MARKET OVERVIEW

The global screen printing market has been a crucial segment of the printing industry for years, catering to a broad spectrum of applications in textiles, electronics, advertising, and packaging. With the passage beyond conventional horizons, this industry will evolve from being a manufacturing aid to a vibrant solution integrated into fresh technologies and upcoming industries. This change will not only be the process of adjusting current techniques but will be the process of reestablishing the way screen printing converges with the digital era and green production level.

The global screen printing market in the future will not only serve mass production needs but will welcome niche orders with demands for precision, ruggedness, and creative versatility. One of the greatest changes will be in functional printing specifically, in printed electronics and intelligent packaging. With smart labels, flexible circuits, and wearable sensors being on the rise, screen printing will play a key role because it can deposit thick, uniform coatings of functional materials. This oft-overlooked ability will become progressively more crucial to manufacturing dependable and durable electronic components in volume.

In addition, the global screen printing market will be driven by increasing demand from industries such as biotechnology, automotive, and aerospace, where technical printing is a must. Screen printing will be used not merely for branding or looks but for performance like creating conductive traces or using protective coatings on surfaces under harsh conditions. This function-based printing will gain more applicability and create a new standard for what can be done through the process.

Environmental accountability will have an increasingly powerful role to play in transforming this industry. As international pressure grows on industries to lower their environmental footprint, the Global Screen Printing industry will see a greater adoption of water-based inks, reusable substrates, and waste-reduction technologies. It will not only be about meeting regulations but about creating a cleaner, circular system that is viable over the long term. Print services companies and brands will probably be looking for screen printing solutions that fit with their greater sustainability goals.

The shift of the global screen printing market will also be driven by hybrid manufacturing processes. With the blending of digital print with screen methods, manufacturers will create hybrid platforms that are the best of both speed and customization along with material resilience. Hybrid models will form the backbone of operations seeking to scale at a nimble pace while addressing varied customer demands.

At the consumer level, personalization will be more than just a trend; it will be a necessity. In apparel, interior design, and specialty items, companies will demand short-run and highly customized imagery that screen printing can provide with enhanced ink vibrancy and tactile appeal. The process will become more of a creative tool for designers to get away from pixel-based limitations and provide something more substantial and permanent.

As it advances, the global screen printing market will not be anchored to its heritage uses. It will burst into new domains, driven by technology, sustainability, and cross-sectoral demand. As long as it maintains its existing bases, its future will depend on how successfully it reimagines itself to address an evolving industrial and environmental context.

