MARKET OVERVIEW

The Global Industrial Plugs and Socket market is an important segment in the electrical components industry and plays a crucial role in ensuring that power transmission is safe and reliable in many sectors. This market involves the design, manufacture, and distribution of plugs and sockets designed especially to meet industrial requirements. The components connect electrical devices to power sources and let power flow efficiently in manufacturing plants and other applications like construction sites. Industrial plugs and sockets are quite different from those used in homes mainly because they can take quite high voltages and can make resistance in harsh conditions, thus ensuring durability and safe operation in difficult settings.

The industrial plugs and sockets market consists of diversified sectors such as manufacturing, construction, oil and gas, mining, and power generation, among other wide-ranging industries. All these sectors have a great need for consistency in performance and rely heavily on the dependability of their electrical systems; therefore, there will be increasing demand for reliable, rugged, and dependable plugs and sockets. The products of this market are designed to operate under intense conditions. Many of these products need to be operated by exposure to factors such as dust, moisture, and temperature fluctuations. Thus, manufacturers are innovating ways in which durability and longevity of these components can come out strong, to ensure required safety requirements are met by industrial users.

Industrial plugs and socket market is highly driven by the trend observed in industrial automation and electrification. This means, with higher degrees of automation in the industries, there will be more need for advanced electrical contacts that will cope with the increasing energy demands of the future, yet remain safely secure. Advanced contact technology, including high-tech plugs and sockets, will be created to interconnect and function in complete harmony with modern equipment and control systems, as the push toward the automation continues. With more stimulus globally towards sustainability, energy efficiency will be promoted in the market, and producers will seek to reduce power wastage by enhancing electrical conductivity.

Standardization is a major part of Global Industrial Plugs and Socket. Products must adhere to a strict, rigorous national and international standard for ensuring that they are not only compatible but also safe. Regional regulatory bodies would still impose requirements on industrial plugs and sockets to meet specific performance parameters and would have implications on the products available in the marketplace. Compliance with Global Standards would result in manufacturers eventually embracing international markets where a wide range of other competing products is widely produced, and also facilitates interoperability, facilitating industry integration and furthering global trade within the industry.

Near Term Outlook The technical paths pursued in the Global Industrial Plugs and Socket market will be clear trends. The integration of IoT in various industries will open the doors for further diffusion of such new products as smart plugs and sockets, which allow for real-time monitoring and control of all electrical connections. In this way, industrial users will be able to control their power consumption more effectively, thus eliminating energy waste. At the same time, this will improve operational efficiency. As industries grow and expand their endeavors, the demand for more intelligent, reliable, and robust electrical connections will intensify, thus setting up the market for further expansion.

The Global Industrial Plugs and Socket market is a very essential component of electrical infrastructure required by various industrial sectors and will continue to evolve with the ongoing technological change, the update on the regulatory front, and growing emphasis on energy efficiency and industrial automation in an industrial world.

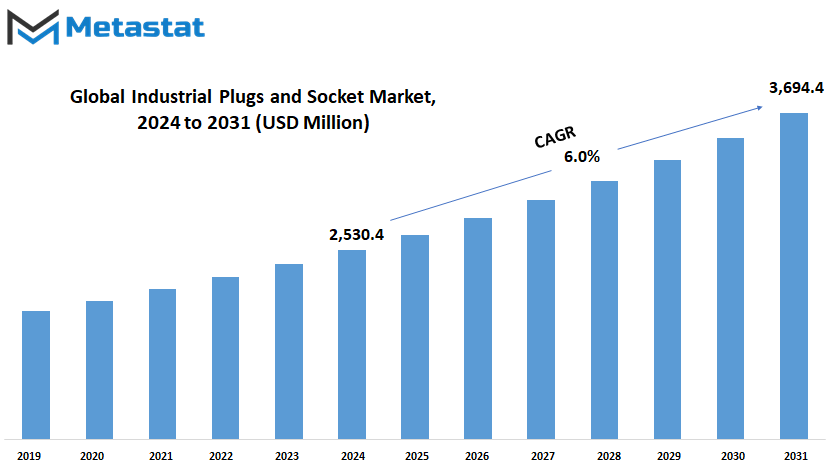

Global Industrial Plugs and Socket market is estimated to reach $3,694.4 Million by 2031; growing at a CAGR of 6.0% from 2024 to 2031.

