MARKET OVERVIEW

Global Process Separation Spiral Membrane Market Part of a much larger filtration and separation industry, it will find ways to advance across applications such as water treatment, food and beverage processing, and pharmaceutical manufacturing. These membranes with a spiral-wound configuration can achieve very high efficiency at the molecular level in the separation of molecules, and at the same time, be ensured of being pure and sustainable. As industries become more conscious of the environment and resource-saving, the demand for effective separation technologies will definitely rise, and the Global Process Separation Spiral Membrane market shall lead this change.

The design feature of spiral membranes will be its compact structure for substantial surface area in a limited footprint. This innovation will make operation more efficient and therefore very attractive to many industries. In the coming years, companies will invest in developing new research and development, membranes with advanced selectivity, permeability, and fouling resistance that most improve performance under challenging conditions. The attention on innovations will result in new materials and fabrication techniques that will further raise the superiority of spiral membranes in the application.

The Global Process Separation Spiral Membrane market will play a very important role in addressing the rising global water scarcity and pollution challenges in the water treatment industry. Because the cities are expanding and populations are growing, the demand for efficient wastewater treatment and potable water production will be increased. This will make it possible for communities to have access to safe and clean water through the efficient solution of desalination and advanced water treatment processes using spiral membranes. The integration of these membranes into existing infrastructure will equally prompt resource use efficiency, such that aligns with sustainability goals increasingly pursued by many governments and organizations globally.

The market for Global Process Separation Spiral Membrane in the food and beverage industry will improve production as well as quality of different products. This membrane will allow processes like juice clarification, milk processing, and beer production. They will also ensure the manufacturers have a higher yield and intact product. The component separation capability will make the process of production more efficient, less wasteful, and increase the overall efficiency, making spiral membranes a crucial tool in food production. As the consumption of healthier and more natural products continues to gain momentum, the market for effective separation technologies will be driven by this trend; hence, the foundation for this market is crucial.

In this respect, even the pharmaceutical industry undergoes a complete turn around with Global Process Separation Spiral Membrane market. Spiraling membranes are used to purify and concentrate the active pharmaceutical ingredient for products that have stringent quality and safety demands. Increases in trends involving biopharmaceuticals and personalized medicine shall open new avenues for the utilization of spiral membranes because of their scalable solutions to the often-critical task of separation. They will improve drug manufacturing processes and support new therapies designed to meet unmet medical needs.

The global process separation spiral membrane market will prove to be the epicenter for sustainable and efficient separation technologies. Stakeholders will begin recognizing advantages of spiral membranes across various industries, thereby propelling more profound penetration and integration into current processes. Continuous advancements in membrane technologies will lead to increased productivity as well as environmental sustainability, thus opening oneself up to a future where separation technologies will prove to be more effective, reliable, and environmentally friendly.

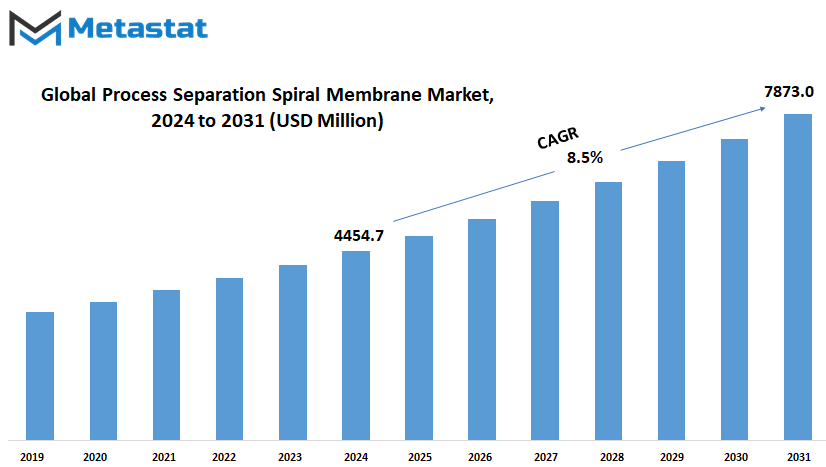

Global Process Separation Spiral Membrane market is estimated to reach $7873.0 Million by 2031; growing at a CAGR of 8.5% from 2024 to 2031.

