MARKET OVERVIEW

The Global Wind Power Paint market is one of the specialized segments of the renewable energy industry, and it encompasses the development, production, and application of protective coatings designed especially for wind turbine components. These coatings are very vital in enhancing the efficiency, durability, and life of the wind turbines, which are put under extreme environmental conditions, including high temperatures, high humidity, and abrasive wind forces. As the pressure to adopt renewable energy around the world mounts, this market will continue growing in popularity because of an increasing trend towards the adoption of wind energy as a basic component of clean energy strategies.

Wind energy paint is more than a cosmetic enhancement, but an essential component to the operational efficiency and cost effectiveness of a wind farm. This paint used in this industry provides a corrosion-resistant formula as well as UV radiation attenuation effects and minimizes life cycle costs for maintenance over turbine lifespan. It also aids in ensuring the structural integrity of the blades, towers, among other components of the turbines to prevent wear and tear resulting from continuous exposure of elements. Material science innovations are likely to introduce advanced coatings, including self-healing coatings or aerodynamic coatings that will give the turbine operator a significant edge in terms of efficiency and operational uptime.

The Global Wind Power Paint market is likely to have diverse applications in both onshore and offshore wind energy projects. Offshore turbines require stronger protective measures because of the harsh environment in marine environments. Therefore, the demand for high-performance coatings specifically designed for such environments will define the dynamics of the market. Also, as wind turbines get larger and their capacity increases, the demand for more sophisticated and long-lasting paints will also increase. Manufacturers will be likely to develop eco-friendly and low-emission coatings that meet global environmental standards, adding another layer of complexity and opportunity to the market landscape.