GROWTH FACTORS

Thus, industrial plugs and socket market is likely to have a bright prospect for the years ahead as per market growth. This is primarily due to increased industrialization and infrastructure development, which most significantly drives the demand in the global scenario. Manufacturing, construction, and energy industries mainly require practical electrical connections in such environments, which are exactly where industrial plugs and sockets step into prominence. They guarantee safe and reliable connections, which are essential for most industrial operations to perform efficiently. Due to the increasing push to modernize and advance technology of the world, these components are gaining importance especially in countries that are developing their infrastructural systems rapidly.

Among other factors that will drive this market, the application of strict safety measures and regulations is a critical driver factor in this market. These standards emphasize the quality of electrical connections required in the industrial ambiance, signifying that industries have to incorporate quality plugs and sockets. Industries are always on high alert regarding safety, and the importance of solid and secure electrical connection grows even higher. This push for strict safety norms will create demand for robust and secure electrical connections in industrial settings, thus fueling growth in the industrial plugs and sockets market.

However, at the same time, there are also challenges that would slow the growth of this market. Some of the key among these challenges is the very high initial cost of good quality industrial plugs and sockets. Small to medium-sized enterprises or projects with tight budgets can be restrained at the outset because of such costs. Hence, a few organizations would be reluctant to spend on these fundamental components that could act as a restraint to the growth of the market. Apart from this, compatibility and standardization issues across regions and applications add to the intricacy in the selection and installation of appropriate products. The consumer will be confused with choosing a suitable product for their region and application, and business organizations operating across various regions will find problems in their market expansion.

However, the future outlook of the global industrial plugs and socket market seems promising when smart and IoT-enabled components are embedded. These innovations offer superior monitoring and control, with predictive maintenance capabilities that allow industries to perform more efficiently and reduce down time. Further trends in smart technology are said to precipitate new developments in the market and enhance opportunities for growth. The global industrial plugs and sockets market would move forward to the next years with increasing penetration of smart features while remaining concerned with safety and efficiency.

MARKET SEGMENTATION

By Type

Global Industrial Plugs and Sockets is certainly an integral element of the modern industry, facilitating the most critical connections of several electrical applications. Today, demands for energy efficiency just keep rising, so this market has undergone many changes down the years. Now the industry can be segmented into three: plugs and sockets rated up to 32 A, those rated from 32 to 125 A, and products above 125 A. There is a particular utility for each type with respective requirements in the varied markets.

Products that range from 32 A are mainly used for small operations, such as particular kinds of workshops and light manufacturing plants. The needed plugs and sockets to connect machinery, tools, and equipment are those with a lower power level. As more processes adapt to automation and smart technology, so will this demand for smaller types of plugs. Most of the companies invest in highly technological techniques with miniaturized equipment. This would, in turn, raise the demand for dependable connections in this range.

Rating in the medium range falls between 32 to 125 A that is mainly used in heavy industrial settings like factories and construction areas. These products are intended for meeting medium to high power loads, and thus suitable for machinery and equipment that have to be provided with significant electrical inputs. As industries are developing, this principle of safety and efficiency will become all the more important. This movement toward security and efficiency will see changes in design and material content available for this range, so that such products meet all the current safety specifications and at the same time increase their performance.

The rated plugs and sockets space above 125 A is crucial in very heavy industries with high energy generation, mining, and large-scale manufacturing industries. These products are designed to handle huge power demands and are quite imperative as far as connecting high-capacity machinery is concerned. With an increase in global energy use, the demand for strong connections will be overwhelming. Manufacturers will need to formulate solutions that do not only withstand some of the most brutal environmental conditions but ensure optimal performance and safety at all times.

