MARKET OVERVIEW

The us phenolic foam market will evolve in ways that go far beyond conventional parameters, branching into areas yet to be fully explored or tapped. Phenolic foam, most commonly known for its exceptional insulation and fire-resistance capabilities, will find uses branching into markets where material performance and sustainability merge with emerging technologies and regulatory mandates. This change will shift the significance of the market from merely an insulation solution to a pioneer for various industries.

One of the industries that the us phenolic foam market will also affect is the construction sector, but not in the traditional aspect of insulation per se. The potential of the material to offer both thermal resistance and fire safety will serve as a basis for future building envelopes that will be required to comply with more stringent energy codes and safety regulations. Beyond the residential and commercial construction, infrastructure initiatives like transportation centers and critical facilities will embrace phenolic foam in new configurations. Its lightweight combined with the potential to include structural supports will see it at the forefront of modular building methods, which will gain popularity as demand for cheap, efficient building solutions expands.

The us phenolic foam market will also coincide with the automotive and aerospace industries in new ways. With car makers struggling to get cars lighter but more energy-efficient, the characteristics of phenolic foam will enable better thermal management systems and fire barriers. Future electric vehicles and airplane cabins will feature this foam for not only insulation but noise reduction and occupant protection enhancement. This will be away from single-functional purposes to multipurpose applications to make the overall vehicle better and more comfortable for passengers.

Environmental concerns will also shape the direction of the us phenolic foam market. With increasing emphasis on carbon footprint and material lifecycle emissions, industry firms will look for bio-based and recyclable phenolic foam options. This shift will be fueled by both regulatory pressure and consumer pressure for greener material. Producing these sustainable choices will help the market to provide green building certifications and attain circular economy goals, establishing new standards in material creation within the insulation segment.

In addition, the US Phenolic Foam industry will aid energy infrastructure improvement. With increasingly sophisticated power generation and transmission networks as renewables are added, phenolic foam insulation capabilities will play a central role in protecting exposed equipment. Solar panel arrays, electrical substations, and battery storage devices will become more dependent on phenolic foam components to optimize operating performance and longevity. This proposal will further highlight to what degree the market reaches beyond conventional building insulation, its stature in the emerging energy environment.

Technologically, the US Phenolic Foam industry will be driven by new manufacturing processes. The technologies of improved foam formulations, additive manufacturing, and precision molding will promote increased design freedom. These new technologies will allow for the creation of complex structures and customized insulation solutions that fit special industry requirements. The resultant flexibility will see new uses in such fields as electronics, refrigeration, and even specialty packaging, opening the material up to new and non-conventional markets.

Lastly, collaboration between material scientists, industry players, and regulatory authorities will take the us phenolic foam market to new territories. R&D efforts focused on enhancing fire resistance, reducing environmental impact, and incorporating smart features such as embedded sensors will reshape the potential of phenolic foam. The market will thus be transformed not just as a supplier of insulator materials but also as a driver of safer, smarter, and more environmentally friendly applications.

Briefly, the us phenolic foam market will extend beyond its typical boundary by converging with a number of industries including construction, transport, energy, and technology. Its destiny will be material innovation, sustainability, and multi-functionality, and thus become a critical component in industries looking for more sophisticated solutions.

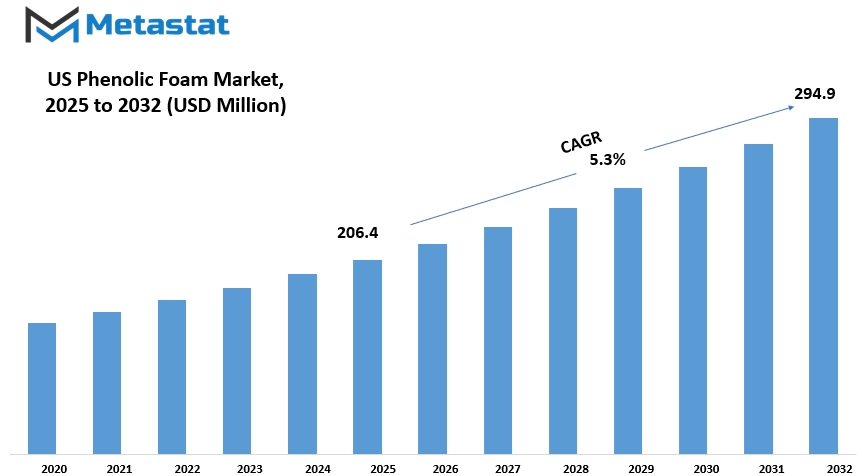

US phenolic foam market is estimated to reach $294.9 Million by 2032; growing at a CAGR of 5.3% from 2025 to 2032.

