MARKET OVERVIEW

The Global Wind Power Fastener market is an elite segment in the renewable energy industry focused on the provision of all crucial parts that ensure structural integrity and functionality of the wind turbine. These fasteners are not just supporting elements; they are a critical component to the functioning, safety, and life span of wind power installations. With the increasing emphasis on sustainable energy sources, the market is poised to see major developments as it caters to the demands of wind turbine manufacturers, operators, and maintenance services.

At its core, the Global Wind Power Fastener market is all about addressing the demand for highly durable and reliable fastening solutions. Wind turbines face environmental exposure that involves high wind, thermal fluctuations, and corrosive environment. Thus, bolts, nuts, washers, and other specialty fasteners used to assemble turbine towers, blades, nacelles, and other parts require resistance to stresses associated with each application. They should be as strong as possible yet flexible and wear-resistant, in order not to shut down the equipment for long periods and to provide efficient operation.

The scope of the Global Wind Power Fastener market spans across both onshore and offshore wind energy projects. Offshore wind farms, in particular, demand fasteners with enhanced corrosion resistance due to their exposure to saline environments. Meanwhile, onshore installations prioritize ease of assembly and long-term reliability, given the logistical challenges of accessing remote or rugged locations. The further the geographical deployment of wind power is set in regions with unusual climatic and geological conditions, the further the market shall diversify in an attempt to adapt to those location-specific needs.

Advancements in Wind Turbine Technology This market is highly inter-related with wind turbine technology improvements. With turbines becoming greater in size and power generation, fasteners must upgrade to keep up with increased loads and vibrations. The trend toward modular construction and hybrid materials in turbines will drive the development of innovative fastening systems, further shaping the landscape of the Global Wind Power Fastener market. The integration of smart technologies, such as sensors embedded in fasteners to monitor stress and corrosion, is expected to redefine how maintenance is approached, ensuring proactive interventions and reducing costs associated with unexpected failures.