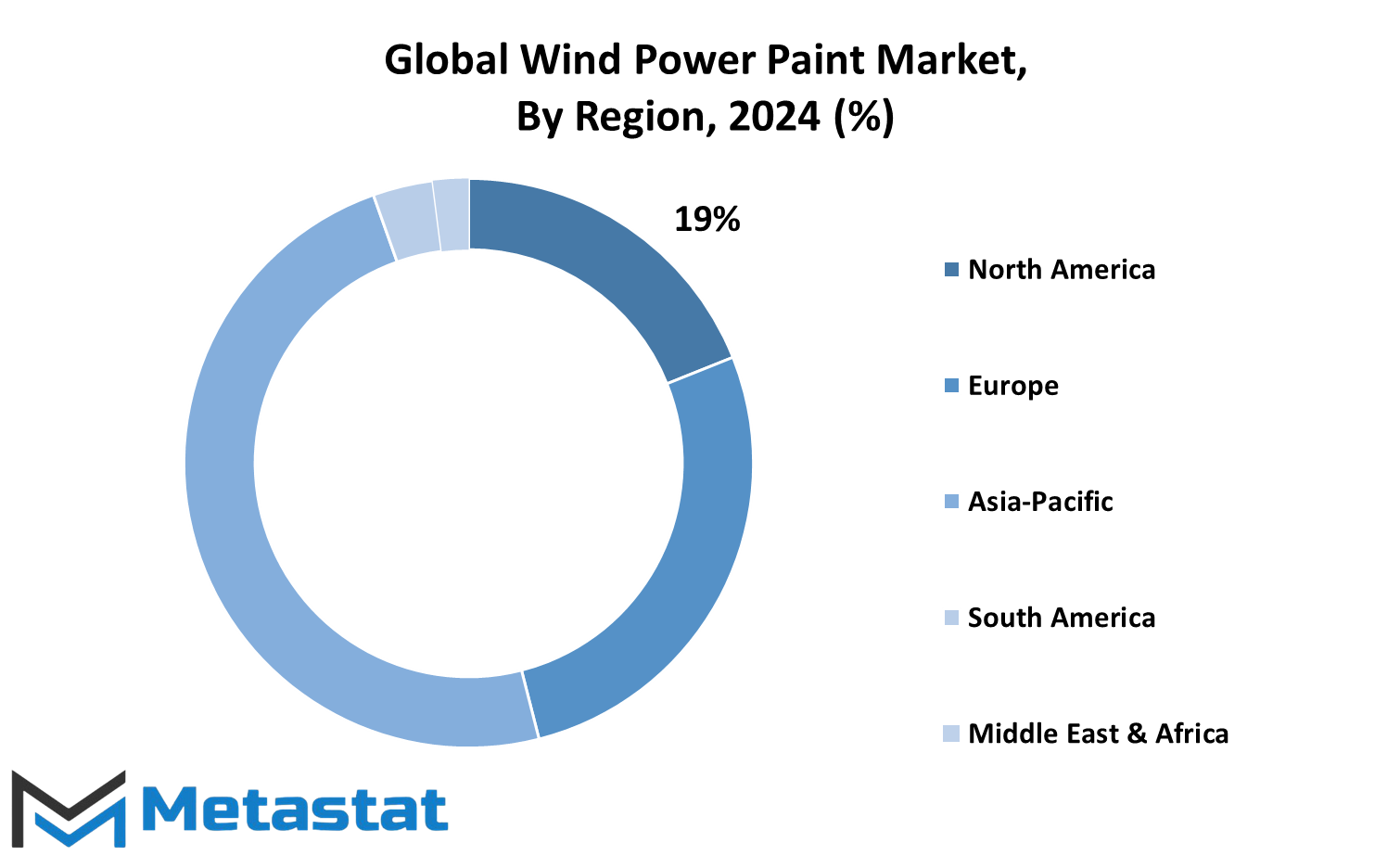

This market will also reflect variations in regional growth, that is, depending on governmental policy, renewable energy targets in place, and the developed extent of wind power in local areas. Europe, of course, will continue its dominance because of its already laid out offshore wind infrastructure combined with its aggressive renewable goals. Meanwhile, the Asia-Pacific region, led by the likes of China and India, will showcase strong demand for wind power coatings, fueled by their large-scale investments in renewable energy projects. North America, with its expanding onshore wind farms, will also contribute significantly to the industry.

In terms of competition, the Global Wind Power Paint market is likely to attract established chemical and coatings manufacturers as well as emerging players who specialize in renewable energy solutions. In this regard, collaboration between the wind turbine manufacturers and the paint producers is likely to drive innovation toward the creation of products that are more attuned to the specific needs of the wind energy sector.

In conclusion, the Global Wind Power Paint market will be an important part of the renewable energy industry, playing a vital role in ensuring efficiency, safety, and sustainability of wind power installations. Accelerating transition to renewable sources of energy globally will require innovative, high-performance coatings tailored to the unique challenges of wind energy, hence shaping the future of this market, emphasizing its role in long-term energy sustainability.

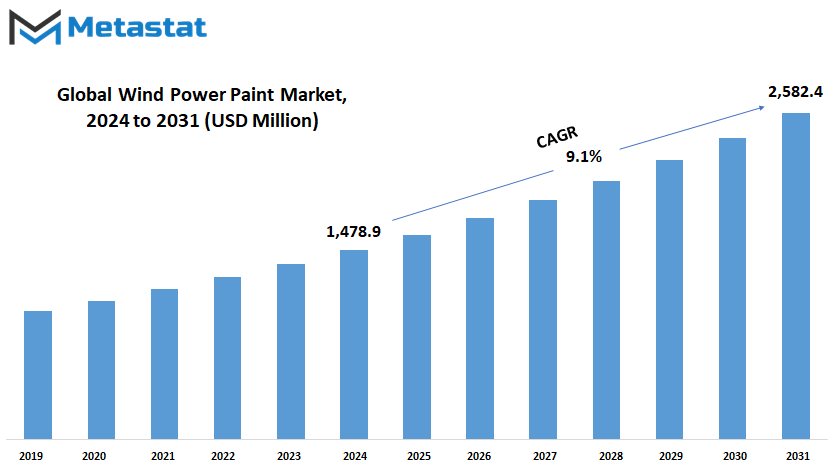

Global Wind Power Paint market is estimated to reach $2,582.4 Million by 2031; growing at a CAGR of 9.1% from 2024 to 2031.