GROWTH FACTORS

The Global Process Separation Spiral Membrane market is expected to rise in the coming years due to several factors. The increase in demand for clean water from various industries and the resultant growing needs for more efficient treatments of wastewater are two such factors. Since industrial growth does not grow steadily, the need for efficient separation processes never declines. As a result, the spiral membrane is one of the most significant entities. Another significant reason is the increase in environmental regulations being implemented by governments worldwide. This has made it imperative for the industrial sector to adopt practices friendly to the environment. Therefore, the growing interest in sustainable development is upping demand for separation technologies, which in turn is bolstering the growth prospects of the spiral membrane market.

However, there are also a few growth inhibitors that can be observed in the market. One major challenge remains that the setup and maintenance cost of these systems is rather high. It may be a considerable barrier for mass adoption of spiral membrane technologies among smaller-sized companies. The market is further constrained by lesser awareness among certain sectors about the benefits of advanced separation processes, thereby not helping the advancement of the market. Therefore, facing these challenges will be an important consideration for the continued growth of the market.

Future prospects for the Global Process Separation Spiral Membrane market include major opportunities provided by technology advancement. Nanotechnology and better material properties should improve efficiency and durability, meaning reduced operational costs and making the systems available to a larger number of industries. The circular economy and resource recovery are also gaining increased focus, creating an exciting opportunity for development. Innovations which would allow higher efficient reuse of water and materials will probably drive the market further ahead because the need to minimize waste and improve overall efficiency in operations propels the industries.

Key Players in Related Industries are Expected to Shape the Future of this Market, Including Halliburton, Baker Hughes Company, and Schlumberger Limited. Such companies have a history of innovation and thus can contribute to the development of innovation in the separation membrane sector through their best knowledge and resources. Most certainly, cooperation between these well-established industry leaders and emerging providers of technology will make significant contributions to the growth of new solutions.

Despite several drawbacks, the Global Process Separation Spiral Membrane market is expected to grow at a rapid pace. It finds more profound growth as people are demanding high innovation and sustainability-based separation solutions. Constant technological advancements support lucrative business opportunities in the industry. The future prospects look exciting and full of promise.

MARKET SEGMENTATION

By Type

The Global Process Separation Spiral Membrane market is growing with a lot of advancements and innovation that shape its future. It also separates its markets depending on types of spiral membranes, namely, Reverse Osmosis (RO), Nanofiltration (NF), Ultrafiltration (UF), and Microfiltration (MF) membranes. Each of the technologies has a specific function in line with the filtration level required. RO membranes can be termed as the most frequently applied membranes for eliminating salts and other contaminants from water. It offers a very high level of filtration. The two different membrane systems are of NF and RO. The main variation is that NF enables membranes to separate ions selectively. These are useful for water softening industries and food processing industries. In general, UF membranes are utilized for separating larger particles, including bacteria and proteins, whereas MF membranes are suitable for filtering even larger particles such as sediment and suspended solids.

As the world industries expand continuously, there will be continuous growth in the demand for clean water and efficient filtration systems. It is in this direction that the Global Process Separation Spiral Membrane market is likely to move ahead in the future. The growth of demand for fresh water in developed countries as well as developing countries has compelled industries to use more sophisticated filtration technologies. Environment regulations and increased concern about sustainability drive the market as companies try for efficient solutions to cut waste and increase water recycling.

Most probably, the future of this market will be driven by technological advancement. New materials and designs may come up for spirals in order to improve their durability as well as efficiency. More efficient spiral membranes are likely to offer support toward new applications in an even broader range of industrial sectors. The increasing pressure to reduce energy consumption during filtration processes is also likely to stimulate the search for new ways of improving performance and lowering operational costs for manufacturers.

High potential market sectors include pharmaceutical, food and beverage, and chemical processing. These industries need more complex filtration technologies. Such an increase in demand will fuel growth in the Global Process Separation Spiral Membrane market once again. More crucial, however will be the role of advanced filtration systems in more specialized industries where the demand for higher purity levels increases.

The Global Process Separation Spiral Membrane market will exhibit continuous growth as the industries keep demanding more efficient filtration processes. With improved membrane technology and sustainability towards cleaner water, this market shares its future with trends that go even higher towards awareness and sustainability.

By Application

Global Process Separation Spiral Membrane Market and Industry Overview In the next few years, the growth in the Global Process Separation Spiral Membrane market will be moderate because of more sophisticated filtration and separation solutions being needed in various industries. One application for this process is the production of high-purity water, particularly in the field of microelectronics, in which ultra-clean water is needed in the production of microchips, a demand that is likely to be higher with the increasing rate of technological advancement. Removing impurities at a microscopic level will be vital in ensuring the high performance and reliability of electronic components. This demand is likely to significantly boost the Global Process Separation Spiral Membrane market.

