to reach $10,301.9 Million by 2031; growing at a CAGR of 5.8% from 2024 to 2031.

GROWTH FACTORS

The global stainless steel foil market is witnessing a consistent upward trend due to the numerous factors that have influenced its growth. Some of the major drivers behind the growth of this market include growing demand from the electronics, automotive, aerospace, and renewable energy industries. Increasing demand for strength, durability, and resistance to corrosion due to advancing technology are also some of the primary reasons. With good properties, especially weightless and high strength, stainless steel foil becomes so popular.

The electronic device industry is an example wherein miniaturization gives them a way of design as the components get to become smaller but with bigger or more powerful power inside while requiring materials that should with such high temperatures and resistive to corrosion but give high reliability in small packages. Stainless steel foil meets all these requirements as it provides strength along with elasticity that is needed in the modern electronic components. Thus, the increasing demand for miniaturized electronic products is sure to take the global stainless steel foil market size upward in the future also.

Similarly, this growth in market is further driven by the rising demands from automobile and aeronautics sectors also. The demands of such industries include producing lightweight products which compromise their strength and performance. In case of stainless steel foils, the producers could arrive at light components but in no way would these affect the strength and the performance that it provides. Because of these demands, stainless steel foil production has been increased by those persons in society who want more and more fuel-efficient vehicles with superior aircraft designs among others.

Although the growth conditions are favorable, there are still challenges facing the global stainless steel foil market. The first of these concerns is the high cost of raw materials needed in producing stainless steel foil. Additionally, the processes of manufacture for these foils tend to be energy-intensive, thus making the final product expensive as compared to other products. Such factors may limit the uptake of stainless steel foil in cost-sensitive industries.

The poor recyclability of stainless steel foil and its environmental impacts could further limit its widespread use, particularly in industries that are oriented towards sustainability. With a growing focus on reducing carbon footprint and waste minimization globally, the meager environmental benefits of stainless steel foil may make some industries refrain from using it.

Expansion in the scope of applications of renewable sources of energy, such as fuel cells and solar panels, is likely to bring favorable opportunities to the global stainless steel foil market. Properties of stainless steel foil may noticeably improve the performance and operational life of such energy systems. Therefore, this material is highly relevant for companies operating in the business of renewable energy. As the world evolves toward cleaner and sustainable energy sources, demand for materials that will support such innovations is higher.

With these challenges aside, the future of the global stainless steel foil market appears bright. The constant demand in the electronics, automotive, aerospace, and renewable energy sectors, along with further advancements in material science, will continue to create room for growth and opportunity over the next few years.

MARKET SEGMENTATION

By Product

The global market for stainless steel foil is growing and continues to increase as industries seek more resilient and versatile materials for various uses. This material, being strong, flexible, and corrosion-resistant, plays a very vital role in a variety of industries, from manufacturing to electronics. As industries seek higher efficiency and cost-effectiveness, the demand for stainless steel foil is expected to rise. The division of stainless steel foil into product type, especially width, determines the global stainless steel foil market. So, three main widths of stainless steel foil are taken: Width < 100mm, Width 100mm – 500mm, and Width > 500mm.

Each of these groups will meet the demands of various industries. The subgroup with a width of less than 100mm is anticipated to grow rapidly because of their use in precision electronics, components for automobiles, and medical products. As the demand increases for smaller, more complex items, the demand for thinner, better-cut stainless steel foils may increase. Demand for this segment will also be driven by the further advancement in microelectronics and wearable technology. As these industries grow, there will clearly be a huge demand for thinner foils that meet the very demanding design and performance specifications required for modern products.

On the other hand, the 100mm – 500mm grade of stainless steel foils will also experience good growth due to its vast use in food packaging, heat exchangers, and industrial machinery applications. This width is ideal for the construction of durable products that require both resistance to heat and corrosion, offering a balance of strength and flexibility. With the continued development of food processing, automobile, and construction industries, this range of foils is going to be in significant demand, offering a strategic resource for products that need both formability and durability.

The largest segment stainless steel foil with a width greater than 500mm will continue to rise steadily in the next years. This category is mainly used for larger-scale applications, such as aerospace and energy. These industries require strong, high-performance materials that can withstand extreme conditions. As these sectors will go on innovating and making developments, the requirements of broad stainless steel foils will remain critical and may see further development in terms of material strength and processing technique.

By Grade Type

The global stainless steel foil market has been growing steadily in the last few years. This is mainly because of technological advancements and increased applications. This market is also diversified as it caters to several industries, such as automotive, aerospace, electronics, and packaging. The different grades of stainless steel foil play a significant role in shaping the market's development and will continue to influence its trajectory in the coming years.

