MARKET OVERVIEW

The global membranes market as industries begin to realize the potential advantages that advanced filtration systems could bring. Indeed, with continuous improvement and a lot of adoption, membrane technologies will have the integrated needy part for the years to come in ensuring the availability of clean water, effective industrial processes, and sustainable management of resources.

Optimal membranes form the prime engine among several industries and application fields in providing critical solutions for filtration, separation, and purification processes. Membranes in the treatment of water, medicines, food, and beverages, and biotechnology demonstrate the heart of effective and sustainable mechanisms. The relentless progress in material science and membrane technology will evaluate how industries enhance resource optimization, waste reduction, and product quality. Therefore, the global membranes market is sure to evolve toward greener solutions according to ever-increasing environmental regulations and demand for purified resources.

As industries continue their pursuit toward the development of renewable energy sources and eco-friendly technology, membranes will slowly start to dominate applications in hydrogen fuel cells, energy storage systems, and carbon capture systems. This will not only change the face of the industrial setting but will set higher standards for energy efficiency. In addition, the pharmaceutical industry will focus on developing membrane technology for drug formulation, bioprocessing, and targeted drug delivery, taking precision medicine to the highest level. Moreover, the healthcare sector's demand for high-performance membranes will spur interest in biocompatible and self-cleaning materials that promote better patient outcomes.

The threats of global warming and the consequent need for water sustainability will keep forcing membrane technology frontiers. Desalination plants, wastewater treatment plants, and industrial water-reusing units will increasingly adopt advanced membrane solutions to deal with water contamination challenges. The trend toward decentralized water treatment plants will foster the adoption of compact and high-efficiency membranes that will allow industries and municipalities to safeguard water security with the least environmental harm.

Food and beverage industries will see a major turnover as membranes improve the safety of food, extend shelf life, and make production processes more efficient. Be it from filtering out an ingredient like milk to clearing a beverage or anything else, these substances have a considerable impact on the purity of products without marring taste and nutritional value. Selectively separating unwanted components of ingredients will refine them and meet the rising demand of consumers for more clean-label and preservative-free products.

With the growth of bioprocessing and biomanufacturing on an industrial scale, membrane technology will come to play its role in precision fermentation, enzyme production, and microbial separation. In supporting the global shift to bio-based alternatives to synthetic chemicals, membranes will therefore gain importance as enablers for the creation of cost-effective and sustainable production methods.

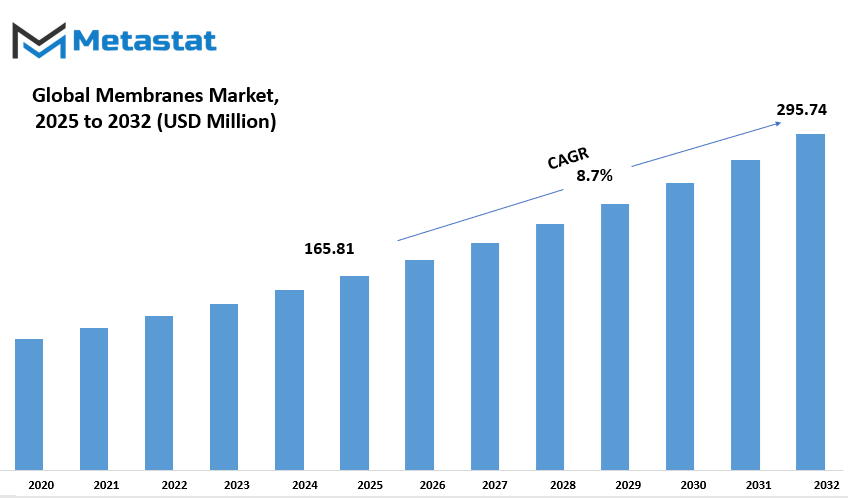

Global membranes market is estimated to reach $295.74 Million by 2032; growing at a CAGR of 8.7% from 2025 to 2032.

