Jun 27, 2025

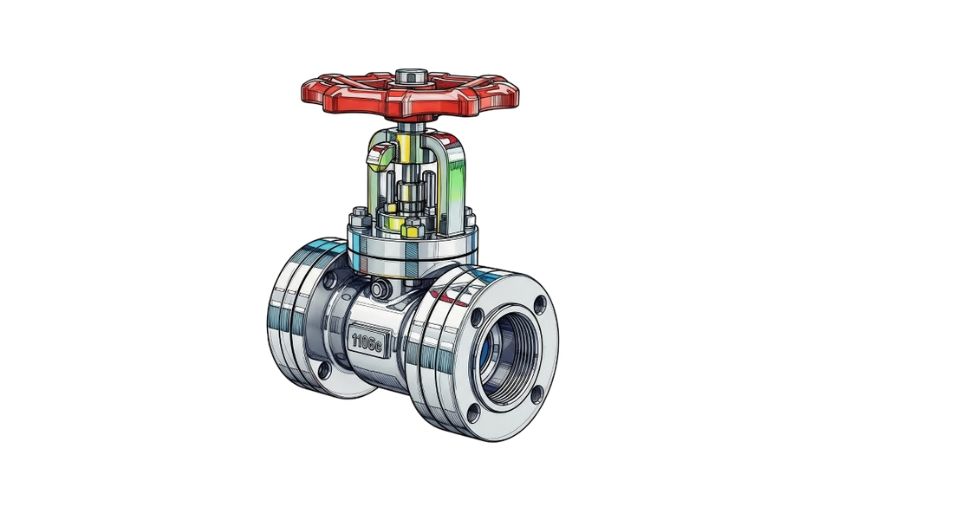

As emphasized in the report edited by Metastat Insight, the Global Sanitary Valves market has been growing in relevance for industries that have high levels of hygiene and contamination management requirements. The valve has increasingly become part of production setups where control of fluids and cleanliness is not just a preference but a matter of operations essentiality. The utilization of sanitary valves has become increasingly significant in industries like food processing, dairy, pharmaceuticals, and biotechnology, where accuracy, longevity, and cleanability are deal-makers to success.

Global Sanitary Valves market is estimated to reach $1,890.90 million in 2025 with a CAGR of 4.2% from 2025 to 2032.

Hiding at the center of this market is necessity for equipment that does not simply meet its mechanical purpose but also compliance with stringent regulatory standards for safety and sanitation. These valves are planned so as to minimize the risk of contamination, ensuring easy passage and regulation of liquids and gases without adding foreign particles or bacteria. Their design, frequently using materials such as stainless steel and seals of food-grade elastomers, demonstrates attention to preventing residue accumulation and promoting easy sterilization. With rising global standards in production environments regarding hygiene, companies are more keenly focused on the machinery that underpins their operational base.

Where sanitary valves are distinguished from traditional ones is not just in materials, but also in the extent of design detail specific to application. Whether in a dairy line moving milk or a pharmaceutical facility moving chemical blends, the configuration of the valve needs to be appropriate to the process lest there be delays in operation or compromise of quality. Suppliers are reacting with specialized products, designed to operate under varied pressures, temperatures, and flow conditions. This product-specific detail contributes to the level of depth and breadth in the Global Sanitary Valves market.

Technology is playing its part in this market in subtle yet influential ways. Whereas digitalization is not the first thing one might think of when considering valves, intelligent process control systems increasingly need parts that would integrate into automated systems properly. This need has driven the development of sanitary valves that can provide performance data, accept control signals, or even signal operators to perform maintenance. The incorporation of such features enables manufacturers to run more effectively and minimize downtime a crucial factor in determining operational priorities.

Local differences also have played a role in structuring the market. In regions of the globe where robust food and drug regulations are already entrenched, firms long have accepted leading-edge valve technologies. At the same time, in emerging markets, domestic producers and manufacturers have an infection to move to global standards to reach broad markets. As a result of this effort, the demand for sanitary valves has increased, which conform to global expectations, leading to new trade opportunities for suppliers from various geography.

Even with Rosie possibilities, ensuring stability in the quality of production is a complex issue for manufacturers. The sanitary nature of the valve demands careful craftsmanship because small flaws may result in control or hygiene failure. The accuracy of production, carefully testing and quality control should be maintained along the production line. Therefore, manufacturers are investing not only in materials and designs but also in production methods that allow more accurate assembly and inspection. All these developments work to strengthen the trust of customers working within sensitive industries.

No one can ignore the role of regulatory systems in determining demand. Sanitary valves, being technical items, have their application more intimately connected with public health issues. The instruments applied in consumable goods manufacturing are strictly controlled by international agencies and domestic authorities. Production companies have to make frequent changes in their products to meet such requirements that often keep changing over time. This creates a constant re-evaluation of product lines and a steadfast commitment to conformity that extends far beyond performance.

Market relationships also determine how this industry evolves. End-users of sanitary valves are often closely involved with producers in designing solutions specific to given industrial processes. These relationships extend beyond initial sale and into training, maintenance, and extended technical support. The outcome is a product ecosystem founded not only on transactional supply but sustained interaction and mutual priorities. Such partnerships are a subtle yet influential force for innovation and quality of service in the industry.

Summing up based on the observations from the report prepared by Metastat Insight, the Global Sanitary Valves market remains to play an indispensable role in industries where cleanliness and accuracy are not separable from success. With greater focus on safety and efficiency, these valves have become more than parts they are pillars to the integrity of entire processes. As the demand continues to increase and the standards get tighter, the industry is on a consistent trajectory of refinement, guided by a combination of engineering expertise and application-specific innovation.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479