MARKET OVERVIEW

The Global Glass Reactors market is an intrinsic segment of the chemical and pharmaceutical industries. Known for their versatility and strength, these reactors are fundamentally used in various chemical reactions, synthesis, and distillation processes. Their unique properties, which include transparency, the possibility to obtain resistance to chemicals, and ease of cleaning, will further continue to drive their market in specialized applications.

The global glass reactors market will experience incredible developments resulting from an increased demand for processing environments that require high-purity and freedom from contamination. This is envisioned to be very vital in the pharmaceutical industry, which has several strict regulations that will be supplemented with advanced reactor technologies. Glass reactors are transparent, so reactions can be followed up in real-time, allowing quality to be controlled in pharmaceutical production. ForObjectsequently, high-quality drug and therapeutics productions will rely greatly on these reactors within the pharmaceutical sector.

The chemical industries will turn, more and more, to glass reactors that are resistant to very different temperatures—so from very low up to very high—and corrosive substances. The latter will help in the synthesis of many new chemical compounds and development of materials. Glass reactors will foster the precision involved in research and development laboratories that deal with studying new chemical processes and formulations, hence the successes that such scientists will obtain. Fireproofing of glass reactors will further extend their sphere of application to the food and beverage industry, besides already established service in the chemical and pharmaceutical sectors.

Contamination-free condition of reactors guarantees the purity and safety of foodstuffs. The transparency will let see the processes in real-time that is going to improve food processing techniques for better and more stable product quality. Given the high consumer demand for high quality and safe food products, the application of glass reactors in food processing will strongly rise. The future of the Global Glass Reactors market will also be shaped by technological advancements in reactor design and automation, which would enhance the efficiency and productivity of chemical processes.

Advanced sensors and control systems of automated glass reactors will allow better control over reaction parameters, improving yields and reducing residues. The impact of technological advancements on the adoption of glass reactors across industries is likely to be high, as companies strive to improve the process of production for cost savings. Sustainability will form an important part in the development of the Global Glass Reactors market. As concerns for the environment continue to rise, industries will shift towards greener and more sustainable solutions for their processes.

Being inert and fully recyclable, table glass reactors set very positively against the backdrop of reducing ecological footprints. More and more companies will invest in technologies of glass reactors that minimize energy consumption and waste generation to meet the ever-increasing demand for a more sustainable present and future. This, slowly, will ultimately change the competitive landscape of the market for Global Glass Reactors. With their innovation and product portfolios, established players will have to keep up with changing industries continuously. New entrants will bring new perspectives and new technologies that will make things further competitive with steep growth curves. Collaborations and partnerships will also emerge where companies can leverage the strengths and resources of others. The glass reactor market is forging into the future with dynamic and changing years.

Glass reactors will have growing applications in the chemical, pharmaceutical, and food industries due to their specific properties and allied advantages. A few of the important factors that would form the future of this market include technological developments, steps toward sustainability, and competitive scenarios. Through efficiency, quality, and sustainability, industries are going to have a stronghold on glass reactors, ensuring continuous relevance and demand for them on the global market.

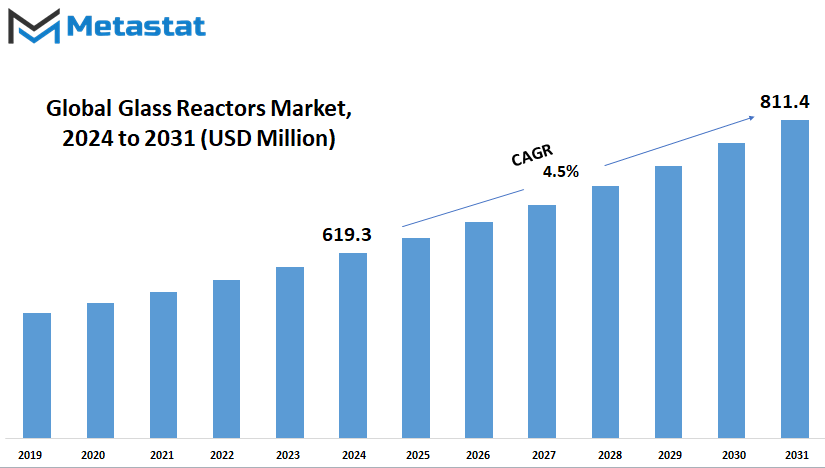

Global Glass Reactors market is estimated to reach $811.4 Million by 2031; growing at a CAGR of 4.5% from 2024 to 2031.