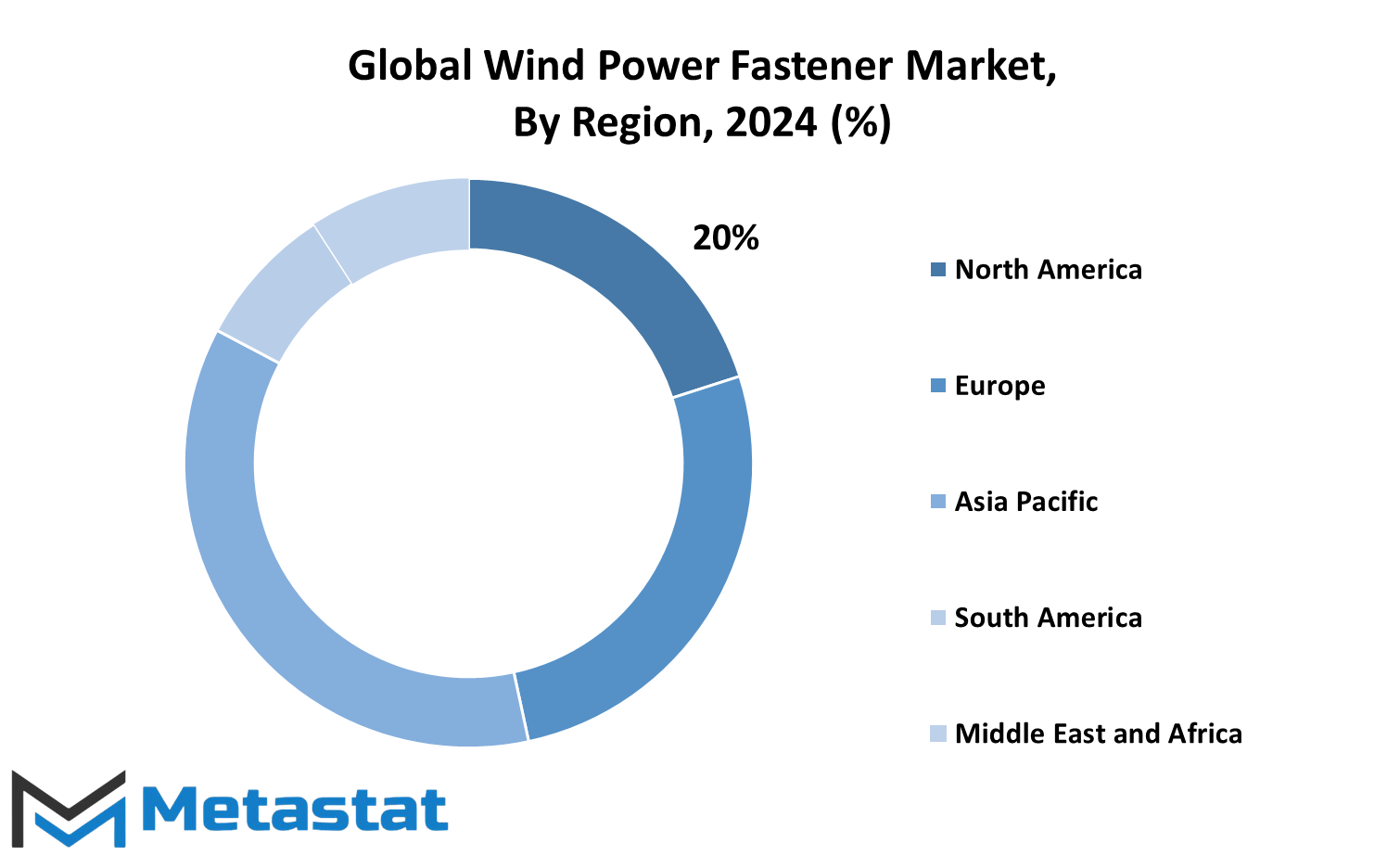

Regional dynamics also shape the Global Wind Power Fastener market. Asia Pacific, with China and India now dominating wind energy installations in the region, has emerged as one of the leading forces there, creating demand for specialized fasteners according to region-specific manufacturing standards and regional environmental conditions. Europe continues to be a leader and innovator in renewable energies, especially in offshore projects, which require advanced fastening solutions. The rising investments in wind energy across North America create a steady demand for high-quality fasteners, thereby making this market one of global nature.

As the world shifts to cleaner energy sources, the Global Wind Power Fastener market will not only support the expansion of wind power but also adapt to the changing needs of the industry. The continuous development of advanced materials, manufacturing processes, and monitoring technologies will position this market as a cornerstone of sustainable energy infrastructure.

Global Wind Power Fastener market is estimated to reach $2,717.4 Million by 2031; growing at a CAGR of 7.1% from 2024 to 2031.

GROWTH FACTORS

Technological innovations in the design and construction of wind turbines will continue to fuel the expansion of this market. It would seem that the increasing number of large, efficient turbines made precision engineering fasteners of importance than ever before. After all, fasteners do play an important role in supporting the structural integrity of the turbines, especially if these structures are designed and optimized to yield more energy efficiency as well. As wind turbines grow in size and capacity, the fasteners used in these structures must meet higher specifications, driving the demand for more advanced materials and engineering solutions.

Despite these positive growth factors, the market faces challenges that could slow its expansion. One of the highest barriers to entry is in the costs of manufacturing-fasteners meeting the quality and durability criteria set by the wind power industry. The expensive manufacturing process and use of specialized materials increase the expense of producing these fasteners, and this can present a difficulty for manufacturers to control their production costs. Moreover, the variability in raw material prices also increases the instability of cost in fasteners, thus potentially affecting the manufacturers who prefer to have a stable cost structure to ensure profitability.

Offshore wind projects have shown promise for the market, however. Offshore wind farms are being developed for wind energy harvesting in marine environments where the turbines are expected to face saltwater corrosion and extreme weather conditions. This creates an increased demand for corrosion-resistant and special fasteners designed to resist marine environments. The demand for specialized fasteners will increase because of the growth in offshore wind projects, which provides rich opportunities for manufacturers to experience significant growth.