Future prospects look even brighter for the Global Industrial Plugs and Socket market, as innovation continues on a constant path and more emphasis is given to energy efficiency. Sustainability will drive the development of this product line, driving away energy consumption and offering eco-friendly solutions for consumers. The adaptation of plug and socket systems to the latest technologies and ever-changing demands is critical for successful and efficient industries in the future.

By Current

Global Industrial Plugs and Sockets is certainly an integral element of the modern industry, facilitating the most critical connections of several electrical applications. Today, demands for energy efficiency just keep rising, so this market has undergone many changes down the years. Now the industry can be segmented into three: plugs and sockets rated up to 32 A, those rated from 32 to 125 A, and products above 125 A. There is a particular utility for each type with respective requirements in the varied markets.

Products that range from 32 A are mainly used for small operations, such as particular kinds of workshops and light manufacturing plants. The needed plugs and sockets to connect machinery, tools, and equipment are those with a lower power level. As more processes adapt to automation and smart technology, so will this demand for smaller types of plugs. Most of the companies invest in highly technological techniques with miniaturized equipment. This would, in turn, raise the demand for dependable connections in this range.

Rating in the medium range falls between 32 to 125 A that is mainly used in heavy industrial settings like factories and construction areas. These products are intended for meeting medium to high power loads, and thus suitable for machinery and equipment that have to be provided with significant electrical inputs. As industries are developing, this principle of safety and efficiency will become all the more important. This movement toward security and efficiency will see changes in design and material content available for this range, so that such products meet all the current safety specifications and at the same time increase their performance.

The rated plugs and sockets space above 125 A is crucial in very heavy industries with high energy generation, mining, and large-scale manufacturing industries. These products are designed to handle huge power demands and are quite imperative as far as connecting high-capacity machinery is concerned. With an increase in global energy use, the demand for strong connections will be overwhelming. Manufacturers will need to formulate solutions that do not only withstand some of the most brutal environmental conditions but ensure optimal performance and safety at all times.

By Protection

The Global Industrial Plugs and Socket market is poised for significant growth in the coming years, driven by advancements in technology and increasing demand across various sectors. As industries evolve and require more efficient and reliable electrical connections, the importance of robust and specialized industrial plugs and sockets becomes more apparent. These components play a crucial role in ensuring safe and effective power distribution in environments where standard equipment may not suffice.

In this context, the market is segmented based on protection types, which are essential for ensuring the longevity and functionality of electrical systems. The first category, Dustproof and Splash Proof, includes plugs and sockets designed to resist the infiltration of dust and moisture. These products are vital in settings such as manufacturing plants and outdoor construction sites, where environmental factors can jeopardize equipment performance. The ability of these connectors to withstand harsh conditions means they will be increasingly sought after as industries prioritize durability and reliability in their operations.

Another segment, Waterproof industrial plugs and sockets, caters to applications in areas that are regularly exposed to water or other liquids. Industries like food processing, marine, and chemical manufacturing require equipment that can operate effectively without being affected by moisture. As such, the demand for waterproof solutions will likely rise, prompting manufacturers to innovate and produce connectors that not only meet safety standards but also enhance operational efficiency.

Furthermore, the Explosion Proof category is critical in sectors where there is a risk of hazardous explosions due to flammable materials. These specialized plugs and sockets are designed to prevent sparks and ensure safe electrical connections in environments such as oil and gas production, petrochemical plants, and mining. The ongoing focus on workplace safety and regulatory compliance will drive the need for explosion-proof solutions, pushing manufacturers to invest in research and development to create more advanced and reliable products.