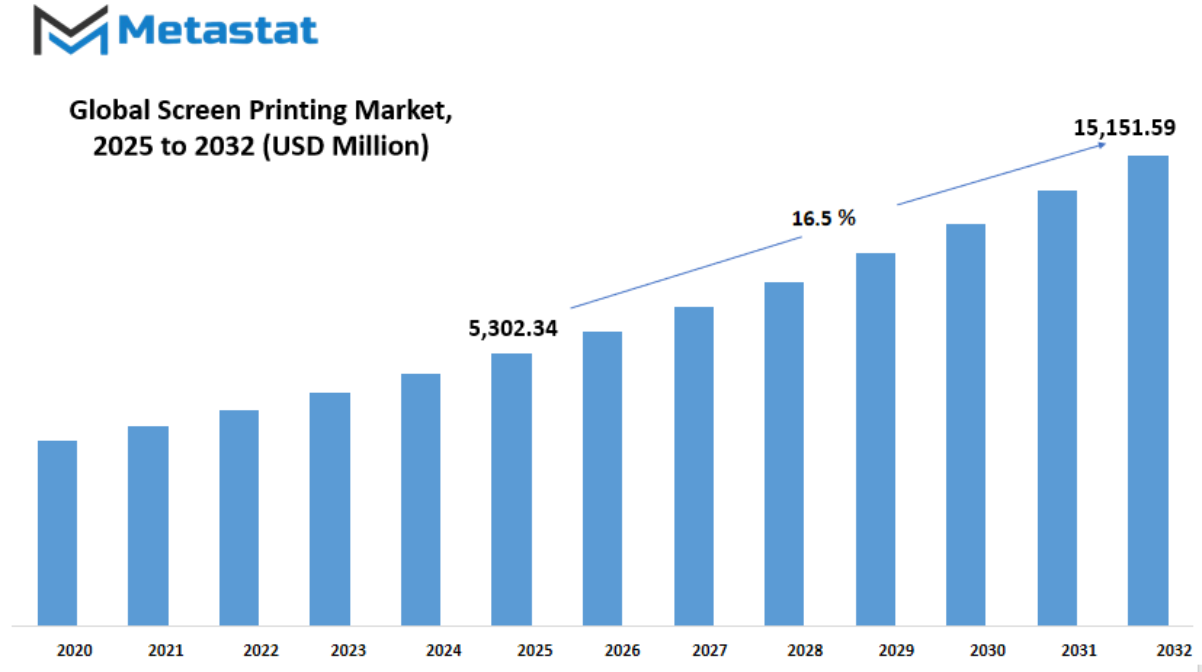

Global screen printing market is estimated to reach $15,151.59 Million by 2032; growing at a CAGR of 16.5% from 2025 to 2032.

GROWTH FACTORS

The global screen printing market is being influenced by changing consumer behavior and industrial demands. Among the key drivers propelling this growth is the increased demand for personalized apparel and products. Individuals desire commodities that capture their persona be it a t-shirt with a preferred quote or a tote bag with a custom logo. Companies, small and large, are answering this demand, relying on screen printing as a consistent and versatile solution. Its capacity for high-volume orders with the same consistency that makes it a go-to solution for a wide range of clothing brands and promotional product firms.

The rising use of screen printing in industries such as electronics and packaging is also a major growth driver in the market. From circuit boards to fine labels and branding details on packs, screen printing is an essential process when quality and longevity are a concern. It provides heavy ink deposits and fine layering, ideal for certain industrial applications where other processes let users down. These industries continue to appreciate the method, particularly where durability and fine detailing are required.

Yet, the global screen printing market also has significant challenges. One of the biggest issues is the eco-friendliness of conventional screen printing processes. The process tends to include inks and chemicals that are wasteful and may be harmful to health as well as the environment. Regulatory pressure and increasing pressure for environmental sustainability are making companies reconsider their ways of working. Another source of problem is the elevated trend towards virtual printing. Unlike display printing, digital techniques provide faster turnarounds for small orders, making them appealing for contemporary companies centered on pace and customization without the setup hassles.

However, these hurdles are also making new doors available. Eco-savvy and water-based inks are increasingly becoming popular, which not only lower the environmental impact but also appeal to environmentally conscious consumers and companies wanting to align their plans with sustainability. Breakthroughs in this sector are likely to inject fresh life into conventional screen printing so that it continues to be competitive while adjusting to the times.

In addition, the sharp acceleration of e-commerce has opened new avenues for the screen printing industry. As more goods are delivered to customers directly, there is growing demand for branded packaging and customized touches. Firms are employing screen printing not only for the products themselves but also to make unique unboxing experiences using printed boxes, tissue paper, and other packaging materials. This synergy of print with brand strategy is providing the industry with a new thrust, making screen printing ever-relevant in the digital era.

MARKET SEGMENTATION

Type of Printing Equipment

The global screen printing market is acquiring constant interest as it has extensive-ranging uses in textiles, electronics, packaging, and advertising and marketing. With the growth in call for for customized and outstanding prints, companies are opting for display screen printing due to its capacity to deliver rich and lengthy-lasting prints. It is a flexible printing procedure that comes both in huge portions and in smaller, revolutionary tasks. With this growing reputation, there is been a great exchange inside the device types used, especially because corporations are searching for to maximise output even as minimizing guide mistakes.

The most common of these kinds within the market is the Manual Screen Printing Machine, which has a market price of $1,199.93 million. The system is best for small productions, craft paintings, and institutions where precision subjects and volume is restrained. They are usually preferred through small businesses and startups that have constrained portions of custom merchandise. Although they are less productive in excessive-pace environments, hand machines nevertheless discover programs due to the fact they may be less expensive and easy to perform, specifically for small workshops and startups.

