MARKET OVERVIEW

The Global Shape Memory Alloy market and its industry is an odd and special field in the domain of materials science, entirely around the research, manufacture, and applications of SMAs. These smart materials have the novel property to recover their predefined shape after deformation, driven by temperature variations or applied stresses. This has given way for the application of SMAs in high-performance and challenging applications, hence the role played by this market as the spearhead for technological improvements across several sectors.

It involves researching, producing, and selling of alloys like nickel-titanium (NiTi), copper-based, and iron-based SMAs. These alloys have properties such as superelasticity, high damping capacity, and good biocompatibility, which depend on their composition and application. The industry is based on its ability to service the specific needs of the aerospace, automotive, health care, consumer electronics, and robotics industries. In health care, for example, SMAs are used in the creation of stents, orthodontic wires, and other medical equipment that rely on their elasticity and strength.

The scope of the Global Shape Memory Alloy market is vast, and it reaches beyond traditional applications to encompass emerging fields. For example, in robotics, SMAs are being integrated into actuators to create more compact, lightweight, and energy-efficient mechanisms. Similarly, in aerospace and defense, these alloys are used in advanced components that require precise control over shape and motion under extreme conditions. Those materials find their applications because of the ability to operate reliably under harsh environments.

Further innovation will continue to redefine the market as technology advances. The integration of SMAs with additive manufacturing will open up new avenues for the development of highly customized components that enhance their functionality and extend their applications. Research into new alloy compositions and the development of hybrid materials is likely to further push the boundaries of performance and durability.

In the future, collaboration among industries, academic institutions, and research organizations in the Global Shape Memory Alloy market will continue to increase. Such collaborations will accelerate the discovery of new applications and help overcome issues related to cost, scalability, and long-term reliability. The growing emphasis on sustainability and energy efficiency will further drive adoption of SMAs, as their unique properties contribute to the development of lightweight, low-energy systems.

The consistent evolution and adaptation of the market to emerging demands speak to its economic and technological significance. As industries grow increasingly dependent on smart materials, the Global Shape Memory Alloy market will play an increasingly important role in addressing complex challenges and unlocking new possibilities across a broad range of applications. This dynamic interplay of material innovation and application expansion ensures that the market will remain a critical area of interest for both researchers, manufacturers, and end-users. In a nutshell, the Global Shape Memory Alloy market is situated at the intersection of material science and application innovation with transformative solutions shaping the future for multiple industries. Its wide scope and potential make it a vibrant and essential element of modern technological progress.

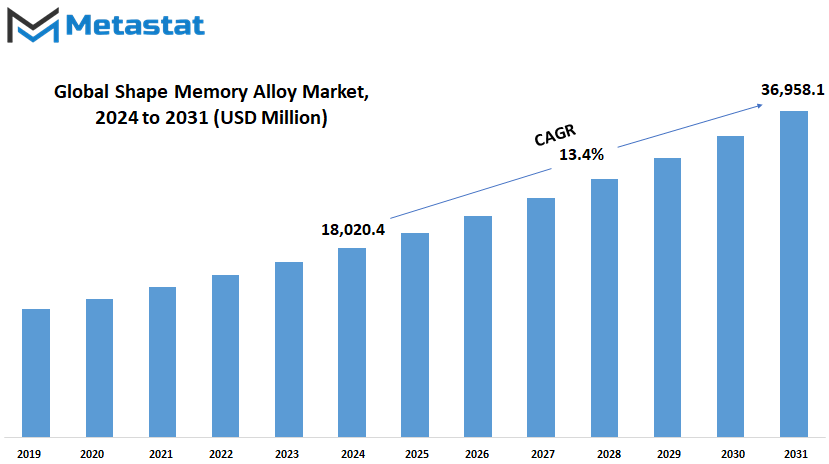

Global Shape Memory Alloy market is estimated to reach $36,958.1 Million by 2031; growing at a CAGR of 13.4% from 2024 to 2031.

