MARKET OVERVIEW

The Global Offshore Inspection, Repair, and Maintenance market includes all specialized services related to maintaining performance and safety levels of offshore installations. Inspection activities include various intensive assessments down to levels of subsea pipelines, risers, and platforms to identify issues, corrosion, or potential failures from the structural perspective. This is being increasingly done through advanced technologies such as remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs). Repair services constitute intense damage found in inspections and include subsequent actions by welding, replacing damaged parts, or reinforcing the negatively affected structure. Maintenance would aim to keep the offshore facility in condition by servicing, cleaning, or protective measures.

With the operations and safety performance demonstrated for the offshore assets, the Global Offshore Inspection, Repair, and Maintenance market and industry would have carved out a crucial role. Primarily, it has to deal with sustaining an entire subsea infrastructure along with offshore platforms, wind farms, and all marine facilities. Furthermore, the demand for exceptional inspection, repair, and maintenance services will continue to rise as exploration and production of offshore oil and natural gas continue to thrive. Services exist to address the issue, as equipment is subject all day long to extreme weather conditions, high pressures, and corrosive environments. Mostly, this makes equipment fail, downtime reduction, and extension of the life cycle of offshore assets.

Maintenance has its phenomenal share in the Glo-bal Offshore Inspection, Repair, and Maintenance market and industry, which would represent a significant portion of the operation and safety performance of offshore assets. It includes an entire subsea infrastructure maintenance range, offshore platforms, wind farms, and all other marine facilities, as the demand continues to grow for quality inspection, repair, and maintenance services as exploration and production of oil and natural gas offshore take flight. Services deal directly with the fact that equipment incurs very harsh environmental conditions, high pressures, and corrosive places all day long. Mostly, it prevents equipment failure, downtime reduction, and extension of the life cycle of offshore assets.

The Global Offshore Inspection, Repair, and Maintenance market covers all the specialized services keeping afloat the performance and safety levels of offshore installations. Inspection activities consist of various thorough assessments that take place down to levels of subsea pipelines, risers, and platforms to structurally identify issues, corrosion, or potential failures. Advanced technologies like remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) are increasingly being used to increase the accuracy and efficiency of these inspections. Repair services focus on damage detected during inspections by welding, replacing damaged components, or reinforcing the affected structure. While maintenance ensures the offshore facility is kept in working condition by regular servicing, cleaning, and using protective measures.

Covers all aspects related to Global Offshore Inspection, Repair, and Maintenance markets from several offshore sectors such as oil and gas, renewable energy, and the maritime industry. These include the operations of drilling rigs, production platforms, and subsea systems maintaining operations in the oil and gas sector. The offshore wind energy sector relies on these services to ensure wind turbines as well as undersea cables are maintained and, hence, the energy output and infrastructure integrity are safeguarded. Besides that, the maritime industry is accessed via inspection, repair, and maintenance services for vessels and port facilities. It serves amply for illustrating the market's significance in varying industries relying on offshore operations.

New offshoots in the Future Global Offshore Inspection, Repair and Maintenance market will be highlighted by applying more advanced and futuristic technology and providing solutions that are more straightforward and cost-effective. The use of artificial intelligence, machine learning, and big data in the processes of inspection will enhance predictive maintenance, allowing easy identification of potential problems and reducing the likelihood of suffering from sudden failure in equipment. Innovations in robotics and automation will further streamline repair and maintenance capabilities, increase precision and safety, and reduce human interaction in dangerous environments.

Therefore, the market would be positioned with challenges and opportunities around future innovation as offshore operations proceed to deeper waters and. To meet such environmental challenges, considerably advanced inspection tools and repair methods should be developed. Growth in environmental sustainability and protection will also nourish the impetus for adoption of green maintenance practices and materials.

The Global Offshore Inspection, Repair, and Maintenance market will keep evolving, transforming and adapting to all the technological innovations and changes in industry needs. The type of effluent treatment required will highlight its critical importance across multiple sectors by maintaining the efficiency, safety, and longevity of offshore infrastructure. As the markets for this go further in terms of continuous advancements of and commitment to operational excellence, more stability and success will be assured in the offshore industries around the world.

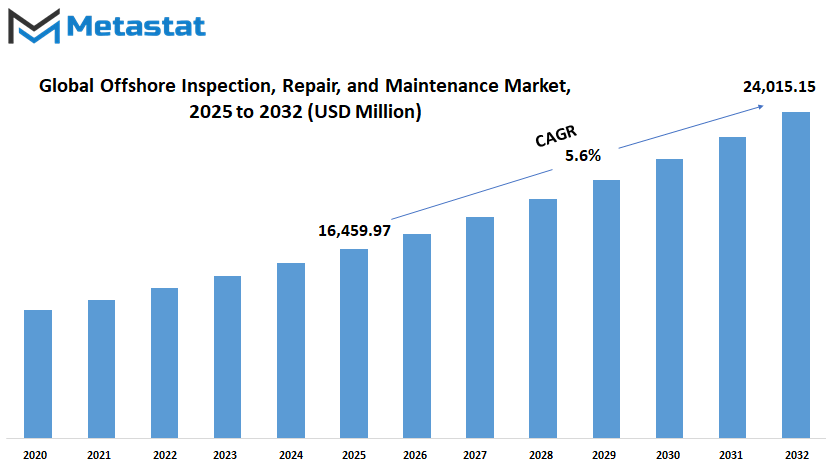

Global Offshore Inspection, Repair, and Maintenance market is estimated to reach $24,015.15 Million by 2032; growing at a CAGR of 5.6% from 2025 to 2032.