As businesses enlarge and call for faster turnaround times, Semi-automated Screen Printing Machines are a popular desire. The machines provide a compromise between control and efficiency. Operators retain some control over certain parts of the process but have automation deal with the more repetitive or technically complex elements, resulting in improved consistency and quicker production. Semi-automatic solutions tend to find their way into mid-sized operations that need increased output without fully forgoing operator interaction or customization.

For companies that work on a much bigger scale, Fully Automatic Screen Printing Machines are the first preference. These machines have the functionality to work at excessive pace with minimal intervention, permitting corporations to create lots of merchandise with uniform fine. Companies like electronics and big-format printing use this form of equipment considerably to meet orders without sacrificing precision. While the fee of funding is extra, the payoff is in terms of decrease labor prices and faster delivery instances, which might be quintessential in aggressive markets.

The screen printing commercial enterprise will hold evolving as generation advances and client wishes shift. Businesses will also make more investments in automated technology to sustain demand while ensuring quality. Yet the existence of manual and semi-automatic machines implies that one size does not fit all. Each equipment type has a specific purpose, depending on the size, objective, and character of the business. This harmony of tradition and innovation will define the world of screen printing in the future.

By Ink Type

The global display screen printing enterprise stays inside the limelight because of its consistent call for in textiles, advertising, electronics, and packaging sectors. With evolving print technology turning into extra sophisticated, display printing has remained solid with its ability to obtain super, durable prints in portions. Unlike virtual tactics, which are typically favored for low runs, screen printing affords value-effectiveness and exceptional for bulk production. This old approach continues to be relevant in the whole lot from t-blouse pictures to published circuit boards.

A primary defining characteristic of this marketplace is the form of ink that is used. Every type of ink has a different function based on what's being achieved and what cloth is getting used. Plastisol ink remains widely used, especially in printing clothing, because it's so long lasting and colour-opaque. It's simple to work with and may not dry except cured, so it is safe for predictable effects. Environmental strain has brought on a flow closer to greener options, developing new possibilities for substitutes.

Water-primarily based ink is becoming famous as companies are looking for sustainable selections without sacrificing softness or end. It absorbs into the material rather than resting on its surface, making it more breathable of a print perfect for fashion-oriented clothes. Conversely, discharge ink permits a gentler touch on dark colors through removal of the initial dye and substitution with a paler pigment. Although more specialized, it plays a useful role for high-end designs and period styles.

In non-fabric uses, UV-curable ink and solvent-based totally ink are crucial. UV-curable ink cures straight away upon publicity to UV light, saving manufacturing time and best for excessive-pace commercial processes like printing onto plastic, glass, or steel surfaces. Solvent-primarily based inks are carried out wherein excessive adhesion is a demand, in particular for outside signage subjected to climatic conditions. The inks are still a staple for his or her nice, although regulation concerning their use has driven some manufacturers in the direction of low-VOC alternatives.

With growing international demand and persisted trends in environmentally-pleasant production, the market for display printing will expand similarly alongside lines that combine way of life and development. With industries encouraging customization and sustainability, the selection of ink will no longer only dictate the best of the product however also have an effect on the path of the global screen printing market.

By Application

The global screen printing market will keep developing as groups and industries search for cost-efficient and adaptive printing solutions. Screen printing, with its suitability to produce colourful and durable prints, has become a go-to option in numerous industries. The approach is effective on quite a few materials, which makes it in particular popular for both mass manufacturing and personalised printing. As human beings an increasing number of are searching for wonderful, lengthy-lasting pictures, display screen printing remains a reliable choice.

The garb and textile quarter has one in all the biggest uses of display screen printing. From t-shirts to tote baggage, the manner is used drastically to produce special designs which might be resistant to fading and wear. Fashion designers, game teams, and promotion houses use screen printing to mass-produce garb with uniform first-class. Screen printing is likewise preferred for its potential to cope with complicated designs and distinctiveness inks inclusive of metallics and fluorescents, that are trending in cutting-edge style and branding.

In the electronic industry, display screen printing is essential, particularly for printing on PCBs (Printed Circuit Boards). It permits producers to create complicated patterns on circuits with accuracy, making sure the reliability and performance of electronic components. Outside electronics, even the advertisement and signage sector finds extensive application of screen printing. Its capability to create large, clear, and vibrant displays makes it a perfect application for banners, posters, and store signs, which are subjected to the outdoors and must be visually robust over time.

