MARKET OVERVIEW

The Global Wholesale Adhesives market is a key industry area within industrial manufacturing, providing bonding solutions across various industries. Adhesives are the backbone of automotive assembly, construction, packaging, electronics, and medical applications for longevity and sustainability. These products are supplied in bulk to businesses involved in large-scale production and are thus cost and time-efficient for the wholesale market.

Beyond the traditional supply-demand cycles, the market involves numerous complicated logistics, laws, and recent technological innovations that are being introduced as the new operational landscape. Distributors and manufacturers must confront hurdles that transcend simple buying and selling as they keep getting influenced by changing industry standards and ever-changing expectations of consumers.

Environmental concerns are modifying the picture for product development, with suppliers confronted with the necessity to research alternative formulations compatible with sustainability objectives. When environmental parameters like a carbon footprint become a major concern, there will be a stern outlook on adhesive development strategies through modifying the chemical formulations affecting the raw material procurement and production systems.

In a way that uses global economic agreements and international relations to steer the course of the market, finite supply potential must also weigh in as glue ingredients are raw materials predominantly imported from foreign sources. Thus tariffs, export bans, and geopolitical upheavals affect the sourcing of raw materials and in turn affect production costs and pricing strategies.

In essence, wholesale distributors will need to somehow start preparing for the anticipated changes and develop contingency plans to mitigate these disruptions. Supply chain resiliency will have now come into play, and it will be a point of focus for firms in sourcing diversifying and applying predictive analytics to manage inventory.

Innovation in adhesive formulations will be shaped by developments in technological obsolescence. Increased application potential will be given to smart adhesives that are predisposed to respond to changes in environmental conditions like temperature and pressure in high-tech areas. A further shift away from synthetic compounds will be stimulated by the introduction of bio-based adhesives. This shift will not only impact product performance sets but also trigger and change safety and compliant assessments, requiring the re-evaluation of existing formulations by manufacturers.

Consumer demand for advanced packaging will further influence adhesive requirements. Growing demand for flexible packaging due to e-commerce and sustainability will call for specialized adhesives to improve product integrity and meet recycling requirements. Packaging adhesives will continue to evolve, calibrated along the strength-biodegradability axis to satisfy industrial needs and environmental ambitions.

Competition in the Global Wholesale Adhesives market will move beyond price negotiations, as businesses will increasingly focus on service quality, customized solutions, and supply chain reliability. The role of distributors will adapt to include the use of digital platforms for the procurement process and customer engagement.

Real-time order tracking, automated order processing, and data-driven analytics of consumer behavior will become the new paradigm for operational efficiency, thus awarding businesses the opportunity for wise purchase decisions. The earlier the players adopt advanced digital integration, the better storefronts they will build against the ever-increasing competitive pressure.

The regulatory environment is set to shape market dynamics by increasingly stringent regulations pertaining to adhesive construction, emissions, and disposal methods. Companies will continuously adapt to comply with international standards, thus affecting product development cycles as well as operational costs. Noncompliance with the ever-evolving regulatory regime will further restrict any company's market access, reinforcing the importance of forward-thinking compliance approaches.

With adaptability as the key to success in this industry, the Global Wholesale Adhesive market stakeholders will be the first to embrace technological change, sustainable solutions, and strategic alliances along with these ingredients into environmental responsibility, innovation, and regulatory compliance. This completeness in itself will continue to shape what the market has in stock.

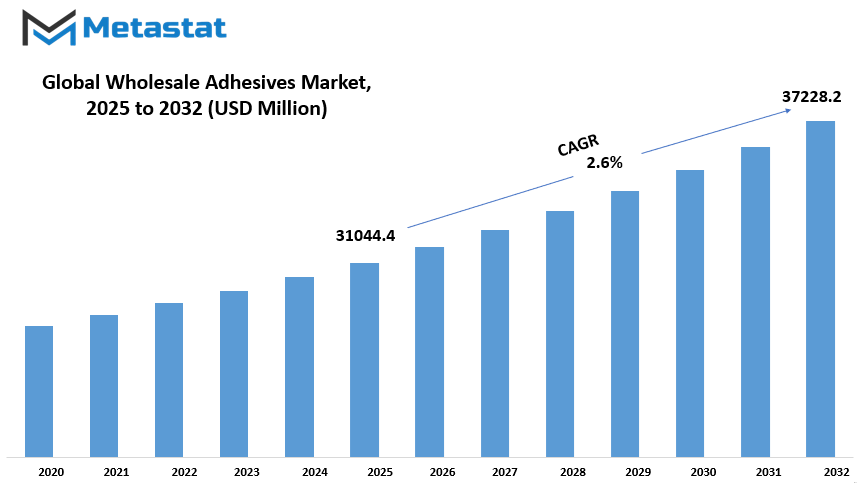

Global Wholesale Adhesives market is estimated to reach $37228.2 Million by 2032; growing at a CAGR of 2.6% from 2025 to 2032.

