MARKET OVERVIEW

The Global Rubber Gaskets and Seals market is a very important sector in industrial manufacturing as it plays a critical role in several applications, including reliability in sealing and insulation. Rubber gaskets and seals market production and distribution prevent leakage, maintain pressure, and enhance efficiency in all industrial sectors such as automotive, aerospace, oil and gas, and electronics. Rubber gaskets and seals carry the meaning of solving an imperative need to present solutions for any place in which there must not be an alternation in terms of durability and performance. Rubber gaskets and seals are specifically engineered to exactly meet the needs of their applications.

It ensures that the rubber gaskets and seals can accommodate various conditions such as high or low temperatures, pressures, and chemicals. Typically, these products will be made from materials of quality, such as natural rubber, silicone, and EPDM, which offer a unique combination of flexibility, resilience, and resistance to environmental stressors. The Global Rubber Gaskets and Seals market can be regarded to have a dynamic nature with increasing demands for more advanced, customized solutions over time as the importance of operational efficiency and sustainability in industries rises. This market serves diversified end-use industries with unique needs. For instance, the automobile sector consumes rubber gaskets and seals owing to the necessity to safeguard the performance of its internal combustion engines and good mileage.

The oil and gas industry needs rubber gaskets and seals for high-pressure applications, especially when the temperature is very high; in the electronics field, rubber gaskets and seals are vital to prevent dust, moisture, or other external factors that may come to sensitive parts.

This diversity of applications underlines the versatility and importance of the Global Rubber Gaskets and Seals market. Market manufacturers are opting for high-tech technologies to create products that strictly follow industry standards and regulations. Right from the use of high-end simulation software in the optimization of design to integrating eco-friendly materials, innovation at every point will be witnessed by the industry. Further, the automation and digitalization of the manufacturing process will result in efficient production processes and more consistency in product output, which will help in reaching the maximum level of innovation in the Global Rubber Gaskets and Seals market.

This market has an established player presence and new entrants. The companies are heavily investing in research and development for introducing high-performance products catering to the evolving needs of various industries. Market participants will also use collaboration with end-user industries for co-development initiatives, thereby ensuring that the solutions offered by them are perfectly aligned with customer needs.

As global industrialization expands, the Global Rubber Gaskets and Seals market will remain one of the cornerstones of manufacturing into the future. Its adaptation to the changing landscape will define the future of its journey. For all of these reasons, the future market promises to hold in high regard its importance due to the relentless pursuit of efficiency and innovation, which shall not allow it to be dropped off from the checklist of essential components by the industries.

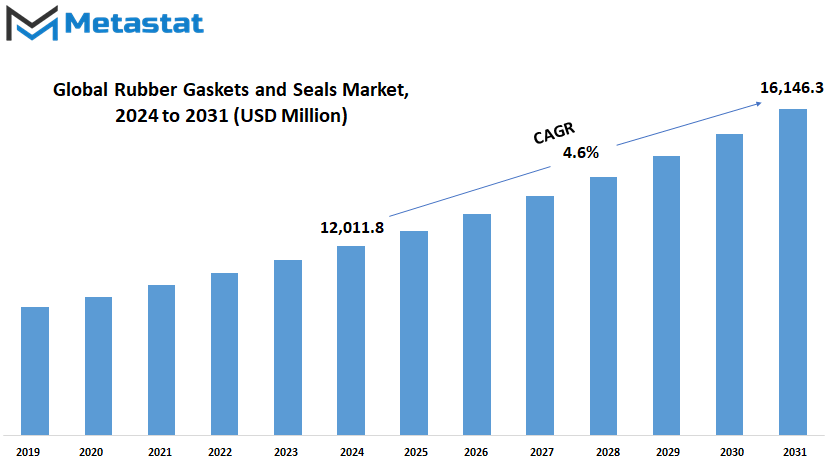

Global Rubber Gaskets and Seals market is estimated to reach $16,146.3 Million by 2031; growing at a CAGR of 4.6% from 2024 to 2031.

GROWTH FACTORS

The Global Rubber Gaskets and Seals market is expected to grow significantly because various industries are demanding more and more reliable sealing solutions. The automotive and aerospace industry is constantly evolving, increasing the demand for products enhancing performance and safety. Thus, rubber gaskets and seals are essential for achieving efficiency, minimizing leaks, and ensuring the longevity of all critical components. These features make them a must in environments requiring high precision and reliability. This is further supported by the increased industrialization and infrastructure development, where fluid containment systems are essential for smooth running. The increase in global infrastructure projects has amplified the need for high-quality gaskets and seals, especially in construction, oil and gas, and manufacturing sectors.

