MARKET OVERVIEW

The Global Surface Protection Tapes Market is an important market in the adhesive industry that serves various industries that require the most efficient solution to protect surfaces in the production, transportation, and storage of various products. Surface protection tapes are intended to protect materials from scratches, abrasions, and contamination by contaminants for metals, glass, plastics, and painted surfaces. This market plays a significant role in ensuring that high-quality finishes are retained throughout the manufacturing and construction processes while ensuring the integrity of the products before they reach their end-users.

This industry represents a range of innovative products developed to meet specific needs arising from the complexity of industrial processes and the variety of materials involved. These tapes differ in adhesive strength, thickness, and durability and are, therefore, applied for both temporary and permanent use. Their functionality is of prime importance in such industries as automotive, electronics, construction, and aerospace where precision and aesthetics hold paramount importance. The application of protective tapes is not restricted to their traditional usage but extends to specialized applications as well, reflecting the adaptability of the market to evolving industrial needs.

In the future, advanced materials and environmental-friendly solutions are expected to dominate the Global Surface Protection Tapes Market. With the growing demand for sustainability and adherence to regulations, this market is bound to evolve further. The manufacturers are going to introduce novel materials that will protect surfaces even better and also decrease the environmental burden associated with the products. New developments in adhesives, such as pressure-sensitive and residue-free formulations, will continue to improve the performance of the tapes as per the requirement of efficiency and precision from the industry.

Geographically, the market spans regions with diverse industrial bases, ranging from established economies with robust manufacturing sectors to emerging markets experiencing rapid industrialization. The interplay between technological advancements and regional dynamics will shape the trajectory of this market, influencing product innovations and distribution strategies. Companies operating within the market will continually refine their offerings to address region-specific requirements, ensuring that the tapes cater to localized manufacturing standards and consumer expectations.

Besides the physical properties of surface protection tapes, digitalization and data integration may also change the landscape of the market. The use of smart technologies, such as RFID tracking and performance monitoring, could make these products more useful in industrial applications. This may make supply chains more efficient, minimize waste, and make manufacturing processes more efficient.

The Global Surface Protection Tapes Market will also face challenges associated with cost optimization and availability of raw materials. Material price volatility and supply chain restrictions might prompt companies to find new alternative materials and manufacturing methods. These changes will most likely lead to a competitive market environment, which will induce more collaborations and partnerships to maintain positions in the market.

In conclusion, the global surface protection tapes market is expected to shape up as industries increasingly give importance to the preservation of the quality of products. In this regard, the sustainability of this market will be reflected in its ability to meet the technological advancements, environment, and regional requirements. While it continues to evolve, the industry will represent the dynamic interplay between innovation, functionality, and sustainability, underlining the integral role it plays in protecting surfaces across a wide variety of applications.

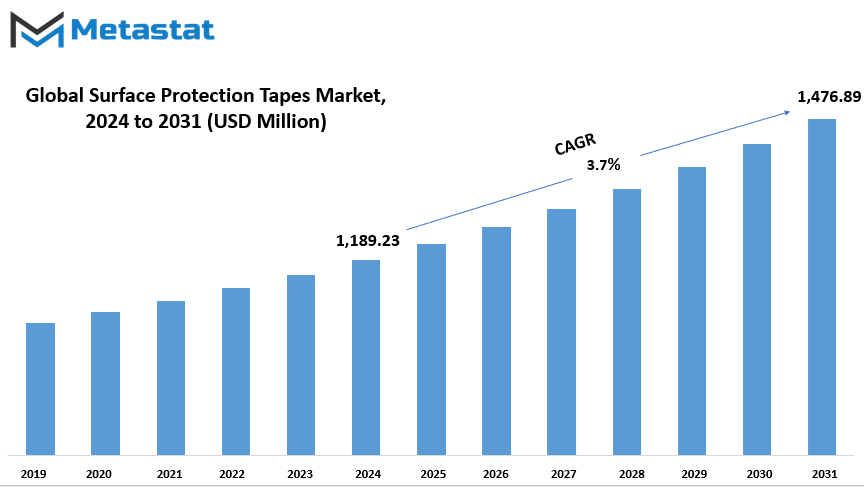

Global Surface Protection Tapes market is estimated to reach $1,476.89 Million by 2031; growing at a CAGR of 3.7% from 2024 to 2031.