Packaging and industrial labels are any other marketplace wherein display printing will keep to keep sway. The method is often used for printing on bottles, containers, and different packing substances to help manufacturers cut via the clutter on the shelf with crisp, placing visuals. Industrial labels, which need to face up to moisture, chemical compounds, and abrasion, additionally take advantage of the durability of display screen-published images. Such toughness, coupled with sturdy colour payoff, makes display screen printing a tried-and-proper option for tough environments.

Another application of screen printing include printing on promotional items, ceramics, and glass surfaces, just to show how versatile the process can be. Whether for creative, commercial, or technical use, screen printing remains a trusted method over many industries. As more sectors search for high-quality printing with long-lasting results, the screen printing market will stay relevant and grow into newer areas.

By End-Use Industry

The global screen printing market has developed into a universal and integral component of various industries. For its strength and rich output, this printing method has established a niche in fields that require both quality and mass production. With continuous innovation in materials and equipment, screen printing continues to accommodate mass production requirements while addressing creative and design-based needs. Be it logos on clothing or printed circuit boards, screen printing has consistently maintained its position as a trusted option.

Within the world of fashion and apparel, screen printing has been a favored process for printing designs onto clothing, accessories, and shoes. The visibility of rich colors and the durability of the prints make it suitable for both big fashion brands and smaller independent labels. Designers appreciate it for the freedom of creativity it allows, particularly with various fabrics and textures. The market segment will remain one of the key drivers in the global screen printing market, with the unabated consumer demand for custom, trend-right apparel and branded merchandise.

Consumer electronics is another large category where screen printing is employed extensively. From decorative panels to working displays and printed circuitry, screen printing is what manufacturers look to for precise specifications. Its application to touchscreens and membrane switches is especially critical to ensure quality and accuracy. With electronic devices increasingly becoming part of everyday life, high-quality screen-printed components will be increasingly in demand, particularly in mobile phones, household appliances, and wearable technology.

The automotive industry also has a significant impact in this sector. Screen printing is implemented to dashboard panels, indicator lighting, and different indoors factors. It offers both a classy and purposeful benefit through fade-resistant graphics and durable surface coatings. As the automotive enterprise drives toward innovation and customization, particularly in electric cars, screen printing will shape an critical issue of both indoors and outdoors layout strategies.

Other specialty markets include packaging, safety signs, promotional items, and industrial manufacturing, which also employ screen printing for labeling, safety signs, packaging, and promotion. Reliability and durability are the requirements in these markets. Screen printing achieves this with its high level of output on a myriad of surfaces, such as metal, glass, and plastic. With these sectors being continually automated and increasing, screen printing will remain an economical and versatile application to assist in branding, instructions, and identification requirements on millions of products.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$5,302.34 million |

