MARKET OVERVIEW

The Global Post-Tensioning Products market is part of the construction industry, imparting evolving trends and concepts in structural engineering and major infrastructural works. They serve great assistance in enhancing concrete structures' strength, durability, and flexibility, putting them high on the list in projects that require high performance and longevity. As urbanization continues to alter the face of the world, an even greater application of post-tensioning techniques in bridges, commercial buildings, and residential complexes is felt to be required. The market for Post-Tensioning Products extends far beyond conventional construction scenarios and encompasses highly specialized engineering domains such as nuclear power plants, stadiums, and subsurface structures, where maintaining structural integrity becomes an important issue.

The increasing demand for high-strength materials sufficiently able to withstand environmental and heavy loads has dictated the adoption of post-tensioning products. Solutions that enable longer spans with less use of material and better seismic resistance are what engineers and developers look for. That's where post-tensioning technology comes into play. Material innovation dictates advancements in product development, such as corrosion-resistant strands or smart monitoring systems capable of assessing structural health in real time. These advancements will enhance the service life of structures and lessen their long-term maintenance costs, thus increasing the attractiveness of post-tensioning solutions for project developers.

Another characteristic of the Global Post-Tensioning Products market is that, owing to rapid infrastructure development, it is gaining faster acceptance in those regions. In built-up urban regions where space restrictions bring about design solutions, post tensioning allows for thinner slabs and tall buildings without compromising safety. Advanced engineering software will now produce precise calculations, optimizing stress distribution across concrete members, thereby bettering performance and sustainability by saving on material consumption and construction waste.

The direction towards which design procedures and building codes are headed would probably shape the future of post-tensioning applications. As construction norms are becoming increasingly stringent, manufacturers and suppliers in the Global Post-Tensioning Products market will be pushed to adapt their offerings to suit industry standards and environmental considerations. Research on new bonding techniques and material composites could ultimately develop more sophisticated anchorage systems with higher load-bearing capacity. Nevertheless, construction automation will also simplify the installation process and allow post-tensioning to be extended to numerous other projects.

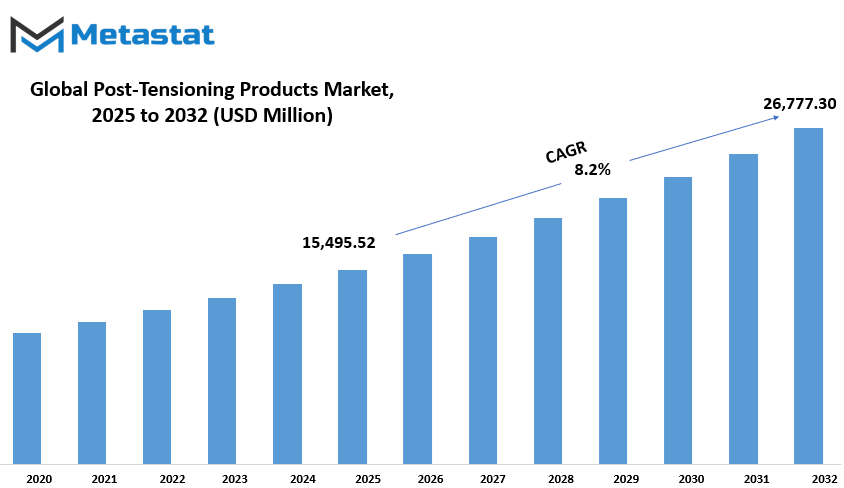

Global Post-Tensioning Products market is estimated to reach $26,777.30 Million by 2032; growing at a CAGR of 8.2% from 2025 to 2032.

GROWTH FACTORS

The Global Post-Tensioning Products market is growing owing, primarily, to an increase in demand for durable and economical construction materials. Rising infrastructure development, especially in developing countries, is increasing the demand for efficient methods of construction. In modern construction methods, post-tensioning products increase the strength of structures and the efficient use of resources. Post-tensioning finds application in residential, commercial, and industrial projects, where it provides feasible solutions for longer structures, bridges, and superhigh-rise buildings.

This infrastructure boom emphasizes highways, bridges, and urban development, and very aptly feeds into market expansion. The expenditure on construction is huge, be it government undertakings or private projects, to serve a growing population and economic demands. However, the communities are demanding post-tensioning systems so that these can provide longevity, low maintenance requirements, and overall safety for such infrastructure. Proponents of post-tensioning systems assert that while these are low in conventional reinforcement, they enable construction cost savings and hence maintain their market demand.