Looking ahead, the Global Industrial Plugs and Socket market will not only expand due to increasing industrialization but also because of technological advancements. As industries continue to embrace automation and smart technology, the demand for innovative and secure electrical connections will grow. This shift will encourage manufacturers to prioritize the development of versatile products that can meet the diverse needs of various sectors while ensuring safety and efficiency. Ultimately, the market will play a vital role in supporting the ongoing evolution of industries worldwide, emphasizing the significance of reliable power solutions in today’s economy.

By End User

The Global Industrial Plugs and Socket market is expected to grow with various industries. As every industry progresses and develops, the role of the market increases regarding efficiency and safety in various applications of electrical connections. A good understanding of the end users in this market will be beneficial for any business working towards improvement in their operations. The larger end users of industrial plugs and sockets include heavy industries, oil and gas, chemicals and pharmaceuticals, power generation, and a few others.

Heavy industries are among the significant sectors for the global industrial plugs and socket market. Various manufacturing and construction sectors require strong and reliable electrical connections to run machines and equipment. The demand for dependable and safe electrical systems will rise over time as heavy industries continue to increase productivity and reduce downtime. These will be in infrastructures and technological sites, so manufacturers should be able to come up with answers that will suit these industries.

In the oil and gas industry, there is an enormous call for specific plugs and sockets. The condition is extreme here as this product meets dangerous climate conditions. Its possible vulnerability to explosion increases its fragility. Thus, their products have to be safe for this particular market. This will probably increase the need for safe connections on the electricity supply side of this business because expansion in these lines will be needed. Companies will want innovative solutions that improve safety as they try to keep efficiency in their operations.

The chemicals and pharmaceuticals sectors also make up a significant share in the Global Industrial Plugs and Socket market. These sectors require dependable connections that can withstand corrosive environments and meet strict regulations. As these sectors continue to grow, along with growing global demands for healthcare and chemical products, the need for dependable electrical connections will be more pronounced.

This also encompasses another vital end consumer, that is generation of power. A transition towards renewable energy source, for example wind and solar, is altering the prospect in this market. The adoption of novel technologies will be determined by the requirement of efficient electric connections that can withstand the quantum of demand these sources impose before them. Sustainability will also impact innovation in this market and result in more developed products with reliability and performance.

The Global Industrial Plugs and Socket market will continue growing as these industries reach for more improvements on safety, efficiency, and sustainability. The operations complexity associated, both from heavy industries to oil, gas, chemicals and pharmaceutical, as well as electric power generation, will drive demand in reliable electricity connections. Manufacturers must meet their advanced needs to survive and remain competitive but still offer solutions that fit future needs better.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$2,530.4 Million |

|

Market Size by 2031 |

$3,694.4 Million |

|

Growth Rate from 2024 to 2031 |

6.0% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The industrial plugs and sockets in the global market are experiencing developments on a very critical level, especially while aligning with needs and preferences in different regions. All regions carry different characteristics and demands that shape up the overall landscape for the market. For instance, North America comprises the United States, Canada, and Mexico, with more focus now being placed on safety standards and energy efficiency. Companies in this region are always developing innovations that meet regulatory demands yet stay friendly and accessible to the users. Growth in construction and manufacturing industries increases demand and creates competition where technology and quality stand out.

In Europe, things take an entirely different course with its diversified regulatory systems and environmental factors. This market consists of huge countries like the UK, Germany, France, and Italy. Here, there seems to be a focus on sustainability and reduction of carbon footprints. In line with that, European manufacturers are responding to it by devising plugs and sockets that not only comply with local regulations but further support renewable energy initiatives. Indeed, towards greener solutions, the market is likely to get shaped in coming years, moving designers and companies to develop proper and feasible concepts.

The Asia-Pacific region is rapidly industrializing and urbanizing, and in the region that includes India, China, Japan, and South Korea, a young population and a growing middle class are further implying improved investments in infrastructure and energy; hence, the demand will be higher for reliable and durable electrical connections. Those manufacturers here are focused on cost-effective solutions, maintaining the high standards of quality thereof, which is going to be pretty crucial in sustaining growth in a competitive global marketplace.