GROWTH FACTORS

The Global Wind Power Paint market is witnessing significant momentum because of the increasing demand for wind energy worldwide. This growth is driven by increased investments in wind energy projects that seek to meet energy needs through green sources. Since wind turbines are exposed to harsh weather, they need specialized protective paints to ensure their durability and performance. These coatings are necessary to prevent corrosion, wear and tear, and extend the operational life of the turbines. Therefore, the demand for high-performance paints for wind energy systems is increasing in the market, which also leads to high market growth.

One of the major reasons for this trend includes the emphasis on minimizing operational stoppages and maintenance expenses for offshore wind farms. As many maintenance operations are both resource-intensive and time-consuming in nature, operators are gravitating toward advanced coatings withstanding extreme conditions and minimum touch-ups. Such paint is of high quality in ensuring that the turbines serve for a longer period without interrupting the process.

However, the market also faces significant challenges. The high cost of advanced protective coatings is a deterrent for projects that operate under strict budget constraints. Moreover, regulatory hurdles concerning the environmental impact of certain chemicals used in these paints limit the range of materials available for use. These factors can slow the growth of the market, especially in regions where stringent environmental policies are in place.

Despite these challenges, the Global Wind Power Paint market is full of potential in the future. The emergence of green, long-lasting coatings will be a major opportunity to grow. Innovations that align with the goal of the industry to achieve sustainability without maintenance needs are being produced in this area. Manufacturers have the opportunity to attract a more significant customer base by making paints that are both effective and environmentally responsible and contribute to the global transition toward renewable energy sources.

Looking forward, the market seems to be in good shape, driven by the continuous drive for renewable energy and the advancement of protective materials. Although cost and regulatory issues remain, the trend toward sustainability and low-maintenance solutions is expected to open new doors. As countries continue to invest in clean energy initiatives, the demand for efficient and durable wind turbine coatings will likely grow, making this market an integral part of the global energy landscape.

MARKET SEGMENTATION

By Type of Paint

Global Wind Power Paint market is garnering much attention due to a constant hike in demand for the need for sustainable energy resources. This market specializes in painting that is used on turbines specifically with the intention of boosting wind power efficiency and durability. They therefore protect wind turbine components against difficult climatic conditions and subsequently safeguard the wind energy systems by way of durability and efficiency. Advances in paint technologies are emerging to meet the specific challenges of the wind energy sector as the push for cleaner energy intensifies.

There are several types of paint used for different purposes, catering to unique operational challenges. Anti-corrosion paints help prevent the rusting of turbines in offshore installations that have a tendency to corrode with saltwater. Abrasion-resistant paints help reduce the wear and tear caused by dust and debris in high-wind areas. UV-resistant coatings prevent surfaces from damage by sun rays for a long time that cause degradation of materials with time. Likewise, heat-resistant paints prevent overheating of turbines that run at extreme temperatures.

Specialized solutions introduced by innovative developments include anti-icing and de-icing coatings. These paints prevent ice buildup, which could limit the performance of turbines in cold climates. Self-cleaning coatings are designed to minimize maintenance requirements, as they allow dirt and other contaminants to be removed with relatively little effort. Biocidal and anti-fouling coatings are increasingly used to stop microbial growth or the accretion of marine organisms on turbine surfaces, especially in offshore locations.

In the future, the Global Wind Power Paint market will continue to expand rapidly, with more investment in renewable energy infrastructure. Around the world, governments And industries have ambitious targets for wind energy and will push for the adoption of high-performance paints and coatings that will help extend the life of turbines. This market is likely to see more significant roles played by the advancements in nanotechnology and green materials in the future, meaning that the coatings used should not only be effective but also sustainable.