This technology is also crucial in desalination for industrial purposes. The world is already facing a serious scarcity of water and is likely to worsen with time, which means a tremendous number of industries would look for ways to convert sea water to usable fresh water. Removing salt and filtering out other contaminants-are successful processes of this spiral membrane, which makes it a critical tool to combat the continuously growing requirement for pure water in various industrial operations. The demand for this application is bound to increase more due to further expansion by industries around the globe.

Another application of chemical manufacturing through process separation is the separation of chemicals using spiral membranes. This ensures that products are of quality. Higher demand for chemicals followed by increasing predictability in separation technologies will be the crucial aspects that will form a part of process streamlining in industries, which will dominate the markets in the future. Related to this aspect is an increase in complexity and the need for more precision, which will also be reflected in the chemical production sector in the near future.

Filtration is an essential process in the food and beverage industry to preserve the quality and safety of it. Spiral membranes filter out impurities in products, as well as compliance with health and safety measures are realized. Companies are expected to embrace advanced filtration technologies as demand for higher-quality food and beverages increases amongst consumers, because it will meet customer expectations and fuel the growth of this market.

In terms of sectoral growth, pharmaceutical and biotechnology filtration is growing in its application of spiral membrane technology. The changing face of the healthcare industry has made drug production require more clean, safe, and precise filtration processes. Subsequently, coupled with advances in biotechnology, this trend may take the market for spiral membranes even further ahead in the years to come.

Filtration of process streams in power generation is a high-value process, critical for sustaining energy systems at the highest efficiencies possible. And as demand for energy will rise all over the world, filtration needs will grow and fill this support for continued market expansion.

By End User

Its wide applications in various industries related to this production are the primary reason why the Global Process Separation Spiral Membrane market is likely to grow in the following years. Majorly, the most common application sector where the membranes are used is in microelectronics manufacture. Increased demands and requirements for microelectronics manufacturers are made on miniaturized electronic units, and they would continue to require advanced filtration technologies. The spiral membranes are considered among the greatest assets in ensuring the steps carried out in producing these parts are clean and highly efficient. This way, quality standards for the final product will be quite high.

Another large market for chemical manufacturers includes the fact that such manufacturers rely on these spiral membranes to separate and purify substances in the production of other products too. With the increased importance of sustainability, the chemical industry is expected to invest more in technologies that are centered towards more efficient usage and less waste. What makes the spiral membrane system a very attractive technology for chemical processes is the ability to operate cost-effectively. This technology will form the heart on which chemical companies will continue meeting these hard environmental regulations as the chemical industry continues on its move towards making things more eco-friendly.

Third, food and beverage manufacturers are the other critical types of end-use customers. Filtration in this industry is a critical parameter for quality, especially for its interaction with product safety and shelf life. Now that consumers are becoming increasingly health-conscious and demanding higher standards of safe production protocols, companies in this line of business would look more toward using spiral membranes and other high-tech filtration systems to raise their efficiency in production processes.

Another significant customer will be pharmaceutical and biotech companies. The new drugs and therapies will continue to rise and create a demand for the high-performance filtration systems. Spiral membranes pride themselves on their precision in separating and purifying substances, which makes them a necessity for pharmaceutical products to ensure their effectiveness and safety. Biotechnology, with its new therapeutic and consumer products, will further heighten the demand for these membranes.

Another significant end user is power generation facilities, which need efficient separation technologies for clean water supplies and avoid waste. As the world shifts toward more renewable sources of energy, these facilities will most likely require complex separation solutions for optimizing their processes.

This Global Process Separation Spiral Membrane market is projected to continue growing, with an ever-increasing dependence on all diversified industrial applications. The technology will be driven by a need for more precision, sustainability, and efficiency and generate broad streams of demand throughout different sectors and open up the path to further innovation and growth.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$4454.7 million |

