MARKET OVERVIEW

The Global Hafnium Market will be going through somewhat of a unique trajectory. Part of the advanced materials industry, hafnium is amongst the privileged materials in having high heat resistance and being workable under futuristic processes. Hafnium is not your run-of-the-mill commodity used in every industry. It finds specialized applications in industries where precision in performance and survival is absolute. Therefore, going forward, the landscape will witness dynamic changes according to scientific breakthroughs and niche manufacturing requirements.

Demand scenarios could most likely undergo change and especially so with the evolution and maturity of next-generation semiconductors. Such excellent attributes with respect to microchip production would thereby incite manufacturers to look further into and refine extraction and processing methods. Today's application areas, heavily channeled toward aerospace and electronics sectors, could perhaps find future space in a much wider scientific ambit, notably nuclear technology and energy storage solution. Researching organizations spread across global boundaries will set the bar high for how hafnium technology can be applied, changing production priorities and distribution channels.

The complexity of the market will increase further because of the tightening regulatory regime. With tighter environmental and safety regulations, producers will be forced to adopt innovative ways to process, which might become a challenge, but also an opportunity, for further advancement. These changes will influence cost structures, partnerships, and trade relations. Also, the transparency and traceability of hafnium sourcing will come to the fore, pushing an environmentally and ethically conscious agenda.

Geopolitical scenarios will build another factor influencing the course of the Global Hafnium Market. Since hafnium is mostly obtained during zirconium refining, the supply chains will remain sensitive to mining and trade-policy changes. Countries having good deposits of zirconium may tighten their hold over exports of hafnium, leading to some changes in supply dynamics around the world. Meanwhile, intensively dependent zones on imports will engage in the research of substitution materials or recycling methods to keep industrial productivity on level grounds.

Yet, the developments take a very transformative turn with the integration of new technologies. With automation and data analytics, another iteration is set to bring a sharp edge to production and supply chain-ensuring efficiency. AI and machine learning are under consideration to assist ore sorting, logistics planning, management, and execution with low wastage and high precision. The benefits of these technological upgrades will further maximize profit generation while supporting compliance with increasingly demanding environmental standards.

Looking to the future, both innovation and cooperation will Mould the competitive landscape. Partnerships must be formed that allow sharing expertise, sharing risks, and speeding up the launch of new solutions. While customer requirements will become more exacting, the market will reward agility and foresight in meeting specialized needs.

To sum up, while the Global Hafnium Market has so far served some specific industrial sectors, its future will become an evolving interplay of technology, regulation, and global strategy. Hence, this transition promises to bring a paradigm shift for expectations and set a new standard for advanced materials industries.

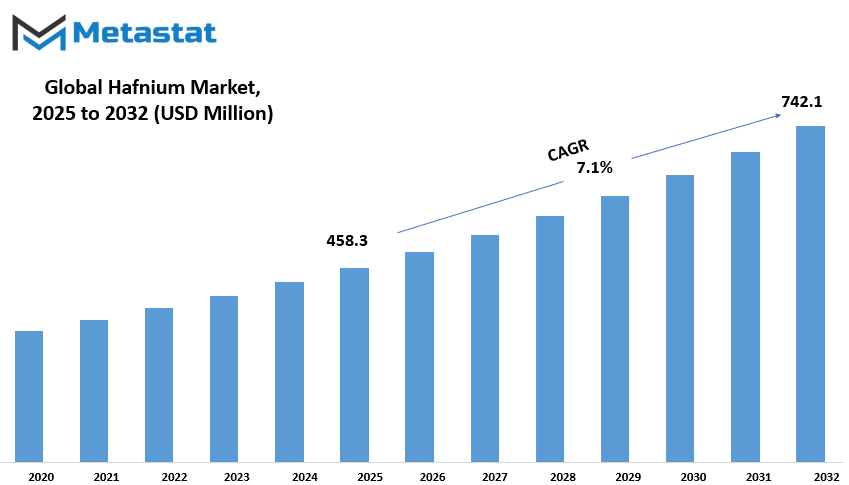

Global Hafnium market is estimated to reach $742.1 Million by 2032; growing at a CAGR of 7.1% from 2025 to 2032.