GROWTH FACTORS

This surface protection market is growing steadily with the rising need for reliable solutions across industries, including automotive and construction. Both sectors depend on surface protection for keeping the quality and durability of products intact during manufacturing, transportation, and installation. Increasing usage of surface protection tapes is one major factor contributing to this growth. These tapes are preferred for the eco-friendly nature and also for easy removal, making it a convenient choice for wide applications. Its ability to preserve surfaces without damaging it during its removal process has made this a popular choice for industrial purposes as well as commercial usage.

However, some of these challenges could restrict the potential growth of the market:. The availability of alternative solutions, such as protective films and coatings, offers customers more options, which could reduce the reliance on surface protection tapes. Additionally, the volatility in raw material prices poses a significant challenge for manufacturers. Fluctuating costs directly affect the overall production expenses, which can impact pricing and, consequently, demand. Companies operating in this space must find ways to manage these challenges to maintain competitiveness and profitability.

The other end is more promising with increased interest in sustainable solutions. As people continue to bring environmental concerns to the fore, biodegradable and eco-friendly surface protection tapes are increasingly being in demand as they meet the global standards of sustainable practice, mainly in those sectors that strive to minimize their negative impact on the environment. Manufacturers that focus more on innovativeness and release such goods are likely to experience benefits regarding this trend since they enjoy a competitive edge.

Market future for the surface protection industry seems promising, all being said and done, because firms make necessary adjustments to confront emerging chances. The sustainability alternatives offered, coupled with the drive for cost effectiveness, helps the industry grow, accommodating demands that change with time. Versatile surface protection tapes and rising demand would make sure it continues to be one of the critical components used for the protection of surfaces in diversified applications, though its success depends on finding the balance between innovation and its capacity to face the market's challenges with a chance of growth in the following years.

MARKET SEGMENTATION

By Material

There are many types of materials, categorized according to the composition and nature of each material. A simple classification is by types of plastics, namely Polyethylene (PE), Polypropylene (PP), Polyurethane (PU), Polyethylene Terephthalate (PET), PVC (Polyvinyl Chloride), and any other types that do not fall under the above classifications.

Amongst them all is PE. This plastic is mostly common; these include bags, bottles as well as containers. Yet the plastic is not limited by just one kind. Besides Polyethylene, another plastic was introduced: polypropylene or short-handed as PP. It ranges to use in packaging, a clothing, as well as automobiles' parts. It shows great resistance against heat, in addition to chemical resistance due to its uses in industrials.

Polyurethane is another term used to represent the abbreviated form PU, which refers to a type of plastic, mainly applied in foam products. This can include cushions, mattresses, and insulation materials. Polyurethane also has an excellent bonding ability that makes it applicable for use in coatings, adhesives, and sealants. Another popular type of plastic is Polyethylene Terephthalate, abbreviated as PET, and widely used in bottles containing beverages, food containers, and clothes. Its strengths include high strength, transparency, and recyclability.

PVC stands for Polyvinyl Chloride. It is one of the most commonly used plastics, and in fact, one can find this plastic used extensively in the construction materials, pipes, and flooring. The plastic material is highly strong as well as moisture resistant. Thus, it is immensely used in plumbing and building applications. Lastly, there are those that cannot fit into any of the previously mentioned categories but are still very essential to many sectors. Such as the plastics or composites based on their properties which could be used for particular applications.

All these materials have inherent properties that are valuable for certain applications. It can range from packaging, construction to more specialized industries, such as electronics or textiles. Every plastic has inherent characteristics which may be moulded, shaped and used as suitable for certain needs. By understanding these differences, industry selects the appropriate material best suited for the production of goods and services.

By Adhesion Type

The market for adhesives is usually segmented by adhesion type into two categories: single-sided adhesive and double-sided adhesive. Single-sided adhesive refers to products where the adhesive is applied to only one side of the material. This type of adhesive is often used for tasks where one surface needs to be attached to another, such as in mounting posters, labels, or bonding items to a surface. It can provide an easy solution in the event of needing only one side fixed in place.