|

Market Size by 2032 |

$15,151.59 Million |

|

Growth Rate from 2025 to 2032 |

16.5% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

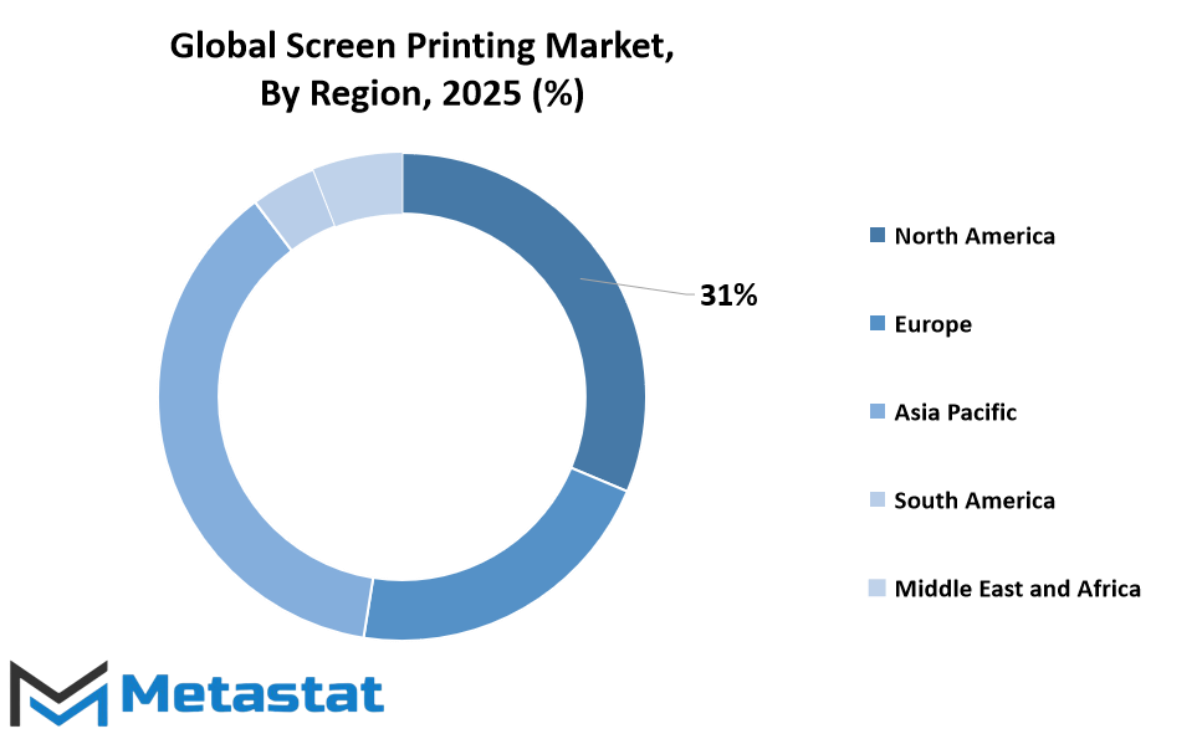

The global screen printing market reaches across a number of significant geographies, with each region reflecting distinct characteristics driven by its economic growth, industrial requirements, and adoption of technology. In the United States' North America, the business is dominantly dominated by the United States itself, followed by Canada and Mexico. The U.S. still experiences consistent demand in industries such as apparel, electronics, and advertising. Sophisticated printing technologies, greater disposable income, and a steady demand for product customization have been strong drivers of maintaining market activity. Canada and Mexico, though smaller compared to the US, add up through industrial and commercial use, with support from cross-border cooperation and regional trade agreements.

Europe's screen printing market comprises the UK, Germany, France, Italy, and the Rest of Europe. These nations enjoy an established manufacturing infrastructure and a robust focus on precision engineering and fashion. Germany, for instance, exhibits robust application of screen printing in automotive and electronics industries, with Italy and France emphasizing more fashion-oriented applications with textile and brand-driven demand. The UK, despite economic changes, continues to have a role to play due to its printing heritage and robust commercial base. The rest of Europe sustains the market with lesser but specialist operations that add up to the overall output of the continent.

Asia-Pacific is amongst the most active markets in this arena, and India, China, Japan, and South Korea are its leading nations. China is specially noted for its low cost of production and mass production capacities, thereby emerging as a leading global supplier of screen-printed products. India is experiencing steady growth with the growth of e-commerce and promotional printing, particularly in textiles and packaging. Japan and South Korea are more innovation- and high-tech-application-oriented, including printed electronics and display panels. The remainder of Asia-Pacific is lesser in dominance but facilitates niche demands and frequently derives advantage from outsourcing trends.

In South America, the leaders are Brazil and Argentina, each with a developing middle class and larger local manufacturing driving the market. Brazil in particular has experienced rising demand in packaging, signage, and textile printing, citing the country's turn towards branded and customized products. Argentina contributes to this momentum as well, albeit more modestly, with regional consumption and small-scale industries. The remaining South America underlines the market with localized services and increasing interest in export-oriented printing enterprises.

The Middle East and Africa complete the worldwide market, with countries such as the GCC states, Egypt, and South Africa at the forefront. Within the GCC market, there is significant demand from advertising, packaging, and décor industries, usually driven by retail development and hospitality expansions. Egypt and South Africa are promising with growing investments in small-scale industries and the creative industry. The rest of the region may still be in the process of developing in infrastructure but is gradually catching up due to growing interest in printed materials and customized goods. Each of these regions contributes to the overall market, influenced by local tastes, use of technology, and economic needs.