GROWTH FACTORS

The global hafnium market has steadily registered growth, being in demand due to its increasingly recognized applications in the major industries. Industries have long practiced in demand of hafnium in their application into many fields, among which aerospace and nuclear reactors stand high. It is considered to resist corrosive and high-temperature environments; hence, this property lent it to a range of use in nuclear reactors as to manufacture the control rods and other components. Since the component parts of aerospace must be reliable and durable, such strength and stability are qualities just as great. This market also drives its advancement due to the increasing use of hafnium-based semiconductors in advanced electronics. As the move of technology proceeds to provide more powerful and smaller devices, materials like hafnium become necessities in enhancing performance and efficiency, more particularly on microchips and high-tech components.

Nevertheless, some barriers exist that may risk the growth of this market. The foremost among them is the possibility of reduced supply of hafnium. It is not freely found in nature and is usually obtained as a by-product of zirconium refining, making its supply based on that of zirconium production. Due to this scarcity and the complicated process of extraction and purification of hafnium, its cost is very high, which would discourage manufacturers and limit the spread of its usage in other industries. Furthermore, stringent environmental and safety regulations act as hindrances toward the mining and processing of hafnium.

In spite of these challenges, there are hopeful opportunities for a potential growth of the hafnium market in coming years. One area of interest with much potential is its implementation within the 5G technology and quantum computer fields. The special features of hafnium would be instrumental in building faster and more reliable electronic devices that worldwide newly matured technologies would demand. Therefore, there are several ongoing studies regarding the application of hafnium-based materials for sustainable energy-related solutions, which may also lead to possible new uses and markets. As the innovations progress and new applications emerge, the prospects for further expansion of the global hafnium market will unfold with hafnium becoming a key material of advanced industries of the future.

MARKET SEGMENTATION

By Type

The global hafnium market is steadily growing, driven by rising demand across various industries. A lustrous, silvery metal, hafnium is famed for being highly resistant to corrosion and capable of withstand very high temperatures. The aerospace, nuclear, and electronics industries heavily rely on these characteristics. The continuous development of these industries will likely drive the demand for hafnium in the foreseeable future.

Hafnium increases the strength of alloys and their resistance to heat hence an aircraft-engine-grade material for jet engines operating at extreme conditions. In nuclear power plants, hafnium finds much value for its neutron-absorbing abilities, making it useful in control rods that govern the nuclear fission process safely. In contrast, the electronics industry adopts hafnium in semiconductor manufacturing to fabricate high-performance transistors. The need for improved devices would, however, augment the significance of hafnium in this particular industry.

The market is segmented according to type, with every type serving different needs. The hafnium metal market is an important segment with a value of $246.6 million. Another type is hafnium oxide, which finds application in microchips and coatings because of its good insulating properties. Hafnium carbide is valued for its extreme hardness and high melting point; hence, it finds use in cutting tools and protective coatings. Depending on the requirements of various industries, other types of hafnium shall find application.

From the future perspective, the global hafnium market is expected to be conducive to technological advancements and the rising importance of clean energy. These will be further enhanced by recent breakthroughs in space exploration and nuclear energy. Although hafnium is not much known among metals, it is, for its peculiarity, indispensable in many current technologies. As industries grow in their innovations and their quest for stronger and more durable materials, hafnium shall remain at the front of this progress. Its current market shall continue in what seems to be established due to the growing applications and the rising demand for high-performance materials across the globe.

By Product Form

The Global Hafnium Market is steadily growing in various industries where the demand for hafnium products exists. On the basis of shape, the market is segmented into rods, plates, sheets, and powders. In consideration of the uses among the peculiar properties of hafnium in its different forms are very high melting temperature, corrosion resistance, and absorption of neutrons. Hafnium rods are used as control rods in nuclear reactors, wherein neutron absorption is a necessity for safety and stability. Plates and sheets find farther applications in the aerospace and industrial manufacturing field, where they resist extreme temperature. Hafnium powders are important in placing superalloys along with other materials that require precision and high performance.

Primarily, a growing demand in the nuclear power sector drives the market. Nuclear power still remains a strong option for most countries as they pursue cleaner and efficient energy sources, thereby providing a huge industrial platform for hafnium. The aerospace sector, conversely, is another heavily driven industry, where hafnium is used in components capable of withstanding extreme heat and pressure. The electronics industry stands as another major mill, where hafnium materials are used in semiconductors as well as integrated circuits because of their excellent insulation properties.

Hafnium reserves are tied along with zirconium reserves, i.e., hafnium is generally a byproduct there. This dependency sometimes creates an occurrence in irregular supply when there is a slowdown in the production of zirconium. Nonetheless, with the help of continued research and development activities in extraction and refining processes, the supply of this metal could become steadier in the future.