MARKET SEGMENTATION

By Product Type

The global wind power industry is growing with a very healthy pace. It is very much supported by the high demand for renewable sources of energy. In terms of the fact that the whole world is moving towards clean sources of energy, it will contribute to lesser carbon footprints and make the process even more sustainable. In this light, the global wind power fastener market is observing decent growth. Fasteners are an integral part of wind turbines' construction, ensuring stability and durability. With growth in the industry, demand for quality fasteners to withstand harsh environmental conditions would also grow. The market of wind power fasteners may be categorized into several types of products, each type has a different function.

For instance, bolts are mainly used to fasten turbine parts together so as to provide the strength required for long-term performance. Nuts are also very common with bolts so as to provide tightness and prevent loosening in stress. Screws are another important product that is widely applied in fastening smaller turbine components. Washers play a vital role in the distribution of load from bolts and screws to provide even pressure and avoid damaging the surfaces, hence improving the overall lifespan of wind turbines. Studs are normally used for applications where there is a need to join two distinct parts together for a secure joint. Anchors are used in the foundation of wind turbines to anchor the structure to the ground for stability, especially in windy areas. Threaded rods, part of the product segment, are used to secure critical components like blades and nacelles to the tower of the turbine.

The diversity of fasteners in the market ensures that every part in the wind turbine is well held, and it can sustain the forces and weather conditions that emerge in operational environments. The development of the renewable energy market will continue to influence growth in the wind power fastener market from the future. As wind turbine technology advances, so will the need for greater strength and more resistant fasteners withstanding extreme weather conditions. Correspondingly, materials used in such fasteners must improve to better withstand wear and corrosion. Further demand for more efficiency and size in wind turbines will drive the fastening design into innovation, therefore developing new solutions that will be able to respond to the challenges of an expanding wind power industry. As the global clean energy demand continues to grow, it will certainly have an impact on the growing importance of reliable fasteners in the construction of wind turbines, thus ensuring stability and sustainability in the long term for this industry.

By Material Type

The Global Wind Power Fastener market is a crucial business that underpins the thriving renewable energy industry, most particularly the wind power source. The increasing trend in the global shift to more sustainable sources of energy increases the demand for quality and strong fasteners. These fasteners provide essentiality in the designing and the construction of wind turbines; these fasteners form a whole system, securing its structure. The materials used form an important part of their performance. In the future, the ongoing advancement of material technologies and rising demands for anticorrosion capabilities that arise because of harsh service environments are likely to determine the Global Wind Power Fastener market.

This market for wind power fasteners can be further categorized into materials like stainless steel, alloy steel, carbon steel, nickel alloy, and others corrosion-resistant alloys. Each of these materials possesses its own distinct properties making it suitable for specific applications in the wind energy industry. One of the most commonly used materials is stainless steel, which has a high strength, excellent resistance to corrosion, and extreme weather resistance. These make it very common in construction for wind turbines, particularly in areas with a lot of humidity and salty air.

Another type of material widely used is alloy steel, which presents both the strength of steel combined with the additional benefits resulting from alloying elements, particularly in chromium, nickel, and molybdenum. They can enhance the resistance of such a material to wear and corrosion as well as improve it at high temperatures, useful especially for critical components of the wind turbine. Fasteners will probably be in high demand from the alloy steel sector due to the growing industry's need for more durable and long-lasting parts.

Carbon steel fasteners, though less resistant to corrosion compared to stainless and alloy steels, are less expensive options where corrosion resistance is less of a priority. Some wind turbine parts will continue to be made of carbon steel because of their strength and low cost. Nickel alloy, with its superior resistance to high temperatures and corrosion, will continue to play an essential role in specialized applications where high performance is needed, especially in turbine engines and systems exposed to extreme conditions.

These, apart from the materials above, are other corrosion-resistant alloys that will find their footing with the industry's urge to innovate. As the industry advances wind power, the demand for such materials in the wind turbine system increases as it is exposed to high conditions. This would thus push the market of fasteners in wind power towards a more diverse array of materials, making the system in wind energy more robust and efficient in the near future.