The future demand for certain grades of steel foil because of their special properties will highly influence the global stainless steel foil market. The market is categorized into several key grades. Austenitic Stainless Steel Foil continues to lead in the global stainless steel foil market and includes the 300 series, such as 304 and 316. It is highly valued because of corrosion resistance and is used for usage in chemical processing, food production, and in medical equipment. The 304 grade is particularly known to be versatile, whereas 316 has improved resistance to chlorine and other chemicals, making it the best suited for use in marine and industrial settings. These foils are likely to have further growing demands as industries look for durable, longer-lasting materials.

On the other hand, Ferritic Stainless Steel Foil, in the 400 series, such as 430, is becoming increasingly popular as a cost-effective and oxidation-resistant material. Increasingly, these foils are used in applications where heat and corrosion resistance are needed but at a lower cost. In the coming years, the global stainless steel foil market is likely to expand further as developing countries' industries seek dependable yet affordable alternatives for construction, automotive parts, and household appliances.

The martensitic stainless steel foil, due to its high strength and hardness, will also play a very important role, especially in applications where the wear resistance needs to be high, such as in manufacturing tools and machinery. This grade of foil is more brittle than the other grades but its strength makes it indispensable in the creation of specific, high-performance components.

Duplex Stainless Steel Foil is going to be even more dominant in the applications in the future, with a characteristic of both austenitic and ferritic steel. Owing to its ability to withstand any environmental condition of extreme stress and corrosion, duplex stainless steel foil will find an opportunity in oil and gas and high-temperature applications. Its strength and resistance are going to propel duplex stainless steel foil to a market growth.

Precipitation Hardening Stainless Steel Foil is going to become even bigger as it can harden to very high strength values while still retaining good corrosion resistance. This type of foil is used in industries such as aerospace, defense, and other demanding applications and would continue to find its niches in high-performance conditions.

The trend in this regard will be increasing since there are industries emerging and developing new technologies that will increase the demand for specialized stainless steel foils. The global stainless steel foil market will more grade, depending on various requirements of the sector because each sector requires different grades of stainless steel foil. In the near future, there will be a very bright future since continuous innovation would enhance the demand for high-quality durable materials capable of performing through various challenges.

By Application

The global stainless steel foil market is in a promising growth path with the rising demand for stainless steel foil on account of its specific properties and wide applications. The stainless steel foil is becoming indispensable in various industries due to strength, flexibility, and resistance towards heat and corrosion. This market will continue to grow in the future as well to cater to various industries. With the improvement in technology, the demand for both strength and flexibility of the materials is increasing. Currently, stainless steel foil is one of the most demanded materials in many high-demand fields. Stainless steel foil is now being used in the electronics field to make battery component parts and circuit boards.

Its strong resistance to a higher temperature along with excellent electrical conductivity allows it to make long-lasting, reliable electronic devices. In accordance with the demand of dependency on electronics from mobile phones to electric vehicles, the stainless steel foil used in these applications will have to increase its demand. Innovation in the battery technology for electric vehicles and renewable energy storage systems is going to demand more high-performance stainless steel foil. Another field where stainless steel foil is going to experience an increased demand is from the automobile industry. In gaskets and heat shields, the parts required are materials that can withstand extreme temperatures and durability.

Stainless steel foil is suitable for applications requiring such properties owing to the material's good corrosion resistance and high stress. The automobile industry is now turning more toward more eco-friendly products, and electric vehicles gradually gain hold. This move will increase the demand for stainless steel foil even more to improve its efficiency and safety. Stainless steel foil also holds an auspicious future in the aerospace field.

It has the uses of thermal insulation and shielding, thereby keeping delicate machinery from the harshest temperatures. Air travel continues to increase and expand in the quest for space. With increased space travel and more expeditions into outer space, the need for strong materials that are also reliable is expected to be a constantly growing market. Stainless steel foil is utilized for catalyst support and precision machinery parts in the industrial sector.

The demand for high-performance materials in manufacturing would grow as industries shift towards more efficient production processes. Medical industry would also grow as it is utilizing stainless steel foil for surgical instruments and implants. Its strength coupled with biocompatibility makes it perfect for use in medical devices, which are essential to the patient care.

Another area where stainless steel foil has been found useful is in the packaging industry, particularly for pharmaceutical and food packaging. Being non-reactive, stainless steel protects the products within it from contamination, an important factor in the preservation of sensitive items. As packaged goods increase globally, stainless steel foil will remain of utmost importance in ensuring that packaged products are safe and long-lasting.

The energy sector will also contribute to the growth of the global stainless steel foil market, especially in fuel cells and solar panels. Due to its role in improving efficiency and lifespan, stainless steel foil is a valuable material for renewable energy solutions. As the world continues to shift toward more sustainable energy sources, demand for stainless steel foil in energy applications will only increase.