GROWTH FACTORS

The global membranes market is going to make a difference in the form of becoming advanced by industries in search of effective filtration and purification solutions. Growing concerns about the environment have resulted in a need for water treatment solutions, placing membrane technology at the core of obligations to deal with water shortages and pollution. Governments and private organizations have constructed a new environment where-adopting advanced membranes systems becomes inevitable for many sectors. However, such an accentuated demand for membranes has been witnessed in industries like pharmaceuticals and food processing, where purity and control of quality are very much emphasized. In addition to this, membrane technology is getting adopted increasingly for separation processes where it provides greater efficiency in cost.

Although gaining importance, multiple challenges are lined before the global membranes market and will serve to hinder its growth. The first is much high and continuous operational costs with respect to capital investment as an anything membrane set up. Budget limitations in addition to requirements of frequent replacements and maintenance shun many companies from utilizing these technologies for their benefit. Apart from these, long-standing issues include fouling and degradation of membrane quality, which translates into reduced operational efficiency with time. Such will, in turn, result in increased operational costs and down time, factors making businesses re-evaluate their long-term viability.

Innovative Technology in these challenging times will with great possibility solve such barriers. New developments in nanotechnology open up facile techniques for making high-performance membranes with well-enhanced filteration powers and longevities. The search to invent bio-based membranes goes on since these would have improved strength and green benefits. These will lead to reduced maintenance costs with improved efficiency making these membranes more appealing to shifts toward high-level application. Further, the expanding application of desalination and wastewater recycling projects worldwide is broadening the horizons for membrane application. The depletion of governments and industries into mega projects to address these crises is also a further boost for market growth.

Global membranes are set to continuously progress witnessing demand increments for these waters in direct proportion to efficient filtration technologies. As there will be gradual solutions toward cost and performance barriers, an increasing number of industries will soon incorporate these systems into their operations. Specific promising research and development projects offer great potential for improved materials and enhanced function. Thus, more of the best-required industries will adopt these innovations. The success of the global membranes market will be based on the combination of regulatory support, advancing technology, and environmental necessity, as this will continue to ensure the healthy growth of this market for future years.

MARKET SEGMENTATION

By Material

Membranes have subjected a transformation in most industrial fields both as ways to improve efficiency and sustainability within varied industries. They play an essential role in many industrial processes such as water treatment, pharmaceuticals, food and beverages, and biotechnology because they separate, purify, and concentrate materials. As the demand for pollutant-reduced and quality filtration increases, more and more industries put constant effort into searching for more effective and durable membrane materials according to their needs.

Material selection is the critical stage in determining performance and lifespan in membranes. Polymeric membrane valued at $94.20 million is still the most common because it is cheap, flexible, and applicable for wider applications. It has been finding uses in water treatment and industrial filtrations as the pressure ranges and constituents become a factor. However, recently, ceramic membranes became more attractive due to their superior durability, extreme temperature resistance, and chemical stability. Such properties make them more applicable in difficult environments than polymeric options are. Other specialized materials are further being evaluated for advancing filtration efficiency and addressing specific industrial issues.

There is a significant improvement in the resource management of industries adopting membrane technology and lowering costs of operations. Membranes are particularly used in purification of drinking water and pollutant removal in water treatment plants, in addition to reducing reliance on conventional filtration treatment options. Membranes find further application in the pharmaceutical industry in separating and purifying drugs for quality and precision of products. Processes in food and beverage that utilize membranes include liquid clarification, concentration of flavors, and maintaining product integrity. Furthermore, in biotechnology, cell separation and protein purification rely on membranes as a technology that would boost medical and scientific advancement.

Innovation is continually pushing the global membranes market into high-technology. Investment in novel materials and coatings, along with fabrication techniques, has been made by researchers and companies to enhance the overall lifespan and efficiency of membranes. Sustainability is one of the driving forces behind technology these days, as they even look into greener products that could minimize waste and energy consumption. There may be an argument made that many companies implementing greener technologies will, accordingly, make membranes a suitable option for modern industrial applications.

Demand for high-performance membranes will, in turn, continue to increase as more industries develop advanced filtration systems. Continued research and technology advancement will continue to make waves within the industry in future, bringing about so many different solutions providing their filtration and purification needs across many sectors.