GROWTH FACTORS

The Global Shape Memory Alloy (SMA) market is ready to experience a lot of change in the years ahead. The increasing application of SMAs in health care, aerospace, and automotive sectors drives this change. These materials are valuable due to their ability to recover their pre-defined shape after specific conditions are met, thus finding a crucial place in the modern technological world. The rising demand for SMAs in medical devices, such as stents, orthodontic wires, and surgical instruments, is primarily attributed to their biocompatibility and efficiency. The integration of SMAs into aerospace and automotive systems also brings about lightweight and highly efficient actuator and sensor solutions that have made them increasingly popular within those fields.

The bright positive trend notwithstanding, there are problems in the Global Shape Memory Alloy market. SMA material and manufacturing are costly in terms of price, so it remains a major bottleneck to production. Another issue that seems problematic about their use is their long-term resistance to fatigue and limited resistance to cyclic conditions, both repeated and cumulative. This would hinder market growth unless solutions to such cost-effective methods of manufacture and material are found.

Despite this, the future of the Global Shape Memory Alloy market looks bright with emerging opportunities in diversified applications. Advancements in material science and manufacturing techniques are opening up the scope for using SMA in consumer electronics, robotics, and 3D printing applications. These fields greatly utilize the adaptability and precision offered by SMAs, providing a basis for innovative designs and functionality. For instance, the use of SMA elements within robotics systems may help in better performance and precision. Consumer electronics may benefit from the toughness and resistance of the material to retain shape.

An opportunity as significant as this one that also integrates SMAs in 3D printing further creates groundbreaking possibilities. Using this technology, it makes possible the production of more complicated structures with SMA tailored to need requirements while it creates new avenues for individual customizations and efficiency. Applications that continue to develop make business prospects in the market large enough.

Whereas the costs are a barrier and the durability an issue, the Global Shape Memory Alloy market is going to remain on its growth trajectory. This trend is further assured in healthcare, aerospace, and automotive industries by increasing demand, and advancements in consumer electronics, robotics, and 3D printing.

MARKET SEGMENTATION

By Type

The Global Shape Memory Alloy market is expected to grow significantly, mainly due to the innovative applications of these materials in various industries. SMAs have unique properties, such as returning to a pre-defined shape upon exposure to specific temperature changes. This transformative feature makes them valuable in fields such as aerospace, healthcare, and automotive. The market is anticipated to grow with emerging new technologies and uses of these alloys.

The NiTi Nickel-Titanium Alloys are one of the primary segments in the market because they have high flexibility, strength, and biocompatibility. They are being increasingly used in medical appliances, such as stents, dental wires, and surgical instruments. Precision and versatility have made them inevitable for the healthcare sector as it seeks more minimally invasive operations. The increasing need in the field of medical science to develop even more reliable materials will continue to promote the use of Nickel-Titanium Alloys.

The Cu-Al and Cu-Zn-based alloys also account for a substantial percentage in this market. Copper-based alloys are known to offer low-cost, along with good thermal properties that contribute to its application in the electric system and construction fields. Alloys that require high structural flexibility, along with efficient heat transfer, are also incorporated. With sustainable and energy-efficient infrastructure projects being built day by day, there will be a high demand for copper-based SMAs in the market.

Next to aluminum, iron-based alloys hold an important position. Their added strength and affordability make these alloys valuable for industries such as industrial machinery and consumer electronics where mechanical stability, coupled with cost considerations, is essential. Titanium Alloys, on the other hand, are gaining mileage, especially in the aerospace and automotive sectors, due to its lightweight and corrosion-resistant features. They help reduce the weight and energy consumption to make greener transportation.

There are also other highly specialized alloys that serve special niches. These were designed for specific purposes. For instance, shape memory alloys have increasingly been used with robotics and wearable technologies and have made devices capable of adjusting according to the specific needs of the user.

Looking forward, the Global Shape Memory Alloy market is likely to benefit from continued research and development efforts and expansion into new industries. With the advancement of technology, the versatility of these alloys will open doors to applications that were previously unimaginable and shape a future where innovation and functionality go hand in hand.

