MARKET OVERVIEW

The North America Heat Resistant Alloys Commercial Captive Heat Treatment market is of considerable importance in the industrial segment of the region. It is supposed to provide treatment for such types of alloys that could bear heat at very high temperatures. Such alloys find colossal applications in aerospace, automotive, power generation, and the petrochemical sector where durability and resistance to thermal decay may be thought to be primary issues.

This market addresses the demand for upgrading the quality of heat-resistance alloys through captive heat treatment procedures. Annealing, quenching, and tempering are a few of the different practices carried out to enhance mechanical properties and performance in such alloys. These techniques enable the industries to guarantee that the base material of the alloy will not deteriorate with time and will sustain structural integrity and functional efficiency even under extreme operating conditions.

The characteristically qualitative and accurate shape is what sets the pace in the North America Heat Resistant Alloys Commercial Captive Heat Treatment market. Companies into this market invest heavily in sophisticated technologies and equipment to carry out the heat treatment process with highly accurate parameters. Indeed, this level of precision is unavoidable because even slight deviations in the heat treatment process may lead to substantial differences in the performance of the treated alloys.

Besides the technological aspects, this market also needs to work within strict boundaries concerning industry standards and regulations. Compliance with such standards is not only a compulsion but also an important ingredient to gain client confidence, which depends upon the high performance of these alloys to sustain their operations. Certification and regular audits, in this regard, are common features within this market to ensure proper benchmarking of heat treatment processes.

Also, the market is driven by continuous research and development so as to come up with new alloy composition and also perfection of existing techniques of heat treatment. The collaboration among industrial players, research institutions, and academic bodies is very significant in this market; hence bringing innovations that improve efficiency and effectiveness in heat-resistant alloys. The North America Heat Resistant Alloys Commercial Captive Heat Treatment market is very crucial as far as strategy is concerned. The aerospace industry has a continuous need for materials that can bear high temperatures and stress, as well as the automotive industry's demand for better-quality alloys for increased performance and longer engine life. In addition to these industries, turbines and other equipment used in the power generation industry are bound to be made up of materials that resist exposure to high temperatures over long periods of time without giving way to loss of structural integrity.

Going forward, the industry will remain committed to embedding green strategies in a way that ensures the reduction of environmental harm. The current state is only partial and has been spurred partly by increasing regulatory pressures, coupled with a growing belief that one could gain at the expense of the competition through sustainability. In all likelihood, the companies will invest in eco-friendly heat treatment methods and revisit alternatives of renewable sources of energy for powering their operations.

Therefore, due to the rapid development of technologies and increasing demand in all spheres of industries, it cannot be otherwise but promising. It is going to be a continued evolution of finding the perfect material that will serve best at high temperatures, keeping this market at the forefront of industrial innovation. It thus follows that the more industries seek materials that are reliable and durable, the more this market becomes of vital importance to the supply of high-quality heat-resistant alloys.

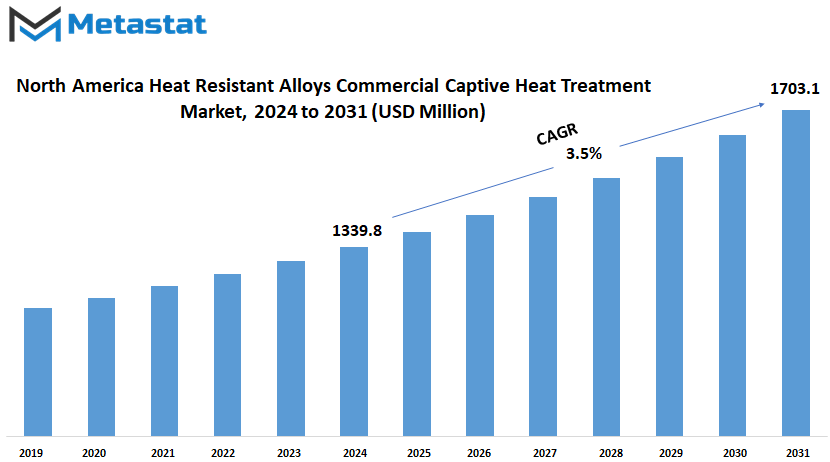

North America Heat Resistant Alloys Commercial Captive Heat Treatment market is estimated to reach $1703.1 Million by 2031; growing at a CAGR of 3.5% from 2024 to 2031.