By End User

The global stainless steel foil market is in a promising growth path with the increasing demand for stainless steel foil due to its specific properties and versatile applications. The stainless steel foil is becoming essential in several industries due to its strength, flexibility, and resistance to heat and corrosion. It is expected that this market will grow further in the future to meet the demands of different industries. With the advancement of technology, the demand for materials that are both strong and flexible is increasing. Stainless steel foil is now one of the most demanded materials in many high-demand fields.

In the electronics field, stainless steel foil is being used to make battery component parts and circuit boards. Its resistance to high temperature and excellent electrical conductivity enable it to be used to make long-lasting, reliable electronic devices. In line with the trend of dependence on electronics in mobile phones to electric vehicles, the stainless steel foil used in these applications will have to increase its demand. Innovation in the battery technology for electric vehicles and renewable energy storage systems will be further demanding materials like stainless steel foil, having high performance.

The other field where stainless steel foil is going to see an increased demand is in the automobile industry. Components such as gaskets and heat shields require materials that can stand extreme temperatures and offer durability. Stainless steel foil is an ideal candidate for such applications because of its resistance to corrosion and high stress tolerance. The automotive industry is shifting towards more environmentally friendly solutions, and electric vehicles are slowly taking over. This trend will propel the global stainless steel foil market to further heights in search of enhancing efficiency and safety.

Stainless steel foil also holds an auspicious future in the aerospace field. It has the uses of thermal insulation and shielding, thereby keeping delicate machinery from the harshest temperatures. Air travel continues to increase and expand in the quest for space. With increased space travel and more expeditions into outer space, the need for strong materials that are also reliable is expected to be a constantly growing market.

In the industrial sector, stainless steel foil is used for catalyst support and precision machinery parts. The need for high-performance materials in manufacturing will increase as industries move toward more efficient production processes. The medical industry, which relies on stainless steel foil for surgical instruments and implants, will also see growth. Stainless steel's biocompatibility, along with its strength, makes it ideal for use in medical devices that are essential for patient care.

The packaging industry is also one area where stainless steel foil has found utility, especially for pharmaceutical and food packaging. Since it is non-reactive, stainless steel protects the products inside it from contamination, an important factor in the preservation of sensitive items. As packaged goods continue to increase globally, stainless steel foil will continue to be of utmost importance in ensuring that packaged products are safe and long-lasting.

The energy sector will also play a part in the growth of the global stainless steel foil market, especially in fuel cells and solar panels. The role of stainless steel foil in improving the efficiency and lifespan of these technologies makes it a valuable material for renewable energy solutions. As the world continues to shift toward more sustainable energy sources, demand for stainless steel foil in energy applications will only increase.

The future of the global stainless steel foil market seems to be bright. Industries evolve to demand more durable, efficient, and versatile materials. At the forefront of such advancements will be stainless steel foil, meeting a variety of applications.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$7,751.4 million |

|

Market Size by 2031 |

$10,301.9 million |

|

Growth Rate from 2024 to 2031 |

5.8% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global stainless steel foil market will continue to grow as it continues to expand its usage across different industries. Stainless steel foil, which is known to be very durable, corrosive resistant, and flexible, is a key user of various industries such as electronics, automotive, and packaging. As the latter expands, so will be the demand for high-grade stainless steel foil, which propels the growth of the market.

In examining the market based on geography, different regions will uniquely contribute toward developing this industry. The market in North America, which covers the U.S., Canada, and Mexico, is very likely to be a stable market because of its technological advancement and extensive base for manufacturing. The United States remains as the most prominent customer of high-performance materials in this market and will continue to be that way in the global stainless steel foil market. Conversely, Canada and Mexico are placed to benefit from the emergent industries where demand for stainless steel foil increases, including the automotive and electronics sector.

However, the leading region in this global market is still Europe where major powers lie such as UK, Germany, France, and Italy among others. Europe's heavy industrial base, which encompasses automotive and manufacturing industries, will continue to drive demand for stainless steel foil. The growing emphasis on sustainability and the adoption of energy-efficient technologies in the region also means new applications for stainless steel foil, which will support market growth. Growth is also expected in the Rest of Europe, especially from the emerging markets where industrialization is happening at a high pace.

Asia-Pacific, with key players China, Japan, South Korea, and India, will be one of the fastest-growing regions in the global stainless steel foil market. China, being the largest manufacturer of steel in the world, is expected to continue its dominance in the production and consumption of stainless steel foil. India and Japan, with their expanding electronics and automotive industries, will also play significant roles in driving demand. The Rest of Asia-Pacific will benefit from the region’s industrial development, particularly in countries like Indonesia and Vietnam, where manufacturing sectors are booming.