By Form

The global shape memory alloy market has potential for growth given the ever-increasing requirement for high-tech materials based on continuing technological advancements, and continues to shape their future. Shape memory alloys (SMAs) constitute materials which can return towards their original shape after having been deformed by various stimuli like heat. Their unique ability to respond to external conditions makes them invaluable in various industries, including aerospace, healthcare, robotics, and automotive. The growing reliance on SMAs points to the potential for this market to expand and adapt to emerging needs in different sectors.

The market is categorized by the form in which SMAs are utilized. Wires, for instance, dominate applications requiring flexibility and precision, such as medical devices like stents and orthodontic braces. These wires provide exceptional reliability and functionality, making them a preferred choice in minimally invasive procedures. Similarly, tubes are commonly employed in industries requiring structural stability and high-performance capabilities, including aerospace and mechanical engineering. Tubes of SMAs are in high demand due to their efficiency in providing durability along with weight reduction. This is a critical requirement in energy-efficient and environment-friendly industries.

Sheets and springs are another area of the Global Shape Memory Alloy market where industries are in need of versatile applications. Sheets are flat in design and highly adaptable in the construction of sensors, actuators, and thermal controls. On the other hand, springs provide resilience and also some precision. This serves devices that require repeated change of shape without affecting function in any way. This indicates the various uses SMAs can have to solve distinct needs in different areas of operation.

Other forms, like rods and strips, offer even more variety and functionality for specific uses. Industries are exploring these options to create components that are both strong and versatile, opening up the possibilities for smarter, more efficient systems. These areas seem to have good potential for innovation, thus promising the market a future of continued technological advancement.

The global demand for lightweight, durable, and energy-efficient materials is sure to expand the application base of the Global Shape Memory Alloy market into previously untouched industries. Increased interest in sustainability and efficiency also makes sure that SMAs will remain at the center of material innovation, and, thus, at the core of shaping the future of global industries.

By Application

The Global Shape Memory Alloy market is poised to witness significant strides as technology advances at an unprecedented rate. Shape memory alloys are known for their unique property of returning to a predetermined shape when subjected to certain stimuli. The approach to problem-solving has been revolutionized in numerous industries due to these materials. These materials are a unique combination of strength, flexibility, and durability and are therefore highly sought after for various applications.

Shape memory alloys have already revolutionized the development of devices such as stents and orthopedic implants in the medical field. Their ability to adapt to the biocompatibility and the nature of the materials allows for minimally invasive procedures that enhance patient outcomes. Integration of artificial intelligence with these materials is going to pave the way for even smarter medical devices that will improve precision and efficiency in treatments.

Shape memory alloys are gaining popularity in the automotive sector for applications such as actuators and lightweight parts, enhancing fuel efficiency and vehicle performance. Future developments in this area may be aimed at improving the energy efficiency and sustainability of these materials, aligning with the global trend towards greener technologies.

The promising fields of using shape memory alloys in space applications involve the aerospace arena. Shape memory materials are being used more crucially due to the growing need to produce aircraft and spacecraft component parts, such as lightweight robust components. Their demand shall increase due to rising space traveling activities that intensify these efforts for more commercial spaces. Such endurance under intense conditions ensures the industry keeps them irreplaceable.

Shape memory alloys opened doors to more adaptive and lifelike designs in robotics. Their ability to simulate natural movements is worth its value in developing robust systems of robots that exhibit increased agility. Future generations of robots may have the capacity to perform complicated maneuvers, such as healthcare tasks, manufacturing, or even disaster response, by harnessing shape memory alloys.

Consumer electronics also benefit greatly from shape memory alloys, particularly in devices requiring flexibility, such as foldable phones and wearable gadgets. As innovation in electronics continues, these materials will likely play a pivotal role in meeting consumer demands for smaller, smarter, and more versatile products.