GROWTH FACTORS

The Offshore Inspection, Repair, and Maintenance Market is predicted to experience a significant growth rate in the coming years due to the various forces that shapes the offshore industry. One of why this market is proliferating is that there is going to be increased exploration for and production of offshore oil and gas. The high demand for energy pushes up global energy consumption, thus taking more energy companies into previously unvisited offshore regions to secure reserve access. This requires constant inspection and maintenance of offshore infrastructures, hence creating a market for inspection, repair, and maintenance services.

Another driver of growth for this market is investment in offshore wind energy development. Offshore wind farms that are found, as the world moves to cleaner and more sustainable energy sources, have become integral to the energy mix. These big wind projects need regular inspection and maintenance checks to operate efficiently and safely under often difficult sea conditions. This renewable energy transition creates not only environmental benefits but also new opportunities for companies providing offshore maintenance services.

Although this market has a good prospect, it will still encounter challenges that would hinder its growth. One of the greatest obstacles in front is high operating costs. Offshore operations are, indeed, expensive, even those associated with special equipment and skilled personnel, as well as sophisticated technology to enable it all to run smoothly. In addition, due to the extreme and harsh environmental conditions usually found offshore site such as extreme weather, strong ocean currents, and deepwater pressure, maintenance work is rendered more complicated and expensive. All these factors could result in augmenting time and resources necessary for regular inspections and emergency repairs.

However, some of these hurdles have a good place for technological advancement. Robotics and AI-based inspection tools are being developed and adopted, and these would seem to transform offshore maintenance activities. Drones, underwater robots, and other automated systems incorporating top-end sensors and data analytics capabilities can conduct inspections without human intervention. This would reduce reliability on human presence in dangerous offshore environments and improve efficiency and accuracy. Early detection of possible issues can be realized by AI-driven analysis to reduce costly breakdowns and thus also downtimes in operations.

In fact, Global Offshore Inspection, Repair and Maintenance market forecasts indicate that this sector will continue to grow on the back of increasing energy demands and a shift toward renewable energy. Maintenance solutions will demand greater application as more companies develop offshore infrastructure. The use of advanced technologies, managing costs, innovative solutions, and promoting sustainable development through energy security will ensure a profitable future for this market.

MARKET SEGMENTATION

By Type

All the above-mentioned goings-on in the Offshore Inspection, Repair, and Maintenance market would very well determine the bright yet challenging future of offshore industries. Offshore infrastructures suffer attacks by vast forces of nature and tend to wear down; for example oil rigs, wind farms, and underwater pipelines. Thus, it is crucial to ensure that these systems are never interrupted in their operational status and are protected from unforeseen failures by performing round-the-clock monitoring and immediate intervention. This is what entails the Global Offshore Inspection, Repair and Maintenance Market, offering know-how along with services to maintain safety and efficiency.

However, the market itself can be divided generally into three segments based on the types of services: inspection, repair, and maintenance. Inspection services aim at establishing the condition of offshore structures and equipment. All of these will become a lot more accurate and efficient owing to technological evolution. Maxi-Drone, for example, will find application in oil drilling and post-nickel inspections in offshore wind platforms, and its advanced imaging techniques will become a norm in inspection work for safety and adeptly rapid execution of tasks. Otherwise, early issue detection would have made minor defects into major problems.

Such equally important services go hand in hand with repair. These structures will be capable of experiencing extremes in the weather, to strong currents, and steady pressure, all of which can gradually be expected to cause damage to these offshore structures. And repair would go forward to the future, becoming better and faster and so requiring less shutdown time through advanced equipment and techniques. Automatic repair systems developed for harsh environments and unique materials be conceived to maintain the integrity of offshore installations.

Maintenance services maintain offshore facilities in optimal performance levels. With routine maintenance, risks of failure of equipment and higher efficiency become minimized. Predictive maintenance is likely to gain prominence in the future wherein analyses and data predict prospective hindrances even before they occur. In that, there is time saving, a resource-saving, and scheduling can be done without disturbance to the operational activities.

As the offshore industry moves from deep into waters into harsher environments, so the demand for such services will only continue to increase. Thus, the Global Offshore Inspection, Repair and Maintenance market will have to evolve and become smarter, quicker, and greener in its offering. Well, last but not least, service providers will continue investing in the latest technologies and skilled personnel to provide for future needs in this industry.

The future of this market appears bright due to innovation and the persistent need to maintain offshore infrastructure. Based on advanced inspection methodologies, efficient repair processes, and proactive maintenance strategies, the Global Offshore Inspection, Repair and Maintenance market will ensure the offshore operations are safely conducted, reliably supported, and sustainably serviced.