GROWTH FACTORS

Currently, developments in the global wholesale adhesives market are salient. Mention-worthy among the factors driving demand in several industries is the new breed of sustainable and eco-friendly adhesives. This is how industries are entering the arena of reducing their impacts on the environment; manufacturers are thinking of adhesives with a minimum effect on nature.

This trend is especially important for packaging, in which businesses are seeking biodegradable or recyclable solutions to appease consumer demand and regulatory stipulations. Growth in the automotive sector creates demand for adhesives for assembling vehicles, lightweight materials, and structural bonding, in which adhesives are considered to reduce the overall weight of vehicles. Manufacturers, in turn, prioritize meeting emission standards; hence adhesives render a special role in fuel efficiency.

On the other hand, some constraints hinder the growth of this market. Price fluctuations of raw materials remain one of the major concerns. Prices of the major constituents used in the production of adhesives vary widely due to supply chain disruptions on account of geopolitical factors and changes in the demand pattern. They change according to the production cost criteria, making it difficult to keep the prices steady by producers. Another challenge is the environmental regulations governing formulations of adhesives.

These stringent norms and regulations imposed by the governments and regulatory bodies made some chemicals used in adhesives failed for manufacture of adhesives. This may be highly health and environment-friendly but may result in extra burdens for industries due to investment in research and development for compliance with ever changing standards.

Yet, the market provides great opportunities for increased growth. It is actually one of the most popular trends at present- getting more and more into bio-based adhesives. Construction, medical and even furniture industries are adopting bio-adhesives from plant tissues and renewable natural sources. This potentially creates a viable substitute for historic petroleum-based products that can satisfy sustainability goals. Another promising area is technological advancement.

Various advanced companies are providing such extended adhesive solutions that offer improved bonding strength, durability, and resistance to extreme conditions. Adhese technology innovations enable the industries to use new applications and enhance product performance, resulting in heightened market demand.

MARKET SEGMENTATION

By Type

That really says a lot about how adhesives are being accepted in a variety of pilot and user. A broad range of adhesives serve a great deal to improve the durability and performance of other products, manufactured through the construction, packaging, and automotive industries. With advanced technology development, adhesive manufacturers are now concentrating on the new trends of consumer demand and the need for new industry work by developing those adhesives that would be sustainable and exportable.

Rapid increase in demand for adhesive-related markets greatly focused on them being eco-friendly. This has driven many to develop even more water-based adhesives, which many industries are shifting to for their less harmful environment effects when compared to solvent-based adhesives. Water-based adhesives own a huge chunk of the market, worth $11060.1 million, and are still very popular with low volumes of volatile organic compound (VOC) emissions.

Solvent-based adhesives are still waiting for applications that require high-resistance moisture and temperature fluctuations. Hot melt adhesives are also very advantageous in terms of speed, primarily in packaging and assembly processes, because it offers quick bonding and short drying time. Moreover, the reactive adhesives give much excellent chemical resistance and durability, thereby becoming the best candidates for demanding applications in construction and automotive.

On top of this, the growing urbanization and industrialization in developing countries is also facilitating an increase in the consumption of adhesives. The construction segment, specifically, makes use of the advantages introduced by use of adhesives in floor, insulation, and panel bonding applications allowing efficiency and life enhancing for structures.

For example, an automobile manufacturer uses adhesives to save weight without sacrificing strength and safety, leading to fuel efficiency and sustainability initiatives. In much the same way, the packaging industry has benefited from new adhesive formulations that provide safe and tamper-proof sealants, making it very critical for food safety and product safeguarding.

Future market shaping will mainly be through innovation in adhesive technologies under which companies will invest in research and development and innovation to develop high-performance products. Hybrid adhesives are much better in their effectiveness and have started acquiring much attention for their durability and adaptiveness owing to the combination of various into a hybrid adhesive that combines their best properties. Additionally, the stricter rules that are being enforced by regulatory authorities on the adhesives formulated will push the companies to produce low emission, non-toxic alternatives to comply with environmental demands.