With constant industrial pursuit of practicable and efficient solutions across numerous applications such as sensors and actuators, the global shape memory alloy market stands poised for expansion into even more diversified applications. Shape memory materials are potential breakthroughs to redefine any established system, inspire a wide range of new technologies, and serve as an invaluable cornerstone for future innovations toward limitless growth.

By End-Use

The Global Shape Memory Alloy market is expected to rise remarkably in the next coming years due to advancement in numerous industries and growing demand for innovative materials. Shape memory alloys, due to the property of returning to a previously established shape upon being subjected to certain conditions, such as temperature changes, are becoming very popular due to their wide versatility and strength. This has diverse and is being applied to multiple sectors which are developing in terms of technological demands.

These materials are widely used in healthcare and medical devices for stents, surgical tools, and orthodontic wires. Their properties are quite unique, thus they provide better patient outcomes by means of minimally invasive procedures. Because of the rising demand for advanced healthcare solutions, it is expected that the healthcare sector will continue to contribute highly to the growth of the Shape Memory Alloy market. These materials are also in high demand within the aerospace and defense industries for lightweight and high-strength features. This enables their applications in actuators, fasteners, and other critical components with the increased need for fuel-efficient and sustainable aviation technologies.

The automotive industry is also an important contributor to the growth of the market. In their pursuit of better fuel efficiency and advanced features, manufacturers are incorporating shape memory alloys into vehicle components such as actuators, sensors, and temperature-responsive systems. This trend is further accelerated by electric vehicles, where shape memory alloys are being explored for innovative uses in battery systems and energy management.

In consumer electronics, compactness, efficiency, and responsiveness have become the primary demands driving the adoption of these alloys. From foldable displays to temperature-sensitive circuits, their use is molding the future of gadgets. Robotics and automation also are experiencing a positive impact due to these alloys, which help create more precise and flexible robotic systems. These innovations may revolutionize industries from manufacturing to healthcare.

These materials are being applied in industrial applications, oil and gas, and manufacturing for their ability to sustain harsh environments and perform dependably. Other sectors such as construction and fashion also look into their potential applications.

The future of the Global Shape Memory Alloy market seems bright with the basis of technological innovation, increasing industrial demand, and material uniqueness. With time, these alloys will find a place in every industry’s mainstream and be a crucial part of the global economy.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$18,020.4 million |

|

Market Size by 2031 |

$36,958.1 Million |

|

Growth Rate from 2024 to 2031 |

13.4% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

Advancement in technology and increasing demand from the various industries are likely to provide remarkable growth for the global Shape Memory Alloy market over multiple regions. These materials, popularly known for their return to original shape upon certain conditions such as heat exposure, are widely being adopted in healthcare, aerospace, and robotics sectors. This transformational potential is opening doors for regional markets to be at the forefront of the industry's growth.