|

Market Size by 2031 |

$7873.0 Million |

|

Growth Rate from 2024 to 2031 |

8.5% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

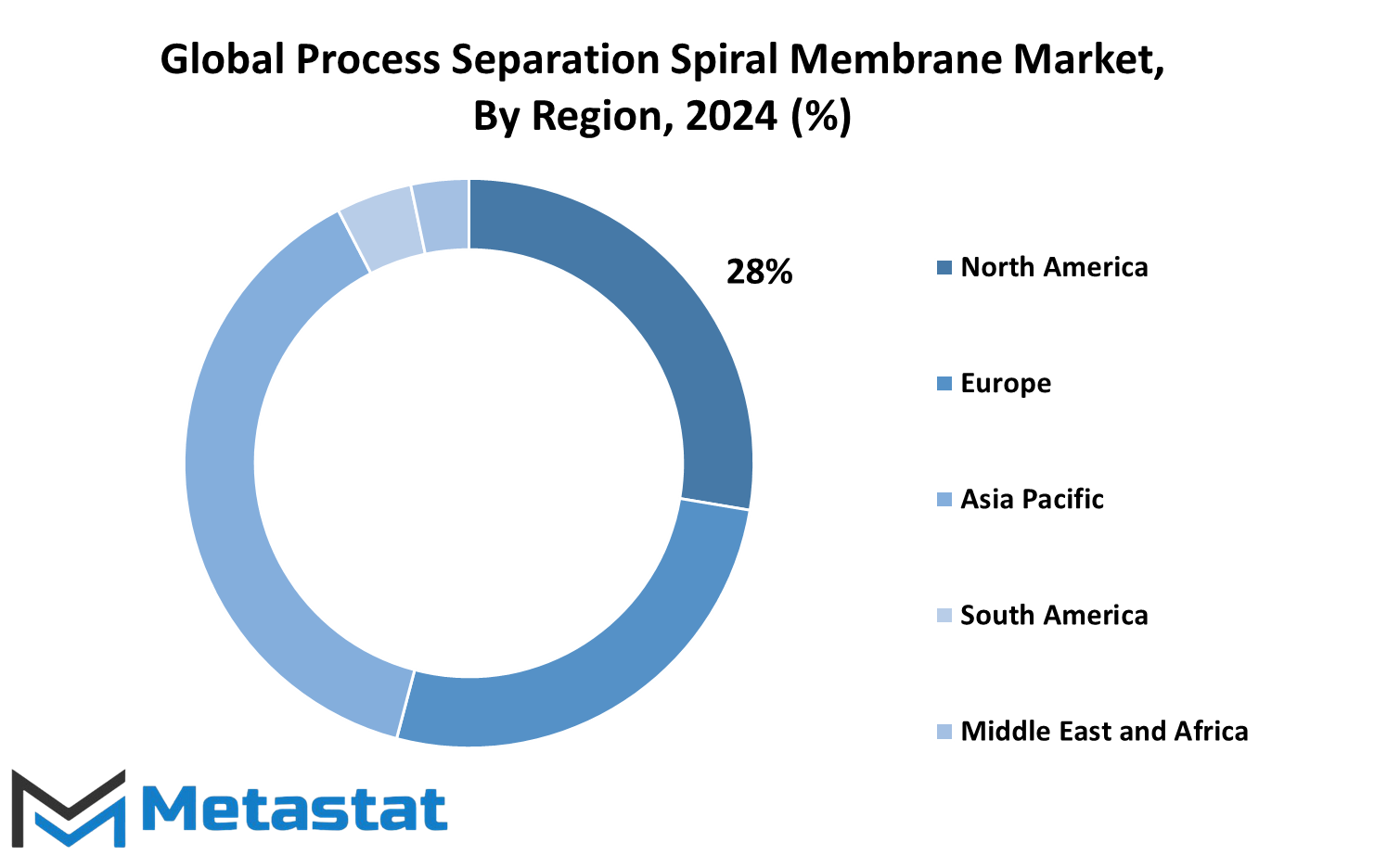

The Global Process Separation Spiral Membrane market across various regions remains promising for growth in the near future. This will be primarily because of the increasing demand for efficient technologies in filtration, such as water treatment processes, food and beverage industries, and pharmaceutical industries. Regional Analysis of this market indicates important areas of growth to be expected, stimulated by economic as well as industrial development.

Growth in North America The North America region is going to experience growth at a steady rate due to the fast development of its industrial sectors, mainly in the U.S. and Canada. The region focuses on water treatment processes and has also maintained very strict environmental regulations, making them rapidly adopt advanced separation technologies. Mexico is also bound to contribute to this volume of growth due to the modernization of industries in the region. Fuel to the fire will be an upsurge in demand for clean water and efficient waste management in this region.

The other region for consideration is Europe. This is because Europe plays a crucial role in the Global Process Separation Spiral Membrane market. Germany, the UK, and France are at the forefront, taking the lead in the implementation of sustainable principles to their industrial processes. Emdorsement of sustainability in the European market along with stringent environmental policies, is likely to propel demand for separation technologies. Pharma, chemical, and food processing industries are scaling and voluming up, which will require advanced filtration techniques, making the European Market continue its growth trajectory.