As industries are expanding and turning more into efficiency, the global wholesale adhesives market can expect a steady increase in the future. Hence, investing in green, high-performance adhesive solutions will lead to a competitive advantage on the part of companies over others in meeting the heightened demands of the numerous applications.

Indeed, the global wholesale adhesives market is molded under the interaction of growing demand with industry expansion, regulatory challenges, and technological progress. Although doubts about fluctuating raw material costs, as well as strict environmental restrictions, tend to slow down the pace, the increased use of sustainable adhesives with advancements in formulation technique create a brighter perspective for growth in the future.

By Material

Adhesives are in widespread use today with expanding sales of efficient bonding in various applications around the world, making it possible for the development of the construction, automotive, packaging, and electronics industries where very strong and reliable bonding is a must. High-performance adhesive demand has increasingly arisen because manufacturers are stressing the requirement for improved durability and performance. These are the solutions that companies seek: those that grant strength and flexibility, resist various environmental factors, and are cost-effective.

Classes of Adhesives include Acrylics, Epoxy and Polyurethane Adhesives. Among these, acrylics are the fastest curing and among-the-strongest, which makes them very well suited for applications that require quick assembling and durability. The other one, well-known, epoxy adhesives are also very strong, in addition to being chemically resistant and thermic varied resistant, and therefore primarily in use. In industries seeking tough, strong, long-lasting bonds, polyurethane adhesives impart flexibility along with impact resistance and thus find application in any necessary strong uses incorporating elastic properties.

There is also growing interest in ecology and sustainability in adhesives spread to many industries. The high majority of companies invest a huge amount of money on research and development to come up with formulations for adhesives that have less and less of volatile organic compounds and more environmentally benign compositions to use. This movement is chiefly on account of regulatory framework and growing consumer mindfulness on sustainability. The adhesive manufacturers are also enhancing their formulations to offer better bonding performance with lesser environmental side effects.

Technological advancements are laying their own influence on the market as well. Adhesive formulation innovations have improved bonding efficiency and versatility in application. Development of hybrid adhesives is increasingly bringing together the best of various materials to make bonding much stronger and durable. Automation in production processes provided an impetus for the increased use of adhesives, enabling quicker and more accurate assembly.

The adhesive demand across regions varies, with most growth coming from industrial expansion and infrastructure development. Consumption in emerging economies is on the rise due to urbanization and industrialization. The developed world will still see application for very high-performance adhesives, especially in automotive and aerospace applications.

Despite these very encouraging positive growth parameters, the adhesives and sealants market is faced with challenges of varying prices for raw materials and stringent environmental regulations. Some companies have shifted towards sustainable sourcing and bio-based adhesives as options to counter these challenges. Competition among major players remains high, with the business being reliant on innovation and partnerships for competitive upper hand.

The global wholesale adhesives market is changing to accommodate evolving industrial needs. With the advancement of technology and the growing importance assigned to sustainability, we will be witnessing adhesive manufacturers striving and customarily delivering answers for better performance, efficiency, and environmental benefit.

By Technology

The adhesive wholesale market worldwide is slowly progressing due to industrial bonding methods adopted for many applications. Most adhesives are used in manufacturing, packaging, construction, and automotive, with highly efficient alternatives for traditional locking methods such as screws or welding. Demand for new types of adhesives is premised on technology, environmental concerns, and cheaper production methods.

Technological segmentation is categorized into Pressure-sensitive Adhesives (PSA), Structural Adhesives, and Non-structural Adhesives. Unlike other types, pressure-sensitive adhesives are applied to a large number of tapes, labels, and medical applications because they stick upon the application of very slight pressure. Their prime assets of formability and ease of use come into play when used primarily in packaging and consumer goods.

Structural Adhesives are mainly used for high-strength applications that generally replace mechanical fasteners in even aerospace, automotive, and construction. They provide durability while reducing weight, improving fuel efficiency and overall performance. Non-structural adhesives are not for where strong bonding is not critical but still a must, such as in furniture assembly, bookbinding, and the textile industry.

Sustained consideration for the environment has led to the development of many eco-friendly options. The push for greener practices has led to a rise in the popularity of water-based and bio-based adhesives as industries aim to reduce carbon footprints and conform to environmental regulations.Research is being carried out by various firms to develop adhesives that offer secure bonding while proving safe for users and the environment.

