MARKET OVERVIEW

The Global Continuous Fiber Composites market offers engineering solutions within the advanced materials industry, with applications in high-strength, lightweight, and structurally durable items. It will include those materials built with continuous strands of fibers embedded in a matrix for application advantages in environments where mechanical reliability under stress is a primary concern. Most of the above applications will continue to serve as core components in industries such as aerospace, automotive, wind energy, construction, where traditional metals prove inadequate due to concerns about weight or corrosion.

The Global Continuous Fiber Composites market, product design will find increasing suitability in the use of these continuous fiber system technologies that display consistent mechanical properties throughout a structure. Continuous fiber materials consist of a variety of fiber types such as carbon, glass, or aramid, which will be selected according to the specific needs of the application. The matrix material, usually a thermoset or thermoplastic resin, is used for binding and maintaining the fiber alignment as well as uniformly distributing the loads. Gradually, the market would change fiber architecture according to advanced research and new technical issues for specific application areas.

The Global Continuous Fiber Composites market would stretch its boundaries with customized processing technologies. This would include enhanced filament winding and automated fiber placement, as well as pultrusion techniques to address improved efficiency in line with increased reproducibility, especially for most high-scale productions. Automation and very precise manufacturing would allow companies in such markets to have concurrent homogenous product qualities while providing reduced material waste. When properly processed by continuous fiber reinforcement, products can extend the lifespan and reduce the frequency or need for maintenance in end markets.

Engineers and designers will increasingly incorporate continuous fiber composites into structural elements for their high tensile strength and their ability to reduce energy consumption throughout the entire lifecycle of a product. Low weight will be critical to achieve reduced fuel consumption and emissions in transportation and aerospace. In infrastructure, these composites would form bridge reinforcements, structural panels, and pipelines, leading to less environmental exposure damage compared to most metal or concrete systems.

For material traceability and testing standards, the Global Continuous Fiber Composites market will change. Companies will have to ensure strict documentation and quality assurance for regulatory and use-specific certifications. Testing practices will be performance-specific for fatigue, impact, and temperature variation.

Collaborative development under features through availability of raw material suppliers, process engineers, and OEMs will take research into the Global Continuous Fiber Composites market. As shifting towards creating multifunctional materials-design requirements will require composite materials for load bearing, thermal, electrical or acoustic requirements, this market will be served to hybrid composition and innovative resin systems. Proteins and continuous fibers will be the foundations of such multifunctional platforms.

Global Continuous Fiber Composites look way beyond towards applications in future with emerging priorities in regulation and evolving material innovation. Its course will be worked out by performance requirements and precision engineering and the industry's thrust toward sustainable and high-efficiency design systems.

Global Continuous Fiber Composites market is estimated to reach $4,237.33 Million by 2032; growing at a CAGR of 5.4% from 2025 to 2032.

GROWTH FACTORS

The Global Continuous Fiber Composites market is propelling the future at a steadily paced speed where performance and sustainability have become equally important as efficiency in selecting the material. Continuous composite filament will become vital to most industries creating lighter, stronger, and more durable products. These materials are already being put to use in aerospace and automotive applications where it is indispensable to reduce weight without sacrificing strength. Running lighter vehicles and aircraft consume less fuel and emit fewer emissions, thus being more efficient and responsible. Therefore, the requirement for these composites will continue to thrive as more people seek cleaner, faster, and even more advanced modes of transportation.

Wind energy is another area where these materials are gaining attention. Wind turbine blades must be very strong, yet light to enable their efficient operation under constant force from the elements. Continuous fiber composites achieve an excellent balance between flexibility and toughness, allowing the blades to maximize their life and performance. Such applications are emerging in sporting goods; bicycles, tennis rackets, and any other high-performance equipment now are intended to use these materials. The user gains a competitive advantage due to the combination of strength and weight that athletes and manufacturers cherish.

Many advantages have been thrown to the material; however, there are certain barriers, which could delay its widespread use. The foremost barrier is cost. Production and processing of continuous fiber composites are expensive, thereby limiting their usage in cost-sensitive applications. In addition to that, methods of making these composites would not usually be considered simple. Special tools and skilled labor usually contribute to the cost and difficulty to small companies of using them.

