MARKET OVERVIEW

Global Wire Rope Flaw Detectors is a niche group in the NDT business that deals with the inspection and maintenance of wire ropes in various industries. They are crucial tools for finding structural anomalies, including cracks, corrosion, and inner wear, which are usually invisible to the naked eye. This market has importance to it as it helps in the safety, reliability, and performance assurance of wire ropes used under heavy-duty applications such as construction, mining, oil and gas, and even maritime operations.

Wire rope flaw detectors provide accurate diagnoses with advanced technologies such as MFL and ultrasonic testing. These tools enable operators to inspect wire ropes in real time, thus reducing the risk of accidents and downtime. The Global Wire Rope Flaw Detectors market is defined by its capability to address the rigorous standards of safety and efficiency required by industries. Since these wire ropes are often placed under extreme mechanical stresses and extreme environmental conditions, regular inspections that are precise are nonnegotiable, and flaw detectors are indispensable.

The scope of the market is vast, covering various ranges of industries and applications. For cranes and lifting equipment, within construction, flaw detectors play an integral role in ensuring that a level of safety regulation can be met and also cut the rate of failure from this equipment. The hoisting systems in mining industry assure full operational integrity through the application of such tools. Maritime applications further extend the scope of the market since flaw detectors are a crucial aspect of the maintenance of ropes used for mooring and towing in saline environments. Energy, in general, and offshore oil and gas exploration, also find utility in wire rope flaw detectors to improve safety and efficiency of operations.

The growth in this market is only a precursor to what future holds in terms of technology for this market. Enhanced sensors and software-driven analytics will likely enable even greater accuracy in detecting flaws and predicting rope lifespans. Integration with IoT systems may emerge as a transformative trend, allowing operators to access real-time data on wire rope conditions and proactively schedule maintenance. This innovation will reinforce the value proposition of wire rope flaw detectors as a preventative tool that enhances safety and reduces long-term costs.