GROWTH FACTORS

The captive heat treatment market for heat-resistant alloys will have enormous potential in North America in the near future. The growth factors are expected to be governed by a few major factors. Growing demand from various industries for high-performance materials is one of the major growth factors driving the market. It is expected that with the growth in aerospace, automotive, and power generation industries, demand will increase for materials that can withstand very hostile environments at high temperatures. Applications of these kinds require the use of tough, heat-resistant alloys to provide toughness and overall performance.

Other key drivers for the market in question will also be innovations and technological advances. Companies are continuously investing a lot in research and development to make efficient and effective processes of heat treatment. This, in turn, results not only in high-quality alloys but also costlier processes of production. Advanced technologies, including artificial intelligence and machine learning, will also go further in integrating into the process of heat treatment and will optimize operations for higher productivity and reduced costs.

This notwithstanding, there are some challenges that may stand in the way of growth in this market. First of all, it is the cost of raw materials involved in making heat-resistant alloys. Quite often, these materials can be very expensive, and their price might fluctuate-that affects the entire cost of production. The process of the heat treatment itself may get too complicated to undertake for some, especially the low-technicalERENCE manufacturers. This requires skilled manpower and advanced equipment, which are expensive.

Despite these challenges, enormous growth opportunities exist in the North America Heat Resistant Alloys Commercial Captive Heat Treatment market. Due to the growing awareness of sustainability and environmental legislation, demand for non-polluting, eco-friendly efficient heat treatment processes is on the increase. Any company able to develop such a process and actually implement it in practice can stay ahead of the competition. Apart from this trend, the increase in demand for higher light weight and improved fuel efficiency in the automotive sector has also emerged as another growth-promoting factor for heat-resistant alloys. These materials have enormous applications in the manufacturing of high-temperature resistant components that reduce the net weight of the vehicle.

The North America Heat Resistant Alloys Commercial Captive Heat Treatment market is at an edge of heavy growth owing to the rising demand for high performance material and technology advancement. Ranging from high raw material cost to process complexity, while there is a raft of challenges, the opportunities still continue to be huge, and the trends of sustainability and lightweight materials in the automotive continue to open up scope for market growth. Heat-resistant alloys will be more and more vital in the future as industries continue to evolve.

