MARKET OVERVIEW

The Global Plastic Valves market stands as a dynamic and transformative segment within the broader industrial landscape. Plastic valves, once relegated to the sidelines, have emerged as key components in various industries, offering a range of advantages over traditional materials. This market segment has witnessed significant growth and innovation, reshaping the way industries approach fluid control systems.

Plastic valves, characterized by their lightweight, corrosion resistance, and cost-effectiveness, have found applications across diverse sectors. One notable area where these valves have gained prominence is in water treatment. The demand for efficient and durable valves in water management systems has led to an increased adoption of plastic valves, contributing to the market’s expansion.

Moreover, the chemical industry has embraced the use of plastic valves due to their compatibility with a wide range of chemicals. The ability to withstand corrosive environments and harsh chemical conditions makes plastic valves an attractive choice for companies seeking reliable and durable fluid handling solutions.

In the context of environmental consciousness, the Global Plastic Valves market has experienced a surge in demand as industries look for sustainable alternatives. Plastic valves, with their recyclability and reduced environmental impact compared to traditional materials, align with the growing emphasis on eco-friendly practices.

The market dynamics are also influenced by technological advancements, with the integration of smart and automated features in plastic valve systems. This shift towards automation enhances precision and efficiency in fluid control processes, catering to the evolving needs of industries striving for increased productivity.

As the market continues to evolve, the Global Plastic Valves segment is poised to play a vital role in shaping the future of fluid control systems. The versatility, cost-effectiveness, and sustainability of plastic valves position them as indispensable components across a spectrum of industries, ensuring a significant and lasting impact on the global industrial landscape.

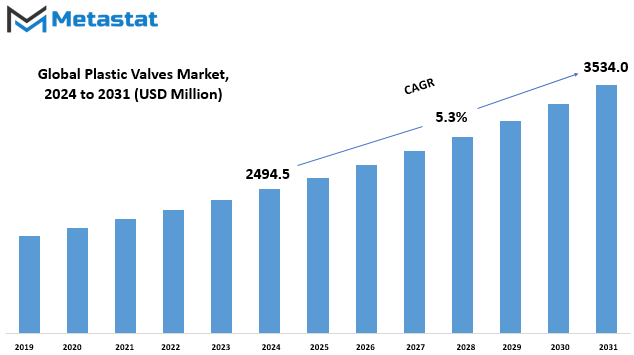

Global Plastic Valves market is estimated to reach $3534.0 Million by 2031; growing at a CAGR of 5.3% from 2024 to 2031.

GROWTH FACTORS

The Global Plastic Valves market experiences notable growth influenced by various key factors. Understanding these growth factors is crucial to grasping the trajectory of the market. On the flip side, certain challenges pose potential obstacles to this growth. Examining both aspects allows for a comprehensive view of the market dynamics.

One of the primary drivers propelling the Global Plastic Valves market forward is the continuous evolution of technology. As technology advances, the demand for efficient and innovative solutions in various industries grows. Plastic valves, being a vital component in numerous applications, benefit from this trend. The integration of advanced technologies enhances the performance and reliability of plastic valves, thereby contributing to the market's upward trajectory.

Additionally, the increasing emphasis on environmental sustainability plays a pivotal role in driving the demand for plastic valves. As industries and businesses adopt eco-friendly practices, the preference for plastic valves, which are often more sustainable than traditional alternatives, surges. This shift aligns with a global push towards greener solutions, promoting the growth of the plastic valves market.

However, despite these positive trends, challenges exist that may impede the market's growth. Economic fluctuations and uncertainties can adversely affect the demand for plastic valves. Industries may face budget constraints, leading to reduced investments in infrastructure and projects, ultimately impacting the market negatively.

Furthermore, regulatory hurdles pose another potential challenge. Stringent regulations related to the manufacturing and usage of plastic materials can create obstacles for the plastic valves market. Compliance with these regulations requires additional efforts and resources, affecting both production processes and market accessibility.

