Apr 15, 2025

It's precise because-a-recent publication from-the Metastat Insight-newly thrusts-some necessary insights into the landscapes that shape the Global Continuous Fiber Composites Market, where institutional innovation stands balanced in a segment on applications focused development. This market occupies a very special intersection of demands of material science and engineering in which durability and weight efficiency are usually the silent drivers behind making design decisions across industries. The as-of-late moving spaces tell a story of subtle transformation, built under technological alignment, as opposed to revolutionary disruption.

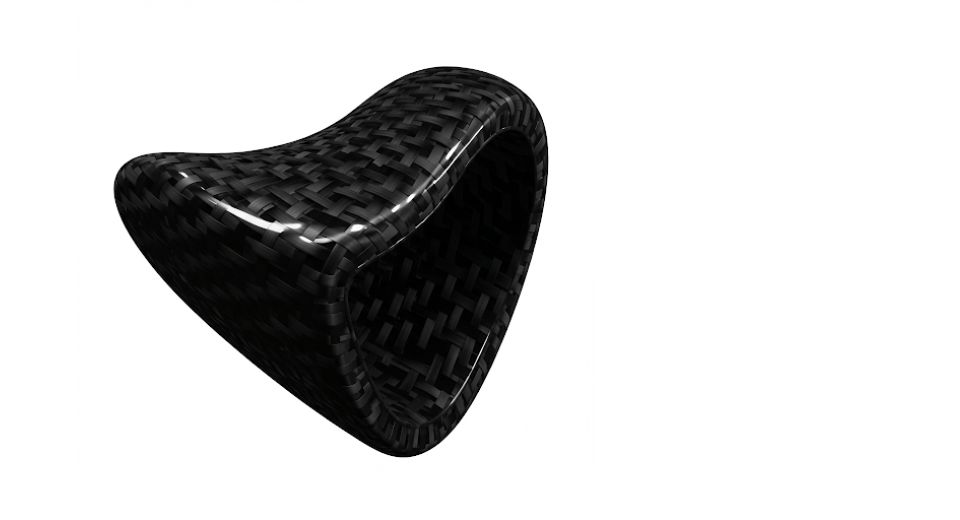

So-called continuous fiber composites make their mark, not for trend-following, to meet needs that endure. Their very make-up, woven or aligned fibers in a matrix, is conducive to very high tensile strength and stiffness, such that they can be used in structural components where performance cannot be compromised. Whether in aerospace, automotive, industrial machinery, or energy applications, these materials aren't merely added for the sake of novelty. Instead, they serve as a response to performance restrictions fixed on working parameters that traditional materials cannot navigate very effectively. It is this function-first identity that acquires them the slow yet firm adoption by the manufacturers into their design processes searching for longevity and reliability.

Strength-to-weight ratio is a distinguishing feature of continuous fiber composites consisting of complex shapes. These shapes can be molded consistently, thus offering product engineers an avenue for design freedom while still being within operational thresholds. One of these instances is in aerospace, where it becomes an enabling factor when it involves the heaviness of structures about overall safety and other various aspects. A similar approach is happening with the recent developments of vehicle design language along with sustainability requirements. The contribution is stretched across sectors as it converges structural requirements with the design intention, reflective of a degree of material flexibility that can hardly be substituted.

Another defining parameter of the Global Continuous Fiber Composites Market has to do closely with processing technologies. Manufacturing with these composites usually involves specialty processes such as filament winding, pultrusion, and resin transfer molding. All these methods have actually evolved as specific processes to take advantage of the different characteristics that continuous fibers provide, allowing engineers or operators to scale their various processes without compromise in any benefits associated with the materials. Thus, it is in the course of deepening the manufacturers knowledge about those production systems that this kind of entry is made into sophisticated pathways that produce more fluid integration of composite fabrication into manufacturing operations.

The decision on the choice of materials in modern industries has generally been dictated by lifecycle expectations. Cost-effective does not mean the first price but rather maintenance cycles, reduced downtime, and a certain degree of performance under pressure. Such long-term thoughts are somehow supported by continuous fiber composites. They go long on not requiring repairs shortening the period of uselessness, are less susceptible to being eroded by the environment, and give weak deformation under sustained loads. Long-term planning across the board becomes a factor due to these properties. For several engineers and procurement specialists, the acceptance of these materials has been less an instant choice and more a journey of proofs along operational cycles.

There is also a much larger story going on behind the curtain: how industries that have historically depended on metal are re-evaluating baseline assumptions. It’s not ever about dumping the old guard but about providing a second set of materials that challenge the very concept that you have to choose between strength and lightness. Continuous fiber composites represent the understanding that these materials not only have to perform but that they have to retain their ability to adapt. This adaptation happens not in great waves but steadily, increment by increment, product by product, until a critical mass becomes apparent.

As global operations expand and intersect across borders, the supply chains supporting the Global Continuous Fiber Composites Market have also developed a kind of quiet sophistication. From fiber sourcing to resin formulation, from processing facilities to distribution nodes, the coordination required to keep production cycles smooth is nuanced and methodical. It is within this framework that producers find confidence to increase their use of these materials, knowing that the backend supporting them is as strong as the composites themselves.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479