Asia-Pacific currently dominates the hafnium market. Countries such as China, Japan, and India have major demand for nuclear energy, electronics, and aerospace industries. North America and Europe follow with smaller shares of the market, and these markets are well supported by advanced research establishments and industrial bases.

The summary shows the Global Hafnium Market being shaped by rising demand in the nuclear, aerospace, and electronic fields. While supply-side constraints are present, better extraction methods and steady industrial growth are expected to push the market forward. Each product form- rods, plates, sheets, powders-will continue to serve a vital role, catering to the varied requirements of industries that make use of this peculiar property of hafnium.

By Application

Applications that are the setting for the developments in the global hafnium market that are promoting demand for it. Hafnium, as a metal, enjoys an esteemed position in anti-corrosive wear industries and those requiring materials with high melting points for durable and dependable applications; these industries are well-served by hafnium. Superalloys are the principal applications that provide demand for hafnium. These alloys are prepared to withstand severe environments, more so in aerospace and industrial gas turbine environments. Hafnium, therefore, provides these alloys with strength and resistance against heat, which in turn enhances their service life and performance under pressure. Optical coatings are another significant application for hafnium. Such coatings are applied to lenses, mirrors, and varied optical instruments to increase their performance. Hafnium dioxide is a compound of hafnium with a high refractive index and durability; manufacturers prefer it to develop optical instruments with real contrast and efficiency.

The metal is widely considered in the nuclear industry because of its effective neutron absorption. It finds application in control rods within the nuclear reactor, where it controls fission and thus mediates the safety and stability of the reactor. With increasing interest across the globe in nuclear energy, the demand for hafnium in this particular field is likely to stay strong.

Apart from these major applications, hafnium finds other uses as well. It is used in the production of semiconductors, wherein its insulating properties come into play while aiming at making transistors smaller and more efficient. Since the tech world continues to push for faster and more powerful devices, hafnium will probably take on an even bigger role in electronics. In essence, the global hafnium market is influenced by its range of uses spread over various industries. Each application benefits from this special metal, keeping demand steady and hafnium alive as an important material in modern-day technology and manufacturing-from aerospace to electronics.

By End-Users

Every end-user significantly drives demand and growth; thus, the global hafnium market finds shaping through several end-users. Industrial metal, being hafnium, is used for corrosion and heat-resistant purposes. Another major end-user is the aerospace industry: konwingalus taking one with an extremely high melting point and alloy-strengthing property for jet engines and other airplane equipment. This particular function is very much dependent on hafnium, which also works under extreme conditions of temperature and stress to ensure performance and safety.

With the nuclear industry as the other main consumer for hafnium, nuclear reactors now employ the neutron absorption capability of hafnium without producing radioactive by-products. Control rods with which the metal is associated regulate the procedure of slowing down fission so that heat can be ejected harmoniously for power within the reactor. This quality renders hafnium irreplaceable when it comes to certifying the stability and efficiency of nuclear power plants.

The electronics industry also uses hafnium during the manufacture of semiconductors and integrated circuits. Hafnium oxide insulates transistors that are at the heart of the working of modern electronic devices-from cell phones to laptop computers to tablets. With technological changes, the demand for even smaller and more compact instruments is exerting pressure on the let of hafnium-based materials.

In manufacturing industries, hafnium sees a number of uses where corrosion resistance and heat resistance are key. Plasma cutting tip, electrode, or tool are just the names of things which must perform reliably under harsh conditions. The smaller-day work life of the equipment thus enhances overall productivity in industrial plants.

Apart from these major industries, hafnium finds application in other areas. There are times when research laboratories and specialty manufacture require hafnium for certain experiments or custom parts. This smaller usage collectively goes towards creating demand and demonstrates the versatility of the metal.

In a nutshell, the global hafnium market results from the metal's advantageous properties and the critical roles it plays in several industries. Across aerospace, nuclear power, electronics, and industrial manufacturing, hafnium is employed in several technologies and processes. As industries strive for greater performance and efficiency, hafnium demand will continue to expand, sustaining the presence of this metal in the worldwide market.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$458.3 million |