With an increase in automation and advancement of technology, the adhesive market replenished even further. Industries are looking for fast-curing adhesives that can withstand varying environmental conditions and ensure efficiency in production lines. Smart adhesives and advancements in nanotechnology are expected within the market to introduce creative solutions increasing performance and durability.

Fluctuating raw material prices and stringent regulations continue to present challenges, which ultimately affect production costs and product formulations. Manufacturers, however, are moving toward alternative raw materials and refining formulations to ensure compliance with industry standards.

Most industries are calling for the growth of demand tend to drive the wholesale adhesive market, engineering-related advancements and sustainability will be its main driving force. Demands are being engendered with increased application of adhesives to lightweight materials and energy-efficient products. Thus, adhesive facilities will keep on engulfing an important link in the chain of modern technological and industrial production, having rapidly grown and continued implying higher levels of performance and concern toward environmental embeds.

By End-Users

The global wholesale adhesives market will be determined by specific industries needing bonding solutions for their products and applications. Actually, these adhesives are in practice to bring durable, efficient, and performance-based applications over multiple ends. Due to industrialization and many advancements in manufacturing, there increases the demand for good quality high-performing variety of adhesives which can influence very much how the market trends and processes take place in manufacturing.

The automotive and transport sectors generally have appropriate adhesives for bonding, increasing the structural stiffness of the overall structure yet reducing weight at the same time. Different materials including metal and glass and plastics enhance fuel efficiency and safety. These trends have prompted further development in adhesives because with the electric vehicle paradigm shift, heavy consideration is laid on heat and electric conduction.

The construction and building sector make good use of adhesives in flooring, insulation, roofing, and all panel applications. These agents offer bond strength and resist spurious environmental conditions such as moisture, heat, and chemicals. Therefore, in order to be compatible with evolving processes, the construction world requires innovations in sustainable and energy-efficient adhesives, which means there will be continued high demand for these products, subsequently influencing innovations and development.

Adhesives find extensive application in packaging for sealing and lamination. This Industry includes food and beverage, pharmaceuticals, and e-commerce, all of which require reliable adhesive solutions for tamper-proof packaging. Biodegradable and sustainable adhesives are now gaining foothold in discussions as firms aim toward reducing the environmental footprint without compromising product quality.

Consumer products use adhesives for household items, appliances, and electronics. It secures products from assembling gadgets to securing decorative elements for flexibility and durability. Manufacturers are striving to meet the demands of evolving consumers with ever-stronger and adaptable adhesives as technology moves forward.

In healthcare, adhesives are a common necessity for medical devices, wound-care, and surgical applications. Such adhesives are expected to be safe for human use so that they can be melded with several therapeutic interventions with the aid of comfort and effectiveness. Therefore, an ever-increasing demand is exerted for skin-friendly, hypoallergenic, and long-lasting adhesives; thus, paving the way for solutions in healthcare.

Other domains, such as aerospace, textiles, and renewable energy, also contribute to the growing wholesale adhesives market. As industries innovate and perfect their manufacturing processes, demand for specialized adhesives continues to largely augment.

This continuous growth of aforementioned applications only shows the relevance of adhesive solutions in modern manufacturing and industrial applications. The emergence of new materials and technologies to provide more efficient and sustainable solutions on a worldwide scale indicates that the market will continue to grow.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$31044.4 million |