Such projects require durable solutions to withstand harsh conditions, making rubber gaskets and seals the preferred choice. Increased adoption of electric vehicles and renewable energy systems also present major opportunities for specialized products. With a shift to alternative energy sources, these materials will likely see an uptick in usage for their adaptability and performance in certain environmental conditions. The increasing investment in renewable technologies will make the specialized gaskets and seals even more important in ensuring durability and efficiency. Despite this promising future, the market still faces challenges.

The main challenge facing the market is volatility in raw material prices. This has a direct effect on the production cost and pricing strategies of manufacturers. Such fluctuations may impede profitability for manufacturers and complicate cost prediction. Besides these factors, other challenges include competition from alternatives such as thermoplastics and advanced composites. Thermoplastics and advanced composites are usually lighter, with specific advantages in various applications, thus reducing demand for rubber-based solutions. Nonetheless, the inherent properties of rubber, including flexibility and resilience, will continue to remain relevant in applications requiring better sealing capabilities. The future of the Global Rubber Gaskets and Seals market will also be dependent on technological advancements.

Innovations in creating better material performance and reducing environmental impact are bound to fuel growth. It is expected that companies investing into research and development to bring out eco-friendly and high-performance products will be leading the pack. The future of the market is bright due to the transformative trends such as sustainability and efficiency within industries in the coming years. It will significantly expand the market as challenges are addressed and opportunities which have just emerged are seized by catering to evolving industry requirements and contributing to global industrial progress.

MARKET SEGMENTATION

By Material Type

The Global Rubber Gaskets and Seals market is slowly but surely gaining importance as industries become increasingly concerned with efficiency, durability, and sustainability in their operations. These crucial components ensure tight seals and effective insulation in an extremely wide range of applications from automotive to manufacturing and construction. Advances in materials science and changes in industrial requirements will make this market transform significantly, promising innovative solutions for challenges that require precision and reliability.

By material type, it provides a wide range of different types, each aimed to fulfill particular needs and environments. Natural rubber is elastic in nature and thus ideal for applications where low cost alternatives are needed. On the other hand, nitrile rubber, abbreviated NBR, is very suitable when oils and fuels resistances are required. Such resists are widely applicable in automotive and petroleum-based products industries. The silicone rubber, valued for thermal stability, has its usage in high-temperature extreme seals applications. While EPDM, the weather resistance characteristic makes it quite valuable for being widely appreciated.

Fluoroelastomers (FKM) are characterized by excellent chemical and heat resistance and have a huge demand in aerospace and industrial applications. Neoprene rubber has durability and good resistance to weathering. Styrene-Butadiene Rubber (SBR) is relatively inexpensive with consistent performance. Polyurethane gaskets and seals are in demand due to its strength and versatility, mostly used in heavy-duty equipment.

As industries advance, the Global Rubber Gaskets and Seals market is expected to experience a higher demand for materials safe for the environment. Some of the sustainable practices and innovations that will likely play a role in shaping this market include biodegradable or recyclable rubber product development. Also, improvements in automation and smart systems that are being introduced into the manufacturing process are expected to influence innovations in gasket and seal designs to suit better with high-precision machinery.

As the global presence of industries grows, the role of materials will always lie in flexibility and reliability-able to change with almost every situation. The importance of investing in research and development will also continue for future breakthroughs in terms of materials and manufacturing technology.

The Global Rubber Gaskets and Seals market is poised to not only sustain but also enhance its importance as industries embrace efficiency and innovation in the years ahead. Its materials and solutions will undoubtedly shape the future of numerous industries worldwide.

By Product Type

The Global Rubber Gaskets and Seals market will see a huge growth as most industries worldwide continue to require high-performance sealing solutions. Such parts are critical for ensuring safe and efficient machinery and equipment, hence their use is crucial in all sectors such as automotive, aerospace, manufacturing, and construction. The market has segmented into gaskets and seals, differentiated according to respective purpose but all addressing the need for strength and flexibility and resilience to harsh conditions.

Gaskets are prepared to seal leakage as they fill up the gap between two or more surfaces. They are generally used in equipment which needs accurate sealing. Applications like engines, pumps, and pipes include such examples. On the other hand, seals are used for sealing off or restricting movement of fluids within a dynamic system which can be either a shaft or rotating members. Both these products play a vital role in smooth working of the system and risk-free operation of equipment.