Asia-Pacific: The market here is going to soar at a rapid rate. Countries like China, India, and Japan are going to take lead here. Along with industrialization and urbanization comes an increasingly critical environmental issue: water pollution and industrial waste. A trend to be seen in the adoption of process separation technologies arises here as these countries seek to resolve these issues while at the same time increasing their output in the industrially productive sector. Efficient filtration that does not break the bank will be critical to the future growth of this market in the region.

South America, specifically countries like Brazil and Argentina, is likely to continue at a moderate growth trend driven primarily by the development of industry and the urgent need for water treatment systems. The same can be said regarding the Middle East and Africa market, which will likely continue to be developed incrementally, taking into account the countries in the GCC as well as South Africa, where concerns over water scarcity and strong demands for clean water with effective waste treatment practices are becoming more sensitive.

This will see a considerable growth in the Global Process Separation Spiral Membrane market as each region will continue to build on respective measures for every industrial and environmental need. The push for efficiency and sustainability in all sectors will ensure this market continues growing worldwide.

COMPETITIVE PLAYERS

The Global Process Separation Spiral Membrane market has a wide scope for massive growth, as the importance of superior technologies in filtration will dawn upon industries increasingly. Spiral membrane technology holds immense significance in the various sectors of water treatment, food and beverage processing, pharmaceuticals, and chemical manufacturing. Whenever separation processes become more efficient and more sustainable, key players will play a significant role in developing the future of membrane technology in the field.

Major players in Global Process Separation Spiral Membrane include Synder Filtration, Inc., DuPont de Nemours, Inc., and Veolia, Inc. These have been the leading producers in innovation in the market; their membranes result in performance enhancement while having as minimal effects on the environment as possible. For instance, Synder Filtration has several membrane solutions it offers depending on specific industrial needs, showing commitment to providing products tailored specifically for performance enhancement. In the same vein, DuPont de Nemours, Inc. taps into the complexity of its research capabilities to make membranes that not only increase efficiency but also endure harsh operating conditions.

Hydranautics is a part of Nitto Group, though it can differentiate itself because of significant presence in the market. The company has high-quality membrane products in line to support multifaceted applications and strictly adheres to stringent standards by industries throughout the world. Corporate AB Alfa Laval and Toray Industries Inc also known for their creativity in membrane technology and contributions will most likely define the future of process separation.

Pall Corporation and Fujifilm Group are some of the other prominent players in Global Process Separation Spiral Membrane market. Both of them support research and development seriously and continually innovate their product lines to suit the shifting requirements of customers. New Logic Research as well as PCI Membranes enhance the competition landscape by catering to niche markets in this industry through their specialized solutions.

The Global Process Separation Spiral Membrane market will probably face improvement in the efficiency and sustainability of separation processes. Future growth in the industry will revolve around how responses to current market demands are formulated, as well as restructuring necessary for future requirements. Environmental responsibility will thus yield significant R&D effort with the goal of developing solutions that reduce waste and energy consumption.

This is going to result in a significant prospective growth in the Global Process Separation Spiral Membrane market in the short and long term. Since a number of giant companies have begun investing in technology and innovation, the prospect seems to be quite optimistic. This kind of intermediate effect will make these companies the leaders in the market as they would be promoting effective and sustainable operations

Process Separation Spiral Membrane Market Key Segments:

By Type

- Reverse Osmosis (RO) Spiral Membranes

- Nanofiltration (NF) Spiral Membranes

- Ultrafiltration (UF) Spiral Membranes

- Microfiltration (MF) Spiral Membranes

By Application

- High-Purity Water for Microelectronics

- Desalination for Industrial Applications

- Process Separations in Chemical Manufacturing

- Food and Beverage Processing

- Pharmaceutical and Biotechnology Filtration

- High-Value Process Stream Filtration in Power Generation

By End User

- Microelectronics Manufacturers

- Chemical Manufacturers

- Food & Beverage Producers

- Pharmaceutical and Biotech Companies

- Power Generation Facilities

- Other Industrial Application

Key Global Process Separation Spiral Membrane Industry Players

- Synder Filtration, Inc.

- DuPont de Nemours, Inc.

- Veolia, Inc.

- Hydranautics (A Nitto Group Company)

- Alfa Laval Corporate AB

- Toray Industries, Inc.

- Pall Corporation

- Fujifilm Group

- New Logic Research

- PCI Membranes

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383