The double-sided adhesive provides adhesion on both sides of the material. These adhesives are primarily used where two surfaces must be bonded together with minimal, or no visible, adhesion. These can be applied in a variety of applications, especially in those with products for packaging, electronics, and automobile. It is applied as it creates a strong bonding between the components without necessarily changing the aesthetic appearance of the product. They may appear in the form of foam tapes, double-sided tape, and bonding films, among others.

For application, single-sided and double-sided adhesive differ mainly based on the specific need of the application. Single-sided adhesive is suitable for easier one-sided bonding, while two-sided adhesive offers more opportunities to achieve a seamless interface between two surfaces. This comes in handy in lots of applications, from merely sticking household items together in your home to more special applications in industry. Each of these adhesives has its strengths. Therefore, the choice about which one to use should primarily depend on the need for strength, convenience, or type of bond required by the application.

By Adhesive Material

Adhesive materials are used in all types of industries to bind different materials. There are three main categories within the adhesive material market: Acrylic-Based Adhesives, Rubber-Based Adhesives, and Silicone-Based Adhesives. There are special features for these three types of adhesives and for the applications; thus they have to be used differently.

The Acrylic-Based Adhesives possess a good bonding ability and resistance to weathering. They are widely used in areas that demand durability such as in the automobile, construction, and sign application industries. They possess an excellent adhesive strength toward various surfaces, including metals, plastics, and glass and show resistance to UV light; this makes them much more favorable for outdoor applications.

Rubber-Based Adhesives can offer flexibility for providing high strength bonding to any material. They are extensively used in applications bonding materials containing a flexibility level, for example in packaging, electrical and automotive. Adhesives in rubber are best for places where temperature or vibrational changes can be experienced as they can easily withstand losing their functionality by movement.

Silicone-Based Adhesives offer excellent resistance to heat and performance in extreme conditions. The adhesive is used in that industry where the material to be used has to be resistant to heat, such as in electronics, aerospace, automobiles, etc. Silicone adhesives are also water-resistant; hence, it is used in those applications where moisture is anticipated. The adhesive is used very frequently in sealing applications where reliability of the bond has to be ensured so that leakage does not take place.

With the growing need in industries for better and more reliable bonding solutions, so will the demand for adhesive materials grow. Depending on its respective properties, one kind of adhesive material will find its application in various areas.

By End-Use Industry

The Global Surface Protection Tapes market has vast growth potential since it protects surfaces in various industries. Tapes are specifically made to guard delicate or valuable materials against damage, contamination, or wear during production, transportation, and installation. In such a scenario, the growth in these tapes is expected to expand more, as industries develop and require better finishes and more efficient protection solutions.

Surface protection tapes are also important in the electronics and semiconductors industry due to their emphasis on accuracy. They are used to protect delicate components from scratches or other contaminants at various stages in the manufacturing process, ensuring finished products free of such scratches or contaminants. With the growing application of complex technologies, including smartphones, wearable devices, and high-performance computing systems, demand for protective solutions will rise in this industry segment. This means there is a possibility of new product developments using material requirements like high-temperature resistance and compatibility with complex manufacturing processes.

These tapes are also heavily used in the automotive industry to protect parts and surfaces during assembly and transportation. As market trends continue to shift toward electric vehicles and lightweight designs, demand for specialized protection solutions will rise. Surface protection tapes will be highly sought after, especially those specifically designed for lightweight composite materials and complex battery components.

These tapes are crucial for glass, aluminum, and painted surfaces, as well as many others in building and construction for their appearance and functionality. The world continues to build tall skyscrapers and new modern infrastructure; the tapes used in protecting surfaces will forever remain an important aspect of how to ensure that materials arrive at their respective project sites in a pristine state.

In addition to these, healthcare, metal processing, aerospace, and appliances require protection solutions also. Innovation in material science will ensure that the surface protection tapes that are biodegradable or recyclable emerge to cope with the emerging demand on sustainability. This also follows a huge increase in the level of global trade and thereby its demand in packaging and transportation of products.