MARKET SEGMENTATION

By Alloys Type

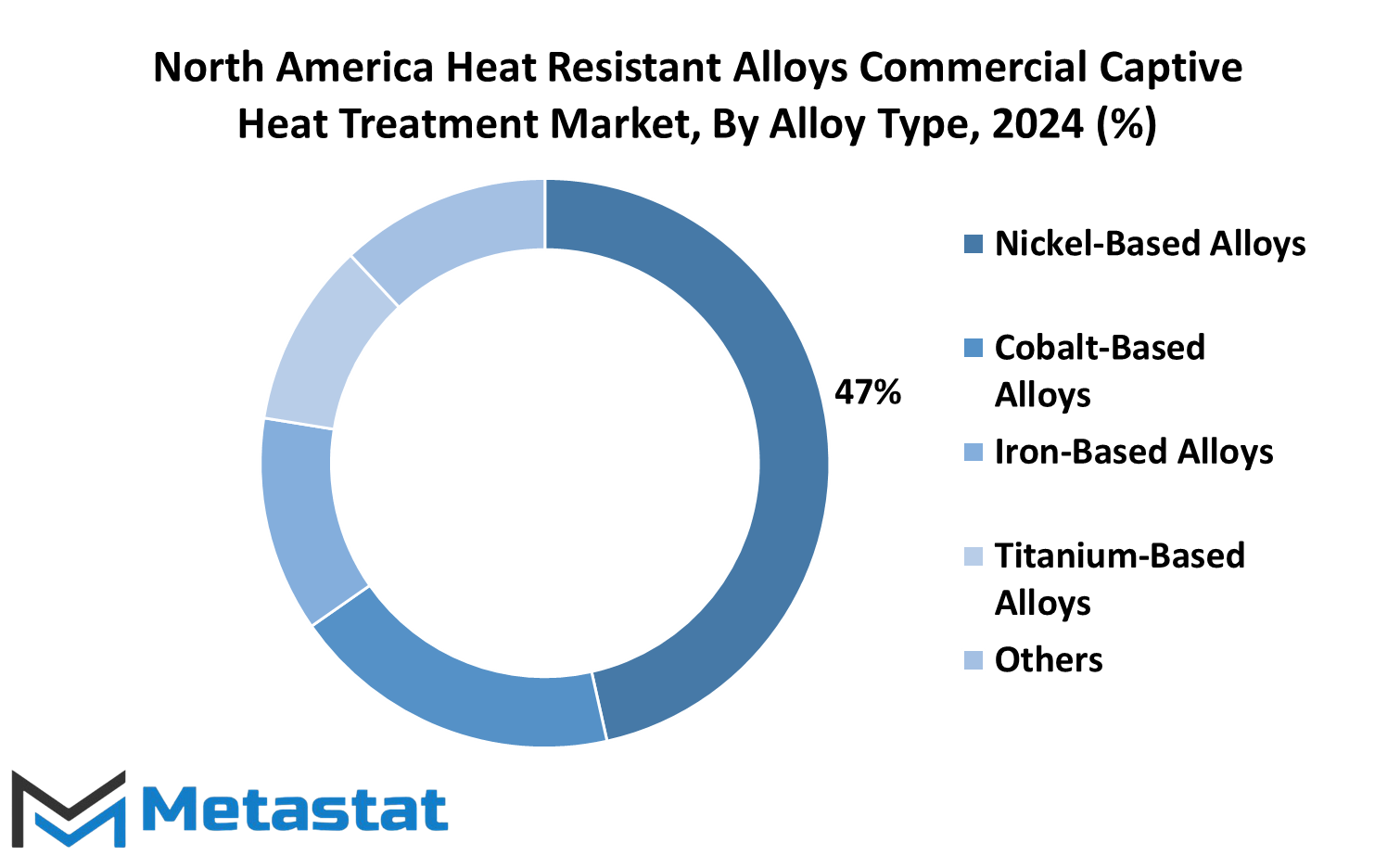

The future outlook for North America Heat Resistant Alloys Commercial Captive Heat Treatment appears to be pretty good and significantly growing. It pertains to the treatment of several types of alloys, some of which include Nickel-Based Alloys, Cobalt-Based Alloys, Iron-Based Alloys, Titanium-Based Alloys, among many others. These alloys have wide applications in industries dealing with high-temperature applications and materials whose properties do not deteriorate with an increase in temperature.

This, along with advancement in technology, creates a bright scope where heat-resistant alloys will definitely be in higher demand. These alloys find their place in aerospace, automotive, and power generation industries where the components are in a very vulnerable condition. The North American heat-resistant alloys commercial captive heat treatment market will contribute tremendously to these specific industries with advanced materials that guarantee safety with efficiency in the coming years.

New applications for the alloys will also drive further growth in the market. There has been a recent surge in investment in renewable technologies due to the greater interest in green sustainable energy solutions. Heat-resistant alloys are needed to work efficiently under differing conditions in wind turbines and solar power plants. This in turn provides extra impetus to the demand in the market for such materials, thus offering greater opportunities.

Further innovations in heat treatment processes will go a long way in improving the outlook for this market. The efforts by researchers and manufacturing concerns have been one of enhancing heat-resistant alloys in durability and performance. Advanced techniques in heat treatment will thus enable the production of better alloys with improved properties to serve the changing needs of industry applications. These are expected to lower the costs and increase the use of heat-resistant alloys in new applications, further raising the market.

With North America continuing to be the center for technological innovation and industrial growth, infrastructure here will continue to grow. This would hold good, especially for the aerospace and defense industries, which are on an increasing spree, thereby allowing them to meet the expanding requirements with respect to more efficient, resilient, and lightweight aircraft and defense systems by consuming more high-performance alloys. Thus, this will, in turn, fuel the North America Heat Resistant Alloys Commercial Captive Heat Treatment market.

Further development of refractory alloys will help growth in the automotive sector. With more and more electric vehicles reaching the roads, the demand for such materials will increase that will not lose performance with increasing temperature. This will make Nickel-Based Alloys, Cobalt-Based Alloys, Iron-Based Alloys, Titanium-Based Alloys, and others highly crucial in the components of EVs and hence very potential for market growth in times to come as well.

The North America heat-resistant alloys commercial captive heat treatment market is growing at an exceptionally fast rate. Rising demand for advanced materials in industries such as aerospace, automotive, power generation, and renewable energy, along with innovations in heat treatment processes, would drive the growth of the market. Further, developments in the industrial and technological landscape in North America show a positive outlook toward keeping this market robust and dynamic for many years to come.

By Heat Treatment Processes

The North America heat-resistant alloys commercial captive heat treatment market will see a very good future in the near term. Advanced manufacturing and industrial application development will be the path of development for this market, which in turn will increase with the increase in demand for heat-resistant materials. This market will be segregated based on a couple of heat treatment processes, all of which play an important role in enhancing the properties of the alloys.