Richard looking to cavalcade, however, holds high hope to that market in future. Because technology has altered the scene already, automated systems come up that will hasten production and cut the labor cost involved. Recycling techniques are also being improved to make such materials reusable instead of throwing them away. This term has made continuous fiber composites a lot more attractive to industries that seek to lessen their footprint on the environment. In the fullness of time, as these new solutions will be available, the Global Continuous Fiber Composites market will likely expand into more sectors, unlocking new avenues for design and manufacturing.

MARKET SEGMENTATION

By Product Type

The Global Continuous Fiber Composites market is slowly coming of age, as an industry-wide shift occurs toward lighter, stronger, and more efficient materials. These materials will serve increasingly well across various fields: automotive, aerospace, construction, and energy. With the shift toward sustainable manufacturing and the use of continuous fiber composites in consideration, these materials are thought to form a major part of this method. Technologies and processes will be the key players within various types of products in this market and how industries will adapt to them in the future.

Among the product types, woven fabric will remain the one with a much-deserved reputation among many. It boasts a remarkable balance of strength and flexibility for a myriad of applications. Woven fabric is able to be configured to fit complicated designs while yielding strength because of this very property. Steady demand for woven fabrics will remain due to their reliability and adaptability. Woven fabrics are usually used wherever strength and design flexibility are desired in a single product, particularly in applications where cyclic loading or some degree of movement is expected.

Another product category gaining acceptance is non-crimp fabrics. Unlike the other, non-crimp fabrics are laid without interweaving. This process preserves the integrity of fiber strength, resulting in enhanced performance under load. The performance characteristics of non-crimp fabrics will fit the industry needing maximum performance with minimum material weight. With evolving designs and engineering, this product type will probably see more applications in advanced work requiring accurate precision and strength.

Uni-directional tape has one specifically useful function-it transmits strength in one direction only. This is appropriate in parts or assemblies where the pressure or force comes from one side. Its usage is very specific and so well designed for areas where every layer of material must work at its optimum. The more advanced and customized the products become, the more the use of unidirectional tape will expand in industries such as aerospace and advanced vehicle manufacturing.

Other types of continuous fiber composites will hold their own, especially as custom demands and novel designs come into play. These could include hybrid fabrics or new composites developed to serve some specific need. With continuing research, it is expected there will be new forms of continuous fiber materials that would equip designers and manufacturers with even more means to satisfy performance and environmental goals. The Global Continuous Fiber Composites market will continue to grow as long as there is a demand for smarter, stronger, and lighter materials.

By Material Type

In those very sectors where lightness, strength, and durability matter, the demand and use of these composites have seen a gradual increase. Thus, composites acquire increasing significance in the automotive, aerospace, construction, and sport goods domains. As the demand increases for fuel economy, high performance, and sustainability, there is an ever-increasing interest in materials that can combine strength with lightweight properties. Fiber selection is one of the most important deciding factors for the performance of such materials, and each type of such choice will engineer the market tomorrow in its own way.

Glass fiber composites shall mostly be used, as they provide a very good performance versus price ratio. The most inexpensive applications, in which the concern is more with cost than with performance, use glass-fiber composites. Very commonly, for example, they are used in construction for panels and reinforcement. Glass will increasingly find application as builders and designers look for alternatives to conventional materials, especially where extreme strength is not a priority, but reliability is still important.

Carbon fiber composites are expected to see maximum growth because of the attractiveness of strength-to-weight ratio. They are typically used in aerospace, advanced automobiles, and high-end performance applications. As electric vehicles gain popularity and as newer aircraft designs are being developed, carbon fiber would play an even bigger role in weight reduction with durability and safety in mind. Even though it is costlier as compared to others, the advantages are encouraging manufacturers to use it in more products. With advances in manufacturing techniques and price reductions, it will soon find more applications.

Being heat- and impact-resistant composites, aramid fibers will continue to find applications in protective wear, defence products, and some industrial machinery. Far less common in civilian goods, compression under extreme conditions proves valuable in some industries. Such fibers would be included in designs emphasizing safety which require that performance under strain be counterweighed with comfort.

Natural fiber composites are making their way into the spotlight as companies strive to go eco-friendly. While they may not meet the strength offered by synthetic options, they create a sustainable alternative. With stricter environmental regulations and more businesses adopting green practices, these fibers are likely to go up in demand, especially in products where weight and super strength are of less concern. These combinations of materials will determine the progress of the Global Continuous Fiber Composites market for the years to come.

