MARKET OVERVIEW

The Global Polymer Fillers market encompasses its industry as an important sector in the broader realm of materials where the properties and performance made possible with polymeric products are significantly improved. The area relates to the advancement, manufacture, and use of fillers that are mixed in polymer matrices for strengthening, durability, lighter in weight and cost-effectiveness. These materials offer critical applications in the sectors of automotive, construction, packaging, and electronics and can be very flexible solutions for changing manufacturing needs.

The broadest scope of the Global Polymer Fillers covers these various classes of fillers-filling agents- organic and inorganic. Organic filler usually takes part from natural sources and therefore is a step toward sustainable eco-friendliness in themselves. There are, on the other hand, inorganic fillers-this include calcium carbonate, silica, clay, and many others-these form a major chunk of the market because of the mechanistic advantages it tends to offer in terms of structural integrity and thermal resistance. The very diversely subdividing applications of these fillers ensure that the marketplace stays vigorous in respect of industrial verticals.

The Global Polymer Fillers market is clearly characterized by the technology constant innovations driving product development and use. Researchers and manufacturers would therefore typically to work on improving filler technologies for better compatibility towards polymer matrices while optimizing performance without compromise with their properties. Emerging high performance composites and engineered materials are among the expected drivers of such demand with increased focus on lightweight solutions and eco-friendly practices.