Advancements in materials and manufacturing processes are determining the future of the Global Rubber Gaskets and Seals market. Innovative ideas of high-performance elastomers, and customized designs are letting these products meet the up-coming demands for resistance applications of high pressure and temperature. Besides, the increase of automation in industries has led to a growing demand for durable sealing solutions that will assure proper functionality of complex machinery. To this end, manufacturers of rubber gaskets and seals designed them to be environmentally friendly as the industry turns its pages on efficiency and sustainability.

Such products include biodegradable and recyclable ones are, of course, the most common examples. The future of the Global Rubber Gaskets and Seals market also lies in its ability to satisfy emerging trends. The automobile industry is shifting toward electric and hybrid vehicles, with the demand for specific sealing solutions for battery packs and cooling systems. In addition, increasing renewable energy projects such as wind turbines and solar farms require tougher sealing products that can sustain harsh environmental conditions.

As industries continue to develop, the demand for strong, affordable, and hardy rubber gaskets and seals will only increase. There are companies that focus on innovation and sustainability, which, if leveraged well, can have a good chance of emerging as competitive advantages. The market where research and development is focused and emphasized also tends to increase, bringing various opportunities to manufacturers and suppliers across the globe. Steady demand with technological advancements ensures that the Global Rubber Gaskets and Seals market will remain a key player in supporting industrial progress.

By End-Use Industry

The Global Rubber Gaskets and Seals market will experience tremendous growth because most industries worldwide continue to require high-performance sealing solutions. Such parts are critical for ensuring safe and efficient machinery and equipment, hence their use is very important in all sectors including automotive, aerospace, manufacturing, and construction. The market has segmented into gaskets and seals, differentiated according to the respective purpose but all addressing the need for strength and flexibility and resilience to harsh conditions.

Prepared to seal leakage by filling up the gap between two or more surfaces, gaskets are generally applied to equipment that requires exact sealing. Examples include such applications as engines, pumps, and pipes. On the other hand, seals are used for sealing off or restricting movement of fluids within a dynamic system which can either be a shaft or rotating members. Both these products hold a crucial position in smoother working of the system along with risk-free equipment running.

Advancements in the materials and manufacturing processes is determining the future of Global Rubber Gaskets and Seals market. Innovative ideas of high-performance elastomers, and customized designs allow these products to meet upcoming demands for resistance applications of high pressure and temperature. Furthermore, the advancement of automation in industries gives a high demand for reliable sealing solutions that will provide proper functionality of complex machines.

In line with these efforts, manufacturers of rubber gaskets and seals crafted these to be friendly towards the environment as the industry starts to turn pages in their efforts toward efficiency and sustainability. This naturally means biodegradable and recyclable are amongst the most common examples of products in this field. Satisfying emerging trends forms one part of the bright future for the Global Rubber Gaskets and Seals market. There will be a shift in the automotive sector toward electric and hybrid automobiles, where specific sealing products for battery packs and cooling systems would gain importance. Furthermore, expanding wind turbines and solar farms that generate renewable energy necessitate more robust sealing products which can withstand severe environmental exposures.

As industries continue to evolve, the demand for strong, affordable, and hardy rubber gaskets and seals will only surge. There are companies that focus on innovation and sustainability, which, if leveraged well, can have a good chance of emerging as competitive advantages.

The market where research and development is focused and emphasized also tends to increase, bringing various opportunities to manufacturers and suppliers across the globe. Steady demand with technological advancements ensures that the Global Rubber Gaskets and Seals market will remain a key player in supporting industrial progress.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$12,011.8 million |