Technology, as it advances, is going to shift its emphasis to creating coatings that are energy efficiency contributing. This could range from paints that reduce drag or enhance the aerodynamics of the turbine blades. The nexus of innovation in coatings and an increased capacity in wind energy reveals a fundamental role for the Global Wind Power Paint market in creating a greener future.

By Material Type

The Global Wind Power Paint market is expected to have great growth in the years to come as renewable energy becomes an increasingly important solution to the world’s energy problems. With wind energy being one of the leading sources of renewable power, the materials for protection and maintenance of wind turbines are more important than ever. These coatings are vital for ensuring the durability, efficiency, and long-term operation of wind turbines that operate in some of the toughest environmental conditions on Earth. Wind power paints comprise different material types, with each material offering specific advantages tailored to meet the challenges experienced by the wind turbine components.

Epoxy coatings are widely recognized for their high adhesion strength and resistance to corrosion. These coatings are often applied on turbine bases and key structural parts to ensure that it will still be intact, even if the weather turns severe. Polyurethane-based coatings provide excellent UV resistance. This type of coating is used extensively on turbine blades since its performance and appearance last even with prolonged exposure to the sun. Fluoropolymer coatings are highly valued for long-term durability and dirt-repelling properties, minimizing the need for maintenance on surfaces exposed to dust and debris of turbines. Acrylic coatings are less expensive and still provide excellent weather resistance, suitable for less demanding applications.

Zinc-rich coatings are valued for their ability to protect against rust through galvanic action, particularly in coastal regions where turbines face high levels of moisture and salt. The ceramic coatings also offer extreme heat resistance and abrasion protection, very important in a turbine running in a desert where the threat of sand and heat is extremely risky. The nanocoatings, in fact, represent an ultramodern concept available in the market. The unique ability to prevent scratching and reduce drag besides even cleaning themselves results in giving unprecedented performance. Going forward, the market will be pushed further by material and technology advances.

Going ahead, larger and more efficient wind turbines are in high demand, which means there will be a need for coatings that can stand up to such challenges. Governments and industries are spending heavily on wind power globally, so the market for specialized coatings is going to expand alongside this trend. Each material type will remain a critical component, ensuring that the reliability and performance of wind energy infrastructure are achieved for a cleaner and more sustainable future.

By Component

The Global Wind Power Paint market is key to the support of wind turbines in terms of their efficiency and longevity, which have been important for renewable energy. The market is expected to grow steadily with the rising demand for sustainability in all aspects of life. These specialized paints protect the different parts of a wind turbine from environmental factors such as moisture, UV radiation, and extreme temperatures. In doing so, they not only help in saving on maintenance but also contribute to energy efficiency.

Breaking down the market by components clearly shows how paint technology caters to specific needs. For example, wind turbine blades need paints that are capable of withstanding the strain of high-speed winds and frequent exposure to environmental factors. These paints improve the aerodynamic efficiency of the blades but prevent erosion. The same applies to the tower that is exposed to changing weather patterns; protective paints that keep corrosion and structural weakening from occurring over time. In contrast, the nacelle, which houses essential machinery, needs coatings that ensure durability while maintaining internal temperature stability. The hub, another critical component, relies on similar protection to sustain mechanical performance. Other parts of wind turbines also require tailored paint solutions, ensuring that every aspect of the structure operates efficiently.

Looking forward, the Global Wind Power Paint market will be driven by the growing demand for specialized coatings as wind energy expands globally. The governments and organizations are setting very aggressive targets for renewable energy adoption, which will drive bigger wind farms and innovative designs in turbines. As the size of the turbines grows to capture more energy, advanced protective coatings become an essential requirement. Paint manufacturers will most likely develop long-lasting, self-healing, and eco-friendly paint coatings that will require minimal repeated maintenance. Nanotechnology developments and smart coatings may change how the industry works with coats that could adapt to its environment or paint that would relay real-time performance.