GROWTH FACTORS

With several important drivers, the glass reactors market would possibly be very high during the forecast period. One of the major drivers includes the surge in demand for chemical synthesis and pharmaceutical manufacturing. Glass reactors, on account of their better chemical resistance property and transparency, have a rising demand in industries where monitoring of reaction and controlling becomes critical. With the pharmaceuticals industry expanding, demand for high-quality glass reactors will increase, thereby driving the growth of the market. Other drivers are technological advancements in the design of glass reactors. Improvements in durability, with better safety features and efficiency, make glass reactors attractive to end-users. Such developments are hence likely to increase the rate of adoption across all industries, further accelerating the growth in this market.

Even so, there exist factors that can limit the growth of the glass reactors market. First and foremost, the price of glass reactors is usually high as compared to reactors made of other materials. This may affect the scale at which they are adopted, especially by small- and medium-scale enterprises with a low budget. Besides, handling and servicing or maintenance could be difficult for some users; hence, this may limit the market growth.

Despite these odds, many attractive prospects are soon to be open for glass reactors. Increasing emphasis on sustainable and green chemistry processes has been generating demand for green processing equipment. Glass reactors, due to their inherent features such as reduction of contamination and slashing of waste, fit well into the sustainable chemistry practice. This trend is likely to open up newer avenues for market growth in the near future.

Furthermore, increasing investments by public and private sectors in research and development activities are likely to fuel the growth of this market. As more enhanced models of glass reactors are developed and launched into the space, these shall find huge adoption, thereby boosting further market expansion. Collaborations not only by manufacturers but also from research institutions will help in driving innovation and contribute to an overall betterment in the market scenario.

The global glass reactors market is going to grow strongly due to the increased demand from the pharmaceutical and the chemical sectors through technological advancement and a keen effort to attain sustainable methods of operation. Cost and complexity may turn into a problem, but the future outlook is very bright for this market, which retains already enormous opportunity with further innovation and enhanced funding for research and development.

MARKET SEGMENTATION

By Capacity

The global glass reactors market is likely to grow at a steady basis in the future with improvements in technology and a rise in industrial applications. Glass reactors are apparatuses that come with features such as resistance to corrosion, transparency, and versatility, applied in well-known arenas of pharmaceuticals, chemicals, and material science. These reactors permit the combination of mixing, stirring, and reaction monitoring, hence what is always needed in research and development laboratories and the production environment.

In the future, the market will segment based on capacity, contributing to serving diversified industrial needs. These extend from capacities such as up to 5 liters to above 300 liters, giving an exact match for particular requirements. Smallest reactors of up to 5 liters capacity will continue to be in demand for small-scale laboratory research where detailed analysis and experimentation are crucial. These compact reactors will stay fundamental to chemists and researchers in the investigation of new compounds and reactions at small scales. On the contrary, those in the capacity ranges of 5 to 15 liters and 15 to 30 liters would find wide applications in pilot plants and medium-scale production facilities. These reactors can strike a balance between the requirements for larger volume processes and the flexibility needed by different experimental arrangements. Such mid-range reactors would have wide adoption from industries working toward scaling up from laboratory scale-up findings into commercial practices. Moreover, industrial-scale production will be complemented by 30-60 liter and 60-100 liter capacity glass reactors.

These reactors can help in the bulk production of chemicals, pharmaceuticals, and a lot of other materials by giving them the volume required without compromising on the precision and control of a glass reactor. With growing complexity of the industrial process, such reactors will be further in demand, due to the necessity for larger and more efficient methods of production. Capacities ranging from 100 to 300 liters and above 300 liters segment of glass reactors will support large-scale production. These reactors would be the main or central part of the mass production facilities in which large volumes of chemicals and pharmaceuticals are prepared.

In other words, in the future, large reactors will find more significant applications in several industries, mainly requiring high-efficiency production facilities and those involving large reaction volumes. The global glass reactors market would continue growing on the grounds that there would be a wide capacity range available to fulfill the increasing and diversified demands of industries worldwide. Besides, technologies would advance further, with a continuous push for higher efficiency and scalability that ensures that glass reactors remain one of the major constituent parts in research and industrial applications. Capacity level segmentation will lead to targeted solutions supporting small-scale laboratory research on one side and large-scale industrial production at other ends.

By Design

The Global Glass Reactors market is bound to show massive growth in the coming years with improvements in chemical research and their manufacturing processes. On the basis of design, the segmentation of the market includes Multi Jacketed, Double Jacketed, and Single Jacketed glass reactors. Glass reactors are those used to carry out several chemical reactions, synthesis, and process optimization in labs and industries.

The demand for Multi Jacketed glass reactors will rise with the increased temperature control and versatility provided by these devices. It provides better control of reaction conditions and, hence is well-suited for complicated chemical processes. Thus, Multi Jacketed glass reactors will form the basis of industries in the future as well, to bring efficiency into their chemical processes for assured results.