The future of this Global Surface Protection Tapes market rests very much on the advancement in the technology of materials and related sustainability initiatives, coupled with the increasing demands of modern industry. Given such divergent applications, the market is likely to remain all the more integral to protect valuable resources all around the world.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,189.23 million |

|

Market Size by 2031 |

$1,476.89 Million |

|

Growth Rate from 2024 to 2031 |

3.7% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

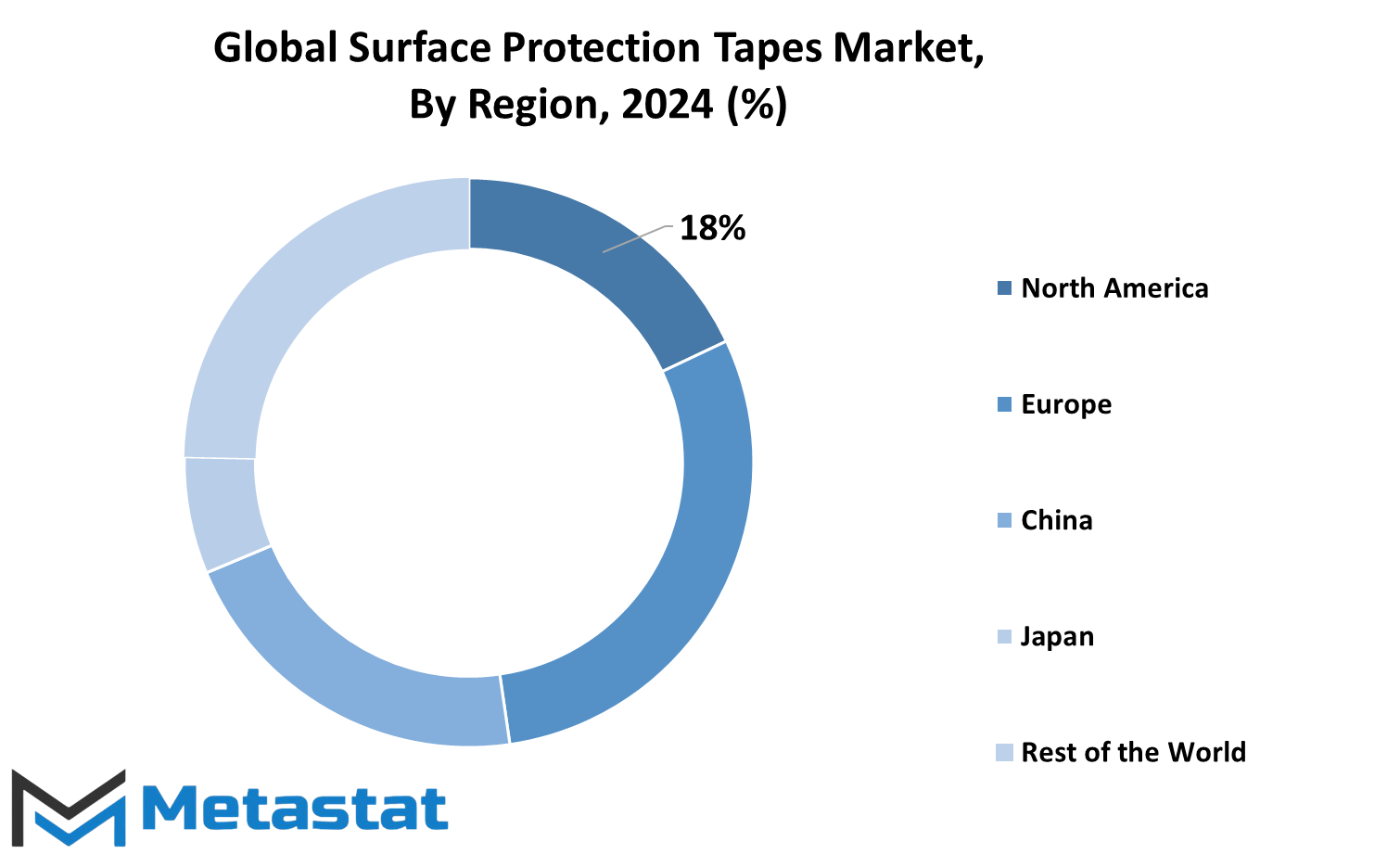

The Surface Protection Tapes market in the world is segmented based on geography into five principal regions: North America, Europe, Asia-Pacific, South America, and Middle East & Africa. Within North America, there are three major countries covered: U.S., Canada, and Mexico. The Europe market includes key markets like UK, Germany, France, and Italy along with other parts of the European region. The Asia-Pacific region consists of India, China, Japan, South Korea, and the rest of the countries in Asia-Pacific. South America comprises large markets such as Brazil and Argentina, along with the rest of the countries in South America. Finally, the Middle East & Africa region is further segmented into several sub-regions, such as GCC countries, Egypt, South Africa, and the rest of the Middle East & Africa.