This market's growth will not only support the global push for clean energy but also encourage innovations in material science. With investments in advanced coatings for turbine components, the industry will ensure that wind energy is a reliable and sustainable source of power for decades to come. The Global Wind Power Paint market is ready to face the challenges of tomorrow with resilience and creativity.

By End-User

The Global Wind Power Paint market supports the renewable energy sector at a growing pace. Worldly, clean and environmentally friendly sources of energy become more in demand, leading to the wind energy option. Wind turbines are vulnerable to extreme weather conditions: strong winds, salty air, and temperature changes. Hence, wind power paints come into play for their effectiveness and durability. These paints protect not only the turbines from corrosion and wear but also optimize their aerodynamic performance, becoming an essential part of the wind energy industry.

On considering the end users, the market can be divided into categories that reflect the needs of the industry. They include wind farm owners and operators who find a way to minimize costs for maintenance and maximize life cycles of turbines. As damage resulting from weathering is lessened, these coatings work to contribute to the wind farm's profitability. The rise of more regions investing in large-scale wind farms, meanwhile, ensures that demand for protective coatings will keep climbing. Such a trend receives support from governments and other entities working toward reducing carbon footprints.

The market also has another crucial category, which is that of wind turbine manufacturers. For these producers, the primary concerns are durability and performance. Wind power paints of high quality can provide not only customer satisfaction but also a competitive advantage in this market. Advancements in material science allow for the development of paints that exhibit self-healing properties and increased UV resistance, among other innovations in this category.

Equally important is the involvement of maintenance and repair service providers. Turbines need constant maintenance to function at peak performance, especially in offshore environments where conditions are most extreme. For these service providers, wind power paints offer a reliable solution to prevent issues before they become costly repairs. As such, the market continues to expand to support the growing network of wind farms globally.

Finally, offshore wind power plant developers count on advanced coatings to assure the success of their projects. Offshore installations are so prone to saltwater corrosion that specialized coatings are required that can face such challenges. In the future, more innovations are expected in terms of paints designed for longer periods of service and less environment degradation.

The Global Wind Power Paint market is expected to grow significantly with the advances in technology and increasing adoption of renewable energy. These specific coatings will remain a very important part of supporting this global shift toward wind energy.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,478.9 million |

|

Market Size by 2031 |

$2,582.4 Million |

|

Growth Rate from 2024 to 2031 |

9.1% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The Global Wind Power Paint market is under steady growth as the demand for renewable energy solutions continues to increase in the world. This is a very important market in the wind energy sector as the protective paints used in the turbines enhance durability, efficiency, and longevity, hence making wind power a possible and cost-effective source of energy. The market in North America is very significant with the Wind Power Paint market in the region valued at 203.1 USD million in 2020. This value, therefore, calls for innovation and investment in renewable energy technologies to achieve increasing energy demand with a low impact on the environment.

Regionally, the Global Wind Power Paint market is categorized into several regions, with each having different dynamics, which influence growth. North America comprises the United States, Canada, and Mexico, where technological advancement and government incentives promote the adoption of renewable energy. The United States is the leader in wind energy production, thus increasing demand for high-quality protective paints. In Europe, Germany, the UK, France, and Italy are the major players due to their commitment to renewable energy goals. Filled with large wind farms and reducing carbon emissions, Europe is still one of the primary drivers of the expansion seen in this market.

Asia-Pacific is seeing countries such as China, India, Japan, and South Korea add rapidly to their wind energy capacity with economic development and concerns about energy security. As a world leader in renewable energy, China has significantly invested in wind turbine technology and infrastructure, thus enhancing the demand for niche coatings. Opportunities are also there in India and Japan, which are increasing their renewable energy projects to meet increasing energy requirements sustainably.