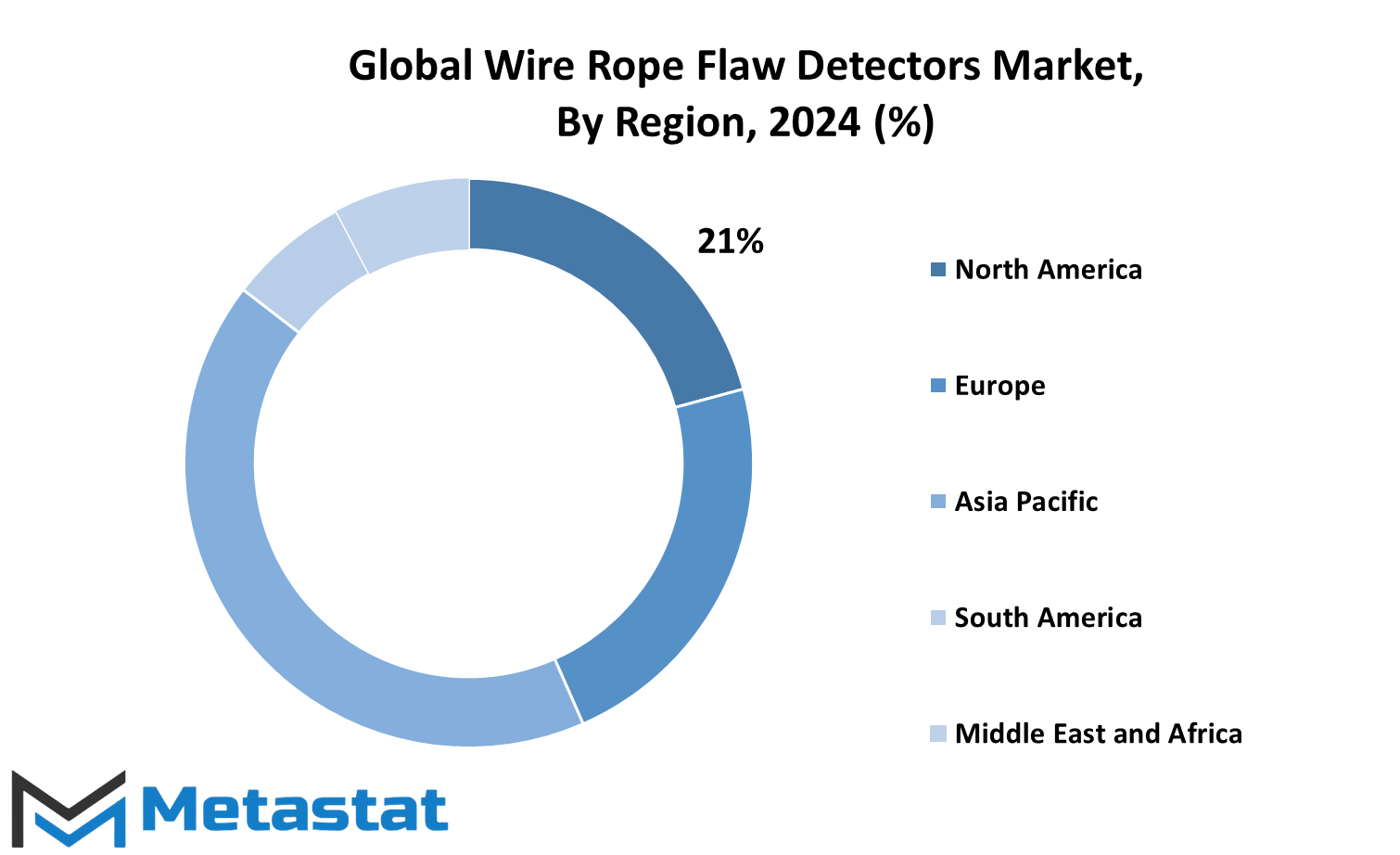

Geographically, regions with high industrial activities dominate the global wire rope flaw detectors market. Asia-Pacific will command a respectable share due to industrialization in countries such as China and India and also infrastructure improvements. North America and Europe will maintain the demand share due to rigid safety regulations set by these geographies along with industry presence already set in these geographical locations that have long been established and dependent on the use of wire ropes.

Therefore, the market is characterized both by established players and emerging ones, each adding to changes in wire rope inspection technology. The manufacturer will try to invest more in its development as industries seek greater accuracy and precision.

The Global Wire Rope Flaw Detectors market is an integral part of industrial safety and maintenance. The relevance of this market will grow as industries increasingly take proactive measures to ensure operational continuity and safety in critical applications. With continued innovation and adaptation to evolving industrial needs, this market will remain a cornerstone of non-destructive testing solutions.

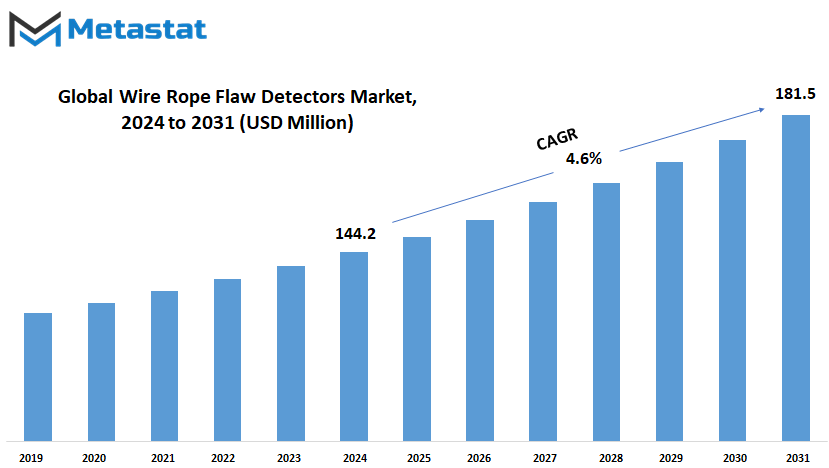

Global Wire Rope Flaw Detectors market is estimated to reach $181.5 Million by 2031; growing at a CAGR of 4.6% from 2024 to 2031.

GROWTH FACTORS

The Global Wire Rope Flaw Detectors market is going to experience great growth with the evolving demands in safety and operational efficiency across industries. With safety at workplaces becoming one of the prime concerns for industries all over the world, such adoption of advanced technologies towards regular inspections is increased. Wire rope flaw detectors are critical in ensuring that safe and reliable conditions are experienced, especially in heavy industry: lifting, hoisting applications, and other high stress usage. This growing concern on implementing industrial safety regulations directly amplifies the demand for this system, which helps provide a critical tool in diminishing the risk and enhancing the potential for productivity. The growth major factor is the rampant adoption of wire ropes, applied in construction, mines, and transportation industries.