Annealing, for instance, will be common in that industries will have to make metals more ductile by reducing their hardness. The process remains important, especially for materials requiring further machining and shaping so that they may remain workable without compromising their integrity. In most of the uses where strength and durability are being put into task, hardening and tempering will equally become useful. These processes will be further honed in creating alloys that resist every kind of extreme condition and therefore are quite appropriate for aerospace, automotive, and heavy machinery industries.

Hardening of cases will still be vital in those parts that need a hard outside and a soft core. This process will remain very instrumental in the manufacture of gears, camshafts among other parts, which have massive friction. Solution treatment will continue to be on the increase because it improves some alloy properties mainly aluminum by dissolving alloying elements, then cooling them fast enough to retain their solid solution.

The precipitation strengthening process, which will offer increased strength to the heat-resistant alloys, is another important process. The technique in essence involves heating of the alloy to a high temperature, followed by cooling to form fine particles that hinder dislocation movement and provide the necessary strength. Stress relieving for getting rid of residual stresses from the metalworking processes will assume greater importance so that the components retain their original shape and performance under operational stresses.

It will still find its use in normalizing the grain structure of steels and thereby improving their machinability and tensile strength. The process is going to become relevant with a view to engendering uniformity and predictability for the easier production of mechanical properties by manufacturers in ensuring high-quality components.

As the North America Heat Resistant Alloys Commercial Captive Heat Treatment market would develop further, such processes would become even more fine-tuned and integrated with newer technologies. Advanced heat treatment methods such as induction heating and laser hardening would be even more in vogue since they allow very tight control over material properties and take relatively little time to apply. Automation and digitalization would rise wherein smart sensors and AI-driven systems would improve accuracy and consistency in the heat treatment processes.

By Application

Growth in the North American commercial captive heat treatment market for heat-resistant alloys will be driven by the many different applications that the treated alloys serve in industries such as aerospace and defense, automotive, power generation, oil and gas, industrial machinery, medical devices, and electronics. Heat-resistant alloys will probably find growing demand with technological advancement, since these materials are critically used for better component performance and durability in high temperatures.

The major application of heat-resistant alloys is in the manufacture of parts in the aerospace and defense industries due to the high usage of material under extreme rugged conditions. Advances in technologies relating to aviation and defense at higher temperatures and maintenance of structural integrity will continue to grow this market. In addition, increasing fuel efficiency and low emission concern in the automobile industries will raise demand for heat-resistant alloys. Such material has its application to manufacture parts like an exhaust system and turbochargers that are liable to bear extremely high temperatures.

Power generation is another sector that can extend North America Heat Resistant Alloys Commercial Captive Heat Treatment market tremendously. With the shift in the world towards sustainable energy, such alloys will be very instrumental in the development of efficient and long-lasting turbines, among other equipment. Another industry with very hostile operational environments is the oil and gas industry, which these alloys will also be useful in, as they form the main components used in the manufacture of equipment capable of working in high-temperature and corrosive environments.

Applications in industrial machinery will keep on advancing and are going to require heat-resistant alloys for improved performance and longevity through different types of machinery. Medical devices will continue to show development in improved methods of sterilization, thus giving an increasing demand for heat-resistant alloys that can support this use without degradation. That will be the fact in the electronic industries in their quest for miniaturization and improvement of performance through devising of components that support increasing heat releases from powerful devices.

The North America Heat Resistant Alloys Commercial Captive Heat Treatment market will have continued growth with these industries finding new applications. Such cooperation will be essential for pushing new technologies and meeting the emerging demands of such industries in the future and will include leading material scientists, engineers, and manufacturers. Likely future developments will be targeted at the elaboration of more effective and less costly heat treatment processes and the search for new composition alloys with improved performance.

In the near term, the North America heat-resistant alloys commercial captive heat treatment market would grow notably. The need for heat-resistant alloys and new heat treatment processes is driven by growth in various industries such as aerospace and defense, automotive, power generation, oil and gas, industrial machinery, medical devices, and electronics. As industries press for even more efficiency and durability, the demand never stops growing.

By End User

Over the coming years, the North America Heat Resistant Alloys Commercial Captive Heat Treatment market will grow at a significant rate. The growth of heat treatment market for commercial captive heat-treated heat-resistant alloys is led by aerospace manufacturers, automotive OEMs and suppliers, operators of power plants, oil and gas companies, manufacturers of industrial equipment, medical device manufacturers and electronics manufacturers among other end-user industries. This demand for sophisticated high-temperature-resistant alloys will be driven from demand in each of these applications.