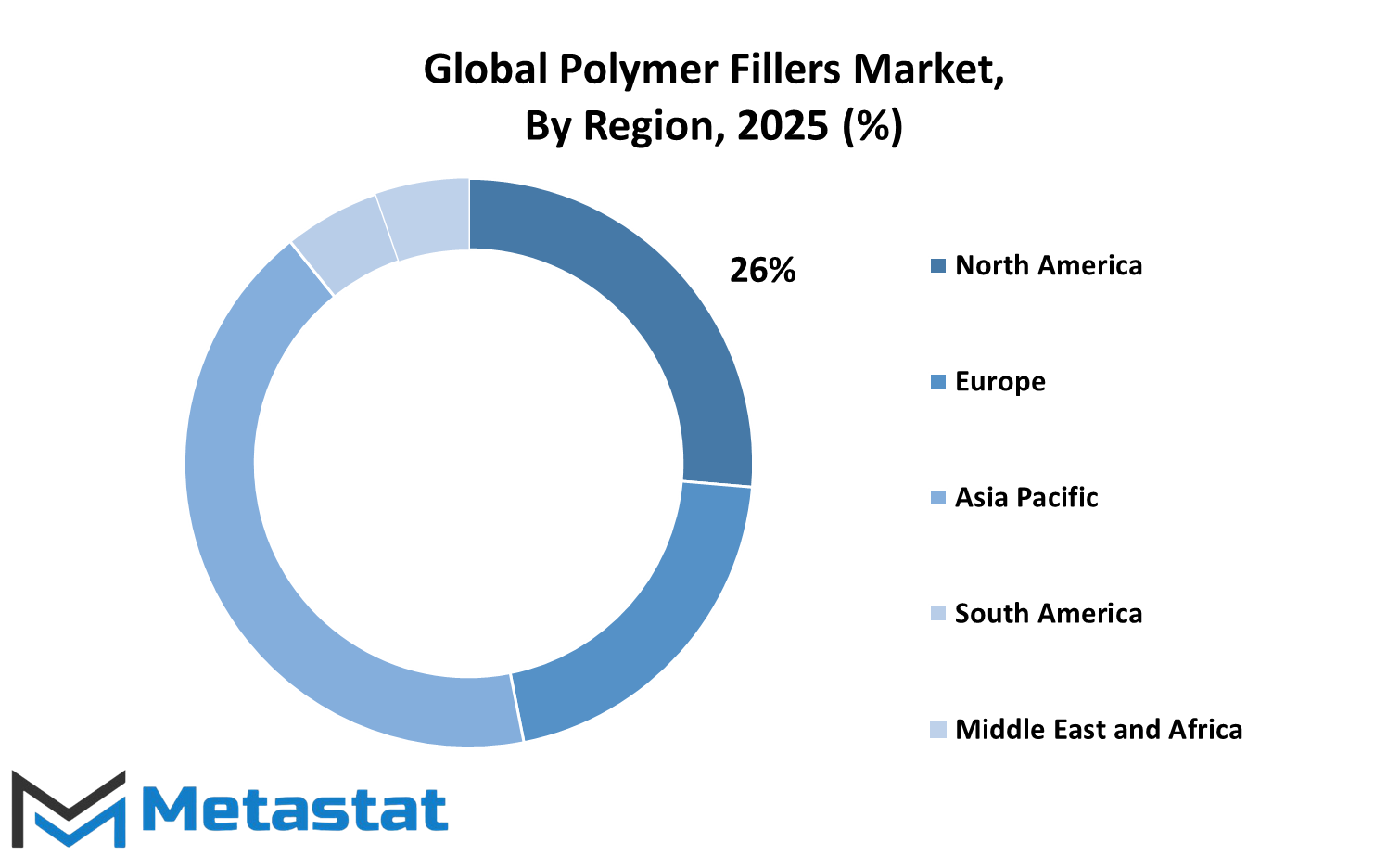

Geographically, its coverage includes North America, Europe, Asia-Pacific, Middle east & Africa each with its unique strength and opportunities contributing to the footprint of the market. Furthermore, Asia-Pacific was anticipated to account for the most consumption as well as production on the back of continued industrial growth and advancement of production capabilities. Established economies in North America and Europe will focus on advanced material innovation and regulatory compliance driving demand for high-quality, performance-driven products.

The entire industry supply chain comprises raw material sourcing, filler manufacture, distribution, and end-use application. Strategic alliance cases between polymer manufacturers and filler manufacturers will appear to influence market dynamics with respect to product offerings, tailor-made solutions for specific applications end uses. In addition, technology developments in material processing and quality control contribute to improved production efficiency and improved product consistency.

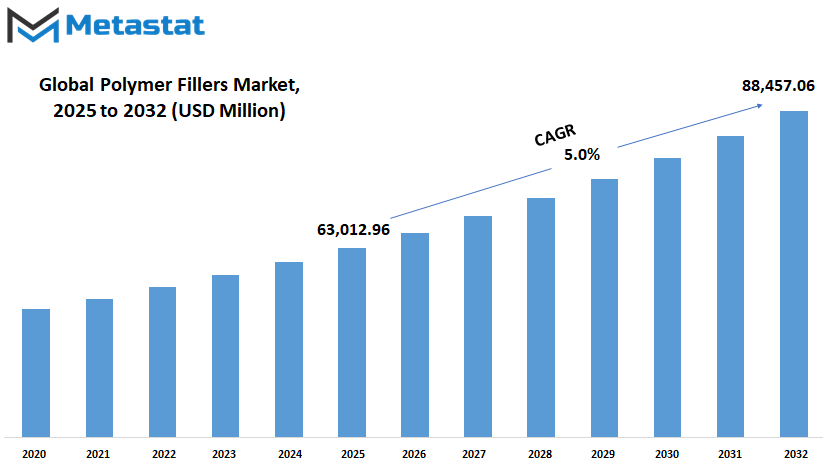

Global Polymer Fillers market is estimated to reach $88,457.06 Million by 2032; growing at a CAGR of 5.0% from 2025 to 2032.

GROWTH FACTORS

The Global Polymer Fillers Market is anticipated to witness tremendous growth in the near future, as lightweight and highly strong materials will be needed in many fields. Since the automotive industry and aerospace are becoming more performance-oriented, demands are increasing for materials that possess strength and versatile performance without adding excess weight in harsh everyday usage. Polymer fillers thus serve as an important means for the enhancement of polymer properties as they become stronger, lighter, and more versatile for various applications. As well, an increasing preference for advanced or advanced materials is actually one major reason that adds to the premise for broadening the scope of the polymer fillers market.

