MARKET OVERVIEW

The Global Wood Based Panel market and its industry form the backbone of modern construction, furniture manufacturing, and interior design. This market deals with engineered wood products, which are alternative sources of solid wood, presenting a flexible, yet cost-effective, solution to many applications. The products fall under the general category of plywood, fiberboard, particleboard, and oriented strand board (OSB). All these together create structural and aesthetic solutions for a variety of sectors. As demand for sustainable and efficient building materials continues to grow, this market will continue to adapt to technological advancements and shifting consumer preferences. The Global Wood Based Panel market spans multiple industries, including residential and commercial construction, automotive, packaging, and furniture production.

Each segment requires specific wood panel types based on durability, strength, and application. Plywood and OSB are also heavily used in the building sector for flooring, walls, and roofs. For manufacturing furniture, it relies on medium-density fiberboard (MDF) and particleboard to produce cost-effective and aesthetically worthwhile outputs. In addition, this market also impacts the packaging industry such that this material offers green alternatives to plastic-based solutions for its packaging purposes. Wood-based panels are engineered products made from wood fibers, particles, or veneers bonded using adhesives under heat and pressure.

Its manufacturing process reinforces the strength of the final product while minimizing wastage compared with solid wood. In addition to this, refinements in technology and production process will further better the quality and environmental impact in the years ahead. Sustainability is essentially the defining trait of the Global Wood Based Panel market. Strong environmental awareness will be coupled with strict regulations of deforestation, carbon emissions etc. to help industry players operate responsibly in light of sourcing responsible materials.

Higher usage of sustainable certified wood and recycled materials - manufacturers will see to it, both regulatory, as well as consumer expectations. Innovations in the formulations of resin and alternative adhesives will further help to sustain the market by reducing formaldehyde-based adhesives. The Global Wood Based Panel market covers regions, with production and consumption hubs distributed across North America, Europe, Asia-Pacific, and other regions. Other production and export leaders include countries rich in forest resources, with strong manufacturing facilities like China, Canada, the United States, and Germany. Rapid urbanization and infrastructure development are leading to growth in emerging markets.

The overall accessibility of a market and its associated cost structures would be dictated by supply chain optimization and changes in trade policies with the development of global trade dynamics. Future trends in the Global Wood Based Panel market will revolve around innovation, regulatory compliance, and sustainable development. Advanced production techniques will result in lighter yet stronger panels, which align with changing architectural and design trends. Digitalization in manufacturing processes, including automation and AI-driven quality control, will enhance efficiency and minimize waste. New product developments, aligned with the changing needs of various end-use sectors, will come out as well through collaborations between industry leaders and research institutions.

Continued reshaping of global industries because of continued urbanization and population growth will keep the demand for flexible and sustainable building materials going. Technological changes, changes in regulatory structures, and shifting consumer preferences will force this Global Wood Based Panel market to change in years to come. Sustainability, optimized production, and smart manufacturing will help to adapt to future challenges while maintaining its position as an important part of modern infrastructure and design.

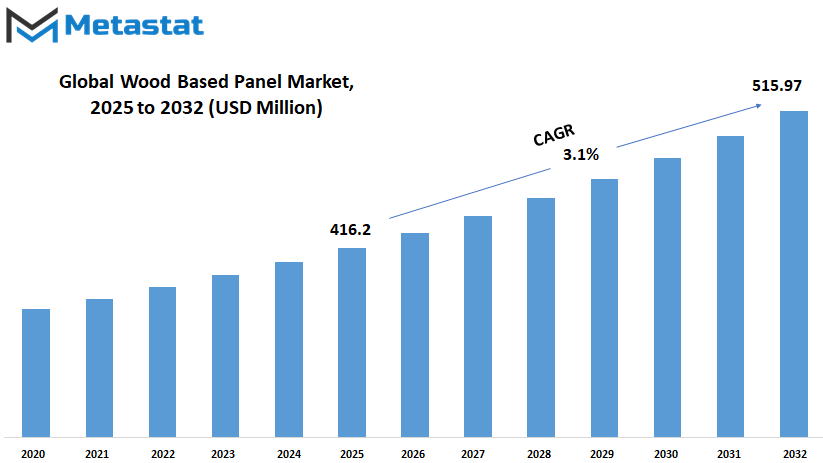

Global Wood Based Panel market is estimated to reach $515.97 Million by 2032; growing at a CAGR of 3.1% from 2025 to 2032.