Challenges still remain that may hinder the growth of the industry. Post-tensioning systems have high installation and maintenance costs, causing concern among some builders. In large-scale applications, they cost relatively more than other systems of conventional reinforcement. Small construction firms may find these systems difficult or impossible to implement. Furthermore, poor or nonexistent systems installation and maintenance skills are yet another potential hindrance. Implementing post-tensioning systems requires people with the right training and expertise to assure structural integrity; without enough trained individuals, some areas may see a slower uptake.

The rise in sustainable construction practices gives the industry the other side of prospects. Post-tensioning products lead to green construction, which means less consumption of material and less carbon emissions. Along with the growing paradigm culture, now systems are being more incorporated by developers into projects for environmental compliance and overall cost savings. Technical enhancements in the field together with R&D would accelerate forward-looking innovations in post-tensioning that will focus on efficiency and market accessibility.

MARKET SEGMENTATION

By Type

The Global Post-Tensioning Products market is steadily advancing in the trend of advanced-solution amperage of structural reinforcement across various industries. These products play a vital role in ameliorating maintenance and load-bearing capacity of structures, including buildings, bridges, and other infrastructure. The need for advanced and resilient post-tensioning systems in construction is also dictated by the construction of high-rise buildings, large-span bridges, and complex structures. Urbanization requires this merging of technology of developers or engineers to ameliorate resource use while the maximum structural performance is achieved.

Ranging from unbonded post-tensioning systems valued at $5,803.07 million for their flexible and ease of implementation to bonded post-tensioning systems that compliment force by restraining tendons within a protective layer of grout for durability, different types of post-tensioning systems are available to meet specific engineering requirements. Mono strand systems fall under the generally cheap category that seems to satisfy the needs for engineering and installation in floor slabs and parking structures in residential and commercial buildings. Multi-strand systems are usually considered for the heavy-load applications of bridges and large-scale industrial projects. Bar systems serve specific applications where precision and resistance to high stresses are required. Grouted systems tend to stabilize structures by providing protection against corrosion and better load transfer. Likewise, external post-tensioning systems serve very well for retrofitting and strengthening existing structures to extend service life and prevent deterioration.

Post-tensioning products will definitely find increased application as the standards for construction evolve. They afford cost-effective construction and sustainable development to engineers and developers in particular. Their role in reducing material consumption while maintaining strength is one of the reasons why they are now viewed as the optimum technology for modern infrastructure. Current advances in research and technology continue to fine-tune these solutions toward enhanced safety, installation, and performance over time. Thus, the Global Post-Tensioning Products market will, in the coming times, present confidence that buildings and infrastructures sustain the pressure exerted in relevance to a growing population and alternated environment.

By Material

The Global Post-Tensioning Products market now advances up to a point where industries are pressing hard on increasing strength and efficiency in structures. This market has numerous applications in the field of construction, where techniques involving post-tensioning are used for strengthening concrete structures to partake in the augmentation of loads and environmental conditions. Post-tensioning systems were established to meet the emerging demand for stronger and more durable infrastructures.

The post-tension core materials are selected for those satisfying the demand of high-pressure, flexibility, and effective reliability. Steel continues to be the prime choice, being very strong and durable. Most large-scale projects such as bridges, high-rise buildings, and tunnels require pure structural integrity adopted by various design elements and materials. Another example of someone who uses materials is galvanized steel; it has its reputation for full use and in combination with the outside structure, yet also offers more corrosion protection than steel made without galvanizing and is, therefore, particularly appropriate for humid and harsh surroundings. The third material, which scientifically counts as non-rust and longer-life metal, is termed stainless steel; it is generally used in structural buildings meant for long life with least maintenance.

Polyethylene (PE) and High-Density Polyethylene (HDPE) have added themselves to the list of elixirs for protection in post-tensioning mostly. They also serve as barriers that keep steel tendons safe from external forces that might deleteriously affect their performance as time goes by. In modern methods of construction, they are important since they are light, flexible, and can withstand attack from chemicals. Structural concrete is the major component in constructing post-tensioning systems which act as the solid base for applied tensioning forces.

There will be an increasing demand for high-performance materials, and it will continue to shape the Global Post-Tensioning Products market. Now, durability and cost efficiency are the focuses of infrastructure works laying all over the world. Manufacturers are being pressed to innovate for structures with enhanced stability. The speed with which urbanization develops, indeed goes together with the number and quality of strong buildings required. Therefore, advances in post-tensioning materials would always be the concern of present-day modern engineering challenges.