GROWTH FACTORS

The us phenolic foam market is experiencing steady growth, mainly due to an increase in demand for energy-efficient insulation in construction. Since builders and developers are looking for a cost effective way to save energy and money in a long time, phenolic foam has been widely accepted for its efficient insulation capacity. It keeps the buildings cool during summer and warm during winter, using energy and reduces bills. This growing demand is running more companies to use phenolic foam in its projects, thus moving the market.

Other factor driving market growth is the growing use of phenolic foam in heating, ventilation and air conditioning (HVAC) systems. These systems require temperature retention properties and must be light weight with simple installation. Phenolic foam is a perfect product for use in this application because of its characteristics, which is why it is greatly needed by HVAC makers and installers. Enhanced efficiency of the system as a result of phenolic foam adds to the rising adoption rate, thereby propelling the market even further.

Despite such favorable conditions, the market also experiences some drawbacks. The main stumbling block is the hefty production cost of phenolic foam. Phenolic foam is even more expensive to produce than other materials that are utilized for purposes of insulation, and this will discourage use in cost-sensitive markets. Customers who prioritize price over performance will opt for something less expensive, limiting the use of the foam in some markets. Budget limit slows wide acceptance, especially where cost constraint is an overriding factor.

Apart from that, there is a place of environmental regulations in the decision-making of the market. Since phenolic foam involves the use of special chemicals, producers will need to adhere to rigorous regulations in safeguarding the environment. The laws can complicate and become costly in the production, as firms will have to ensure products are safe for use. This can be an issue that will decide the rate at which new phenolic foam products get into the market and affect overall growth.

On the other hand, there are available opportunities upon which the market can capitalize. For example, more investments are being put into green building projects, which prioritize sustainability and energy conservation. This trend opens up new uses for phenolic foam since the product is highly suited to the aspirations of such environmentally friendly projects. Apart from this, ongoing innovation in foam formulation promises improved performance, further increasing the attractiveness of phenolic foam to customers. The innovations will undoubtedly help the industry reach new levels of success in the future.