By Application

Considering the rising demand for renewable energy sources, the Global Wind Power Fastener market will grow well in the next few years. It is an extremely responsible market with regard to the operational efficiency and stability of wind turbines. These have different applications which are must-to-advance and maintain wind power systems. With an increasing demand for sustainable energy solutions, there is a chance to witness stronger, durable, and efficient fasteners in wind power systems, with the prospect of business and manufacturer growth in this area. Onshore wind turbines form one of the primary applications of the Global Wind Power Fastener market.

Land-based turbines have the need for fasteners mainly for secure mounting of the different sub components-rotor blades, nacelle, and even tower-in place. Fasteners should be resistant to adverse environmental conditions and vibrations for inshore based turbines for long time reliability of the turbines. It has been clearly stated that demand for fasteners onshore will continue increasing with the upsurge demand onshore wind power. Other significant market segment provided by wind turbines is for the offshore structures. These set-ups of wind turbines lie in oceans or seas and therefore face other troubles due to salt water and strong ocean winds.

To be used for offshore purposes, these wind turbines need rust-free fasteners so that the performance can not get disturbed. The increase in offshore wind farms is also expected to demand specialized fasteners with better resistance and reliability. Turbine towers are another critical component of the wind turbine structure, and fasteners play a vital role in the fixation of such towers to the ground. Fasteners need to withstand heavy loads and extreme environmental conditions. As the number of wind farms increases, the demand for fasteners in the construction of turbine towers will also increase, and therefore, the market will boom. Other critical components that rely on high-quality fasteners include nacelle, rotor blades, and foundations. Nacelles refer to the generator and other mechanical parts housings of a turbine, and rotor blades are critical for the capture of wind energy. Fasteners in these areas must be designed to withstand forces and stresses created by wind power systems.

Foundations also have to give a firm foundation to turbines, and fasteners have to ensure that the turbine structure is firmly attached to the ground. The wind power technology will continue to increase with increasing demands of fasteners in such applications. In the future, the Global Wind Power Fastener market will be very important in the development and expansion of wind energy. Hence, each application will require their fasteners in line with the growing requirement of the industry. This, over the coming years, is going to grow exceptionally good as the demand for energy through renewable sources is witnessing an increase. This sector highly contributes to the efficiency of operation and stability of a wind turbine, and as such, the applications can never be done without.

More robust, durable, and efficient fasteners in wind power systems due to rising demand for sustainable energy solutions are expected to see growth in business and manufacturer growth in this space. The onshore wind turbines have been the leading application in the Global Wind Power Fastener market. Fasteners in land-based turbines are mainly used in secure mounting of the various sub-components: rotor blades, nacelle, and even tower-in place. Onshore-based turbines fasteners have to be resilient towards adverse environmental conditions as well as vibrations for a long period of reliability in the turbines. It is well evident that demands for fasteners onshore will keep rising with an increased demand in onshore wind power. Yet another significant market segment being provided by wind turbines is to offshore structures.

These wind turbine set-ups are in oceans or seas and thus face other challenges due to salt water and strong ocean winds. For offshore applications, these wind turbines need rust-resistant fasteners so that its performance could not be affected. The demand for specialized fasteners is expected to be driven by the expansion of offshore wind farms, which will require higher standards of resistance and reliability. Another important part of the wind turbine structure is turbine towers, and fasteners are necessary in the mounting of such towers to the ground. Fasteners have to withstand high loads and severe environmental conditions. With the wind farms on the rise, the demand for fasteners in the construction of a turbine tower will also increase and therefore the market will also flourish. Some of the other critical components include nacelle, rotor blades, and foundations, which depend on the use of high-quality fasteners.