By Application

In present times, the Global Post-Tensioning Products market has a critical role in providing better solutions to the buildings for structural integrity and durability improvement. The ongoing urbanization and demand for a robust infrastructure fuel the diverse applications of post-tensioning systems. These products provide an efficient method to reinforce concrete structures and free design for a designer; hence, it improves the load-bearing capacity and resistance from external forces. Since the trend of the construction industry is toward cost-effective and sustainable solutions, post-tensioning technology is one of such solutions to beat the challenge.

Bring about improvement in the structure performance and reduce material usage. Such applications are witnessed in very tall buildings, sophisticated bridges, even commercial complexes whereby lengths can be spanned without sacrificing strength. Adoption of this technology continues to rise, as it appeared, with the advent of modern architectural designs demanding such large spaces unencumbered by columns in the immediate vicinity. Cost advantages accrued to construction for safer, more durable structures will be recognized by engineers and developers.

In addition, the vast application area opened post-tensioning products for repair and rehabilitation. The post-tensioning systems will assist in restoring structures that have been damaged to their original strength to prevent further failure and lower their maintenance cost. Strengthening existing assets rather than going for a wholesale replacement has been the approach taken by governments and some private sector organizations in making investments within that focus.

It applies the post-tensioning technology to structural strengthening, making it broadly significant for projects increasing load-carrying capacities. These activities rely primarily on warehousing, manufacturing, and transportation industries providing fair representation of such reinforcements at structures for housing heavy machinery and great inventories along with strong traffic loads. Post-tensioning improves structural performance while accommodating few alteration requirements for many city and commercial applications.

The seismic retrofitting has now become a common practice in places where the earthquakes are likely to occur. Post-tensioning products contribute significantly to the fortification of structures against seismic forces and failure during natural catastrophes. The use of advanced tensioning techniques allows flexibility for buildings, bridges, and other critical infrastructure to be improved and, consequently, stability in earthquake-prone regions enhanced further.

By End-Users

The global market for post-tensioning products will be ascending to great heights, with possibly unprecedented numbers, due to the rising requirements for extreme durability and efficiency in construction. Such products are intended to preserve structures from deterioration due to internal forces, combined heavy external loads, otherwise intense or hostile environmental factors, and structural fatigue and failure. Urbanization along with infrastructural development is presently one of the most tangible contributions all post-tensioning systems have made across various constructions. Infrastructure developers and engineers have continued to trust this system since it allows the most efficient use of structures such as buildings, bridges, tunnels, and other vital infrastructures.

Post-tensioning products serve enhanced flexibility in design for the residential sector, which may subsequently allow open floor plans, larger spans, and thinner slabs without injury to the strength. Space-saving and durability-enhancing, these materials are being used more and more by homebuilders striving to maximize the utility of indoor environments in which life unfolds. For commercial buildings, it is very widely used among all the available states in high-rise structures, office complexes, and shopping malls-the places where loads have to be carried and uses to be maximally efficient. This makes PT very attractive as it provides a large economy for reducing quantities of materials while still maintaining strength.

The post-tensioning products also deal with floors of buildings factory, warehouse, and storage type, which have intensive loads pertaining to heavy machinery and equipment occupying the area. These products prove fruitful in ensuring that such floors could take a load and vibration without causing damage to them and safety and sustainability over time. Bridges and flyovers are greatly dependent on post-tensioning because, with this technique, they can build longer spans, offer low maintenance, and resist better the dynamic forces. Governments and private contractors keep investing funds into innovative post-tensioning solution-based projects, aided by the need for improved transportation networks.

Dams and reservoirs need to be constructed with cost-effective reinforced structures that can withstand a very large amount of water pressure coupled with environmental stress. Most of these large-scale projects take care of the long-term durability and safety of all constructed structures using post-tensioning products. Similar to above, tunnels and underground structures also derive benefits in strength and flexibility from the systems in terms of geological pressure and ultimate failure. Improvements in durability and reduced maintenance costs due to activity and changing loads have been guaranteed by post-tensioning in parking structures.