|

Market Size by 2031 |

$16,146.3 Million |

|

Growth Rate from 2024 to 2031 |

4.6% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

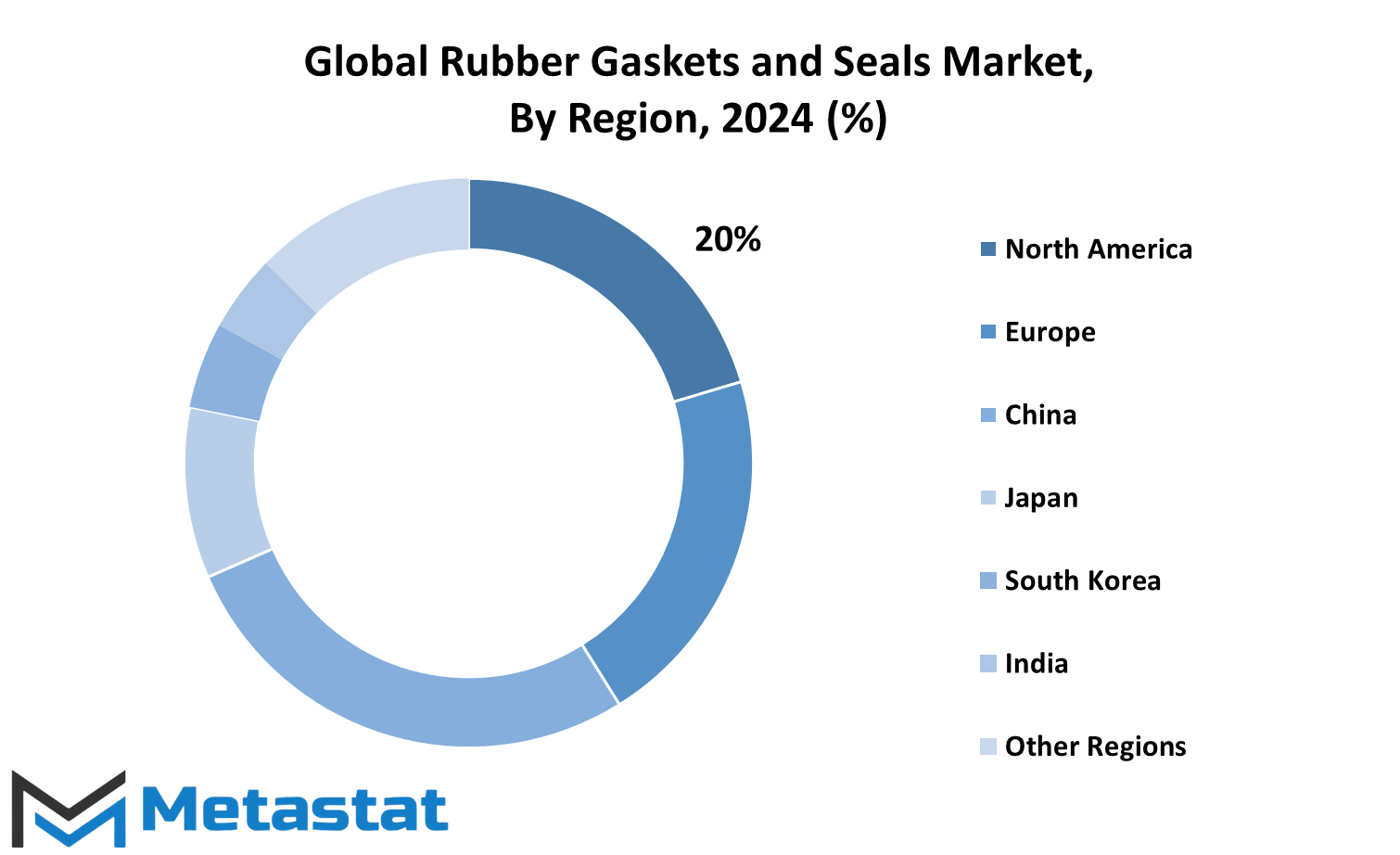

REGIONAL ANALYSIS

The Global Rubber Gaskets and Seals market is a dynamic sector and plays a very important role in many industries. The growth pattern of this market can be seen to differ due to the economic development of the region, industrialization, and technological advancements in some of the regions. Geographically, this market can be divided into North America, Europe, Asia-Pacific, South America, and Middle East & Africa. With each region bringing something new and posing challenges, it finally shapes the overall course of the market.

The market in North America gains strength from well-established markets in automotive, aerospace, and manufacturing. The U.S is leading the region, spearheaded by industrial automation improvement and the growing demand for hard, high-performance sealing. Canada and Mexico are seeing steady growth due to increased infrastructural and industrial investments.

Europe, with its strong industrial backbone, is another important region in this market. The UK, Germany, France, and Italy are key players due to the strength of the automotive and mechanical engineering sectors. The focus on sustainability and innovation in these countries is the driver behind the demand for green and efficient rubber gaskets and seals. The rest of Europe, being very different in terms of industrial capability, contributes to the market through localized production and niche applications.

Asia-Pacific is emerging as a key growth hub, with countries such as China, India, Japan, and South Korea spearheading the market. Rapid industrialization, urbanization, and the expansion of manufacturing activities are propelling demand. China’s dominance in automotive and electronic manufacturing, coupled with India’s growing infrastructure sector, creates opportunities for the adoption of advanced sealing technologies. The rest of the region benefits from ongoing industrial investments, especially in Southeast Asian countries.