The need for sustainable solutions and the growing awareness of environmental issues creates a conducive environment for the plastic valves market to thrive. The integration of smart technologies and the exploration of new applications for plastic valves present lucrative prospects for market players.

The Global Plastic Valves market's growth is shaped by a combination of driving factors and challenges. While technological advancements and environmental considerations fuel expansion, economic uncertainties and regulatory constraints pose potential hindrances. Navigating these dynamics requires a strategic approach, but the market's inherent opportunities make it a compelling space for innovation and growth in the foreseeable future.

MARKET SEGMENTATION

By Material

The global plastic valves market is an expansive landscape, with a key segmentation based on materials. This segmentation delves into the composition of these valves, shedding light on the diverse materials employed in their construction. The materials that form the backbone of this market include PVC, PP, PVDF, and others.

Polyvinyl chloride, commonly known as PVC, stands out as a prominent material in the plastic valves market. Its widespread use can be attributed to its versatility and durability. PVC valves find applications in various industries, benefiting from their ability to resist corrosion and chemical reactions.

Polypropylene, abbreviated as PP, is another significant player. PP valves bring their own set of advantages, such as being lightweight and possessing excellent resistance to moisture and chemicals. These characteristics make them suitable for a range of applications, from water treatment to chemical processing.

PVDF, or polyvinylidene fluoride, represents a distinct category within the market. Known for its high chemical resistance and thermal stability, PVDF valves find utility in demanding environments where exposure to aggressive substances is prevalent. This material’s robust nature ensures a longer lifespan for valves, contributing to its growing presence in the market.

Further, each material within other category brings its unique attributes, catering to specific requirements in different industries. This inclusive classification highlights the adaptability and innovation within the plastic valves market.

The segmentation of the global plastic valves market by material provides a comprehensive view of the choices available in the industry. PVC, PP, PVDF, and other materials each play a crucial role, addressing distinct needs across various sectors. As industries continue to evolve, the significance of these materials in shaping the plastic valves market is set to endure.

By Type

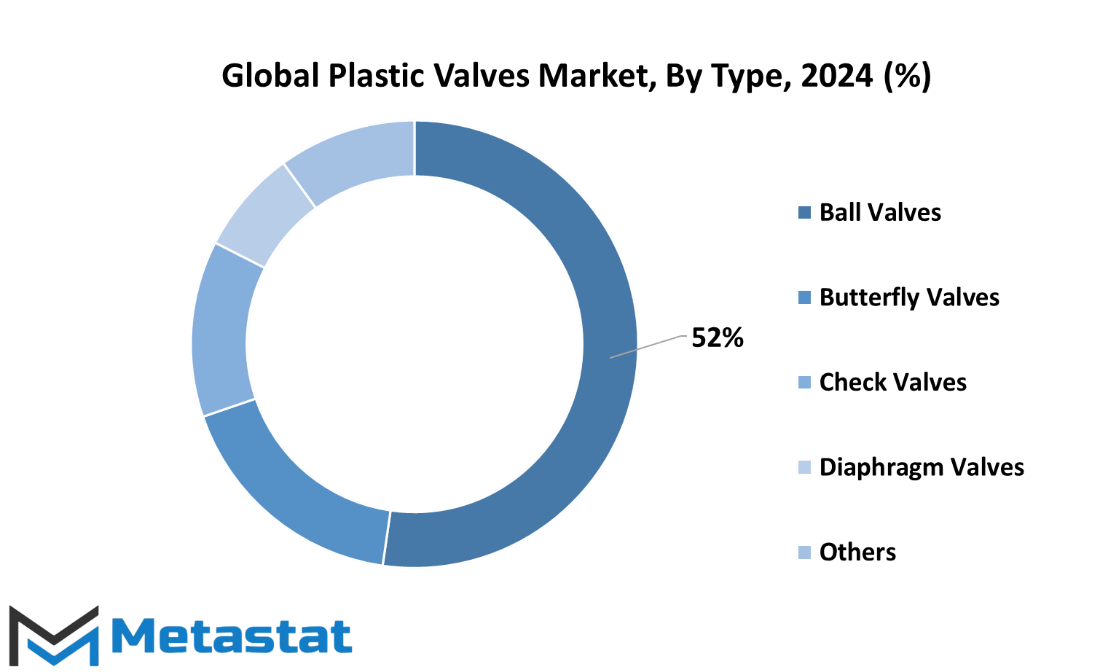

The global plastic valves market is a diverse landscape, segmented by types that cater to various industrial needs. The market categorization includes Ball Valves, Butterfly Valves, Check Valves, Diaphragm Valves, and other miscellaneous types.