|

Market Size by 2032 |

$742.1 Million |

|

Growth Rate from 2025 to 2032 |

7.1% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

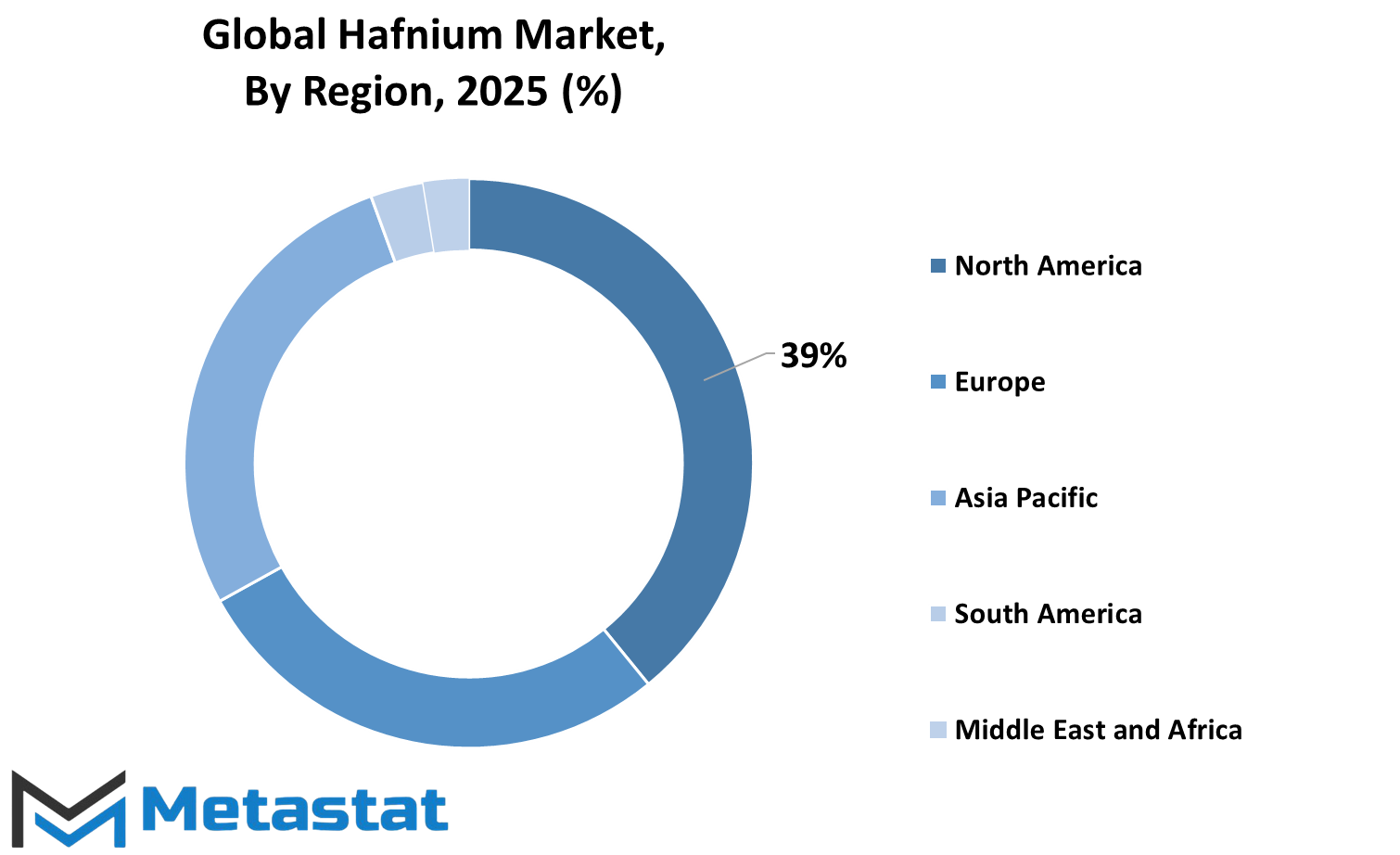

Several key regions note the global hafnium market with all of them significantly deciding their overall trends. These areas include North America, Europe, Asia-Pacific, South America, and the Middle East and Africa. Beyond these, the regions themselves are further divided into countries, all of which, to some extent, provide value that leads to eventual market growth. The United States, Canada, and Mexico primarily create such demand conditions in North America. Being industrial bases, hafnium is demanded in large quantities for use primarily in aerospace and electronic applications where it has unique properties.

In Europe, the major countries to consider are the UK, Germany, France, Italy, and the Rest of Europe. Europe's established manufacturing capacity and forward-looking technology stance assure a steady demand for hafnium in these countries. The Asia-Pacific market is further divided into India, China, Japan, South Korea, and the Rest of Asia-Pacific. This part of the world, with its fast industrial growth and growing technological advancement, continues to fuel the hafnium market. China and Japan are, particularly, very prominent as they have strong electronics and nuclear industries, where hafnium finds its major application.

