MARKET OVERVIEW

The Global Industrial Safety Gloves market is just one noteworthy subsegment of the larger market for safety and protective equipment. These gloves are designed to provide protection in an extremely wide range of industrial settings. As such, gloves can protect hands against chemical exposure, extreme temperatures, cuts, abrasions, and punctures, ensuring workers' safety and compliance with occupational health standards.

There are many types of industrial safety gloves, designed for specific industries and applications. For instance, nitrile gloves show high resistance to the majority of chemicals; thus, their usage is most widespread in the chemical and pharmaceutical industries. Cut-resistant gloves manufactured from Kevlar or stainless steel mesh are actually quite necessary where one deals with sharp objects, as in manufacturing and construction. Heat-resistant gloves are normally fabricated from materials like leather or Kevlar and become very important in industries such as welding and foundry work. As such, governments and industry bodies around the world have set stringent safety regulations and standards where appropriate personal protective equipment should be utilized in order to minimize the incidence of injuries or death in the workplace. Therefore, companies are investing more in quality safety gloves across various industries to comply with regulations and ensure the safety of employees at work. Improving technologies will have a huge impact on the Global Industrial Safety Gloves market.

Development of new materials and associated manufacturing processes have enabled gloves with better protection, comfort, and dexterity. For instance, innovations in coating technologies have resulted in gloves with improved grip and enhanced tactile sensitivity, which have enabled the performance of activities with better precision and safety. Besides, integration of smart technologies like sensors monitoring environmental conditions and providing real-time feedback is going to revolutionize the industrial safety gloves market in the next few years. It is also partly driven by increasing awareness of the need for workplace safety and growing emphasis on creating a much safer working environment. This makes the employer rather quite active in introducing complete safety programs that would incorporate the use of relevant personal protective equipment, wherein safety gloves form only one part. This shift is further fueled through initiatives from safety organizations and industry associations by way of best practices and training on proper use of safety equipment. The Global Industrial Safety Gloves market is swelling in developing economies due to the rapid industrialization and expansion of industries such as construction, manufacturing, and oil and gas. Companies involved in these markets are now acknowledging the importance of worker safety and are investing in high-quality safety gloves in order to reduce potential risks and improve productivity.

In the future, the market will continue to progress because of continuous development in materials science and technology. Trends toward the development of green and eco-friendly materials for manufacturing safety gloves will increase with growing environmental concerns associated with traditional glove materials. Besides, ergonomics and comfort for the user will be addressed through glove development that provides not only superior protection but also enhances wearer comfort and reduces fatigue.

The global industrial safety gloves market becomes one of the most dynamic and important segments pertaining to safety and protective equipment. It is driven by stringent regulatory requirements, burgeoning technological innovations, and increasing concerns toward workplace safety. As industries invest in the well-being of their employees and in new innovative safety solutions, demand for industrial safety gloves will continue to prevail.

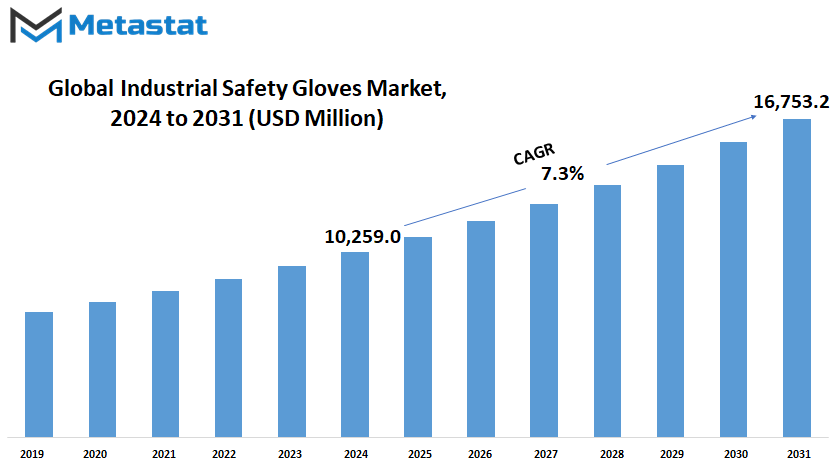

Global Industrial Safety Gloves market is estimated to reach $16753.2 Million by 2031; growing at a CAGR of 7.3% from 2024 to 2031.