GROWTH FACTORS

The Global Wood Based Panel market is likely to experience growth in the future due to a growing demand for sustainable and environmentally friendly construction materials. As industries are increasingly turning towards greener alternatives, wood-based panels have become a favorite in construction and furniture manufacturing. This trend is especially visible in developing regions where urbanization and infrastructure projects are rapidly expanding. The continuous rise in demand for cost-effective and sustainable materials in residential and commercial construction mainly makes the market outlook stronger. The key reason for this is the increased importance placed on sustainability.

Governments and organizations all over the world have developed strict regulations to reduce the carbon footprint. Such regulations push manufacturers to develop ecologically friendly products. Wood-based panels are made from renewable materials and meet these goals. They can therefore be considered a substitute for conventional building materials. Advances in engineered wood technology have also resulted in the manufacture of stronger and more durable panels. This has enabled their use in many applications in various industries. The innovations guarantee that the market will be competitive while responding to the increased demand for high-performance materials. There are still challenges despite the promising growth. Fluctuating raw material prices and deforestation concerns pose challenges to the Global Wood Based Panel market.

Availability and cost of timber can fluctuate with climatic conditions, government policies, and market demand, affecting the production cost and pricing strategy. Environmental concerns due to logging and deforestation have resulted in tighter regulations on sourcing wood, which has become a critical factor for market players to comply with. To address these issues, manufacturers are focusing on responsible forestry practices and adopting certified wood sources, ensuring that production remains both ethical and sustainable. A slowing factor may include competition for these products through the use of steel, plastics, and composite materials.

Since such materials exhibit long-lasting endurance to environmental degradation, they present an important source of competition to both construction and furniture markets. Still, increasing concerns about the sustainability of operations would give wood-based panels the advantage in competitiveness. Through innovation, the growth and future of the Global Wood based Panel market will be carved. The future of high-performance panels with higher levels of moisture resistance, fire retardancy, and longer lifespan will begin to open new avenues.

Advanced manufacturing techniques and superior quality adhesives will enhance product quality and productivity, making wood-based panels more attractive to a larger spectrum of industries. With companies continuing to invest in research and development, this market will continue to expand smoothly while maintaining its prominence even in a world where sustainability and innovation are watchwords.

MARKET SEGMENTATION

By Product Type

Global wood-based panels market is believed to grow steadily in the near future, driven by innovations in product types and shifts in the requirements of the industry. The more regular use of MDF and HDF in furniture production and interior design can be anticipated. In modern furniture, such as ultramodern sleek furniture pieces, it is rather smooth with flexibility, making it ideal. As consumers are hooked into minimalist-contemporary styles and tastes in the contemporary home, the demand for MDF and HDF can soar high.

Oriented strand board, or OSB, is fast gaining acceptance in the construction industry as a material for structural applications like flooring, roofing, and wall sheathing. OSB has grown increasingly popular with structural applications like flooring, roofing, and wall sheathing, where traditional plywood can no longer be preferred for sustainability in construction practices.

Mass-produced, budget-friendly furniture and cabinetry are what particleboard is a part of. The two big advantages for mass-produced furniture are that it is affordable and easy to use, which makes it the first choice when making furniture to put up in urban living.

Due to its density and toughness, hardboard will still find an application niche in the requirements for strong material properties, especially in particular components of furniture and industrial applications. It can be molded into many shapes and is useful in specific design requirements.

Plywood stands out among the most used products because of its versatility and strength. It is used in vast applications in construction, furniture, and packaging. Improvements in the manufacturing process made plywood harder; it resists moisture and is fire retardant. These make the uses more ample.

Others, like lumber panels, softboard, chipboard, and beadboard, continue to fill niche roles in the marketplace. For instance, softboard is used for insulation purposes, while beadboard finds its use in decorative applications. As style directions change, so can these materials be applied in new and emerging ways, which add to diversity in the marketplace.

The advancement of technology features a strong deterministic role in the growth perspective of the wood-based panel market. Adhesive technological innovation and automated production processes have led to producing better quality panels with minimal generation of waste. Digital permits customization, which can be done according to the exact needs of panel thickness, color, texture, and size as per the exact demands of customers.

By Application

It will significantly grow worldwide owing to diversified applications in numerous industries. There are wood-based panels, wherein bonding of wood fibers, particles, or veneers is involved for furniture, construction, and packaging.

The furniture industry simply cannot work without the wood-based panels for its business. Medium-density fiberboard (MDF), particleboard, and plywood are some of the materials in use on a large scale for producing a wide variety of products such as cabinets, tables, and chairs. These materials are cost-effective, durable, and versatile; and that's the reason manufacturers use them to satisfy the changing preferences of consumers. Of late, due to increased demand for customized and pre-assembled furniture, this is likely to increase consumption for household and commercial use.