One serious cause through which market penetration of cheap fillers is being made by end users is that it gradually manages to strike a balance between an upfront investment and the required durability of the manufacturing process. Generally, any manufacturer will try to ensure that durability is increased and try to desperately manage the cost for manufacture. Polymer fillers, on the other hand, provide satisfactory improvement in mechanical properties of polymers and that too at fairly low prices. That gives the balance in quality and pricing through which companies invest across various industries. The requirement of being efficient and cutting costs will further add fuel to the demand.

Although the scenario is positive, certain factors may impede market development. The most important of these is erratic raw material price fluctuations, directly impacting production cost. The polymer sector needs to maintain a constant supply of quality raw materials; if there are any interruptions in this respect, be it in availability or pricing, production costs will course through the roof. Such instability will prove discouraging for manufacturers who wish to embark on large investments in polymer fillers, more so if their budget is tight.

Once again, environmental issues pose another big challenge against the growth of the Global Polymer Fillers market. With greater awareness about the adverse effects of non-biodegradable and synthetic materials, industries are now under pressure to adopt more sustainable methods. Conventional polymer fillers are made mostly from non-renewable sources, resulting in pollution and waste. More stringent regulations could therefore target companies, as well as pressure from stakeholders, to minimize their environmental footprint, which in turn would limited use of synthetic fillers.

The introduction of bio-based and sustainable fillers represents an attractive opportunity for the future of this market. Innovation in this field will persuade more industries to shift toward responsible manufacturing practices. Bio-based fillers have similar strength and durability as synthetics while meeting global agendas to downsize environmental impact. This shift toward sustainable production can generate opportunities and therefore enhance the attractiveness of the market from the standpoint of environmental sustainability.

MARKET SEGMENTATION

By Type

In the foreseeable future, the demand for the Global Polymer Fillers market is potentially expected to grow gradually at a pace owing to the various reasons that increases demand in numerous industries. However, polymer fillers are the materials which are added to the polymers to improve their properties, making the polymers stronger, stiffer, and ultimately making them, inexpensive to process. The fillers thus help in improving the performance of the polymeric product, and they also bring about some cost reduction in production.

Thus, as these booming sectors include automotives, packaging, construction, and electronics, several end users for polymer fillers will continue requiring their high-quality filling solution. Growth is expected to be attributed to the current boost in technology and a more efficient and sustainable materials search.

The Global Polymer Fillers market can be categorized into two major filling types, organic fillers and inorganic fillers. Organic fillers are the fillers that usually originate from a natural source, such as wood flour, starch, and cellulose. Biodegradable and mostly used for the eco-friendliness factor, these types of filler materials are now more interesting to industries that are increasingly focusing on sustainability or environmental protection. They just improve the strength and ductility of polymers; they are also used in lightening and making it lighter and easier to recycle; hence, they are now very attractive in packaging and consumer goods, where sustainability is becoming a primary concern.

In contrast, inorganic fillers consist of substances such as calcium carbonate, silica, and clay, which are not organic. Improving the durability of strength properties, these fillers also exhibit thermal stability with wear and tear-resistive qualities. Where properties such as strength and durability are very essential, especially in the construction materials and automotive components, their usage usually comes into play. In addition to that, inorganic fillers increase the electrical and heat resistance of polymers, which means it is possible to use them in the electronics area. Thus, pursuing these kinds of advantageous performances by polymer usage will make inorganic fillers play a very crucial role in the progress of future polymer-based products as technology develops and the requirement for high-performance material keeps expanding.

The future of the Global Polymer Fillers market would along the lines of innovation and the ever-increasing needs for solutions in this regard. Research hours and a lot of developments are going in the construction of advanced fillers that could enhance the performance of polymers but do not offset the environmental responsibility. The making of eco-filler would not, however, delay due to the initiative towards minimizing carbon footprints and advancing recycling technology. High-strength, heat-resistant materials will still be reserved for industries that rely on the inorganic alternative.

The Global Polymer Fillers market will change as well as the industries evolve along with the consumer perspective here, which is leaning more towards sustainable and durable products. The frontier of this highly competitive environment will be lit by those that discover new filler technologies and sustainable uses into which they pour capital. The future of this market is full of great promise because it offers growth possibilities driven by both environmental and technological changes.