By Technology

Now the global membranes market has given all the industries in the world-between cuts and purifies-as well as technologically imparted separation. Of late it has depended on the scope of their technology predominantly from categories like reverse osmosis (RO), ultrafiltration (UF), microfiltration (MF), nanofiltration (NF), and others. All of them are meant to serve specific functions and are being increasingly used in various applications and concerns such as water treatment, pharmaceuticals, food and beverage processing, and chemical processing.

Reverse Osmosis Desalination and Water Purification are one of the two processes that use reverse osmosis technology: applying high pressure to move water through a semipermeable membrane without water contaminants, salts, and impurities. It's the longstanding sustainable solution for potable water where large-scale municipal and industrial water treatment plants use this method. Ultrafiltration membranes retain bacteria, viruses, and large molecules, and thus ultrafiltration relies on a membrane. Applications include wastewater treatment, dairy processing, and highly demanding applications in medicine.

Microfiltration is a technology capable of separating suspended particles and microorganisms from liquids. Although microfiltration membranes are often used for high-capacity applications such as beverage processing and dairy filtration, they are also being considered for pre-treatment stages in a water purification system due to their larger pores than those of RO and UF. Nanofiltration (NF) technology is considered different from both RO and UF; it removes divalent ions as well as some larger monovalent ions but permits smaller minerals to trespass. NF membranes are used for softening of water, removal of organic compounds, and purification of pharmaceutical ingredients.

The membrane technology is evolving continuously with the changing industrial need of the world for more efficient and green filtration. The future holds bright prospects for the industries that manufacture membranes and invest in R&D programs associated with the same to develop membrane durability and performance, besides energy savings. There is bound to be an increase in the membrane filtration technology demand in the near future because of the many obligations and very strict regulations with respect to industrial waste disposal practices, increasing global concerns about water scarcity and environmental sustainability. It's about making the new applications that would be more beneficial to enhance the operational efficiency like smart membranes with self-cleaning properties and with better resistance to fouling.

By Application

Greater dependence on sophisticated filtration technologies has played an eminent role in developing the global membranes market. Membranes are among the most important constituent elements of applications for the treatment of water and wastewater and for use in various industrial processes. In this regard, with the increasing demand for cleanwater and efficient industrial processes, they are rapidly becoming evidently indispensable. Very many companies and governments across the world are investing in upgrading filtration whereby they want to address global issues of water scarcity through pollution and regulatory compliance concerns.

Membrane technology is primarily applied in water and wastewater treatments. The increasing population and rampant urbanization are making drinking water safe and free from contaminants. Membrane filtration will be implemented by municipalities and industry alike to possibly remove contaminants from the water and have it meet standards set by safety requirements. Applications of membranes in desalination plants, sewage treatment plants, and portable water purification units serve the purpose of holding back various impurities and bacteria as well as all dissolved solids. The increasing awareness ethics of water conservation also wields a lot of influence in raising these technologies since they provide effective and sustainable means for recycling and reusing water.

Beyond water applications, industrial processing is highly dependent on membranes. Membrane separation, purification, and concentration technologies are widely used in various industries, such as food and beverage, pharmaceuticals, and chemicals. Food membranes include milk processing, juice clarification, and sugar refining. In pharmaceuticals, membranes can be used for drug formulation, to ensure the purity and safety of products. These applications are also common in chemical manufacture, especially for separation of valuable components and waste reduction. Thus, membrane technologies are essential across a host of sectors for making possible increased efficiency with continued high product quality.

As industries continue working to make a better world through sustainability and operational efficiency, advanced membranes will continue to have greater and increasing demands. Industry is thus busy making membranes with more durability, higher filtration capacity, and fouling resistance. Many breakthroughs in material science are in fact paving the way for the manufacture of membranes with high effectiveness under harsh conditions for a variety of industrial applications.