|

Market Size by 2032 |

$37228.2 Million |

|

Growth Rate from 2024 to 2031 |

2.6% |

|

Base Year |

2024 |

|

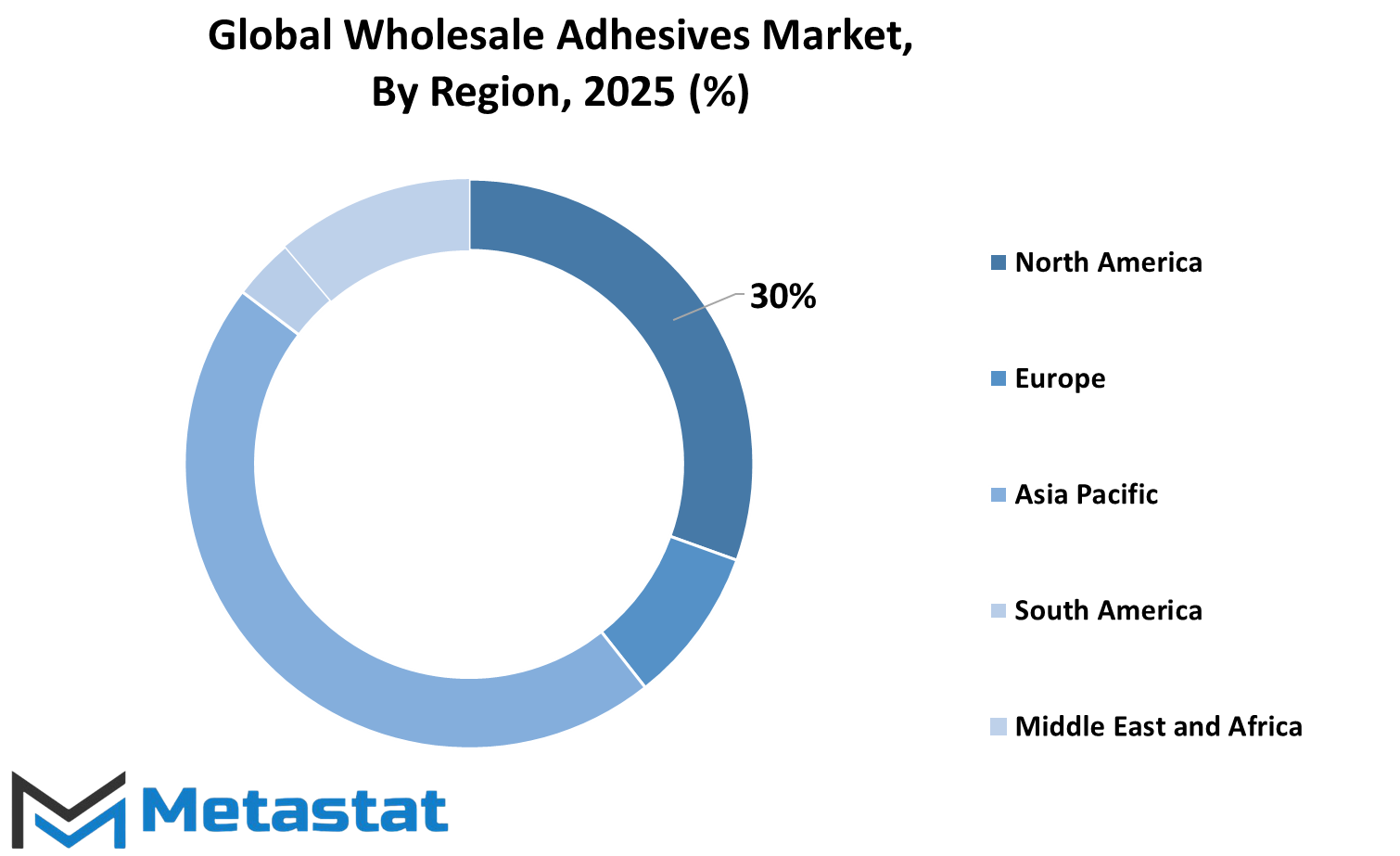

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The geography of the world wholesale adhesives market has importance in many regions that contribute to its growth and development. For the market, geography divides it into North America, Europe, Asia-Pacific, South America, and Middle East Africa. These serve as regions due to respective demands, industrial applications, and advancement in adhesive technology.

North America is the second prominent among all regions in the global market with three major constituent parts; the U.S., Canada, and Mexico. Among them, the U.S. contributes largely to the market growth due to the presence of well-established industries using adhesives in manufacturing, construction, and packaging. Further, adhesive demand has boosted in Canada via automotive and civil engineering projects, and Mexico has experienced rapidly growing infrastructure and automotive needs.

Europe has a vital share of the market and includes the UK, Germany, France, Italy, and others. Germany distinguishes itself due to its highly-developed industrial base with a focus on automotive and construction industries. The UK and France also contribute through their growing manufacturing sectors. Italy, together with other European nations, is still growing because of innovations in adhesive formulations used in many applications.

Asia-Pacific is among the fastest-growing segments, this region consists of India, China, Japan, South Korea, and the rest of Asia-Pacifica. China dominates the market, given its strong manufacturing base, with gluing requirements in electronics, automotive, and packaging. Other countries in the Asia-Pacific benefiting include India with rapid industrialization and infrastructure expansion. Japan and South Korea are shining meant to support demanding applications such as automotive and electronics.