Wood-based panels also play a significant role in the construction industry. They are used in flooring and roofing walls in addition to doors. Asia-Pacific countries that experience more urbanization and high infrastructure construction always need relatively cheap and sustainable building materials hence having structural integrity and aesthetic value maketh wood-based panels best suited for modern architecturally designed buildings. This is why green building practices have made their adoption increasingly popular, owing to the environmentally friendly and energy-efficient nature associated with them.

Another area where wood-based panels have come in handy is packaging. This is because the e-commerce and international trade coupled with the hard-pressed demand for durable, lightweight, and resistant packaging to protect the transported items have been on the rise. Particleboard and MDF are used in making shipping crates, pallets, boxes, and others for ensuring the safety of goods during transport. Strength and flexibility make these perfect panels to produce the packaging, which has to support handling and transit.

Looking forward, the wood-based panels market would continue this positive trend. Manufacturing technology had allowed better properties to be included in the panels. This meant they would now exhibit improved moisture resistance and increased strength. The result would mean an expansion in automotive interior applications as well as industrial prototyping. As consumers and industries become more conscious of the environment, demand for sustainable materials like wood-based panels will rise considerably. Furthermore, sourcing such panels from responsibly managed forests and recycled wood components contributes toward global sustainability goals, increasing demand further.

In summary, the adaptability and sustainability of wood-based panels position them in the most crucial role in many industries. The increasing application of these products in furniture, construction, and packaging is a testament that they will always play a vital role in fulfilling modern needs. The pace of technology continues to accelerate while environmental awareness continues to rise; therefore, the global market for wood-based panels will remain upward over time as they continue to meet the changing needs of the future.

By Construction

Advances in construction applications will have a huge influence on the global wood-based panel market. As the world urbanizes, demand for sustainable and versatile building materials is increasing. Wood-based panels, made from bonded wood fibers, particles, or veneers, have gained popularity and been found suitable for modern construction because of their versatility and many environmental benefits.

They are light but strong enough for flooring and roofing purposes. They can be installed in a pretty smooth manner and last long, and hence are a good fit for modern construction patterns. It becomes clear that during the passage of time, this construction process keeps changing, but people are even more interested to know about what material is utilized because it would serve the objective of structural reliability along with sustaining aspects. It meets both criterions: Wood-based panels, which are helpful and carbon friendly.

Wood-based panels are finer in insulation that can make walls efficient in energy use. They also have aesthetic versatility as their finishes can fulfill many architectural styles. With the continually changing taste of preference in designs, wood-based panels can easily adapt to accommodate these change-of-heart demands from architects and homeowners alike.

These panels make possible the manufacture of doors that will have superior dimensional stability and warp resistance. This is very essential in busy sections as it lasts longer and consistently performs its purpose. Recently, wood-based panels have gained much popularity since they are durable enough to sustain long-term value.

Besides these applications for primary structures, wood-based panels are increasingly adopted in decorative applications, wooden framing, and accessorizing. The materials are soft enough to work in a large spectrum of interior and exterior designs. With both consumers and builders demanding materials with a balance of aesthetics and environment-friendliness, wood-based panels are on a good side of meeting those two demands.

The future of the global wood-based panel market will be upward. This is because the drivers of the trend include the technological advancements in manufacturing, increased focus on sustainable building practices, and the versatility of the material itself. Wood-based panels will be the main players in shaping the building and design industry in the future.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$416.29 million |