By Product Type

The market is classified based on various product types, which include salts, carbon, oxides, silicates, hydroxides, and metals. Each one serves a different purpose and has different characteristics or advantages for that industrial purpose. For example, salts are often employed to enhance the structural integrity of polymers with strength and stability. Such enhancements provide resistance to the environment against heat and moisture, ensuring the longevity of the end product. Carbon, on the other hand, carries fillers that have electrical conductivity and mechanical strength characteristics. It is these properties that make carbon-based fillers indispensable in industries where durability and performance are of utmost concern, such as electronics and automotive manufacture.

Oxides serve a very important function toward the enhancement of thermal stability and chemical stability. They perform well under high-temperature conditions and resist corrosion; these properties greatly help in forming materials that need to withstand the harshest of environments. Silicates, known for their lightweight and reinforcing properties, find frequent utilization in the construction and packaging industries where they help to add strength without burdening weight; this is important to produce efficient and cost-effective product development. Hydroxides are increasingly gain importance because they impart fire resistance, which has become a matter of considerable focus due to tightening safety standards. Their ability of reducing flammability makes them an obvious preference in construction and transportation industries.

The metals are fillers for polymers that provide strength and endurance for heavy-duty work. Resistant to wear and tear, they ensure product quality and performance over time. Advancements would see the advent of the next-generation fillers that are more eco-friendly and economically viable, heightening the prospects for the future of the polymer field in regard to sustainability and performance.

The market of filler materials, therefore, appears to have a bright future with various research studies and investments being put into newer and more versatile filler material development. The industry will, therefore, demand materials that not only enhance product performance but also minimize costs and environmental impact. This demand will directly translate into the development of advanced fillers which will foster growth in the following years and create new opportunities to thrive.

By Polymer

In future years, the Global Polymer Fillers market is predicted to grow by leaps and bounds, as the industries will seek further materials that are of use in enhancing the quality, durability, and cost-efficiency of products. A polymer filler is any component added to polymer materials in order to enhance their physical and chemical properties. Majorly, the fillers are used for strength improvement and reduce production cost while fetching better performance for several applications. With the increase in demand for advanced and sustainable materials, the role of polymer fillers acquires a lot more significance. The trend of this market would continue to further growth focusing on innovation along with new needs for high-performance materials within many industries such as automotive, construction, packaging, and consumer electronics.

The light-weighting and greenening trends cause change in the market. It has reduced the carbon footprint, and polymer fillers can help to enhance the efficiencies of polymer products but maintained the same high grade. The bio-based and recyclable fillers will also open new opportunities because companies are becoming more focused on sustainability, not just for performance. Along with developing technologies to minimize the environmental impacts, this is also part of an evolution toward the innovative materials of the future.

The Global Polymer Fillers is further categorized by polymer type into Thermoplastic Polymer Fillers, Thermoset Polymer Fillers, and Elastomer Polymer Fillers. Each of them has different characteristics and applications, which will continue to shape the demand for them in the coming years. Thermoplastic Polymer Fillers are the ones that can soften by heating and harden by cooling, making them very versatile, and atm. Ideal for industries working towards flexible and efficient manufacturing are reusable and easy to process. This Promises even better growth in the use of these thermoplastic fillers as technology advances.

Thermoset Polymer Fillers, on the other hand, are recognized for their durability and high-temperature and chemical-resistant properties. Once cured, the material keeps its shape and strength, favoring applications for long-lasting performance. The development of products that withstand the most extreme applications will likely increase the demand for thermoset fillers, which will lead to further innovations in this space.

Elastomer Polymer Fillers lend flexibility and elasticity to a product making it one of the basic features of products that need stretch and resilience since it is expected to develop to high-performance elastomers hence the manufacturers exploring the balanced strength and adaptability of materials would increase use in automotive, health care, and consumer products. Future needs for high-performance elastomers will fuel research and development of advanced fillers specifically designed to meet these needs.