South America presents a mix of opportunities and challenges. Its central markets include Brazil and Argentina, led by agricultural machinery, automotive production, and energy industries. Economic swings sometimes affect growth, but these are in the long-term promising as infrastructural improvements and government initiatives take the lead.

The Middle East & Africa region is driven by the oil and gas industry, as well as construction and manufacturing activities. GCC countries such as Saudi Arabia and the UAE are major contributors to the growth, with heavy investments in industrial projects. Egypt and South Africa also provide opportunities for growth, as industrial equipment demand increases and infrastructure continues to expand.

Future aspects of the Global Rubber Gaskets and Seals market rely heavily on innovation, regional adaptations, and developments in the field of materials and technology. The industrial setting within each region will remain different, and the resultant evolution is the holistic and integrated world market.

COMPETITIVE PLAYERS

The Global Rubber Gaskets and Seals market is expected to increase steadily in the years to come, driven by innovations in industrial and automotive technologies. As industries grow, they look for better answers to maintain efficiency and durability, and rubber gaskets and seals play an essential role in ensuring safety and reducing leakage while enhancing equipment performance. They drive growing demand based on their broad-based application across various fields of use such as automobile, aerospace, oil and gas and construction. Leading firms, like Freudenberg Sealing Technologies, Parker Hannifin Corporation and Trelleborg AB continue to innovate in products with improved durability for continuous supremacy over others.

Quality Product With Improved Durability Product development of high quality along with long life so as to cater to industrial-grade requirement remains at the heart of this competition. For example, Freudenberg Sealing Technologies is invested into sustainable solutions and aligned its efforts with the global pursuit towards manufacturing processes that are non-destructive to the environment. Companies such as SKF Group and ElringKlinger AG use the concept of advanced materials and precise engineering to improve product dependability. Increasing concerns on the efficiency of energy production combined with strict environmental regulation propel innovation in this market segment.

Competitive Leaders

Hutchinson SA, Federal-Mogul Corporation, Saint-Gobain S.A. are researching materials that are not only durable but also recyclable and light in weight. These innovations keep the market relevant for a long time while satisfying the urgent need for sustainability. Dow Inc. and Dana Incorporated, among others, are developing solutions that provide superior heat and chemical resistance, enabling these critical components to have a wider range of applications. As industries evolve, collaborations and partnerships among key players are becoming a common strategy to accelerate growth and share technological expertise. For example, organizations like Timken Company and Klinger Limited are emphasizing joint ventures to expand their global presence and offer customized solutions. This collaboration trend is expected to strengthen the supply chain and drive innovation at a faster pace.

The demand of the market is likely to increase in the coming years due to the emerging economies where industrialization and urbanization are on the increase. Flowserve Corporation, James Walker Group Ltd. are some of the key players already positioning themselves in the market to take opportunities. Continuous innovation and a customer-focused approach in companies like Garlock Sealing Technologies and Victor Reinz are the keys to forming the future of the Global Rubber Gaskets and Seals market, in response to both traditional and innovative applications.

Rubber Gaskets and Seals Market Key Segments:

By Material Type

- Natural Rubber

- Nitrile Rubber (NBR)

- Ethylene Propylene Diene Monomer (EPDM)

- Silicone Rubber

- Fluoroelastomers (FKM)

- Neoprene Rubber

- Styrene-Butadiene Rubber (SBR)

- Polyurethane

By Product Type

- Gaskets

- Seals

By End-Use Industry

- Automotive

- Aerospace and Defense

- Oil & Gas

- Electronics and Electricals

- Chemical Processing

- Food and Beverage

- Water and Wastewater Treatment

- Pharmaceuticals

- Construction

- Industrial Machinery

Key Global Rubber Gaskets and Seals Industry Players

- Freudenberg Sealing Technologies

- Parker Hannifin Corporation

- Trelleborg AB

- SKF Group

- ElringKlinger AG

- Hutchinson SA

- Federal-Mogul Corporation

- Dow Inc.

- Saint-Gobain S.A.

- Dana Incorporated

- Timken Company

- Klinger Limited

- Flowserve Corporation

- James Walker Group Ltd.

- Garlock Sealing Technologies

- Victor Reinz (Mahle Group)

- EagleBurgmann (Eagle Industry Co., Ltd.)

- Flexitallic Group

- NOK Corporation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252