With time as the construction industry progresses, there shall come a time when the use of post-tensioning products will be widespread. Advanced solutions that would improve the structural efficiency of whatever they are building while decreasing the amount of material and money involved use these improvements.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$15,495.52 million |

|

Market Size by 2032 |

$26,777.30 Million |

|

Growth Rate from 2025 to 2032 |

8.2% |

|

Base Year |

2025 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

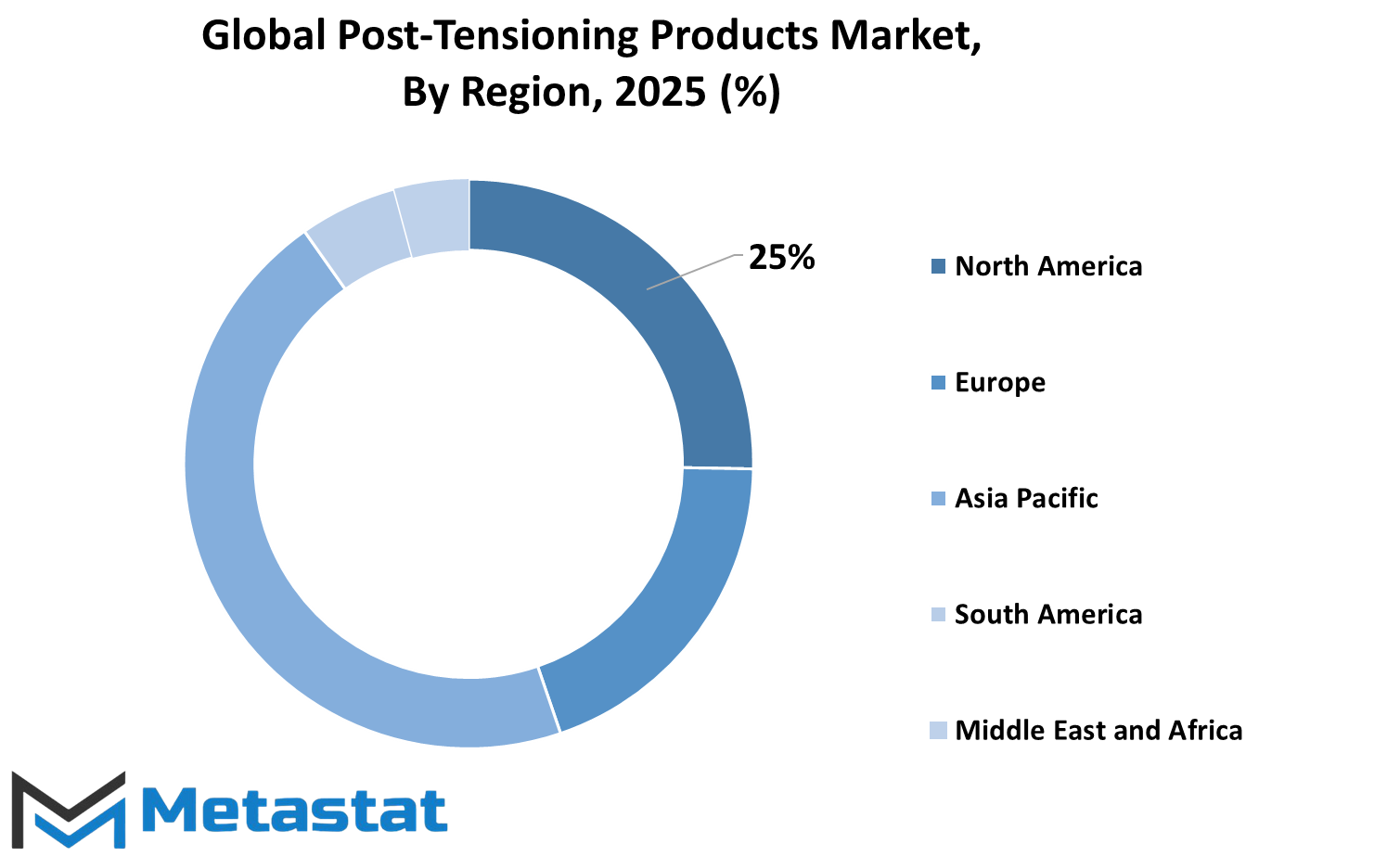

The Post-Tensioning Products global market is divided into various geographic regions, with each representing a significant area of demand: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. The North American region is further classified into the United States, Canada, and Mexico. Major markets in Europe include the U.K., Germany, France, and Italy; all remaining European countries are grouped as Rest of Europe. The Asia-Pacific region, one of the largest, includes countries such as India, China, and Japan, and exhibits other minor markets with names corresponding to Rest of Asia-Pacific.

Though small in comparison to others, South American markets for post-tensioning products also service major countries like Brazil and Argentina, plus a few more, conveniently grouped together as Rest of South America. The Middle East and Africa can be segmented in many ways: one being the GCC countries, which include Saudi Arabia and the UAE, one of the key areas here; other major markets include Egypt, and South Africa, along with Rest of Middle East & Africa.