MARKET SEGMENTATION

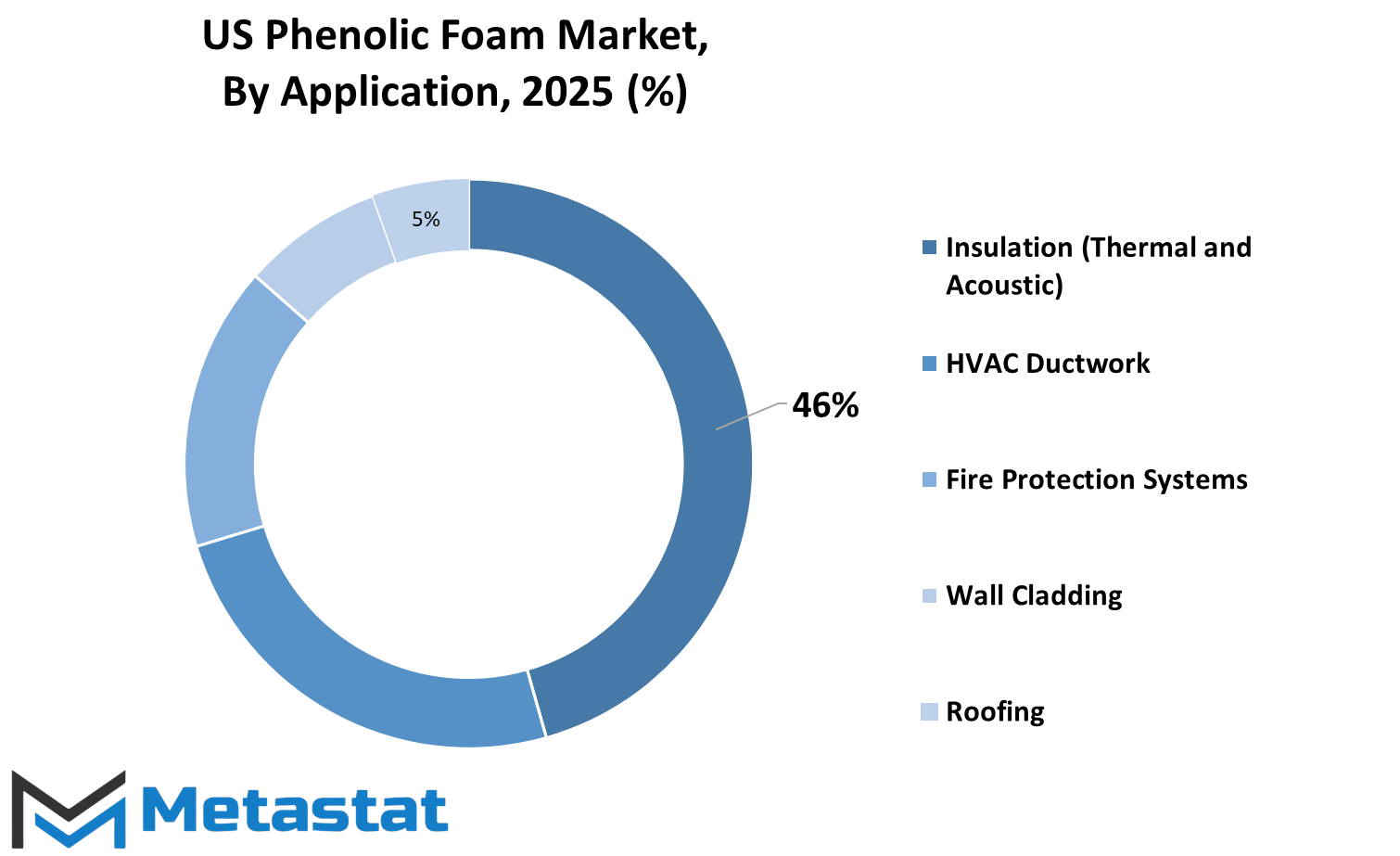

By Application

The us phenolic foam market is growing steadily as it gains wider use in a wide range of construction and industrial applications. Thermal and acoustic insulation accounts for the most prominent application of phenolic foam at a value of $90.8 million. It is utilized for temperature and sound control, saving buildings energy and noise. This is particularly useful where high insulation is required, but also that fire safety requirements must be met. Phenolic foams will not burn easily, and it is one of the main reasons that it is being used more and more in building construction where security is paramount.

In addition to insulation, phenolic foam is widely used in HVAC ducts. Heating, ventilation and air conditioning systems require ingredients that can maintain airflow well when they are able to bear heat and fire. Phenolic foam does this, and it helps to improve indoor air quality and reduce energy loss. Being lightweight with high strength, it is easier and faster to install, and that is time and labor-saving.

Phenolic foam also serves fire protection systems. The material does not readily catch fire and produces minimal smoke, and in this way, it adds an extra layer of safety to buildings. When burning, having materials that are fire-resistant like phenolic foam slows down the progress of the fire and gives people more time to escape unharmed. It is therefore an option to consider for use in schools, hospitals, offices, and residential buildings.

Wall cladding is another area where phenolic foam is gaining ground. It provides good support, weather protection, and improves the aesthetic appeal of a building without much addition to its weight. This makes it easy to use in modern construction. Fenolic foam is also used in the roof for all these reasons. Foam indoor keeps the temperature consistent, which means saving money on heating and cooling over the long term.

It is also applied to other forms, including panels and boards used in different parts of a building where insulation and safety are necessary. Phenolic foam is generally gaining popularity as it solves many problems at once - insulation, fire resistance, and providing support without being very heavy or expensive. With increasingly more industries focusing on safer and more efficient product material, phenolic foam use will continue to rise. Its application in construction, especially in the US market, becomes more and more important as requirements for safety and energy conservation persistently increase.

By End User

The us phenolic foam market is witnessing sustained growth, especially due to rising demand from the building sector. Phenolic foam provides better insulation, resistance to fire, and low smoke emission. Such characteristics are making it highly demanded for various building purposes. With safety and energy efficiency being at the forefront of concerns in building, demand for phenolic foam is growing from builders and developers to offer sustained insulation solutions. Its ability to reduce heat transfer saves on energy expenses, and hence it is appropriate for domestic and commercial properties.

Based on end users, the market divides into four major segments: Residential Construction, Commercial Construction, Industrial Facilities, and Institutional buildings. Application of phenolic foam differs across the various industries. In residential construction of buildings, the application is normally for thermal insulation in walls, roofs, and floors. Homeowners want their homes to be at a comfortable temperature throughout the year, and phenolic foam maintains indoor temperatures better. It also makes homes safe through fire resistance, which is one factor that matters more these days when home design is being planned.

Offices, shopping malls, and hotels benefit in business construction from the temperature regulation and energy conservation capability of phenolic foam. The buildings come with complex systems and high occupancy levels, thus efficiency and safety are important considerations. Phenolic foam is used in HVAC applications, ducts, and other applications, with a light yet a firm durable material. Its long life also reduces the need for frequent replacement, which means that the cost of maintenance will be shorter in a long period.

Industrial plants use phenolic foam aimed at completing obedient safety codes and working with efficiency. Plants with warehouses, factory, and high fire threats prefer to use phenolic foam because it is a fire retardant. Phenolic foam is also moisture- and chemical resistant, which in some industries where heavy equipment or manufacturing may be beneficial.