The South American continent, represented by Brazil, Argentina, and the rest of the continent, also shows growth in the adhesives market. Brazil is a pivotal country in the region where demand rose for adhesives in construction and automotive industries. Argentina and other South American countries are contributing with an increasing application in consumer goods and automobile industry.

The region of the Middle East & Africa is classified into GCC Countries, Egypt, South Africa, and the rest of the Middle East & Africa. In the Gulf Cooperation Council Countries, demand is increasing due to ongoing infrastructure projects and industrial expansion. Egypt and South Africa became prominent in the market with increases in construction and packaging sectors consuming adhesives.

The global wholesale adhesives market is shaped by various regions, each with unique influences. Demand on market trends does come from several industrial advancements and the demand from different sectors in that region concerning various improvements of technological changes of adhesive properties and applications. On account of that, the demand shall be always expected to remain strong for high-quality adhesives around the world as industries keep expanding.

COMPETITIVE PLAYERS

The global wholesale adhesives market is vital to packaging, construction, automotive, and consumer goods industries. Adhesives help in bonding of materials along with durability and performance enhancement. With heightened technological advancements and growing demands across different sectors, the adhesives industry continues to thrive and adapt to ever-changing demands.

One of the strong contributors has been an increased demand among developers and manufacturers for dependable bonding solutions for the production and assembly processes. Industries are on a constant search for adhesive solutions that will provide a balance between strength, flexibility, and environmental resistivity. With the many innovative developments in adhesive formulation, greener and sustainable products came to life that reduced environmental impacts while achieving an impressive performance. As sustainability becomes a core focus for industries, manufacturers are investing heavily in bio-based and recyclable adhesive solutions.

The increase in packaging requirements has been driven by e-commerce and consumer goods, spurring an increase in adhesive requirements. Secured and efficient packaging helps protect products from damage in transit and thereby involves adhesives such as sealing of cartons, labels, and flexible packaging materials. The construction industry also utilizes adhesives in flooring, paneling, and insulation applications. In this case, adhesive solutions that improve insulation and reduce material waste have gained popularity with energy-efficient buildings.

Adhesives are also one way to make the vehicles lighter, improve their performance, and enhance their fuel efficiency. Most adhesives used in modern vehicles work in the context of advanced adhesive technology, which replaces traditional mechanical fasteners and aids lighter and more streamlined design. Another large market for adhesives is in the electronics, bonding and securing the components in high-performance devices.

Several major companies lead in the global wholesale adhesives market. Henkel AG and Co. KGaA, 3M Company, H.B. Fuller Company, Arkema Group, Sika AG, Dow Inc., Ashland Global Holdings Inc., Huntsman Corporation, Avery Dennison Corporation, BASF SE, Permabond LLC, Wacker Chemie AG, ITW Performance Polymers, The Gorilla Glue Company, Krazy Glue, Elmers (Newell Office Brands), Eclectic Products, LLC, Beacon Adhesives, Inc., Plaid Enterprises, Inc., and Aleene's Premium Glue are major companies in this global wholesale adhesive market. They are constantly developing new products to meet the ever-evolving demands of diverse industries.

The growing industries and changing consumer preference will always ensure a demand for high-quality adhesives. In this competitive arena, companies that emphasize research and development, sustainability, and innovative manufacturing will steadily position themselves for success. The global wholesale adhesives market is set to witness continued growth as industries would want dependable and groundbreaking bonding solutions for their products and processes.

Wholesale Adhesives Market Key Segments:

By Type

- Water-based Adhesives

- Solvent-based Adhesives

- Hot Melt Adhesives

- Reactive Adhesives

By Material

- Acrylic

- Epoxy

- Polyurethane

By Technology

- Pressure-sensitive Adhesives (PSAs)

- Structural Adhesives

- Non-structural Adhesives

By End-Users

- Automotive & Transportation

- Building & Construction

- Packaging

- Consumer Goods

- Healthcare

- Others

Key Global Wholesale Adhesives Industry Players

- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- Arkema Group

- Sika AG

- Dow Inc.

- Ashland Global Holdings Inc.

- Huntsman Corporation

- Avery Dennison Corporation

- BASF SE

- Permabond LLC

- Wacker Chemie AG

- ITW Performance Polymers

- The Gorilla Glue Company

- Krazy Glue

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252