In South America, countries like Brazil and Argentina will contribute to the growing demand for stainless steel foil, primarily driven by developments in the automotive and packaging industries. The region's continued industrialization will lead to increased consumption of high-quality materials like stainless steel foil. Other regions are also going to increase in this market, which includes Middle East & Africa, which are the GCC countries, Egypt, and South Africa, among others. Their construction and automobile industries would raise their demand for stainless steel foil, hence providing room for expansion in this market.

The global stainless steel foil market is going to grow, as the industries of almost all regions are becoming more dependent on the production using high-quality long-lasting materials. The prospects for this market look pretty bright, as the advancement of technology and demand of industries will force further innovation and expansion across all the regions.

COMPETITIVE PLAYERS

The global stainless steel foil market is on its way to growth, because stainless steel is becoming in higher demand for use in automobile, electronics, and construction. The versatility of stainless steel foils with its durability and corrosion resistance has become an essential material for use in these industries. With the expansion of industries, there will be a growing requirement for high-temperature resistance, harsh chemical resistance, and mechanical stress. Innovations in technology and material science guarantee that manufacturers can produce more advanced products in the future. Thus, the global stainless steel foil market seems bright in the future.

The key players of global stainless steel foil market like NIPPON STEEL CORPORATION, Jindal Stainless Ltd. and Wieland Rolled Products North America LLC have a vital influence on how the market will be going into the future. Companies continue to improve their production capabilities and meet the needs of its customers. For example, NIPPON STEEL CORPORATION is known for its massive strength in the stainless steel domain and for its innovation potential. Similarly, Jindal Stainless Ltd. and Wieland Rolled Products North America LLC have also built strong positions as a high-quality source of stainless steel products covering various sectors.

Intermediate competition among these prominent players will push forward advancement of manufacturing processes, efficiency will increase, and cost-effectively brought down. Companies like Bhandari Group, Ulbrich Stainless Steels & Special Metals Inc, and All Foils Inc are further facilitating the development of this market by focusing on high-grade stainless steel foils complying with industry-specific demands and fulfilling the demand for their varieties ranging from food packaging to aeronautical components.

Going forward, demand for sustainable materials is going to continue, and the world will give more importance to sustainability. With stainless steel being recyclable and long-lasting, its demand is likely to increase more with increased focus on sustainability. In addition, in manufacturing vehicles and electronics, the trend of lightweight and high-performance material is going to gain momentum more, thereby increasing demand for stainless steel foil. With companies like Jainex Steel and Metal, Braun GmbH Folien-Prägetechnik, and so forth, actively participating, the global stainless steel foil market will see innovations according to changing needs of industries, and this will increase the material's popularity.

In summary, the future of the global stainless steel foil market is bright. The continued efforts of key players to innovate and provide high-quality products will support the market's growth. With increasing applications across various industries and the global push for sustainability, the demand for stainless steel foil will likely continue to rise in the coming years.

Stainless Steel Foil Market Key Segments:

By Product

- Width < 100mm

- Width 100mm – 500mm

- Width > 500mm

By Grade Type

- Austenitic Stainless Steel Foil (300 Series, e.g., 304, 316)

- Ferritic Stainless Steel Foil (400 Series, e.g., 430)

- Martensitic Stainless Steel Foil

- Duplex Stainless Steel Foil

- Precipitation Hardening Stainless Steel Foil

By Application

- Electronics (Battery Components, Circuit Boards)

- Automotive (Gaskets, Heat Shields)

- Aerospace (Thermal Insulation, Shields)

- Industrial (Catalyst Support, Precision Machinery Parts)

- Medical (Surgical Instruments, Medical Implants)

- Packaging (Pharmaceutical and Food Packaging)

- Energy (Fuel Cells, Solar Panels)

By End User

- Electronics and Electrical Manufacturers

- Automotive Manufacturers

- Aerospace and Defense Industry

- Healthcare and Medical Devices

- Industrial Machinery

- Packaging Industry

- Energy Sector

Key Global Stainless Steel Foil Industry Players

- NIPPON STEEL CORPORATION

- Jindal Stainless Ltd.

- Wieland Rolled Products North America Llc

- Bhandari Group

- Ulbrich Stainless Steels & Special Metals Inc

- IUP Jindal Metals & Alloys Limited

- All Foils Inc

- Jainex Steel and Metal

- Braun GmbH Folien-Prägetechnik

- Hasberg-Schneider GmbH

- Riddhi Siddhi Impex

- Hollinbrow Precision Products (UK) Limited

- Elgiloy Specialty Metals.

- Sonic Steel

- Ningbo Yaoyi Stainless Steel Co. Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383