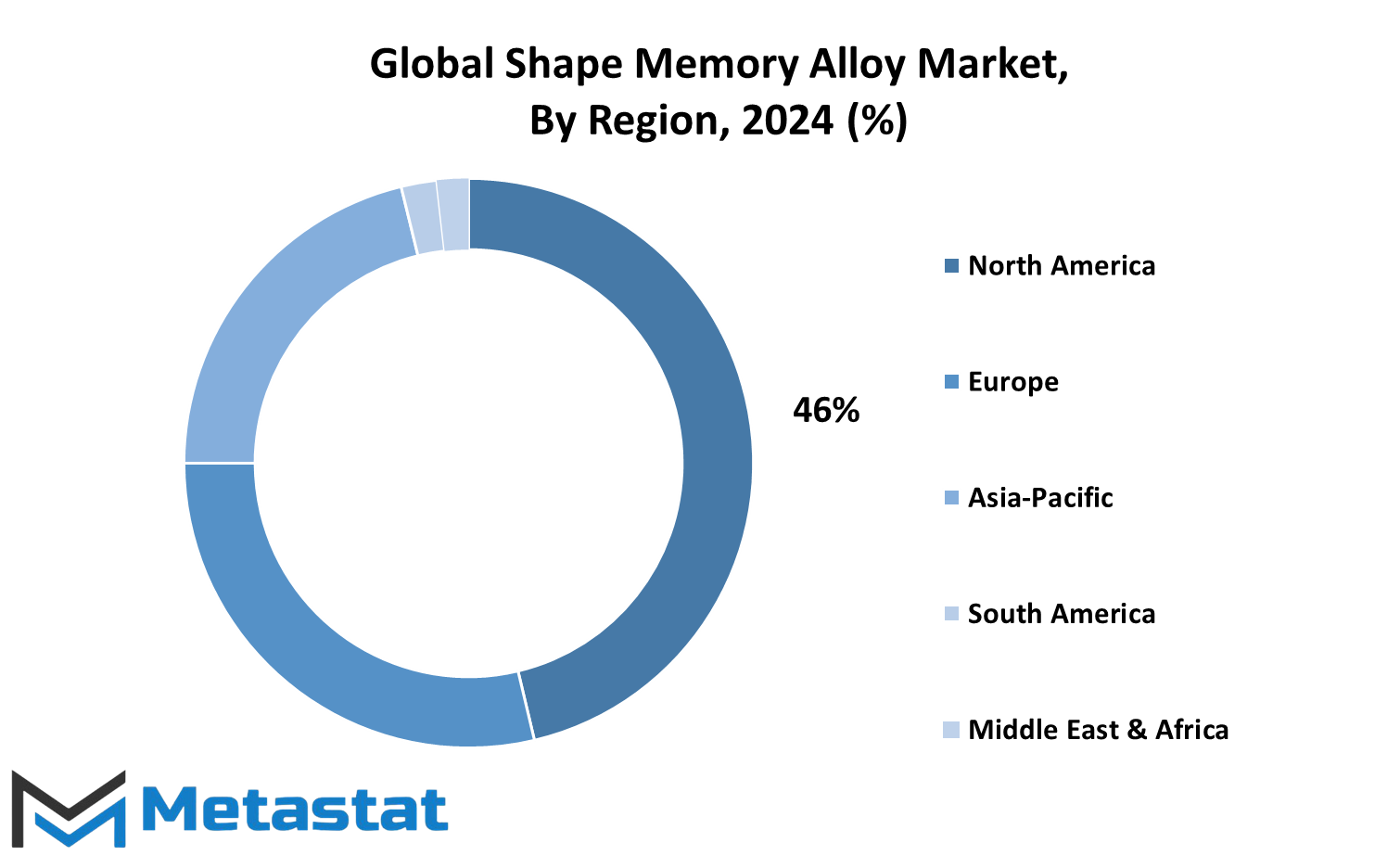

North America continues to be one of the dominant regions in the global Shape Memory Alloy market due to its strong technological infrastructure and robust demand from sectors like medical devices and defense. The United States is the largest contributor in the region, supported by extensive research and development efforts and a well-established healthcare system. Canada and Mexico are also growing, though at a more moderate pace, as they integrate these materials into emerging applications.

Europe is the next closest region, with Germany, the UK, France, and Italy being the leading innovation and application development countries. Germany is particularly strong in its manufacturing base and expertise in engineering, which has helped the country stay ahead of the curve in Shape Memory Alloy advancements. The UK and France are significant contributors to the market through their focus on medical and aerospace technologies. Other countries in the region are also catching up, which creates an opportunity for growth with increased awareness and investments.

Asia-Pacific is becoming a very promising market for Shape Memory Alloys due to the rapid industrialization and increasing technological capabilities of nations like China, Japan, South Korea, and India. China is the leading country in the region, as it has large-scale manufacturing capabilities and increasing investments in smart technologies. Japan and South Korea are the leaders in the field of electronics and robotics. Their innovations in alloy technology will push the bounds of these alloys. It is believed that India with its burgeoning healthcare and automobile industries, will make some significant contributions in the next few years.