These ropes are prone to extreme stress and wear and tear and thus require regular inspections to avoid accidents due to cracks that have not been detected. As a result, industries are investing more in wire rope flaw detectors to ensure consistent performance and reduce downtime. This trend not only highlights the vital role these detectors play in enhancing workplace safety but also underscores their importance in maintaining operational efficiency. However, despite this optimism, some challenges may hinder growth in the market. Advanced flaw detection technologies are too costly for small businesses to make an investment in such systems. The complexity of the devices, and the need for expertise to operate them, would discourage users, especially industries with less technical expertise. Hence, these challenges highlight a need for more accessible solutions which can reach diverse user bases. There will be expansion of the market, albeit positively, through continued technology improvements.

Advancements in more transportable and user-friendly fault detection and efforts to reduce cost are fundamental in expanding the market. It will be easier to establish new markets and smaller industries because it is practical and cheap compared to traditional systems. Such a move towards affordability and ease of use could weigh heavily on adoption rates and open the way to steady growth in years to come. The Global Wire Rope Flaw Detectors market is bound to grow due to the synergistic forces of increased safety regulations and demand for efficient equipment maintenance. With existing challenges, the market is set to deliver innovative solutions that meet the need of a wider spectrum of industries.

MARKET SEGMENTATION

By Technology Type

The Global Wire Rope Flaw Detectors market is presently growing by leaps and bounds as various industries are focussing on safety and effectiveness. A wire rope is used significantly in sectors such as construction, mining, oil and gas industries, as well as transportation. Its defects can create accidents and disrupt activities. Consequently, the development of accurate and efficient detectors for such flaws in ropes is increasingly in demand for industries looking to expand themselves and become more technologically equipped.

These detectors play a very important role in identifying internal and external defects in wire ropes, including corrosion, broken wires, and wear, which cannot be easily detected by the naked eye. The market for these devices is segmented based on technology. Some of the key types of this segment are Magnetic Flux Leakage (MFL) Detection, Ultrasonic Testing (UT), Eddy Current Testing, Visual Inspection Systems, and Combined Technologies. Each type of technology presents different advantages and satisfies the necessities of a specific industry. For example, MFL-based detection is widely used for detection of internal flaws in thick ropes whereas ultrasonic testing is perfect for detailed structural irregularity identification. Eddy current testing is prized for surface defect detection with high accuracy, while visual inspection systems, often integrated with another technology, serve as simple and easy-to-use means to perform routine checks. Combined technologies integrate multiple approaches, delivering comprehensive assessments that enhance accuracy and reliability.

In the future, technological developments will likely redefine the efficiency of wire rope flaw detectors. Integration with artificial intelligence and machine learning will enable predictive maintenance by analyzing patterns and providing real-time diagnostics. This may significantly reduce downtime and improve operational safety. As industries adopt the Internet of Things, connected flaw detectors will enable remote monitoring and instant data sharing, changing the way maintenance is managed.

The growing demand for sustainability and cost-effectiveness also plays a crucial role in the future of this market. Increasing global safety standards are forcing industries to implement high-quality detection systems in line with the standards while also attempting to minimize risks. This aspect of proactive maintenance will propel innovations and increase the adoption of state-of-the-art wire rope flaw detectors across sectors.

In conclusion, the Global Wire Rope Flaw Detectors market will grow to significant proportions due to technological developments and safety awareness. As these detectors remain essential for industrial practices with the advancement of industries, operational reliability and safety are assured, thus marking a critical step forward for global industrial practices.

By Application

The Global Wire Rope Flaw Detectors market is moving toward massive progress due to technology and an increased need in the industry for faster and more reliable solutions to safety and maintenance. Detectors play an important role in finding faults within the wire ropes, which constitute critical parts of various industries. Detection of flaws prevents possible breakdowns that can cause operating disruption or pose safety hazards. This increasing significance has led to the demand in various applications like mining, oil and gas, marine operations, construction, transportation, and energy production.

In the mining industry, wire rope flaw detectors are crucial to ensure the safety and performance of equipment. As deep and challenging mining operations continue, it is essential to identify potential problems in hoisting or dragging ropes. The need for strong safety mechanisms has increased the demand for sophisticated and more accurate detection technologies in this industry. The oil and gas industry also relies heavily on wire ropes in the drilling, lifting, and anchoring operations. In all these operations, flaw detectors ensure reliability and safety in scenarios where equipment failure may precipitate serious economic and environmental consequences.