GROWTH FACTORS

The global industrial safety gloves market is growing at a rapid pace, driven by a few major factors. The primary driver for this growth is increasing workplace safety awareness across industries worldwide. As concern for the well-being of employees is increasing among businesses, the demand for effective safety gear such as industrial safety gloves is also increasing continuously.

Another key driver is the stringent regulatory standards put in place by governments and industrial bodies. These regulations enforce the use of protective equipment to reduce occupational hazards, thus increasing the adoption of industrial safety gloves across various industries.

Although several growth factors have been mentioned, challenges to the market's expansion exist. One of the major challenges could be the high raw material cost for the manufacture of industrial safety gloves. Fluctuations in their prices alter the production cost and, thereby, market dynamics.

The other important issue is the allergic reactions caused by the latex gloves. This has compelled companies to venture into developing gloves using other materials that have equally protective features yet remain non-allergenic. The ability to overcome this challenge will be what determines continued growth of the market as well as increased consumer base.

The outlook for the industrial safety gloves market is promising, with innovation in gloves continuing in the future. Innovations in materials and manufacturing processes are likely to further improve on durability, comfort, and protection capability. These technological developments will satisfy changing safety standards and open up newer opportunities for market players to come up with innovations and product differentiations.

While allergic reactions and raw material costs are temporary challenges, the industrial safety gloves market is expected to register high growth. Growing awareness about workplace safety combined with the impact of regulatory mandates will continue to drive demand in the future also. Besides innovations in glove technology, new growth opportunities will be unlocked, thus ensuring the strong expansion of the market in the near future. On the other hand, whereas industries across the world are increasingly becoming conscious about workforce safety and well-being, this would …… accelerate the importance of industrial safety gloves in mitigating occupational risk.

MARKET SEGMENTATION

By Type

The industrial safety gloves market is likely to grow as a result of heightened awareness and legislation for workplace safety across the globe. Gloves have an application in a myriad of industries by way of segmentation into disposable and reusable gloves.

Disposable gloves find a significant market across many industrial segments where hygiene and prevention of cross-contamination are major concerns. Basically, the material used to make disposable gloves has to consist primarily of nitrile, latex, or vinyl materials to ensure protection from chemicals, pathogens, and other contaminants with single-use convenience. These gloves find a special place in health, food, and laboratories to provide a sterile environment and protect staff from danger.

On the other hand, reusable gloves are designed to be strong and more long-lasting. They are normally fabricated using resilient materials such as rubber, leather, or woven fabrics, which are resistant to cuts, abrasions, and punctures. Reusable gloves have found major applications in the manufacturing, construction, and automotive industries where a worker faces physical risk and requires more solid protection for a longer period.

The global industrial safety gloves market keeps growing with industries taking a serious outlook toward worker safety, alongside stringent regulations, as well. With governments and organizations putting greater emphasis on occupational safety across the world, this has spiked further demand for quality protective gear like industrial safety gloves.

This industry is being driven by innovations in new glove materials and designs. The manufacturers strive to bring improvement in gloves with built-in advanced materials for better protection, comfort, and durability. For example, new synthetic materials are developed for gloves resistant to chemicals and abrasions but more flexible and comfortable to wear for a longer period of time.

Moreover, the trend is shifting toward environmental sustainability in glove manufacturing. Due to the global call for eco-friendliness, businesses have started to invent gloves that are biodegradable or made from recycled materials.