Aerospace manufacturers will become one of the important segments in this market. In the aerospace sector, more sophisticated aircraft and spacecraft will be developed that need high-temperature materials. This will further promote the demand for heat treatment methods to enhance the properties of such alloys for high-performance capability in critical applications.

The second big contribution to the market will come from automotive OEMs and suppliers. As automobile companies increasingly design EVs and more efficient combustion engines, the demand for heat-resistant alloys is going to increase in constructing an element that has to bear high operational temperatures while playing a critical role in ensuring efficiency and safety.

Power plant operators will also be very important in market development. Rapid shifting is taking place towards cleaner sources of energy-for example, natural gas and renewable energy-and thus demands more advanced materials that could bear high heat and stress. This would gradually raise the demand for special heat treatment processes able to enhance the capabilities of durability and efficiency.

Oil and gas companies will drive this market continuously. With the industry moving into an increasingly hostile environment, high-temperature alloy demand is set to go up accordingly. The materials definitely will be of critical importance in ensuring safety and efficiency in equipment which work at very harsh conditions, such as deep-sea drilling or high pressures.

Manufacturers of medical instruments demand these alloys to fabricate devices that need operation under sterilization conditions. The fast-growing medical industry will demand materials which keep up their integrity under repeated heat treatments-assuring safety and effectiveness in operation.

This has also raised the demand for heat-resisting alloys because innovating manufacturers of electronics have fitted electronic equipment with more power and miniaturized them in size. I would say this falls under the same category as above: the question of electronic goods that are able to dissipate heat. This will drive advances in heat treatment processes to improve the performance of these alloys.

Even though the increasing end-use segments makes the North America Heat Resistant Alloys Commercial Captive Heat Treatment market poised to grow exponentially, associated demand from each sector will continue to rise for advanced material and specialized heat treatment processes that aim at ensuring constant development and application of heat-resistant alloys in the relevant industry.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1339.8 million |

|

Market Size by 2031 |

$1703.1 Million |

|

Growth Rate from 2024 to 2031 |

3.5% |

|

Base Year |

2022 |

|

Regions Covered |

US, Canada, Mexico |

REGIONAL ANALYSIS

The North American Heat Resistant Alloys Commercial Captive Heat Treatment market will witness unprecedented growth in the near future. This will be because of growing demand for this material by various high-temperature-loaded bearing applications. Major players in the region, namely the U.S., Canada, and Mexico, will drive accelerating growth in this market with improvement in technology and increase in industrialization.

The country will continue being one of the leading ones within this market due to advanced technologies within manufacturing and because of heavy investments within R&D activities. Within the United States, the aerospace and defense industries will enormously require heat-resistant alloys since these materials are applied within the manufacture of high-performance engines and other critical engine parts. Their application is also likely to increase in order to enhance performance and extend the lifespan of vehicle components in the automotive industry.

The country's industrial base has a deep passion for and commitment to innovation-a fact that will already be a great asset in the market. Emphasis on sustainable and efficient production methods will promote the application of advanced heat treatment processes, challenging Canadian companies toward newer technologies that improve the quality and performance of heat-resistant alloys both for the domestic and foreign markets.

Contrarily, Mexico would have the most rapid growth in the market because of the rapidly developing manufacturing sector in the region. Geographical location and preferential trade agreements favor attracting investments from all major players. The soaring demand from the automobile, aerospace, and industrial machinery sectors shall cause the manufacturers in Mexico to rely on the consumption of heat-resistant alloys. Establishment of new heat-treatment plants in Mexico gives more momentum to the market.

Technology, in addition to growing collaboration among key companies, is expected to play the prime role in driving the overall heat-resistant alloys market in North America. The region is also at an edge of the development of new material and process inventions that would further improve the performance along with durability of the heat-resistant alloys. Hence, business firms will strive to develop alloys with improved heat resistance along with mechanical properties to meet strict specifications of various industries.

Regulations by environmental agencies and the trend toward sustainable business operations will further support the growth of environmentally friendly heat treatment processes. Consequently, companies will be spending on research and development to formulate alloys that provide high performance at high temperatures while having minimal impact on the environment. Such trends toward sustainability will act as key drivers of the North America Heat Resistant Alloys Commercial Captive Heat Treatment market during the forecast period.