|

Market Size by 2032 |

$515.97 Million |

|

Growth Rate from 2024 to 2031 |

3.1% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

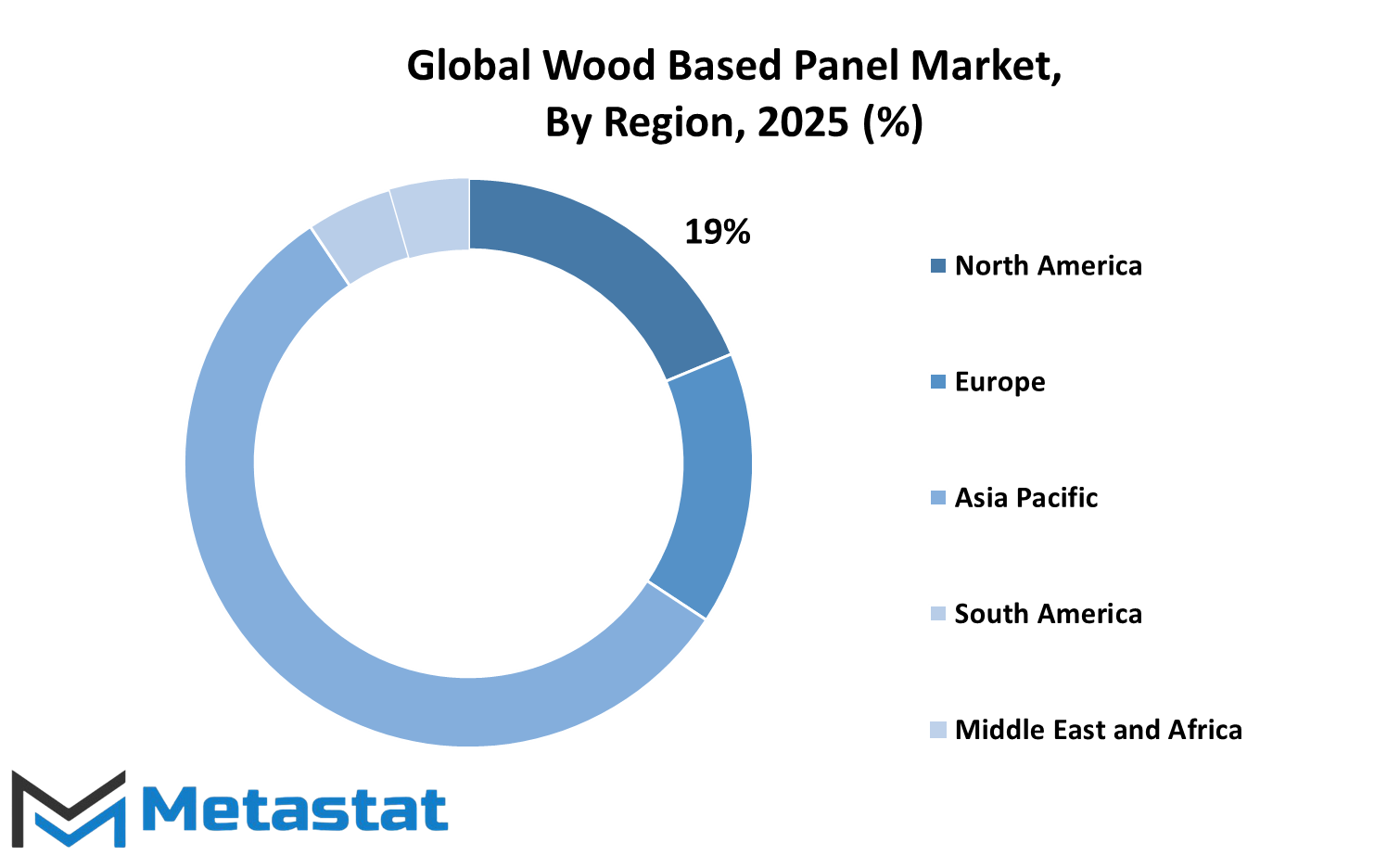

The global wood-based panel market is expected to grow significantly in different regions, with factors such as urbanization, increasing construction activities, and the demand for sustainable materials. Each region has its own opportunities and challenges that influence the overall growth of this market. In North America, the market is influenced by technological advancements and increased demand for eco-friendly building materials. The United States, Canada, and Mexico are important markets, where the U.S. is prominent due to a strong infrastructure sector and a high focus on green construction. Consumers and industries will increasingly opt for environmentally friendly alternatives, and panel manufacturers are working on developing production technologies that offer longer-lasting, more efficient products. Availability of raw materials and government policies in support of green buildings will support demand in this region. Europe is the biggest market for the global wood-based panel market, with Germany, the UK, France, and Italy being key players.

Tight environmental regulations and sustainability policies have pushed the adoption of wood-based panels as an alternative to traditional materials. In Germany, engineered wood products are increasingly being used in residential and commercial projects. Moreover, the demand for high-quality furniture and interior design solutions continues to drive market growth. Manufacturers innovate products to match consumer preferences. The Asia-Pacific region is set to be the growth leader, driven by fast urbanization, population growth, and industrialization. Major contributors include China, India, Japan, and South Korea. China will dominate production and consumption.