By End-Users

The Global Polymer Fillers market is expected to see significant growth in the coming years, driven by increasing demand across a range of industries. As industries evolve and new technologies emerge, the role of polymer fillers will become even more crucial. These materials are widely used to improve the properties of plastics, making them stronger, more durable, and cost-effective. With industries constantly seeking better performance and efficiency in their materials, the demand for polymer fillers will likely keep rising.

One of the primary drivers of this market’s growth is the automotive industry. As the automotive sector moves toward lightweight materials to enhance fuel efficiency and reduce emissions, polymer fillers are playing an important role. They help improve the strength and flexibility of plastic components used in vehicles without adding excessive weight. As electric vehicles and advanced automotive designs become more popular, the need for high-performance materials will only grow, pushing the demand for polymer fillers even further.

The building and construction industry also heavily relies on polymer fillers. These materials are used in a wide range of construction applications, from pipes and fittings to insulation and flooring. Their ability to enhance the durability and stability of construction materials makes them an essential part of modern infrastructure projects. As urbanization continues and smart cities become a focus, the demand for reliable and long-lasting construction materials will drive the need for advanced polymer fillers.

In the electrical and electronics sector, polymer fillers are vital for producing lightweight, heat-resistant, and durable components. As electronic devices become smaller and more powerful, the materials used must meet higher standards of performance. Polymer fillers help achieve these requirements by improving thermal stability and mechanical strength, which ensures that electronic products remain efficient and safe. With the increasing adoption of advanced technologies like 5G, the Internet of Things (IoT), and smart devices, the use of polymer fillers in this industry is set to increase.

The packaging industry also benefits from the advantages offered by polymer fillers. As the need for sustainable, lightweight, and durable packaging grows, these materials help improve the quality and efficiency of plastic packaging. They enhance strength, reduce production costs, and support the development of eco-friendly packaging solutions. With the rising awareness around environmental issues, the packaging industry’s focus on sustainable practices will likely boost the demand for innovative polymer fillers.

Lastly, industrial applications of polymer fillers cover a wide range of uses, from manufacturing equipment to specialized components. Their ability to improve material performance while reducing costs makes them a valuable addition across various industrial processes. As industries aim for greater efficiency and innovation, polymer fillers will continue to play a key role in shaping future manufacturing practices.

In the years ahead, the Global Polymer Fillers market is expected to expand as industries adopt more advanced materials to meet evolving demands. With their ability to enhance performance, reduce costs, and support innovation, polymer fillers will remain essential across automotive, construction, electronics, packaging, and industrial sectors.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$63,012.96 million |

|

Market Size by 2032 |

$88,457.06 Million |

|

Growth Rate from 2025 to 2032 |

5.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global polymer fillers market is expected to experience significant growth in the coming years, driven by increasing demand across various industries and regions. As industries continue to focus on enhancing product performance and sustainability, polymer fillers have become essential due to their ability to improve strength, durability, and cost-efficiency in polymer-based materials. This growing importance is reflected in the regional markets, each contributing to the overall expansion of the industry in unique ways.

North America holds a strong position in this market, with the United States, Canada, and Mexico playing key roles. The U.S., being a hub for technological innovation and advanced manufacturing, is likely to continue driving demand for high-performance polymer fillers. The region’s well-established automotive, construction, and packaging industries heavily rely on these materials to improve product quality and efficiency. Canada and Mexico also support market growth through their expanding industrial sectors and increasing adoption of polymer-based products.

In Europe, countries like the UK, Germany, France, and Italy are significant contributors. Germany’s strong industrial base and expertise in engineering and manufacturing make it a major player. The UK and France also show promising growth, fueled by innovations in automotive and aerospace sectors. Italy, along with other parts of Europe, continues to adopt polymer fillers to enhance product performance and meet the rising demand for sustainable materials.

The Asia-Pacific region is expected to witness the fastest growth in the global polymer fillers market. Countries like China, India, Japan, and South Korea are leading the charge due to rapid industrialization and urbanization. China’s large-scale manufacturing capabilities and India’s expanding construction and automotive sectors create a strong demand for polymer fillers. Japan and South Korea, known for their advancements in technology and high-quality production standards, also contribute to the market’s upward trajectory. This region’s growing population and increasing focus on infrastructure development make it a key driver for future growth.