Nacelles are essentially the housings of the turbine's generator and other mechanical parts. The rotor blades are critical in the process of capturing wind energy. Fasteners in these areas must be designed to withstand forces and stresses generated by power systems from wind power. Foundations should also offer a stable base for turbines and fasteners ensure that there is a good attachment of the turbine structure to the ground. The wind power technology is going to rise with further demands of fasteners in such applications. In the near future, this market for fasteners in the global wind power industry will provide the core for growth in and the expansion of wind power. Correspondingly, each and every application will require fasteners to service an increasing demand by this industry

By End User

The Global Wind Power Fastener market is growing very considerably and has a bright future ahead with more and more of the world committing to renewable energy. This market is very significant to the wind energy industry, as they provide them with essential components for assembling and maintaining wind turbines. The fasteners are highly dependent upon so that the turbines remain dependable and long-lasting as they encounter harsh weather conditions. With the improvement in wind turbine technology and an increased requirement for energy sources that leave low environmental impact, the market is going to change. Wind turbine manufacturers are one of the key segments of the Global Wind Power Fastener market.

These companies play an important role in manufacturing and delivering fasteners designed to withstand mechanical stress and environmental conditions under which wind turbines are exposed. As the manufacturers of wind turbines seek to maximize the efficiency and lifespan of the turbines, the demand for quality fasteners will continue growing. With advancements in technology, turbines are getting bigger and more powerful. So the demand for stronger and longer-lasting fasteners will increase with time. Wind farm operators and developers form the other big chunk of this market. They are responsible for the installation, management, and operation of the wind farms.

Such wind farms require huge numbers of turbines to generate high volumes of energy. Fasteners used in constructing and installing these turbines need to meet strict standards to ensure that the entire wind farm is stable and safe. As the world transitions towards renewable energy, the dependency of wind farms on quality fasteners to remain operationally efficient and cut down maintenance will continue to rise. The other major portion of the market includes maintenance and repair services. As with all other equipment, wind turbines tend to wear out with time and are thus required to be maintained for their smooth performance. A huge contribution in the repair process involves fasteners because they would substitute or hold damaged parts of a wind turbine in position for operation.

The world wind fleet has also experienced increases continuously, therefore pushing forward more demand in terms of repair services, which means a consequent demand for fasteners keeping their turbines running efficiently. The Global Wind Power Fastener market will be on the rise in the coming years as the demand for wind energy increases. Wind turbine manufacturers, operators of a wind farm, and maintenance services will promote this growth. The Global Wind Power Fastener market will, therefore, increase the demand for more and more sophisticated and reliable fasteners. With growing concern for green energy, it will play an important role in the overall transition of the world toward more cleaner energy solutions.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,914.8 million |

|

Market Size by 2031 |

$2,717.4 Million |

|

Growth Rate from 2024 to 2031 |

7.1% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The Global Wind Power Fastener market is growing fast in the world as the planet continues to shift toward renewable sources of energy. Growth here is fueled by an increasingly high demand for renewable energy sources, with wind power constituting a significant portion of this global energy transition. Growth in the fastener markets in the wind power sector are no exception and have been remarkable, cutting across all regions of the world. A closer look at regional markets reveals distinct trends and opportunities for the future.

North America continues to grow its way in the wind power fastener market. The U.S. is one of the leading countries in developing renewable energy infrastructure, including wind farms. Continued investments in clean energy will drive the demand for durable and efficient fasteners used in wind turbine installations. Canada and Mexico are also included in this regional market as both countries concentrate on building their renewable energy sectors. As North America is a leader in the development of wind power, demand for high-performance fasteners will continue to be there.

The other key region for the Global Wind Power Fastener market is Europe. In this region, countries such as the UK, Germany, France, and Italy have taken significant roles in adopting renewable energy. Europe has been a leading country in wind power technology and innovation for a long time. The region is focused on achieving net-zero emissions by 2050, thus ensuring that wind power is a core component of its energy strategy. As such, fasteners that can survive the hostile conditions of both offshore and onshore wind turbines will be in high demand.

In the Asia-Pacific region, China, India, Japan, and South Korea are ramping up their wind energy capacities at a very rapid pace. The largest producer of wind turbines, China, will continue to demand high-quality fasteners. Growing wind energy projects in India and technological advancements in Japan will also drive the growth of the market. This vast population and growing energy demands will create significant demand for wind power fasteners in the Asia-Pacific region in the coming years.