By Material Type

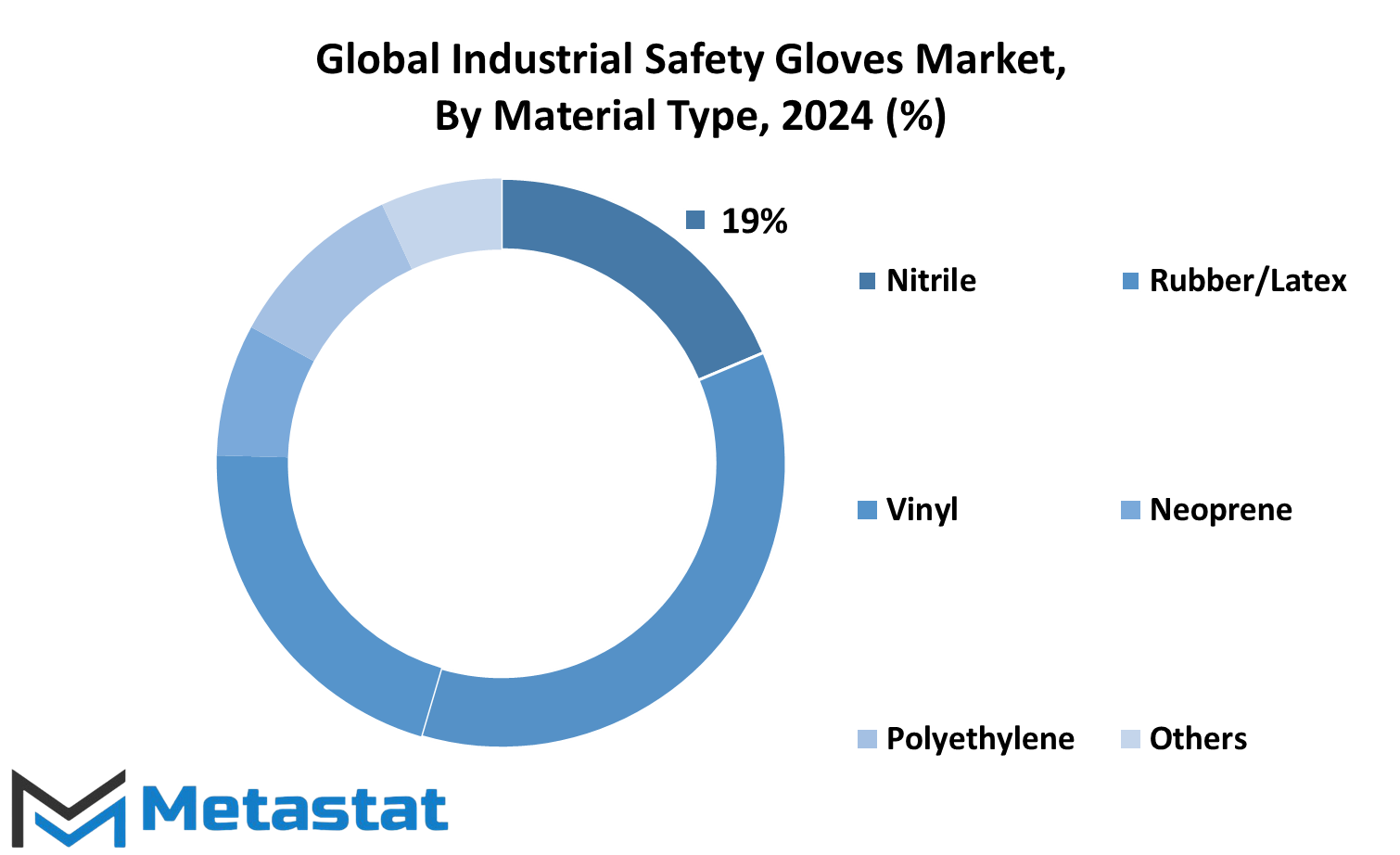

Industrial safety gloves cannot be underappreciated in today's world. These gloves are ready to provide protection to a worker from occupational hazards in different industries. The global industrial safety glove market can thus be segmented according to the type of material used in their production: nitrile, rubber/latex, vinyl, neoprene, polyethylene, and others.

Nitrile gloves have a lot of uses in industries where their property of chemical resistance is very important. They guarantee excellent protection from oils, greases, and chemicals, hence most applied in healthcare, the automobile, and chemical manufacturing. They have durability and puncture-resistance properties that make them quite usable in heavy-duty working conditions.