COMPETITIVE PLAYERS

The global screen printing market is defined by the combination of age-old artisanship and evolving technology, providing companies in every industry a means of creating accurate, reproducible designs on countless substrates. On textiles and apparel to electronics and packaging, screen printing has been a reliable process due to its versatility, scalability, and dependable consistency. It has been modified and refined over the years to accommodate the mounting need for high-quality prints and greater production speeds, particularly with the rise in automation and environmentally friendly practices. The ongoing move toward personalization, green inks, and quicker turnaround times is guiding the market down a new path where quality, longevity, and innovation will count more than ever.

One driver stimulating the global screen printing market is the growth of custom printing in the fashion and promotional product industries. With consumer tastes trending toward distinctive and limited-run designs, companies are looking to screen printing for its capacity to accommodate bulk orders without reducing print quality. The process is also making inroads in industrial processes such as printed circuit boards, solar panels, and medical equipment. These industries require very precise and long-lasting prints, which screen printing is established to provide. The market here is backed up by advancements in materials, ink technology, and incorporating semi or fully automatic machines that make production efficient with less waste.

Industry leaders are making themselves known by constantly optimizing their machines and pushing their global presence. Some of the major players involved are M&R Printing Equipment, Inc., ROQ International, Anatol Equipment Manufacturing Co., Vastex International, Inc., Thieme GmbH & Co. KG., MHM Austria, Systematic Automation, Inc., and Workhorse Products, among others. These players have emphasized lowering manual labor, precision printing, and designing machines to assist today's requirements such as energy efficiency and speedy setup times. Other significant contributors such as ASPE Inc., Aurel Automation S.p.A., ATMA Champ Ent. Corp., and Panasonic Factory Solutions have also launched products that cater to intricate tasks but are still easy to use. They have shown an intimate knowledge of market demand assessing tradition and new trends.

In regions such as Asia-Pacific, where industrialization is swift and textile exports are on the rise, screen printing is in high demand, particularly among small- to mid-sized firms. Local companies like ShriRam Enterprises are catering to regional needs with affordable but effective equipment. At the same time, players such as INX International Ink Co. and SPSI Inc. are playing a part by offering high-quality inks and accessories that enhance the end product and increase machine longevity. Their partnership with machine manufacturers is adding value by helping to ensure smooth operations and compatibility, which becomes critical when ramping up production.

In the future, the global screen printing market will continue to thrive from its capacity to innovate without losing its essential strengths. While digital printing is creating ripples in certain segments, screen printing remains robust in bulk production, durability, and flexibility with ink. The market leaders are not only selling machines they're assisting in building printing ecosystems for the future that take on the challenges of today's production head-on. Through innovation, strategic alliances, and dedication to reliability, the global screen printing market will continue to be a robust presence in print manufacturing for many years to come.

Screen Printing Market Key Segments:

By Type of Printing Equipment

- Manual Screen Printing Machines

- Semi-automatic Screen Printing Machines

- Fully Automatic Screen Printing Machines

By Ink Type

- Plastisol Ink

- Water-based Ink

- Discharge Ink

- UV-curable Ink

- Solvent-based Ink

By Application

- Apparel & Textile

- Electronics (PCB printing)

- Advertising & Signage

- Packaging

- Industrial Labels

- Other

By End-Use Industry

- Fashion and Apparel

- Consumer Electronics

- Automotive

- Industrial Manufacturing

- Other

Key Global Screen Printing Industry Players

- M&R Printing Equipment, Inc.

- ROQ International

- Anatol Equipment Manufacturing Co.

- Vastex International, Inc.

- Thieme GmbH & Co. KG.

- MHM Austria

- Systematic Automation, Inc.

- Workhorse Products

- ASPE Inc. (Automatic Screen Printing Equipment)

- Huned Y. Rangwala.

- Panasonic Factory Solutions

- Aurel Automation S.p.A.

- ShriRam Enterprises

- ATMA Champ Ent. Corp.

- TAS International

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252