Gradually, the South America and the Middle East & Africa region are slowly taking pace within the Wind Power Paint market. Both Brazil and Argentina in the South American region focus on the strategy to have wind power, hence their broader portfolio towards alternative sources of energy. GCC, Egypt and South Africa focus on winds because their idea of energy resources and production lines is on lesser utilization of fossil.

The Global Wind Power Paint market holds a promising future as the world shifts towards renewable energy. Technological advancements, in addition to regional initiatives, will likely spur further growth. This market will play an essential role in ensuring that wind turbines are reliable and efficient and help the world combat climate change and achieve energy sustainability.

COMPETITIVE PLAYERS

Global Wind Power Paint Market The future prospects for the Global Wind Power Paint market remain robust in the coming years as the world prioritizes renewable energy solutions. Given the importance of reducing carbon emissions with wind energy, protecting wind turbines has become essential for maintaining their efficiency and longevity. This market is further being driven by technological innovation, the expansion of projects, and the increased focus worldwide on sustainable practices.

Wind turbines are exposed to harsh environments, including extreme weather conditions and high levels of wear and tear. Thus, specialized coatings, often referred to as wind power paints, are designed to provide protection against corrosion, UV damage, and mechanical stress. Companies such as Hempel A/S, AkzoNobel N.V., PPG Industries, Inc., and Jotun Group are leading innovators in this field, offering high-performance solutions to overcome these challenges. Such coatings will have a higher demand due to the fact that offshore wind farms face more severe conditions than onshore installations.

Furthermore, advancements in materials and coating technologies have enabled manufacturers to offer solutions that enhance the aerodynamic efficiency of turbine blades. These innovations not only reduce maintenance costs but also improve energy output, making wind power a more competitive source of electricity. Key industry players like BASF SE, The Sherwin-Williams Company, and 3M Company are investing heavily in research and development to create environmentally friendly and durable coatings that align with global sustainability goals.

From a futuristic perspective, the Global Wind Power Paint market will be one of the areas where collaboration between manufacturers and renewable energy developers will increase. Companies such as nippon Paint Holdings Co., Ltd., Axalta Coating Systems Ltd., and RPM International Inc. will be looking at expanding their market share using innovations in nanotechnology and eco-friendly materials. This is likely to yield more efficient production processes and easier-to-apply and maintain coatings.

In addition, governments and private entities around the world are investing in large-scale renewable energy projects that will drive demand for protective coatings. Players such as Wacker Chemie AG and Sika AG are well-positioned to capitalize on this demand by offering solutions that meet the unique requirements of wind farms. The market is going to experience steady growth because the technology and sustainability goals are going to converge, ensuring that wind power is a viable and robust energy source.

Wind Power Paint Market Key Segments:

By Type of Paint

- Anti-Corrosion Paints

- Abrasion-Resistant Paints

- UV-Resistant Coatings

- Heat-Resistant Paints

- Anti-Icing and De-Icing Coatings

- Self-Cleaning Coatings

- Biocidal and Anti-Fouling Coatings

By Material Type

- Epoxy Coatings

- Polyurethane Coatings

- Fluoropolymer Coatings

- Acrylic Coatings

- Zinc-Rich Coatings

- Ceramic Coatings

- Nanocoatings

By Component

- Blades

- Tower

- Nacelle

- Hub

- Other Components

By End-User

- Wind Farm Owners and Operators

- Wind Turbine Manufacturers

- Maintenance and Repair Service Providers

- Offshore Wind Power Plant Developers

Key Global Wind Power Paint Industry Players

- Hempel A/S

- AkzoNobel N.V.

- PPG Industries, Inc.

- Jotun Group

- BASF SE

- The Sherwin-Williams Company

- 3M Company

- Kansai Paint Co., Ltd.

- Teknos Group

- Nippon Paint Holdings Co., Ltd.

- Wacker Chemie AG

- Mankiewicz Gebr. & Co.

- H.B. Fuller Company

- RPM International Inc.

- Sika AG

- Axalta Coating Systems Ltd.

- Tikkurila Oyj

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252