The rubber/latex gloves are elastic and comfortable, thus widely used in medical and food handling due to better tactile sensitivity and fitting features. However, concern over latex allergies raises a demand for alternative materials to it like nitrile and vinyl.

The low price of vinyl gloves and excellent resistance to chemicals and contaminants make them very desirable. Though far less resilient than nitrile or latex, they may find a perfect application in jobs with high glove exchange rates, such as food service and janitorial work.

Neoprene gloves are acid-, oil-, and solvent-resistant, so they will do well in tasks requiring exposure to such harsh chemicals. These gloves, in turn, become handy for laboratories, pharmaceutical manufacturing, and industrial cleaning due to their flexibility and comfort.

Lightweight and inexpensive, polyethylene gloves come into use primarily in industries where a change of gloves is necessary to maintain good hygiene standards. They protect from dirt and contaminants but will not protect against chemicals or sharp objects since their puncture resistance is very poor.

Other materials are also put into service manufacturing gloves for specific industries that require heat resistance, anti-static, or specialized chemical protection.

The development of industrial safety gloves in the future will be based on technological development and innovations in material sciences. The manufacturers are oriented to further improve the performance, durability, and comfort of gloves while addressing environmental concerns through sustainable materials and green production practices.

By End Users

Industrial safety gloves have made a difference today, across all sectors. Such gloves were not merely used to serve the purpose of a mandatory accessory but formed a very critical component for the workers' safety at the workspace from various unwanted hazards. Segmentation of the global industrial safety gloves market has been done according to end-users: healthcare, chemical industries, food processing, manufacturing, and others.

These gloves rely on healthcare professionals to prevent infections from reaching them and thereby maintaining hygienic standards during any kind of medical procedures. These gloves are some of the most important equipment in a hospital or a clinic that assure the protection of not only patients but also practitioners.

Industrial protective gloves play quite a significant role in the chemical industries since many of these workers are really exposed to very corrosive chemicals and hazardous substances. They are designed to bear contact with different types of chemicals and hence protect from burns, irritations, and other possible dangers.

Similarly, in the food processing industry, hygiene is of the highest order. Industrial safety gloves are used to protect high cleanliness standards from being contaminated and to ensure adherence to the concerned food products' provisions regarding safety. Gloves are worn by workers handling food products to protect hygiene from cross-contamination.

The applications of industrial safety gloves in the manufacturing industry range across various settings, such as automotive, electronics, and heavy machinery. They give protection against mechanical hazards like cuts, abrasion, and impacts and enhance the safety of workers, thereby reducing the potential for occupational injuries.

The Others category incorporates numerous industries in which industrial safety gloves are applied, from construction and mining to agriculture and laboratories. For instance, the gloves protect workers against physical injuries and harsh environments in construction and mining. Special gloves are used to handle hazardous materials safely in laboratories.

With industries increasingly approaching labor safety and the regulatory bodies coming down heavy on not adhering to stringent safety norms, demand for industrial safety gloves is likely to rise. Companies into this segment are likely to continue innovation in developing gloves to meet not just safety requirements but also to enhance productivity and comfort for workers.

REGIONAL ANALYSIS

The global industrial safety gloves market has been analyzed based on regional distinctions across some of the key continents. North America, including the United States, Canada, and Mexico, forms a key market for industrial safety gloves. Stringent regulatory provisions that provide for compulsory protective equipment in various industries have benefited this region.

In Europe, it encompasses the heavy economies of the UK, Germany, France, Italy, and the rest of Europe, with great emphasis on worker safety and welfare. The strict regulations for workplace safety, coupled with a strong manufacturing sector, drive the market for industrial safety gloves in the region.

Moving on to the Asia-Pacific region, which includes major markets such as India, China, Japan, South Korea, and the rest of Asia-Pacific, demand for industrial safety gloves comes in as a result of rapid industrialization and rising awareness about workplace safety standards. Countries like China and India, with their large manufacturing bases, are witnessing tremendous growth in the usage of safety gloves across industry sectors.