By Resin Type

The Global Continuous Fiber Composites market is expected to witness steady growth in the coming years owing to shifting industry trends and continuous material development. As industries continue to demand stronger, lighter, and more efficient materials, continuous fiber composites are becoming a material of choice across various sectors. These materials have strength and durability characteristics that enable them to find application in several industries, including aerospace, automotive, construction, and wind energy. A huge contributing factor for running this market is the resin used in bonding the fibers, which drastically alters the performance and application of the final product.

The market is primarily segmented based on two types of resins. The first being thermoset composite resins and the second one is thermoplastic composite resins. Each of these has its own share in influencing the utilization and development of continuous fiber composites. Thermoset resins see extensive use on account of their heat resistance and their strong bonding characteristics. Even when heavy loads are accepted, they hold their shape and strength very well after curing, thus constituting a good choice for heavy-duty applications. Such resins find application in industries where an aerospace product must withstand stresses without losing its structural integrity or within large construction projects.

Thermoplastics, on the other hand, have certain benefits like flexibility and potential for fast processing. These are the composites that can be reheated and reformed, which does appeal to fast-paced industries like automotive. Other favorable attributes include the ability to be recycled more easily than thermosets, which basically resonates with today's push towards sustainability. As industries almost everywhere have begun to prefer green alternatives, the demand for thermoplastics is likely to grow.

The Global Continuous Fiber Composites market may be enriched in the years to come through research directed toward enhancing the performance of resin. Both types of resin must be improved to deal with improved heat resistance, faster processing, and cheaper production. As new applications arise, likely in renewables and electric vehicles, there arises a need for materials that can withstand tough situations without encumbering additional weight.

Resin type choice will continue to influence how continuous fiber composites will be made and sustained. Both thermoset and thermoplastic resins will remain important, with value determined by specific industrial requirements. The rising consciousness toward strength, efficiency, and sustainability will carry this industry forward toward new avenues and design for better-grade advanced materials.

By Application

The Global Continuous Fiber Composites market is endowed with promising opportunity for growth in the near future, primarily because of increasing demand for durable, lightweight, and efficient materials in various industries. As technology evolves, continuous fiber composites will find extended applications trades in multiple solutions across various sectors. These novel materials constitute strong and damage-resistant composites as fibers are mixed with resin, rendering them unprecedentedly useful in numerous applications where conventional materials like metals or plastics fail.

Some of the critical applications for continuous fiber composites include structural components. These materials have aptness in developing stronger and, consequently, lighter components in areas like aerospace, automotive, and construction. And because of their strength-to-weight ratio in withstanding stress or loads or enviro-conditions, they become favourable in making parts facing high loads. Continuous fiber composites will then be increasingly mixed into the manufacture of energy-efficient vehicles and high-performance aircraft.

Non-structural applications is another important area and involves applications where less flexibility, resistance to wear, or other properties become the main concern. Storage containers, safety barriers, and some consumer products are examined. As industries look for ways to cut costs on materials while maintaining quality, the demand for continuous fiber composite applications in the non-structural area is bound to gain more momentum, especially in consumer goods and packaging.

Thermal and electrical insulation is another central application for continuous fiber composites. These materials are turned into components able to endure either extreme temperature or extreme electrically harmful environment. There is a need in many industries (electronics, power generation, and construction) for such materials to protect against electrical and heat hazards. Open fields for growth due to the inherent flexibility of continuous fiber composites in these applications will keep growing along that path to a more sustainable and energy-efficient fire.

Also, impact resistance characteristics of continuous fiber composites distinguish themselves in high impact forced applications. Be it protective wear, safety parts for automobiles, or construction materials, demand for materials that resist impact without failing will gain momentum as industries begin to focus more on safety and resilience.

In view of the market advancement, it is certain that the continuous fiber composite will play an essential role in determining the methodology for the design and manufacturing industries themselves in response to the increasing need for materials which cut across a wide range of applications.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,945.41 million |