Double Jacketed glass reactors will also enjoy strong growth, owing to additional layers for enhanced temperature control, making them particularly suited for high-temperature reactions that need stringent thermal control. This will lead to growing demands from the pharmaceutical and specialty chemical industries for Double Jacketed glass reactors in line with an increased demand for high-purity chemical production. Innovations may be expected in the future that can substantially enhance their performance while lowering their operational costs, thus further pushing the demand for this product.

Although much simpler in design, single jacketed glass reactors will still hold a reasonable market share. Ease of use, cost-effectiveness, and broad application in academic institutions find applications in small research laboratories. In the future, material improvement and advances in manufacturing techniques will probably make more resistant to chemical attack and rigors Single Jacketed glass reactors, remaining relevant in academia and industry.

By Application

The glass reactors market is presumed to grow at a considerable rate in the next few years. This will largely be supplemented by a wide range of applications, including pilot plants, mid-large-scale production plants, and portable multi-purpose units. Glass reactors are crucial in these many chemical processes as they ensure a contained pristine environment for reactions. Their transparency makes monitoring easy and provides ideal conditions for various experiments and other production processes.

Glass reactors will turn out to be quite important in pilot plants. These miniature industrial units, under small-scale setups, essentially require the replication of exact conditions and controlled atmosphere for new processed to be tried at an industrial scale. Glass reactors, because of excellent chemical resistance and transparency properties, would present an ideal solution for such experimental sets. As industries keep innovating, the requirement for reliable and efficient equipment for pilot plants will increase commensurately, thus propelling the glass reactors market.

Another key driver will come in the form of mid-scale to large-scale production plants. Plants of this nature require durable, high-capacity equipment since volumes of chemical reactions are large. Glass reactors will find applications here due to their robustness and the ability to maintain the purity of substances being processed. As production scales grow higher, the requirement for reactors that can bear up against such harsh conditions and high-performance needs.

Portable multi-purpose units are going to further add a different dimension to the glass reactors market. These units have flexibility and mobility, which makes them very useful in many applications across different locations. Therefore, the industries that require on-site chemical processing or research will find these versatile units very resourceful. This growing trend towards mobile and adaptable solutions in the chemical industry is going to raise the demand for portable glass reactors.

By End-use

The global market for glass reactors will grow over the years because of its wide end-use application. The reactors play a part in key processes in the chemical, petrochemical refineries, pharmaceuticals, and research institutes. Each of these sectors will increase and contribute a lot to the market, reflecting an increased demand for advanced materials and technologies in various industrial processes.

Glass reactors will help in handling and synthesizing chemical reactions to move on in the chemical process industries. Such reactors must be hardy enough to work with corrosive substances and attain high temperatures, as might be the case with their line of work. The necessity of reliable and long-lasting reactors involves a growing glass reactors market, with the continued development in these sectors. These reactors find immense application, from the production of polymers to processing the crude oils. Their specialty properties include contamination resistance and the innumerable capability of maintaining reaction integrity, which would ensure the importance of glass reactors in these operations. Now, with the whole globe shifting toward clean energies and for those efficient ones, surely the importance of glass reactors will mount in petrochemical refineries.

Another giant participant that will take part in the glass reactor market will be the pharmaceutical industry. The integration of glass reactors in the development and production of drugs is due to the precision and control of the occurring chemical reaction. This will further push the demand higher for supreme reactors, coupled to the industry's very high and strict regulatory demands. Pharmaceutical companies will depend increasingly in the safe and effective production reverberation from glass reactors, as they further advance and develop new compounds found to have beneficial medicinal values.

Research institutes are another important market for glass reactors. These reactors play an important role in academic and industrial research by supporting scientific experiments in a highly accurate, safe manner. In this way, glass reactors adhere to being transparent and many-purpose equipment for the study and analysis of complex reactions. The research activity and surge are in the areas of broadening material science, nanotechnology, and studies on the environment. These reactors are bound to increase the installation in research laboratories.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$619.3 Million |

|

Market Size by 2031 |

$811.4 Million |

|

Growth Rate from 2024 to 2031 |

4.5% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global Glass Reactors market maintains steady growth due to innovation and demand across major geographical sections. Geographic segmentation has discretion in terms of opportunities and prospects in North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

The market is most likely to grow in North America due to the high level of industrial activity and superior technological development in countries such as the United States, Canada, and Mexico. Indeed, such nations will continue investing money in research and development, thus allowing them to bring in innovation and increased efficiency accrued from the use of glass reactors. Moreover, there exist several large chemical and pharmaceutical enterprises that are running operations in these regions, hence fueling demand for glass reactors.