Ball Valves, a prominent player in this arena, offers efficient control over fluid flow. These valves, featuring a spherical disc, permit or obstruct the flow with a simple quarter-turn mechanism. Their versatility makes them suitable for diverse applications across industries.

Butterfly Valves, another significant segment, operate with a disc rotating within the valve body. These valves find utility in regulating flow while maintaining a compact design. Their simplicity and cost-effectiveness contribute to their widespread adoption.

Check Valves, a vital component in the market mix, allow the flow in one direction while preventing reverse flow. The inherent design ensures that fluid moves seamlessly in a specified direction, preventing backflow and maintaining operational efficiency.

Diaphragm Valves, with a flexible diaphragm as a closing mechanism, offer precise control over fluid flow. This type is particularly advantageous in applications requiring accuracy and reliability, such as pharmaceutical and chemical industries.

The category of Others has various valve types that may not fit explicitly into the major classifications but contribute significantly to the market’s dynamism. These valves address specific industry requirements, adding a layer of specialization to the overall plastic valves market.

The global plastic valves market thrives on diversity, with each valve type catering to distinct industrial needs. The versatility of Ball Valves, the simplicity of Butterfly Valves, the directional control of Check Valves, and the precision of Diaphragm Valves collectively contribute to a well-rounded market offering. The inclusion of miscellaneous valve types further enriches the market, ensuring it remains adaptable to evolving industrial demands.

By End User

The global plastic valves market is segmented based on end users, with a focus on applications in water and wastewater treatment, chemical processing, oil and gas, and other sectors. This segmentation helps to tailor the functionality of plastic valves to specific industry needs.

Water and wastewater treatment constitutes a significant portion of the market. Plastic valves play a crucial role in regulating the flow of water and chemicals in treatment plants, contributing to the efficiency and effectiveness of these processes. Their corrosion resistance and durability make them particularly suitable for the demanding conditions of water treatment facilities.

In chemical processing, plastic valves find utility in controlling the flow of various chemicals within manufacturing plants. The corrosion-resistant nature of plastic valves becomes paramount in this setting, where exposure to corrosive substances is a constant factor. The valves ensure a reliable and safe handling of chemicals, promoting operational integrity.

The oil and gas sector represents another key end-user segment for plastic valves. In this industry, these valves facilitate the regulation of fluid flow and pressure in pipelines and processing facilities. Their resilience to harsh environmental conditions and resistance to corrosion make them indispensable components for maintaining the integrity of oil and gas operations.

Beyond these primary sectors, plastic valves also serve various other industries, collectively referred to as others. This diverse category may include applications in pharmaceuticals, food and beverage processing, and any other industry where the controlled flow of fluids is essential. The adaptability of plastic valves makes them versatile solutions for a wide range of applications.

The global plastic valves market, when scrutinized through the lens of end-user segmentation, reveals a nuanced landscape where these valves prove their worth across various industries. Their role in water and wastewater treatment, chemical processing, oil and gas, and other applications underscores their importance in diverse sectors, ensuring the smooth regulation of fluid processes across the board.

REGIONAL ANALYSIS

The global Plastic Valves market is analyzed in terms of geographical distribution, with a focus on North America, Europe, and Asia-Pacific regions. This regional analysis sheds light on the market dynamics and trends specific to each area.

North America, being a major player in industrial advancements, holds a significant share in the Plastic Valves market. The demand for these valves is fueled by the thriving manufacturing sector and the continuous drive for technological innovation. As industries in North America evolve, the Plastic Valves market experiences corresponding shifts, adapting to the changing needs and preferences of the region.