|

Market Size by 2032 |

$4,237.33 Million |

|

Growth Rate from 2025 to 2032 |

5.4% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

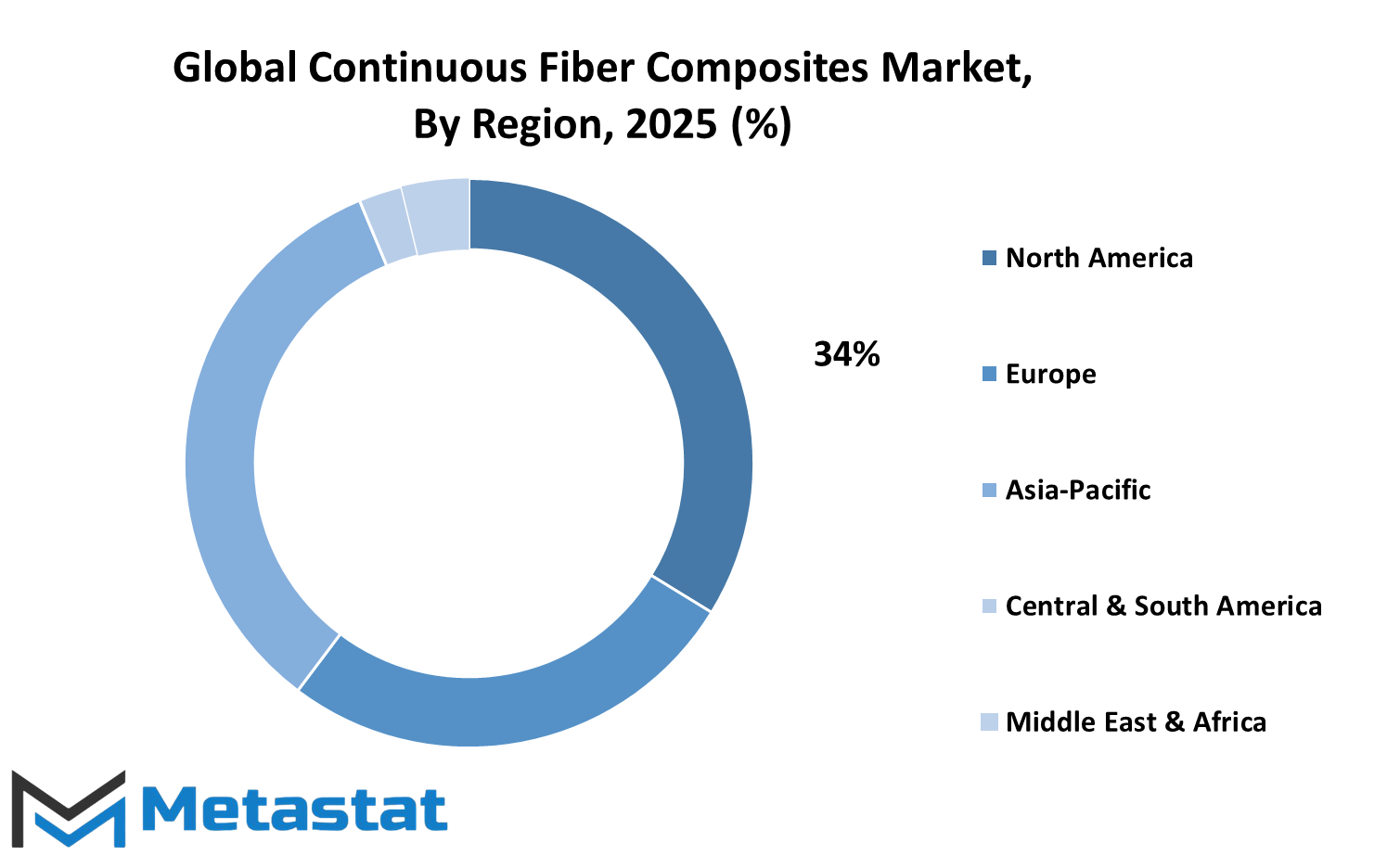

With industries shifting to advanced materials for varied applications, the Global Continuous Fiber Composite market is anticipated to grow on a phenomenal scale. A look into the geographical distribution of this market will thus give insights into how the market is going forward as per the influence of different regions. Each region provides its unique opportunities while facing several challenges, all of which would contribute to the growth of the continuous fiber composites industry.

North America is likely to remain the leading producer and consumer of continuous fiber composites. Key aerospace, automotive, and construction sectors are active, keeping the demand for lightweight and durable materials high. The demand from the aerospace market in the continental U.S., Canada, and Mexico has motivated many innovations in defense. The idea of using sustainable materials for construction in Canada will also advance the use of these composites. Continuous-fiber composites will find increasing integration into North America as industries strive to create high-performing, efficient products.