Wire rope flaw detectors are also applied in marine and offshore operations, where ropes are exposed to saltwater and heavy loads. These harsh environments require consistent inspection with advanced detectors to ensure extended life and minimize the accident rate. In the construction industry, cranes and lifts are often used, hence wire ropes must be consistently monitored to meet the safety standards for operation. Flaw detectors facilitate effective inspection without much downtime.

The transportation and logistics industry also values the wire rope flaw detector, especially for use in cable cars, elevators, and cargo handling systems. These technologies make operational safety better and help companies maintain compliance with standards. Industrial manufacturing and energy generation industries rely on such equipment for the maintenance of their machinery, which operates mostly at high stress levels. This way, detection at the earliest stages ensures proper production runs and reduces maintenance expenses in the event of surprise stoppages.

In the future, the Global Wire Rope Flaw Detectors market will continue to evolve with advancements in artificial intelligence and sensor technology. Such technologies will likely increase the accuracy and efficiency of detection, making them indispensable across industries. As businesses continue to prioritize safety, reliability, and operational efficiency, the adoption of wire rope flaw detectors will expand, driving growth and fostering innovation in this critical market.

By End User

The Global Wire Rope Flaw Detectors market is expected to grow significantly, as the technology advances and the demand for safety increases in various industries. Wire ropes are an essential part of construction, industrial plants, mining, and transportation industries. Their reliability is very important because failure can be catastrophic. Flaw detectors are used to identify wear, corrosion, and internal damages that are not observable from the outside. With increasing interest in operational efficiency and safety standards, demand for these devices is expected to rise steadily.

The market is split between end-users who have various needs and applications. Inspection service companies are part of this division. These companies provide the advanced diagnostic service, and use high technology to assess wire ropes' integrity. Because third-party specialists are hired more and more by businesses for inspection, this group is expected to grow with even stricter rules on work environment safety all over the world.

Manufacturers of wire ropes are also a significant share of the market. For them, flaw detection technology during production guarantees that the ropes meet strict quality standards before they get to the end-users. This not only builds product reliability but also helps to strengthen the manufacturers' position in the market as a result of trust built with the clients.

The other significant category of users consists of Maintenance and Repair Organizations. These organizations essentially ensure that wire ropes last for a longer time by carrying out regular inspections and then repairing them when necessary. The increasing focus of businesses on cost efficiency further makes MROs very important in the sense that they avert unplanned downtime and equipment failure. The adoption of advanced flaw detectors here ensures that there is minimal long-term damage.

In-house inspection teams, typically found in industrial plants and construction sites, also rely heavily on these devices. These teams are tasked with maintaining safety and functionality on-site. As industries embrace automation and digitalization, the integration of sophisticated flaw detection tools with real-time monitoring systems is expected to increase. This will enable quicker decision-making and improve safety outcomes.

This Global Wire Rope Flaw Detectors market is, in fact, on the road to growth, mainly due to continued innovations and a more widespread implementation of preventive maintenance measures. As the industries of safety, efficiency, and cost-effectiveness gain importance, wire rope flaw detectors will only become that much more significant in helping to build the future without risks and maximize productivity.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$144.2 million |

|

Market Size by 2031 |

$181.5 Million |

|

Growth Rate from 2024 to 2031 |

5.4% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

In the forthcoming years, the Global Wire Rope Flaw Detectors market will record significant growth. Rising demand within the construction, mining, transportation, and oil and gas industries is contributing to the projected growth. The main driving force behind this trend would be the rising demand for the implementation of safety measures within key infrastructure. Critical infrastructures significantly rely on wire ropes as a component for smooth operational flows and safety. Wire rope flaw detectors are must-have tools used to identify and locate a potential weakness, which should be prevented with accidents and ensured that the quality of an equipment is properly improved in terms of their reliability.

Geographical classification of global market shows growth patterns across each region. There will be dominant presence of market in North America, particularly in United States, Canada, and Mexico. This is majorly because of the industrial infrastructure and high safety standard in industries like mining and construction. Adoption of latest technologies and continued improvement of detection of wire rope flaws would drive this growth in North America.

The market would be benefited by strict safety rules in industries such as oil and gas, mining, and transportation in Europe. The region is focused on accident prevention, and ensuring the longevity of the equipment will drive demand in advanced wire rope flaw detection systems. Countries like UK, Germany, France, and Italy will lead in Europe because of their advanced manufacturing sectors and high safety standards. As industries continue evolving, the demand for innovative technologies in wire rope flaw detection will increase across Europe.