In Europe, a similar scenario unfolds, albeit with unique characteristics. The Plastic Valves market is influenced by the diverse industrial landscape across European countries. The emphasis on sustainability and environmental consciousness in manufacturing processes adds a distinct flavor to the demand for plastic valves. The market in Europe is marked by a blend of traditional and modern manufacturing practices, creating a dynamic environment for plastic valve usage.

Moving to the Asia-Pacific region, a different set of factors comes into play. The rapid industrialization and economic growth in countries like China and India drive the demand for Plastic Valves. The burgeoning manufacturing activities and increasing infrastructure projects contribute to the growth of the market in this region. The adaptability of plastic valves to various industrial applications aligns with the diverse needs of the Asia-Pacific market.

The regional analysis of the global Plastic Valves market provides insights into the specific factors influencing market trends across North America, Europe, and Asia-Pacific. Each region contributes to the overall dynamics of the Plastic Valves market in a unique way, reflecting the diverse industrial landscapes and economic conditions. As industries in these regions continue to evolve, the Plastic Valves market adjusts and responds to the changing demands, shaping its trajectory accordingly.

COMPETITIVE PLAYERS

The global market for plastic valves is marked by the presence of several key players, each contributing to the industry's dynamics and competitiveness. Among the prominent companies in this sector are Georg Fischer Ltd., Asahi/America, Inc., Spears Manufacturing Company, Plast-O-Matic Valves, Inc., NIBCO INC., Hayward Industries, Inc., Valtorc International, Simtech Process Systems, Emerson Electric Co., and Parker Hannifin Corporation.

These companies play a vital role in shaping the landscape of the plastic valves market, each bringing its unique strengths and offerings to the table. Georg Fischer Ltd., for instance, is recognized for its commitment to quality and innovation, continually striving to meet the evolving needs of the industry. Asahi/America, Inc. stands out with its focus on providing durable and reliable plastic valves, catering to diverse applications.

Spears Manufacturing Company has carved a niche for itself through a dedication to technological advancements and a customer-centric approach. Plast-O-Matic Valves, Inc. brings its expertise to the market with a range of specialized valves, addressing specific requirements within various sectors. NIBCO INC. is known for its comprehensive portfolio of valves, offering a wide array of solutions for different industries.

Hayward Industries, Inc. contributes to the competitive landscape with a focus on efficiency and sustainability in its plastic valve offerings. Valtorc International is recognized for its commitment to customization, providing tailored solutions to meet the unique demands of clients. Simtech Process Systems brings its expertise in fluid handling to the market, ensuring optimal performance of plastic valves in diverse applications.

Emerson Electric Co. stands as a key player, leveraging its extensive experience and technological prowess to offer cutting-edge solutions. Parker Hannifin Corporation, with a rich history in engineering excellence, brings its innovative designs to the plastic valve market, contributing to its overall growth and development.

The plastic valves market is dynamic and competitive, driven by the contributions of key players such as Georg Fischer Ltd., Asahi/America, Inc., Spears Manufacturing Company, Plast-O-Matic Valves, Inc., NIBCO INC., Hayward Industries, Inc., Valtorc International, Simtech Process Systems, Emerson Electric Co., and Parker Hannifin Corporation. Each company's distinct strengths and offerings play a crucial role in shaping the industry and meeting the diverse needs of customers worldwide.

Plastic Valves Market Key Segments:

By Material

- PVC

- PP

- PVDF

- Others

By Type

- Ball Valves

- Butterfly Valves

- Check Valves

- Diaphragm Valves

- Others

By End User

- Water and Wastewater Treatment

- Chemical Processing

- Oil and Gas

- Others

Key Global Plastic Valves Industry Players

- Georg Fischer Ltd.

- Asahi/America, Inc.

- Spears Manufacturing Company

- Plast-O-Matic Valves, Inc.

- NIBCO INC.

- Hayward Industries, Inc

- Valtorc International

- Simtech Process Systems

- Emerson Electric Co.

- Parker Hannifin Corporation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252