The increasing focus on affordable housing projects and infrastructure development has boosted the demand for wood-based panels. Additionally, growing awareness about sustainable materials and deforestation concerns are prompting the adoption of engineered wood products. The region's evolving construction landscape and investment in modern manufacturing processes will further enhance market growth. The opportunities in South America also exist mainly in Brazil and Argentina, wherein the urbanization process and furniture production are becoming larger. Also, raw material availability and increase in renovation work support the expansion of the market. Though issues such as uncertain economic conditions will continue to impact the market, rising investments in the housing industry and consumer's growing interest for green products would boost the regional market.

The Middle East & Africa region is witnessing steady growth with increased infrastructure projects and government-driven activities associated with inculcation of sustainable products in the construction sector. Saudi Arabia, UAE, Egypt, and South Africa are more or less focusing on wood-based panels in modern architectural designs. Challenges still remain with a limited forest resource base. Improvements in import strategies and manufacturing methods will be at the core of the development of this market. Overall, regional economic conditions, policies on the environment, and the construction activities going on will determine the wood-based panel market globally. With technology in place and increasing importance on sustainability, each region will evolve uniquely to shape up the market.

COMPETITIVE PLAYERS

The Global Wood Based Panel market is estimated to experience tremendous growth in the coming years, fueled by the increased need for sustainable and versatile building material usage. Increased urbanization and infrastructure development throughout the world make wood-based panels a more preferred option in residential and commercial construction, furniture production, and interior design. Owing to the renewable nature of these panels and their efficient manufacturing processes, industries are increasingly opting for such eco-friendly solutions.

The rising concerns over the environment and demand for sustainable products fuel this market. Governments worldwide encourage the use of engineered wood as an alternative to traditional solid wood, with benefits of lesser deforestation without the loss of strength and durability. Technological development in panel production also helps upgrade the quality of the products manufactured, such that they become moisture-resistant, fire-resistant, and pest-resistant, which in turn increases their usability and accelerates the growth in the market.

Leading companies in this area are always innovating to further enhance their positions in the market. Some of the significant players who would lead this industry forward are: ARAUCO, CenturyPly, VRG Dongwha MDF, DEXCO, EGGER, Georgia-Pacific Wood Products LLC, GREENPANEL INDUSTRIES LIMITED, Kastamonu Entegre, Kronoplus Limited, Langboard Inc, Louisiana-Pacific Corporation, Pfleiderer, Roseburg Forest Products, SWISS KRONO Group, West Fraser, and Weyerhauser Company. These companies are investing heavily in research and development to enhance panel quality, sustainability, and efficiency in production. Growing consumer demands for aesthetically pleasing, cost-effective, and modern interior designs also add to the rising demand for engineered wood products. With a new trend toward interior design being minimalistic and organic, wood-based panels provide a perfect fit for flooring, cabinetry, and decorative wall elements. The variety of finishes, textures, and colors has therefore been broadened by manufacturers in response to this changing need in consumers and designers.

In the immediate future, digitalization and automation in manufacturing promise much for the industry. Ranging from enhanced efficiency to waste reduction, smart production facilities fitted with artificial intelligence and data analytics are improving efficiency and reducing waste. Innovation in adhesive technology also enables more environmentally friendly panel production by ensuring significantly reduced formaldehyde emissions. Such innovations improve product performance while aligning with stricter global regulations on sustainable materials.

As the Global Wood Based Panel market grows, companies will have to be ahead in the game with sustainable practices, advanced technologies, and a product portfolio. As green building initiatives and circular economy models gain increasing investments, this market promises a bright future. The next growth phase will be defined by the shift toward renewable resources and technological progress, where wood-based panels will become an integral part of modern construction and design solutions.

Wood Based Panel Market Key Segments:

By Product Type

- Medium-density Fiberboard (MDF)/High-density Fiberboard (HDF)

- Oriented Strand Board (OSB)

- Particleboard

- Hardboard

- Plywood

- Other Product Types (Lumber Panels, Softboard, Chipboard, and Beadboard)

By Application

- Furniture

- Construction

- Packaging

- Other Applications (Artistry, Industrial Prototyping, Toys, etc)

By Construction

- Floor and Roof

- Wall

- Door

- Other Constructions (Decorative Applications, Wooden Frames, and Accessories)

Key Global Wood Based Panel Industry Players

- ARAUCO

- CenturyPly

- VRG Dongwha MDF

- DEXCO

- EGGER

- Georgia-Pacific Wood Products LLC

- GREENPANEL INDUSTRIES LIMITED

- Kastamonu Entegre

- Kronoplus Limited

- Langboard Inc

- Louisiana-Pacific Corporation

- Pfleiderer

- Roseburg Forest Products

- SWISS KRONO Group

- West Fraser

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252