The Asia-Pacific region, which includes countries such as India, China, Japan, and South Korea, will be a critical region for the growth of the global market. This region is characterized by rapid industrialization, especially in manufacturing, construction, and infrastructure development. As these industries grow, so too will the need for more reliable and efficient safety systems, such as wire rope flaw detectors. Continuous growth in the regional heavy industries will continue to heighten demand for these products.

In South America, it is anticipated that the wire rope flaw detector market shall be on an upraise in the industries like mines, oil, and natural gases. The demand for it would increase as Brazil and other places in Argentina are building more infrastructure to improve efficiency while making critical operations a safer place. The Middle East and Africa regions, particularly in countries such as Saudi Arabia, South Africa, and Egypt, will continue to grow. Increased infrastructural investments and a higher focus on safety in mining as well as construction will drive further growth in this region as well.

Overall, the Global Wire Rope Flaw Detectors market will grow over all the regions. In the face of growing regulatory requirements concerning safety, this industry seeks to improve the operational efficiency in their productions and will raise the demand for these highly specialized detection systems.

COMPETITIVE PLAYERS

The Global Wire Rope Flaw Detectors market is experiencing high growth because of the increased demand for advanced inspection technologies in the construction, mining, and transportation industries. The increasing need for reliable wire rope maintenance and safety has driven innovation in flaw detection, and several key players have emerged as leaders in this highly competitive market.

Among the major players in the wire rope flaw detection industry, are Nexxis, Mitech and TST Flaw Detection Technology Co., LTD. Each of these companies has assumed a pioneering position in an industry that is concerned with advancing the latest technologies for wire rope flaw detection, to be used in oil and gas, aviation, heavy lifting, among others. Their innovations in NDT technologies, including electromagnetic and ultrasonic testing, have been critical to enhancing the safety and reliability of wire ropes used in cranes, elevators, and other machinery.

Huatec Group, Dandong Flaw Detector Equipment Co., Ltd., and NDT Technologies Inc. are also experts in producing high-quality wire rope inspection solutions. The companies expanded their portfolios by incorporating portable as well as stationary flaw detectors to suit different industries. Their products offer accuracy in use and even detect defects as small as those within the wire ropes.

Other notable players have in this regard been MFL Services Pty Ltd., Fidgeon Ltd., and INTRON Plus. These companies provide products that minimize downtime and reduce maintenance costs, meaning they have largely invested in research and development to advance solutions for wire rope flaw detection, so inspections can be done without interrupting ongoing operations.

AJR NDT CO., LTD., Testex Inc., Cygnus Instruments Ltd., and Olympus Corporation are also making good improvements in the global wire rope flaw detection sector. Their technologies consist of user-friendly interfaces and safe reporting systems, which help industries plan their maintenance schedules and assure that their equipment is safe and sound. Magnetic Analysis Corporation, ETher NDE Ltd., and Luo Yang Wire Rope Inspection Technology Co., Ltd. are the other key competitors that have further contributed to the growth of this market through their continuous product innovations.

As the need for the higher safety measures and technolgy integration in industrial operation arises, the Global Wire Rope Flaw Detectors market is going to shift further into an advanced direction. With the emergence of giants like GAO Tek Inc. and NDTS India (P) Limited across the markets, there would be an upswing of more economical and effective options that can cater to small companies yet adhere to strict industry demands for higher safety criteria set by bigger industries.

Wire Rope Flaw Detectors Market Key Segments:

By Technology Type

- Magnetic Flux Leakage (MFL) Detection

- Ultrasonic Testing (UT)

- Eddy Current Testing

- Visual Inspection Systems

- Combined Technologies

By Application

- Mining Industry

- Oil & Gas Industry

- Marine and Offshore

- Construction Industry

- Transportation and Logistics

- Industrial Manufacturing

- Energy and Power Generation

By End User

- Inspection Service Providers

- Wire Rope Manufacturers

- Maintenance and Repair Organizations (MRO)

- In-house Inspection Teams (Industrial Plants, Construction Sites)

Key Global Wire Rope Flaw Detectors Industry Players

- Nexxis

- Mitech

- TST Flaw Detection Technology Co., LTD

- Huatec Group

- Dandong Flaw Detector Equipment Co., Ltd.

- NDT Technologies Inc.

- INTRON Plus

- MFL Services Pty Ltd.

- Fidgeon Ltd.

- AJR NDT CO., LTD

- Testex Inc.

- Cygnus Instruments Ltd.

- Olympus Corporation

- Magnetic Analysis Corporation

- ETher NDE Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252