The growth of the North America Heat Resistant Alloys Commercial Captive Heat Treatment market will be driven by technological innovation in a nutshell, with growing industrialization and sustainability. This growth will be spearheaded by the U.S., Canada, and Mexico, powered by their manufacturing prowess, capabilities in innovation, and strategic geographical location. This market shall, therefore, always be dynamic by opening up new opportunities while pushing innovations in high-performance materials in various industries.

COMPETITIVE PLAYERS

With technological advances and growing demand in diversified industries, the captive heat treatment market for heat-resistant alloys in North America will experience high growth rates. Competition among the players will also be one of the key drivers due to continuous innovations and expansions taken up by leading service providers to help customers change their needs. The same will bloom with companies striving to enhance the life span and performance of their heat treatment processes.

This leading position is going to be further consolidated by Bodycote Plc through the addition of new technologies and extended geographical locations. Having had several decades of experience in the business and expertise in pioneering heat treatment services, Bodycote will be better placed in advanced solutions that meet strict industry requirements for aerospace, automotive, and energy industries.

Further, Solar Atmospheres will become very important in the growth of the market. Strongly committed to quality and innovation, Solar Atmospheres will be further developing heat-processing processes that continue improving the properties of heat-resistant alloys. The impetus for engaging more in research and development activities will make them offer more state-of-the-art solutions to various current and future high-performance applications.

Paulo enjoys the enviable tag of offering the widest range of heat treatment services, and with an eye on a growing market demand, Paulo continues to expand its capabilities. Equipped with state-of-the-art technologies at the back and tight quality standards, Paulo will henceforth provide reliable and efficient solutions for performance enhancement and life extension of heat-resistant alloys.

Bluewater Thermal Solutions will be leading in the market due to the provisions it makes towards personalizing heat treatment service delivery to meet particular client needs. Their experience in the various types of heat treatment will enable the serving of several industries, ensuring the high performance of heat-resistant alloys across diverse applications.

Applied Thermal Technologies Inc. will continuously move in the direction of innovation and growth. State-of-the-art equipment and processes usher in new heat treatment solutions that allow improved mechanical properties and durability for heat-resistant alloys.

Metallurgical Solutions, Inc. shall be responsive in precision and quality for heat-treated processes, yielding the best products that turn out performance and reliability, thereby satisfying their clients.

Advanced Heat Treat Corp. will also never miss a single step in the market because the improvement in heat treatment techniques is developed day by day. Its inclination toward innovation and quality supports it in delivering solutions to better efficiency and effectiveness while handling heat-resistant alloys.

Specialty Steel Treating will be specializing in special heat treatment services for a wide array of industries. This expertise in the treating of a range of heat-resistant alloys will make it the go-to choice of any client seeking reliable and high-quality treatment solutions.

The other major players that will contribute to the market growth are Thermal-Vac Technology, Braddock Metallurgical, Continental Heat Treating, Inc., and American Metal Treating, Inc. These companies will grow the North America Heat Resistant Alloys Commercial Captive Heat Treatment market through continuous process improvement and expansion in services.

In a nutshell, the major players working relentlessly to invent and develop their services will influence the competitive scenario of the North America Heat Resistant Alloys Commercial Captive Heat Treatment market. These companies will be in a condition to extend their potentials further in the future by limiting technology and quality to cater to their customer's growing needs.

North America Heat Resistant Alloys Commercial Captive Heat Treatment Market Key Segments:

By Alloys Type

- Nickel-Based Alloys

- Cobalt-Based Alloys

- Iron-Based Alloys

- Titanium-Based Alloys

- Others

By Heat Treatment Processes

- Annealing

- Hardening and Tempering

- Case Hardening

- Solution Treatment

- Precipitation Strengthening

- Stress Relieving

- Normalizing

By Application

- Aerospace and Defense

- Automotive

- Power Generation

- Oil and Gas

- Industrial Machinery

- Medical Devices

- Electronics

By End User

- Aerospace Manufacturers

- Automotive OEMs and Suppliers

- Power Plant Operators

- Oil and Gas Companies

- Industrial Equipment Manufacturers

- Medical Device Manufacturers

- Electronics Manufacturers

Key North America Heat Resistant Alloys Commercial Captive Heat Treatment Industry Players

- Bodycote Plc

- Solar Atmospheres

- Paulo

- Bluewater Thermal Solutions

- Applied Thermal Technologies Inc.

- Metallurgical Solutions, Inc.

- Advanced Heat Treat Corp

- Specialty Steel Treating

- Thermal-Vac Technology

- Braddock Metallurgical

- Continental Heat Treating, Inc.

- American Metal Treating, Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252