The heavyweight growth in Europe will be contributed by the UK, Germany, France, Italy, and the Rest of Europe. With a focus on sustainability and green chemistry across the region, demand for glass reactors, which are strong and resistant to harsh chemicals, will further escalate. Besides, stringent environmental regulations will push the industries to invest in reactors of high quality, thus boosting market growth.

Asia-Pacific, including India, China, Japan, South Korea, and the Rest of Asia-Pacific, will be one of the major markets for glass reactors. This is because of rapid industrialization and urbanization witnessed in these countries, which is going to drastically increase demand for efficient and reliable reactors. Demand from the Chinese and Indian markets will increase due to growth in the chemical and pharmaceutical sectors of these countries. A factor that is going to continue driving the markets further is the focus of the region on developing manufacturing processes and the quality of products. Countries such as Brazil and Argentina will take a significant share in the growth of the South American market. This will be improved by the growing chemical industry coupled with increasing research and development activities, further fueling the demand for glass reactors in the region. Governmental support for industrial growth and modernization will also help to encourage market development.

The Middle East & Africa region is, again, likely to be a significant contributor to the growth of the glass reactors market in the future. GCC Countries, Egypt, South Africa, and Rest of Middle East & Africa are likely to show an increased demand from the region owing to its rising industrial activities and demand for advanced chemical processing equipment. Economy diversification efforts with investments in several industries by the region shall enhance the market further.

Overall, the global Glass Reactors market will witness high growth in the region, driven by regional development and a rise in demand for efficient and reliable chemical processing appliances. Since the industries keep developing further in terms of betterment of quality and sustainability, the demand for glass reactors will grow and shape the future of the Glass Reactors market.

COMPETITIVE PLAYERS

To explore the futuristic landscape of the Global Glass Reactors market, it's essential to highlight key players driving innovation and growth in this sector. These players, including Pfaudler, De Dietrich, Büchi AG, Sachin Industries, Ace Glass, 3V Tech, PDC Machines, Thaletec GmbH, Zibo Taiji Industrial Enamel, Standard Glass Lining Technology, and Sigma Scientific Glass, play pivotal roles in shaping the industry's trajectory.

Glass reactors find applications in a myriad of different chemical processes and are, therefore, undergoing tremendous development. They certainly will continue to be indispensable in the production of pharmaceuticals and in many sorts of chemical engineering in research laboratories worldwide. They can provide an effective way of realizing control with exactitude over the reactors while guaranteeing the best conditions both for chemical synthesis and experiments.

In this course, drivers for the market over the next few years will comprise technological advancements. Innovation in material science will increase the durability and chemical resistance of reactors. Automation and digital integration will make operations easier with real-time monitoring and control of reactions remotely.

Market trends show a growing tendency towards sustainability. With glass reactors, inertness and recyclability will position themselves in step with global sustainability objectives. The approach of the manufacturers will be toward enhancing energy efficiency and eco-friendly performance that fulfills not only regulatory requirements but also consumer expectations.

Geographically, this market will achieve maximum growth in Asia-Pacific, impelled by expediting pharmaceutical and chemical industries in countries like China and India, while North America and Europe further innovate, driven by advanced manufacturing capabilities and research infrastructure.

Some of the key market drivers include growing investments in R&D, increasing pharmaceutical applications, and rising demand from specialty chemicals. With these factors, the segment is going to continue its growth path and foster closer collaboration between the industry players and the research institutions in coming up with the latest solutions.

The dynamics of this industry, however, are going to be charted by challenges such as regulatory compliance and the continuous need for innovation to keep up with evolving markets. The market players will look at differentiation by way of product customization and service excellence to meet diverse customer needs.

The global glass reactors market is likely to grow as the market is driven by technological innovation, sustainability initiatives, and an expanding application base in different industries. Some major participants will continuously lead on the basis of innovation, thereby keeping the sector resilient and relevant in the dynamic global economy.

Glass Reactors Market Key Segments:

By Capacity

- Up to 5 Lts.

- 5 to 15 Lts

- 15 to 30 Lts.

- 30 to 60 Lts.

- 60 to 100 Lts.

- 100 to 300 Lts.

- Above 300 Lts.

By Design

- Multi Jacketed

- Double Jacketed

- Single Jacketed

By Application

- Pilot Plants

- Mid-large Scale Production Plants

- Portable Multi-purpose Unit

By End-use

- Chemical Process Industries

- Petrochemical Refineries

- Pharmaceutical

- Research Institutes

Key Global Glass Reactors Industry Players

- Pfaudler

- De Dietrich

- Büchi AG

- Sachin Industries

- Ace Glass

- 3V Tech

- PDC Machines

- Thaletec GmbH

- Zibo Taiji Industrial Enamel

- Standard Glass Lining Technology

- Sigma Scientific Glass

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383