Europe, with its well-developed automotive and manufacturing sectors, is another strategic region that will contribute to the growth of the continuous fiber composites market. Countries including Germany, the UK, and France are leading the transition toward newer technology adoption, especially in the automotive sector, where the reduction of weight and fuel efficiency are key priorities. Demand from the construction and renewable energy sectors will further rise in Italy and other parts of Europe. The quest for sustainability will drive the application of continuous fiber composites by offering strength and a decrease in environmental impact.

Asia-Pacific will emerge as a foremost driver of growth under ongoing stamina, with rapid industrialization and urbanization occurring across nations such as China, India, and Japan. Particularly, in the automotive and wind-energy applications, China will see its manufacturing sector largely rely on advanced composites. India's upcoming automotive sector and infrastructure programs will build demand. Japan will push the technological applications of continuous fiber composites especially in the electronics and automotive industries. The market in the Asia-Pacific will show the fastest growth and constitute an important expansion site.

Countries like Brazil and Argentina are priming investments in infrastructure and manufacturing in South America. As the industries seek continuous modernization and improvement in durability and performance of their products, the demand for continuous fiber composites would grow. Slow but steady will be the growth around Middle East and Africa, especially in construction and energy sectors, with countries in the likes of UAE, Egypt, and South Africa investing vastly in infrastructure projects and renewable energy.

COMPETITIVE PLAYERS

It appears that the future of the Global Continuous Fiber Composites market has bright prospects, with many factors driving growth in different industries such as aerospace, automotive, and construction. The technology must evolve, and the growing demand for stronger and lighter materials will require continuous fiber composites in shaping the materials used in these industries. These composites are made by reinforcing thermosetting or thermoplastic resin with continuous fiber, appreciated for their strength-to-weight ratio and durability. There will be a wider field of applications over time as industries wake up to the potential of these composites to improve performance and sustainability.

The market key players, LANXESS, Toray Advanced Composites, and Celanese Corporation, promote innovation by ensuring that materials produced possess the highest quality. The emphasis laid by such firms is also to improve production for continuous fiber composites on the demand pull. A gradual reduction in fuel consumption resulting from the use of lighter and durable materials will lead the aerospace industry toward a greener, more sustainable future. Also, the automotive industry is beginning to share in the benefits of using lighter, stronger composites to enhance fuel efficiency and vehicle productivity.

Avient Corporation and Tri-Mack Plastics Manufacturing Corporation are two other innovators that continue to stretch the limits of the known with fiber composites. They ensure that the materials meet the high class defined by performance specifications. In construction, composites could help make structures stronger, insuring safety and longevity. As time goes on and construction materials evolve, composites are bound to assume more critical roles.

Globally, other stakeholders like Jiangsu Qiyi Technology Co., Ltd and Chomarat Group are steadily helping the development of the industry with product line extension and the enhancement of the properties of fiber composites. A company such as Hexcel Corporation and Syensqo SE will remain poised to meet the demand for cutting-edge solutions in industries requiring exceptional specific strength and lightweight properties. Meanwhile, Johns Manville and SABIC are likely to sustain their leading position in developing new composites that are cost-effective and highly efficient.

As the demand for continuous fiber composites increases, these key players will not only respond to present needs but anticipate trends and innovations for the future, thereby ensuring a mostly volatile and flexible market to serve various industries. Certainly, the demand for advanced materials will remain the primary driving force behind all developments and enhancements within the domain of Global Continuous Fiber Composites, which in turn will respond to the burgeoning request for stronger, lighter materials and sustainable solutions.

Continuous Fiber Composites Market Key Segments:

By Product Type

- Woven Fabric

- Non-Crimp Fabric

- Unidirectional Tape

- Others

By Material Type

- Glass Fiber Composites

- Carbon Fiber Composites

- Aramid Fiber Composites

- Natural Fiber Composites

By Resin Type

- Thermoset Composite Resins

- Thermoplastic Composite Resins

By Application

- Structural Components

- Non-Structural Applications

- Thermal Insulation

- Electrical Insulation

- Impact Resistance

Key Global Continuous Fiber Composites Industry Players

- LANXESS

- Toray Advanced Composites

- Celanese Corporation

- Avient Corporation

- Tri-Mack Plastics Manufacturing Corporation

- Jiangsu Qiyi Technology Co., Ltd

- Chomarat Group

- Hexcel Corporation

- Syensqo SE

- Johns Manville

- SABIC

- Jiangsu Hengshen Co.,Ltd

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252