As tightening regulations and greater environmental concerns continue to grow, it is expected that such companies and governments will invest more in membrane technologies to provide cleaner water and better industrial processes. Global membranes will remain a standout player in the inevitable weigh-scaling of issues within this contest regarding challenges in water treatment and industrial filtration, from both environmental and economic standpoints.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$165.81 million |

|

Market Size by 2032 |

$295.74 Million |

|

Growth Rate from 2025 to 2032 |

8.7% |

|

Base Year |

2025 |

|

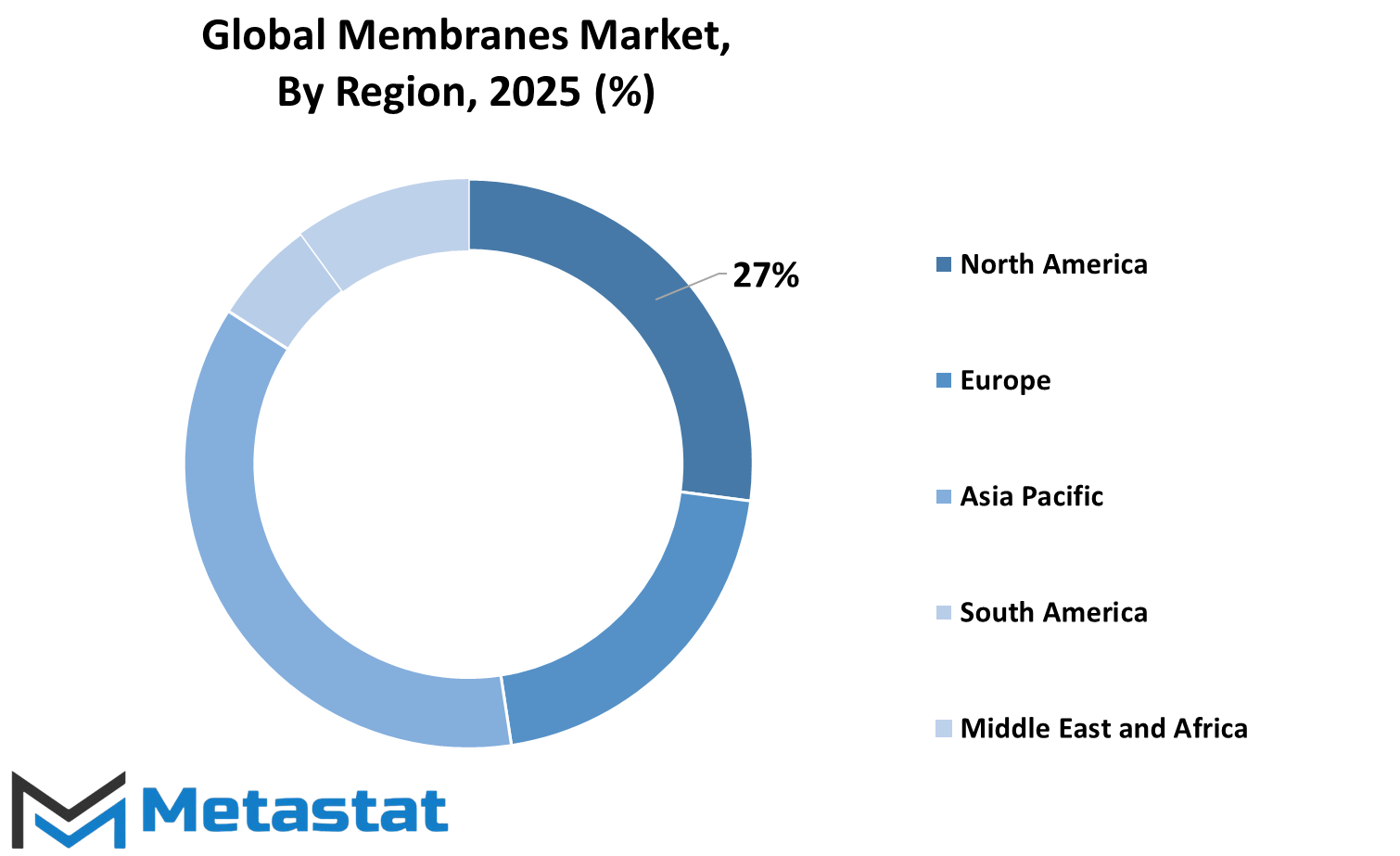

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The membranes market is growing on a global scale as the drive for demand continues across a wide range of industries. Water treatment, pharmaceuticals, food and beverages, and even running through industrial processes are all applications for membranes. Thus, as industries continue to require more efficient filtration and separation processes, the advanced membrane technologies have a growing demand.