One can feel a heightened awareness for workplace safety measures in countries like Brazil and Argentina, and the rest of South America, thus fueling the demand for industrial safety gloves. The wide diversity of industries, ranging from agriculture and mining to manufacturing, further supports growth in the region.

The Middle East & Africa region, comprising GCC Countries, Egypt, South Africa, and the rest of Middle East & Africa, witnesses growing adoption of safety gloves on the back of rising industrialization and stringent safety norms in industries such as oil & gas, construction, and manufacturing.

Each of these regions has different opportunities and challenges for the industrial safety gloves manufacturers and suppliers. The market participants therefore alter their strategies with respect to regional requirements, complying with the local safety standards and regulations. This approach not only ensures compliance but also enhances market penetration and growth prospects in diverse geographical markets.

COMPETITIVE PLAYERS

The most central things in industrial safety are protective gears. An important component in the protection of people at work in different sectors is through the aspect of industrial safety gloves. Gloves in this particular industry act as protective wear for the hands against hazardous materials, sharp objects, and extreme temperatures.

The global industrial safety gloves market is highly competitive, with a number of key players competing based on gaining maximum market share. Companies leading the way include Top Glove Corporation Bhd, Huihong(Nantong)Safety Products Co., Ltd. (GHH), and Ansell Ltd. The companies come up with continuous innovation in materials and design, pushing the envelope of what the gloves can do in terms of safety.

Based in Malaysia, Top Glove Corporation Bhd is the industry leader and offers a wide array of products to its customers based on different industrial requirements. The emphasis on quality and durability of the Malaysian company makes it stand apart from other competitors. Equally, the global leader Ansell Ltd. specializes in advanced ergonomic design that enhances both safety and comfort for workers.

Innovation acts as the major driving force behind this market. Businesses like Honeywell International Inc. and 3M Company keep investing in research and development to launch new gloves with added features. These include developing gloves with better gripping, enhanced properties for resistance against chemicals, and improved tactile sensitivity to serve the demand in industries for specific applications.

The presence of regional players such as Zhejiang Kanglongda Special Protection Technology Co., Ltd. and Shandong Yuyuan Latex Gloves Co., Ltd. further brings localized expertise and price-competitive strategies. All these actors are widening the range of market players, providing healthy competition and wide choices for consumers.

The future looks bright for industrial safety gloves with the development of materials science and manufacturing technologies. Further in line with this trend will be lightweight yet strong materials such as nitrile and high-performance fibers that provide better protection without necessarily trading off dexterity. Equally, smart glove solutions equipped with integral sensors for real-time health monitoring or environmental hazard detection will most likely prevail more.

The industrial safety gloves market is extremely competitive but at the same time dynamic and innovative. With global giants coupled with agile regional players in the market, there will always be a change in the product profile and stringent safety standards. Tightening workplace safety regulations across the world imply continuous demands for reliable high-quality industrial safety gloves—continuously driving further advancements and market growth.

Industrial Safety Gloves Market Key Segments:

By Type

- Disposable Gloves

- Reusable Gloves

By Material Type

- Nitrile

- Rubber/Latex

- Vinyl

- Neoprene

- Polyethylene

- Others

By End Users

- Healthcare

- Chemical

- Food

- Manufacturing

- Others

Key Global Industrial Safety Gloves Industry Players

- Top Glove Corporation Bhd

- Huihong (Nantong)Safety Products Co., Ltd. (GHH)

- Jiangsu Hanvo Safety Product Co., Ltd.

- Protective Industrial Products (PIP)

- Zhejiang Kanglongda Special Protection Technology Co., Ltd

- QA GLOVES (PVT.LTD.)

- ATG Intelligent Glove Solutions

- Ansell Ltd.

- Honeywell International Inc.

- 3M Company

- Kossan Rubber Industries Bhd

- Hartalega Holdings Berhad

- Showa Group

- Kimberly-Clark Worldwide, Inc.

- Uvex Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383