This regional division shall allow a deeper understanding of the functioning of the market in different areas; each region would have a unique dynamic, and its demand for Surface Protection Tapes will be different for every location depending on how much each of them may need. For instance, in North America, the demand will be driven by the strong presence of manufacturing and construction industries, which require reliable protective solutions for a variety of surfaces. Similarly, in Europe, the demand will be driven by automotive and electronics industries.

Asia-Pacific, in particular, has an increased demand for protective tapes as industrialization rapidly expands in China and India. Electronics, automotive, and packaging sectors have become major users of the tape. The South American market is relatively small but should grow as Brazil and Argentina continue to develop their manufacturing capabilities. In the Middle East & Africa, demand is expected to be driven by construction and infrastructure development projects in countries such as UAE, Saudi Arabia, and South Africa.

Segmentation of the market in such a manner will allow for easier tracing of trends and growth in each field, helping businesses target more relevant markets and optimize strategies. Such knowledge of regional differences is essential for firms looking to expand or bolster their Surface Protection Tapes operations.

COMPETITIVE PLAYERS

Some of the major players in the Surface Protection Tapes industry include a number of companies leading the market through innovative products and solutions. These are the 3M Company, which is the global leader and known for its wide array of adhesive products, and Nitto Denko Corporation, the leader that is known for advanced technology in tape manufacturing. Another significant name is Tesa SE, offering a broad range of surface protection tapes used in different industries. Intertape Polymer Group Inc. is another one of the leading manufacturers providing quality adhesive products for surface protection.

Avery Dennison Corporation is a market leader in labeling and packaging materials, while Scapa Group Ltd. specializes in industrial adhesive solutions. Saint-Gobain Performance Plastics is another significant player with high-performance materials for surface protection. Chargeurs S.A. offers specialized products used for various surface protection applications, while Berry Global, Inc. manufactures a range of protective films and tapes.

Toray Industries, Inc. is a company that boasts itself with advanced materials and surface protection solutions. Surface Shields is a company providing protection films that are used specifically to preserve surfaces in case of handling and installation. Mactac is the subsidiary of Lintec, which provides protective adhesives for different industries. Finally, Polifilm Group manufactures surface protection films that can be utilized for various industries to prevent the products from damage throughout production, transportation, and installation.

These companies, with extensive experience and innovative approaches, have contributed a lot to the growth and development of the Surface Protection Tapes industry and therefore contribute to the increased application of these products in a variety of uses. Commitment to offering high-quality solutions ensures the continuous demand and market presence of surface protection tapes in all industries.

Surface Protection Tapes Market Key Segments:

By Material

- Polyethylene (PE)

- Polypropylene (PP)

- Polyurethane (PU)

- Polyethylene Terephthalate (PET)

- PVC (Polyvinyl Chloride)

- Other Materials

By Adhesion Type

- Single-Sided Adhesive

- Double-Sided Adhesive

By Adhesive Material

- Acrylic-Based Adhesives

- Rubber-Based Adhesives

- Silicone-Based Adhesives

By End-Use Industry

- Electronics and Semiconductors

- Automotive

- Building and Construction

- Metal Processing

- Healthcare

- Aerospace

- Appliances

- Other Industries

Key Global Surface Protection Tapes Industry Players

- 3M Company

- Nitto Denko Corporation

- Tesa SE

- Intertape Polymer Group Inc.

- Avery Dennison Corporation

- Scapa Group Ltd.

- Saint-Gobain Performance Plastics

- Chargeurs S.A.

- Berry Global, Inc.

- Toray Industries, Inc.

- Surface Shields

- Mactac (A Lintec Company)

- Polifilm Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383