The driving factors of the South American hafnium market include Brazil and Argentina together with the remaining South America. While Asia and Europe might hold larger markets, the presence of growing industries and infrastructural works would see the demand rise further with time. The divisions in the Middle East & Africa region stands as GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa. This market is influenced by increasing investments in energy and industrial sectors, where hafnium has special uses, particularly in nuclear reactors and high-temperature alloys.

Such splitting will allow easier insight into the role each region and country play in the overall picture. Demand is dependent on each area, lined with some industrial growth, technological progress, and energy needs. Although some areas dominate at present, others show a promising potential for growth, which conversely will indicate the market direction over the next years.

COMPETITIVE PLAYERS

In the last couple of years, the global hafnium market has undergone steady development, spurred by burgeoning need in varied industries. A lustrous, silvery metal, hafnium is applied in nuclear reactors, aerospace components, electronics, and so forth, mainly due to its high corrosion resistance and melting point. Such features make it suitable, i.e., in the manufacture of control rods for nuclear reactors, and also in alloying materials for aerospace, in which materials are tested under extreme conditions. Meanwhile, interest in this market further stems from the usage of hafnium compounds being explored in the semiconductor sector.

The complete model is shaped by the question of new energy options and technological elucidations. The greatest use for hafnium comes from the nuclear sector because it is able to absorb neutrons; therefore, the bigger the country invests in nuclear energy as part of its energy mix, the more halting is the demand for hafnium. The aerospace industry is similarly dependent on hafnium for strength and durability so that the components last longer and perform well in harsh areas.

Key players operating in the Hafnium industry include Advanced Engineering Materials Limited, Thermo Fisher Scientific (Alfa Aesar), Alkane Resources Ltd., Allegheny Technologies Incorporated (ATI), American Elements, Baoji ChuangXin Metal Materials Co., Ltd, Baoji City Hengxin Rare Metal Co., Ltd., Baoji Tianbo Metal Materials Co., Ltd., Chemsavers, Inc., China Nuclear JingHuan Zirconium Industry Co. Ltd., Fine Metals Corporation, Framatome Inc., Luciteria Science, Nanjing Youtian Metal Technology Co., Ltd., Nantong JP New Material Tech co. LTD, Neo Performance Materials, Phelly Materials Inc., Shaanxi Fusheng Titanium Industry Co., Ltd., Shaanxi Yunzhong Metal Technology Co., Ltd., Starfire Systems Inc., and Western Metal Materials Co., Ltd. (WMM, Baoji Titanium Industry Co., Ltd.).

While limited resources and high process costs present certain challenges, research and exploration activities will assist in their gradual mitigation. Simultaneously, the need for specialized materials like hafnium is bound to increase as electronic and defense-related industries flourish. Overall, the market seems promising as more industries discover what this versatile metal can offer, while the manufacturers strengthen efforts to meet growing demand through innovation and sustainability.

Hafnium Market Key Segments:

By Type

- Hafnium Metal

- Hafnium Oxide

- Hafnium Carbide

- Others

By Product Form

- Rods

- Plates

- Sheets

- Powders

By Application

- Super Alloy

- Optical Coating

- Nuclear

- Plasma Cutting

- Others

By End-Users

- Aerospace Industry

- Nuclear Industry

- Electronics Industry

- Industrial Manufacturing

- Others

Key Global Hafnium Industry Players

- Advanced Engineering Materials Limited

- Thermo Fisher Scientific (Alfa Aesar)

- Alkane Resources Ltd.

- Allegheny Technologies Incorporated (ATI)

- American Elements

- Baoji ChuangXin Metal Materials Co., Ltd

- Baoji City Hengxin Rare Metal Co., Ltd.

- Baoji Tianbo Metal Materials Co., Ltd.

- Chemsavers, Inc.

- China Nuclear JingHuan Zirconium Industry Co. Ltd.

- Fine Metals Corporation

- Framatome Inc.

- Luciteria Science

- Nanjing Youtian Metal Technology Co., Ltd.

- Nantong JP New Material Tech co. LTD

- Neo Performance Materials

- Phelly Materials Inc.

- Shaanxi Fusheng Titanium Industry Co., Ltd.

- Shaanxi Yunzhong Metal Technology Co., Ltd.

- Starfire Systems Inc.

- Western Metal Materials Co., Ltd. (WMM

- Baoji Titanium Industry Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252