South America also shows potential, with Brazil and Argentina at the forefront. Brazil’s expanding construction industry and increasing investment in manufacturing drive demand for polymer fillers. Argentina, along with the rest of South America, is gradually adopting these materials as industries seek to improve product quality and cost efficiency.

The Middle East and Africa region, including GCC countries, Egypt, and South Africa, presents a developing market for polymer fillers. Growing construction activities, supported by infrastructure projects and industrial growth, create opportunities for market expansion. As these countries continue to invest in modernization and development, the demand for high-performance materials like polymer fillers will likely increase.

Overall, the global polymer fillers market is poised for growth, with each region offering unique opportunities. As industries innovate and prioritize efficiency and sustainability, the market will evolve to meet the diverse needs of these expanding economies.

COMPETITIVE PLAYERS

Not out of constant and recurrent incidents, the Global Polymer Fillers market is bound to explore newer avenues in the business operations in the years to come as a consequence of growing demand from various industries. Polymer fillers have gained such importance in the present age; it improves performance, increases durability, and reduces costs of polymer-based materials. They are being utilized in different sectors, e.g., automotive, construction, packaging, and consumer goods because of the ability to enhance mechanical strength, thermal stability, and overall quality of the product. The ongoing trend continues to dictate the demand for lightweight, high-strength materials with enhanced properties, further emphasizing the need for polymer fillers.

Among them, the main point of change in the time in Global Polymer Fillers market is viral for the atmosphere. In fact, with stricter environmental regulations and the need to cut down carbon footprints, they will tend to look for new innovative filler materials that can also provide optima performance, yet still care for the environment. Natural fillers like calcium carbonate and silica are already being trumpeted for their availability and low environmental cost. Such practices towards sustainability are likely to be reflected in future development and application of polymer fillers.

Moreover, the Global Polymer Fillers market is expected to benefit heavily from advances in material science and nanotechnology. R&D are focused on high-performance fillers with some improved characteristics, such as dispersion, adhesion, and strength. These newly created fillers are likely to result in advanced polymer composites capable to respond to the new demands put by industries. On the other hand, ongoing technology evolution will surely unleash the possibilities of bringing intelligent fillers into the future, enabling benefits to be shared by manufacturers and end-users alike.

Some of the key players such as Omya AG, Hoffmann Mineral Filler GmbH, Covia Holdings Corporation, LKAB Minerals, and Amco Polymers are among the many major companies that are making considerable strides with their contributions to either innovation or market spread in the Global Polymer Fillers market. These companies owe some of their great reputations to the vast amount of their product portfolio and an intense focus on research and development. Other major players like Quarzwerke GmbH, 20 Microns Limited, GCR Group, Mineral Technologies Inc., Imerys S.A., and Cabot Corporation also play relevant roles in the same market by providing high-quality, specialized fillers needed by various industries. With continued efforts directed toward enhancing product performance and addressing environmental concerns, it is likely that the market's growth will be evidence through this initiative in the future.

As an industry's continuous evolving development happens across continents worldwide, the Global Polymer Fillers market will also remain a critical piece in the jigsaw puzzle of advanced materials development. It will rapidly become a culture of creating innovation, sustainability, and superior products to shape the future of polymer fillers and their applications in various sectors.

Polymer Fillers Market Key Segments:

By Type

- Organic Fillers

- Inorganic Fillers

By Product Type

- Salts

- Carbon

- Oxides

- Silicates

- Hydroxides

- Metals

By Polymer

- Thermoplastic Polymer Fillers

- Thermoset Polymer Fillers

- Elastomer Polymer Fillers

By End-Users

- Automotive

- Building & Construction

- Electrical & Electronics

- Packaging

- Industrial

Key Global Polymer Fillers Industry Players

- Omya AG

- Hoffmann Mineral Filler GmbH

- Covia Holdings Corporation

- LKAB Minerals

- Amco Polymers

- Quarzwerke GmbH

- 20 Microns Limited

- GCR Group

- Minerals Technologies Inc.

- Imerys S.A.

- Cabot Corporation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383