The region also includes South America, with Brazil and Argentina. Economic boom and bust cycles, along with variations in technologically, will still create a roller coaster ride of demand for industrial plugs and sockets in this region. However, the need for high-technology electrical solutions is likely to be on the rise as more investment goes into the upgrading and infrastructure improvement efforts of the countries in this region.

For this purpose, there are the two regions of Middle East and Africa that contain GCC countries, Egypt, and South Africa. This region is also experiencing growth, supported by large-scale projects and growth in industrial activities. Industrial plugs and sockets demand will also be influenced by its region's investments within construction and energy sectors as it creates efforts to raise the ever-increasing energy demands by these populations.

The regional dynamics that are summarized above will define how the global industrial plugs and socket markets are experienced in terms of innovation, sustainability, and responsiveness to meet the changing needs of transforming industries worldwide going forward.

COMPETITIVE PLAYERS

The market for industrial plugs and sockets is unfolding globally, particularly as the technology develops and energy efficiencies become more critical to diverse areas. Extending industries need safe electrical connections that are efficient. From the major companies to small manufacturers, which ensure consistency and innovation in their products, such demand has been met. Some leading groups in this dynamic industry include Amphenol Corporation, ABB, Emerson Electric, Schneider Electric, and Legrand.

All these companies understand that the prospects of the global industrial plugs and socket market would rest upon its products as well as the potential of such companies to respond to the needs of the customers. For instance, Marechal Electric Group and Mennekes are focusing on developing reliable and safe connection systems that could function in rugged environments, thereby keeping industrial applications free from interruptions and increasing productivity.

With the smart technologies merging into industrial plugs and sockets, companies like Eaton and Siemens have also started paying much heed to it. Feeding integrations such as IoT connectivity and extra monitoring capabilities, firms are placing themselves in a powerful position that aids in satisfying increasing demand for smart industrial solutions. It is changing and bounds ahead of the mere functionality of a traditional product by growing energy efficiency and operational optimization through new avenues.

We would look forward to the future of the global industrial plugs and socket market, which would be integrated with a competitive landscape. Leaders in the market, such as Hubbell, Gewiss, and Leviton, would innovate designs and material to enhance performance and sustainability. Industry leaders and emerging companies need to collaborate for specific market needs and a customized solution.

Others are the regulatory changes as well as the sustainability goals that sector companies are looking into. In terms of environmental friendliness, manufacturers need to take into consideration the lifecycle impact of their products. This research and development will ensure that industrial plugs and socket ends continue to be highly relevant and responsive to new trends and changing demands worldwide.

In a nutshell, the market for industrial plugs and sockets is expected to grow enormously with major players in high innovation and excellence. A company will be required to operate with agility and responsiveness to this shift as technology is constantly advancing and sustainability is increasingly focused on. In that respect, the market leaders, through strategic initiatives and further collaboration, would be a leader of the pack for a more efficient and resilient industrial electrical connection future.

Industrial Plugs and Socket Market Key Segments:

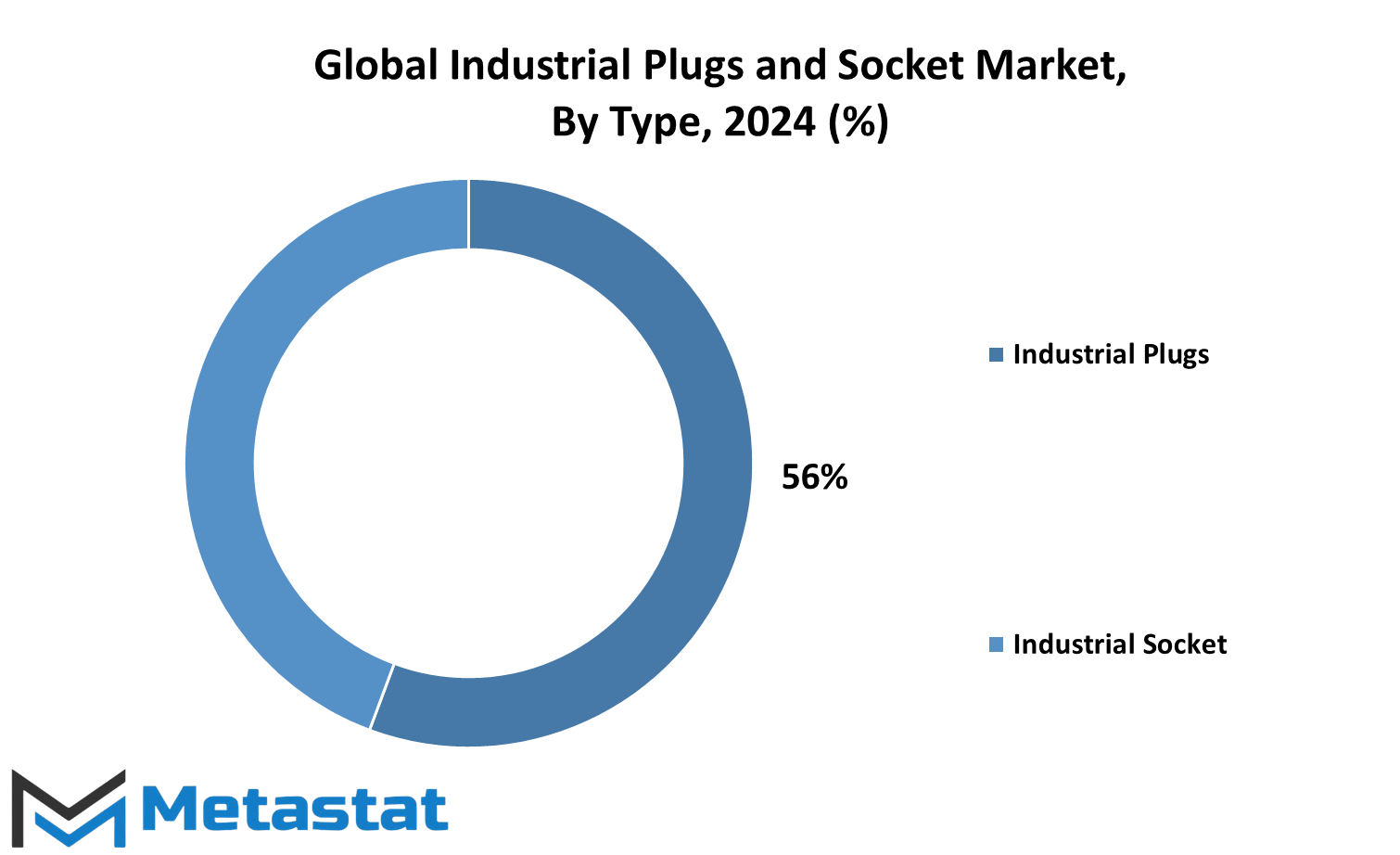

By Type

- Industrial Plugs

- Industrial Sockets

By Current

- Up to 32 A

- 32 to 125 A

- Above 125 A

By Protection

- Dustproof and Splash Proof

- Waterproof

- Explosion Proof

By End User

- Heavy Industries

- Oil and Gas

- Chemicals and Pharmaceuticals

- Power Generation

- Others

Key Global Industrial Plugs and Socket Industry Players

- Amphenol Corporation

- ABB

- Emerson Electric

- Schneider Electric

- Legrand

- Marechal Electric Group

- Mennekes

- Palazolli Group

- SCAME Group

- Eaton

- Siemens

- Hubbell

- Gewiss

- Leviton

- CEE Norm

- Walther Electric

- Phoenix Contact

- Bals Elektrotechnik

- Hensel

- PCE

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252