The global membranes market is broadly categorized into several regions around the world. North America comprises the US, Canada, and Mexico: it is predicted to be one of the most lucrative markets due to the increasing environmental upheaval and stringent water requirements. This market is well matured, consisting of the UK, Germany, France, Italy, and the rest of Europe on the continent. The evolution of filtration technologies in more sustainable solutions fuels the growth in Europe.

The Asia-Pacific, including countries such as India, China, Japan, South Korea, and the rest of Asia-Pacific, will quickly grow under the urban transforms, population increase, and intensified industry activities. Investment for building the water purification structures is also being done heavily in countries such as China and India, which would result in further demands.

South America, especially Brazil, Argentina, and the rest of the region, is displaying slow growth values due primarily to industrial development and the need for such systems to improve water management. The middle east & Africa, which comprises of GCC countries, Egypt, South Africa, and the rest of the region, is also contributing to the expansion of the global membranes market. Water scarcity and increased attention to desalination projects have been the two leading factors in this region propelling the adoption of membranes.

New developments and improving adoption of membrane technology are expected in the forthcoming times, as most industries push toward establishing efficient and sustainable filtration methodologies.

COMPETITIVE PLAYERS

This importance of the global membranes market is further enhanced as industries push for efficient and sustainable solutions in filtration and separation processes. The core applications of membrane technology are in water treatment applications, pharmaceuticals, food and beverages, and processing of chemicals. Demand will soar, given the increasing incidence of deepening water scarcity and pollution of the environment. A key area of investment by many companies is in research and development to improve membranes so that they perform with higher durability and efficiency that matched to new market demands from increasingly diverse industries.

DuPont, Kovalus Separation Solutions, 3M, General Electric (GE), and Toray Industries are among the top companies that focus on technological innovations for improved membrane efficiency. Advanced material science development for industries includes nanofiltration and reverse osmosis membranes, which help industries much in achieving higher purity and efficiency. Companies such as Hydranautics, Koch Membrane Systems, Asahi Kasei Corporation, LG Chem, and Pall Corporation are even enlarging their product offerings based on specific industrial needs. Moreover, integration of smart monitoring and automation is providing better efficiency at reduced maintenance costs in membrane technology.

The other side of the sustainability issue is the membrane industry. Most manufacturers focus on the eco-friendly methods of producing and recyclable membrane materials to have the minimal impact on the environment. Companies including Pentair, Sartorius AG, SUEZ Water Technologies & Solutions, and Dow Chemical Company are working on membrane durability and energy savings with respect to the filtration process. The other companies implementing strategies to improve membrane performance in line with environmental compliance are Veolia Water Technologies, Lanxess, Evoqua Water Technologies, and GEA Group.

The competition is fierce; manufacturers are continually striving to distinguish themselves between product quality, tech innovations, and strategic alliances. For some, the expansion of geographical footprints and partnerships acquiring smaller ones to fortify their market positions in the global scale include Toyobo Co. Ltd., Alfa Laval, Mann+Hummel, and Culligan International. Therefore sturdy will be the global membranes market, steadily proceeding as industries strive hard to develop affordable and high-performance filtration solutions. Companies that have their priorities set on innovation, sustainability, and adaptability are going to lead the industry in a few years to come.

Membranes Market Key Segments:

By Material

- Polymeric

- Ceramic

- Other Materials

By Technology

- Reverse Osmosis (RO)

- Ultrafiltration (UF)

- Microfiltration (MF)

- Nanofiltration (NF)

- Others

By Application

- Water & Wastewater Treatment

- Industrial Processing

Key Global Membranes Industry Players

- DuPont

- Kovalus Separation Solutions

- 3M

- General Electric (GE)

- Toray Industries

- Hydranautics

- Koch Membrane Systems

- Asahi Kasei Corporation

- LG Chem

- Pall Corporation

- Pentair

- Sartorius AG

- SUEZ Water Technologies & Solutions

- Dow Chemical Company

- Veolia Water Technologies

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252