Each of these regions has its own characteristic demand drivers for Post-Tensioning Products. A developed infrastructure market for these products will be based primarily on construction and civil engineering activities in North America. Europe still represents another important region in terms of construction and demand for advanced types of building materials. Rapidly growing infrastructure developments throughout Asia-Pacific would spur serious demand for Post-Tensioning Products, especially in China and India. South America has a growing base, but, compared to other regions, still remains fairly small; but with opportunities being opened by Brazil and Argentina, suppliers of post-tensioning products might just benefit from the South American opportunities. Lastly, the Middle East & Africa will see steady demand for Post-Tensioning Products, driven by large-scale construction and infrastructure projects.

The complete international market for Post-Tensioning Products, classified on a geographical basis, portrays differences in needs and levels of developments across various regions. This segmentation would show the industries in which to rest their strategies in order to harness the growth opportunities. Any region may be a driver of growth, therefore contributing to the overall growth of the Post-Tensioning Products market.

COMPETITIVE PLAYERS

The Global Post-Tensioning Products market continues to play an important part in modern construction with respect to the specified attributes of enhanced structural strength, durability, and flexibility. Because post-tensioning technology can serve fairly large areas of application in infrastructure projects, commercial buildings, and residential constructions, this technology is useful for increasing load-bearing capacity and decreasing the quantity of material use. However, on account of improvements in engineering techniques and a growing emphasis on sustainable construction, significant developments within the industry are being witnessed.

Key players within the industry continue to innovate, thus providing high-performance materials and solutions into the market. VSL International Ltd., DYWIDAG Systems International (DSI), Freyssinet, and Suncoast Post-Tension Ltd. are all recognizable names in the provision of post-tensioning systems. The efficient systems which these companies design improve structural integrity while minimizing costs to the client. Others, such as Amsysco Inc., BBV Systems GmbH, and TMG Global Pte Ltd. contribute to the market by offering specialized products tailored to different construction needs.

Post-tensioning is at the forefront in demand creation due to increasing urbanization and infrastructure development across the countries. Industries such as high-rise buildings, bridges, and transportation networks use these techniques for stability and durability. Furthermore, post-tensioning affords larger span with fewer supports, thus appealing to architects and engineers in search of efficient designs.

Environmental concerns are another influencing factor, as increased emphasis is placed on products with sustainable credentials. Advanced materials and better manufacturing processes are used to reduce the environmental burden of the post-tensioning products available on the market. Usually, companies like SRG Global Infrastructure Pvt. Ltd., OVM International Co., Ltd., and Multistrand Inc. invest further R&D to produce beyond mere sustainability toward high-performance products.

Changes mentioned in the previous paragraph have led to an increase in demand for reliable post-tensioning solutions worldwide with corresponding increased investment in infrastructure projects. The construction of resilient structures capable of withstanding all sorts of severe external pressure has become the focus of governments and private players, further boosting the market. Structural Group Inc. and Macalloy Ltd. are two companies advancing such heavy-duty post-tensioning technologies for diverse applications.

The technological advancement and collaborations will drive the growth of this market. Companies in this sector are putting in constant efforts to improve their product offerings in line with the ever-changing needs and demands of the construction industry.

Post-Tensioning Products Market Key Segments:

By Type

- Unbonded Post-Tensioning Systems

- Bonded Post-Tensioning Systems

- Mono Strand Systems

- Multi Strand Systems

- Bar Systems

- Grouted Systems

- External Post-Tensioning Systems

By Material

- Steel

- Galvanized Steel

- Stainless Steel

- Polyethylene (PE)

- High-Density Polyethylene (HDPE)

- Concrete

By Application

- New Construction

- Repair & Rehabilitation

- Structural Strengthening

- Seismic Retrofitting

- Precast Structures

- Offshore Structures

- Nuclear Containment Structures

By End-Users

- Residential Buildings

- Commercial Buildings

- Industrial Facilities

- Bridges & Flyovers

- Dams & Reservoirs

- Tunnels & Underground Structures

- Parking Structures

Key Global Post-Tensioning Products Industry Players

- VSL International Ltd.

- DYWIDAG Systems International (DSI)

- Freyssinet

- Suncoast Post-Tension Ltd.

- Amsysco Inc.

- BBV Systems GmbH

- TMG Global Pte Ltd.

- SRG Global Infrastructure Pvt. Ltd.

- OVM International Co., Ltd.

- Multistrand Inc.

- Structural Group Inc.

- Macalloy Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252