Institutional buildings such as schools, hospitals and office towers use phenolic foam in rest and safety. There are a large number of people in these buildings who pass through them, and therefore indoor air quality and fire protection becomes extremely important. Fenolic foam provides insulation while meeting strict construction and health standards.

Overall, the us phenolic foam market is still growing with the increasing demand for these end-use applications. With its consistent performance, permanent quality and safety benefits, phenolic foam is becoming a major material in modern construction efforts across the country.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$206.4 million |

|

Market Size by 2032 |

$294.9 Million |

|

Growth Rate from 2025 to 2032 |

5.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The us phenolic foam market can be studied in terms of geographies, which helps in understanding where the demand will come from and how it would change across geographies. Although focus is on the United States, it should also be seen in the larger marketplace. The global map is divided into several major regions like North America, Europe, Asia-Pacific, South America and Middle East and Africa. All these areas are divided into an attempt to create a more accurate picture of market trends and performance.

Starting with North America, the region covers the United States, Canada and Mexico. Of these, the U.S. Plays a major role as it claims a strong construction and insulation market. Canada and Mexico also contribute to their inputs, but not to the same extent. Europe is followed by its own set of countries such as the UK, Germany, France, and Italy, among others in Rest of Europe. All these countries have established infrastructure segments, and legislative activity with regards to energy efficiency has assisted in increasing the consumption of phenolic foam.

The Asia-Pacific is one of the fastest growing regions and includes India, China, Japan and South Korea, the rest in the Asia-Pacific neighboring countries. Urbanization and fire safety and thermal insulation products are demanding increasing awareness in this field. China and India, among others, are especially seeing increasing construction activities, which is driving the market.

South America contributes to the world's perspective with Brazil, Argentina, and the Rest of South America countries. Although this part of the continent does not yet meet up with demand levels experienced in North America or Asia-Pacific, there is a consistent increase in the application of high-tech building materials. Lastly, the Middle East & Africa encompasses GCC Countries, Egypt, South Africa, and the Rest of the region. Many of these countries are investing in real estate, tourism, and commercial properties, which may drive up demand for quality insulation materials such as phenolic foam.

With this realization of geographic segmentation comes the full picture of how the US market is driven by domestic and international trends. It reveals where there are pockets of potential growth, allowing investors and businesses to easily plan their strategy.

COMPETITIVE PLAYERS

The us phenolic foam market has picked up steam for its increased application in construction, refrigeration, and HVAC applications because of its excellent insulation properties and fire resistance. Phenolic foam is a rigid and light material which is derived from phenol-formaldehyde resin. It has a low thermal conductivity, which implies that it insulates buildings without occupying a lot of space. Due to this, it's particularly of value in applications where energy efficiency is critical. In addition to its insulating advantages, phenolic foam is also prized for its fire and smoke resistance, which makes it a more secure option than certain other insulations.

This product is also resistant to moisture, preventing such problems as mold or corrosion in humid areas. Because of these properties, phenolic foam is increasingly used in applications where safety and performance are required. As building codes tighten, and as individuals become more aware of energy consumption and indoor air quality, demand for such high-quality insulation as phenolic foam will most likely continue to grow.

There are some major companies that contribute significantly to the us phenolic foam market. Some of the prime players are Kingspan Group, Fujian Tenlead Advanced Material Co., Ltd., Saint-Gobain, Asahi Kasei Corporation, Johns Manville Inc., Soprema Group (Celotex), Polyguard Products, Inc., Resolco, Inc., Thermal Pipe Shields, and InsulTherm. These firms invest in enhancing the quality of the foam, making it easier to use, and creating novel applications for it in both commercial and residential environments. Their initiative is leading to heightened exposure and access to phenolic foam nationally.

Beyond construction, phenolic foam also appears in industrial piping and ducting systems, particularly where minimizing heat loss is crucial. Phenolic foam's ability to maintain its shape and integrity even under pressure or through the years makes it a worthwhile long-term choice. Cost may be an issue for some contractors, but long-term energy savings and enhanced fire safety usually make the investment worthwhile. As the technology continues to advance and increasing numbers of people realize the advantages, phenolic foam will become an increasingly important factor in how the US constructs safer and more energy-efficient environments.

US Phenolic Foam Market Key Segments:

By Application

- Insulation (Thermal and Acoustic)

- HVAC Ductwork

- Fire Protection Systems

- Wall Cladding

- Roofing

- Others

By End User

- Residential Construction

- Commercial Construction

- Industrial Facilities

- Institutional

Key US Phenolic Foam Industry Players

- Kingspan Group

- Fujian Tenlead Advanced Material Co., Ltd.

- Saint-Gobain

- Asahi Kasei Corporation

- Johns Manville Inc.

- Soprema Group (Celotex)

- Polyguard Products, Inc.

- Resolco, Inc

- Thermal Pipe Shields

- InsulTherm

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383