South America is currently a minnow in the global marketplace for wind energy, but offers a great potential for development. Brazil and Argentina currently lead the pack in wind power development, but more South American countries are expected to invest in the sector. Growing the wind power industry within South America will require a continuous supply of reliable fasteners, putting local manufacturers in a position to meet upcoming demand.

Lastly, the Middle East and Africa region, though often considered low-hanging fruit, will also grow in the wind power sector. The countries in the GCC and South Africa are exploring renewable energy alternatives, and so, demand for wind power fasteners will increase. This region's commitment to sustainable energy solutions will drive new opportunities for fastener manufacturers.

As the world focuses more on cleaner energy alternatives, regional markets for wind power fasteners will adjust to these changing realities. Each region will help guarantee the ongoing success and growth of the wind power industry.

COMPETITIVE PLAYERS

The Global Wind Power Fastener market is experiencing an exciting phase of growth and transformation. This industry is crucial to the continued development of wind energy projects, providing the necessary components that ensure the stability and performance of wind turbines. Key players in this industry are becoming increasingly important as they drive innovation, improve efficiency, and create solutions to meet the growing demand for renewable energy. August Friedberg GmbH, Dokka Fasteners, Dyson Corp., and Graewe GmbH & Co. KG are among the companies already positioning themselves as market leaders through their focus on producing high-quality, long-lasting fasteners optimized for use in wind farms' specific demanding conditions.

As more companies attempt to join the fray, the race to the market becomes fiercer as every participant strives to push new innovations into the market to stay relevant to the industry's evolving needs. For example, ITH Bolting Technology and James Walker Deutschland are known for their experience in manufacturing and supplying fastening solutions that help improve the performance of wind turbines. The companies focus on developing fasteners that can withstand harsh weather conditions, long operational lifespans, and the mechanical stresses experienced by wind turbine components. In addition to these traditional fastener manufacturers, there are other players diversifying their offerings to enable the growth of wind energy around the world.

Peikko Group Corporation is a famous contributor to sustainable construction and infrastructure with its fasteners securing foundation and structure for the winds turbines. Oglaend System AS and RS Randack Spezialschrauben GmbH, meanwhile, provide complete fastening solutions specifically for both onshore and offshore wind turbine installations. Their products ensure secure fastening of turbines so that these can be utilized in varying environmental conditions with efficiency. Companies like Stanley Black & Decker and Howmet Aerospace Inc. would be growing their presence in the wind power fastener market going forward.

These well-known companies bring to bear extensive experience in manufacturing precision parts, and their participation within the wind energy market would most probably spur innovation about fastening technology. Moving forward, an increasing interest of offshore wind farms and greater attention to faster and efficient installation processes could make the players critical stakeholders in setting the future scene for wind power infrastructure. As the market grows, the competitive landscape will shift. The firms that balance product innovation with cost effectiveness and sustainability will stand the best chance of succeeding. Fasteners will be a crucial element of wind turbine technology; therefore, the players in this market must change to suit the requirements of an energy industry in flux.

Wind Power Fastener Market Key Segments:

By Product Type

- Bolts

- Nuts

- Screws

- Washers

- Studs

- Anchors

- Threaded Rods

By Material Type

- Stainless Steel

- Alloy Steel

- Carbon Steel

- Nickel Alloy

- Other Corrosion-Resistant Alloys

By Application

- Onshore Wind Turbines

- Offshore Wind Turbines

- Turbine Towers

- Nacelle

- Rotor Blades

- Foundations

By End User

- Wind Turbine Manufacturers

- Wind Farm Operators and Developers

- Maintenance and Repair Services

Key Global Wind Power Fastener Industry Players

- August Friedberg GmbH

- Dokka Fasteners

- Dyson Corp.

- Finework (Hu Nan) New Energy Technology Co., Ltd.

- Graewe GmbH & Co. KG

- ITH Bolting Technology

- James Walker Deutschland

- Nord-Lock GmbH

- Oglaend System AS

- Peikko Group Corporation

- RS Randack Spezialschrauben GmbH

- Schraubenwerk Zerbst GmbH

- Stanley Black & Decker, Inc

- Howmet Aerospace Inc.

- The Cooper & Turner Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252