Gradually, South America, mainly led by Brazil and Argentina, is adopting Shape Memory Alloys as the industrial sectors in the region become modernized. Similarly, the Middle East & Africa region is exploring the possibilities with these materials, especially in GCC countries and South Africa, where industrial growth and technological adoption are on an increase.

As global industries are embracing innovation, the Shape Memory Alloy market is bound to thrive with each region contributing uniquely to its future trajectory. This collaborative progress underscores the versatile potential of these materials in shaping industries worldwide.

COMPETITIVE PLAYERS

The Global Shape Memory Alloy market will experience enormous developments as the industries continually push to move boundaries through innovation. Shape Memory Alloys are preferred for their unique capability to recover their original shape when stimulated by a change in temperature or other forms of stimuli. Due to their excellent adaptability and high function, these materials are being increasingly used in industry sectors such as aerospace, health care, robotics, and automotive, thereby making key players competitors in this game.

The leading companies researched and developed in this business are Johnson Matthey, Nippon Steel & Sumitomo Metal Corporation, and SAES Getters S.p.A. Their efforts are transforming the market trends as they seek new ways to make SMAs more durable, efficient, and sustainable. As the demand for lightweight yet strong materials is increasing, Furukawa Electric Co., Ltd., Fort Wayne Metals, and Daido Steel Co., Ltd. are using metallurgical developments to create alloys that address specific industrial requirements. For example, in medical practices, SMAs are incorporated in stents and other medical instruments for their high biocompatibility and precise specifications.

As technology advances, companies like G.RAU GmbH & Co. KG and Neomaterial Technologies & Solutions are researching possibilities that may well redefine the boundaries of SMAs. Their nanotechnology and material science research is expected to introduce alloys with superior properties, thus making them even more versatile. Furthermore, companies such as ATI (Allegheny Technologies Incorporated), Advanced Nitinol, and Microfine Materials, Inc. are focusing on scalability, thereby ensuring that SMAs can be produced on a large scale to meet increasing global demand.

Automotive industry demand will be stimulated further by the need to introduce fuel efficiency and innovation in safety. Companies like Goodfellow and Kongsberg Gruppen ASA are likely to contribute by developing parts that enhance vehicle performance but decrease the environmental impact. This same adaptability of SMAs is expected to drive robotics to be more responsive and lifelike with the involvement of manufacturers such as Fushun Special Steel and Jameco.

The Global Shape Memory Alloy market has the potential to expand further since industries are investing in such transformative material. Breakthroughs will be accelerated in this area by collaboration among research institutions and industry leaders such as the Copper Development Association Inc, and SMAs will continue to be a cornerstone for material innovation in the years to come.

Shape Memory Alloy Market Key Segments:

By Type of Alloy

- Nickel-Titanium Alloys (NiTi)

- Copper Alloys (Cu-Al, Cu-Zn)

- Iron-based Alloys

- Titanium Alloys

- Other Alloys

By Form

- Wires

- Tubes

- Sheets

- Springs

- Others (Rods, Strips, etc.)

By Application

- Actuators

- Sensors

- Robotics

- Medical Devices

- Automotive Parts

- Aerospace Components

- Consumer Electronics

- Others

By End-Use Industry

- Healthcare and Medical Devices

- Aerospace and Defense

- Automotive

- Consumer Electronics

- Robotics and Automation

- Industrial Applications

- Others

Key Global Shape Memory Alloy Industry Players

- Johnson Matthey

- Nippon Steel & Sumitomo Metal Corporation

- SAES Getters S.p.A.

- Furukawa Electric Co., Ltd

- Fort Wayne Metals

- Daido Steel Co., Ltd.

- G.RAU GmbH & Co. KG

- Neomaterial Technologies & Solutions

- ATI (Allegheny Technologies Incorporated)

- Advanced Nitinol

- Microfine Materials, Inc.

- Goodfellow

- Kongsberg Gruppen ASA

- Jameco

- Fushun Special Steel

- Copper Development Association Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252