By Service Offering

The Global Offshore Inspection, Repair, and Maintenance market has a good future growth potential as maintenance and improvement needs arise for offshore structures. The offshore oil ad gas exploration advancement and the continuing development of offshore wind farms and other marine infrastructures will create an ever-growing need for effective and efficient maintenance services in the future. Many high-end specialized services would be required at that time to assure safety, longevity, and performance of the offshore installations from preventing failures and reducing downtime.

This includes rope access services as one of the major shards of these services. This is an access technique that allows workers to reach confined areas on the offshore structures without using cranes or scaffolding, thereby requiring heavy equipment. Rope access will continue being a preferred method because it allows quicker inspection and repair cycles, thus reducing overall costs and minimizing disruption to operations. With the rising safety standards, the efficiency and reliability of rope access services would make them an essential method in offshore maintenance.

Robotic inspection and cleaning will become more important within the framework of this market. Industry will sooner trust machines than people to do high-risk and repetitive tasks, with advances in automation and robotics. Robotic systems shall understand and clean mounds such as offshore equipment but with precision and mainly work in horrible conditions that make it a dangerous place for human workers. Thus, an increase in efficiency and the lowering of safety risks and operating costs can be achieved through the robotized systems.

Non-Destructive Testing (NDT) is the other crucial service that would continue ushering the market towards the future. It is the analysis of materials and structures without causing any damage, which allows companies to spot out failures like cracks, corrosion, and other types of wear long before they become significant problems. Increasingly, as offshore installations get older, NDT becomes more critical to ensuring the integrity of the equipment and prolonging its life.

Another area is going to be the subsea ROV (Remotely Operated Vehicle). This would be much needed for inspections and repairs in very deep waters and, very importantly, without the risk of human divers. Cameras, sensors, and tools equipped to these vehicles are capable enough to conduct inspection, maintenance, and complex repairs under extreme underwater conditions. The growing applications of these will definitely put more emphasis on innovations and techniques in the offshore maintenance space.

Welding and fabrication services are crucial for the maintenance and upgrading of offshore infrastructure. With changes in the industry, it will keep on increasing demand for customized spare parts and onsite repairs. It is the skilled welding and fabrication that counts toward keeping structures afloat and functional even under harsh marine conditions.

Corrosion control and coating services will also see increasing demand since saltwater, wind, and other agents expose offshore installations to the disadvantage of degrading materials. Good protective coatings and regular maintenance will do their jobs to mitigate rust and damage and thus keep offshore equipment as safe and effective as possible.

The Global Offshore Inspection, Repair, and Maintenance market would see good and steady development as offshore industries carry on with their expansions and put safety, efficiency, and sustainability first. By new technologies and specialized services, this market would play an important role in the future years into the reliability and longevity of offshore infrastructure.

By Application

The Global Offshore Inspection, Repair, and Maintenance market is anticipated to flourish in the near future with increasing demand for energy and sustainable resources. The market remains a critical element in ensuring that offshore infrastructure is secure, efficient, and operating. Actual offshore facilities undergo harsh environmental conditions ranging from strong currents, weather extremities, and saline water, which leads to wear and tear over time. Thus, consistent inspection, repairs, and maintenance are necessary to avert unforeseen breakdowns leading to prolonged productivity.

One of the primary stimuli for growth in this sector is the rising demand for energy from offshore sources. As reserves onshore dwindle and the world demand for energy rises, companies are turning more toward offshore oil and gas platforms, subsea equipment, and wind turbine platforms. Monitoring and maintenance of these structures is of utmost importance for their proper functioning and avoiding costly downtimes. This is where even advanced technologies such as remote-operated vehicles and automated inspection tools are predicted to take the lead, providing safe and efficient means to inspect and repair.

The application divides the submarkets, each with its requirements and challenges. The oil and gas platforms are amongst the major consumers of inspection, repair, and maintenance services. These operations are under very high pressure and tough conditions, thereby requiring regular inspections of their integrity, safety, and efficiency. Subsea equipment, which mostly includes pipelines and drilling systems, also needs a specialized service for their underwater location. Wind turbine platforms-one most rapidly increasing categories as the world turns its head toward renewable energy-are always being looked at through regular inspections for efficiency and prevention of breakdowns.

Another crucial component of this market would be floating production systems and offshore storage facilities. These systems can be defined as those that will be extracting, processing, and storing resources away from the shore. Being situated at far-off locations means that any failure could result in major disruptions and the High cost of repairs. Pipeline results assurance and maintenance allow the uninterrupted transportation of oil and gas from offshore sites to processing facilities, free from leaks and blockages.

Technological advancements and innovations look likely to be the determinants in the way forward for the Global Offshore Inspection, Repair, and Maintenance market. The use of advanced robotics, AI-based monitoring systems, and predictive maintenance measures will provide companies with added layers of risk reduction and effectiveness. With the continual expansion of offshore operations, the demand for robust and effective maintenance will increase, thus making this market an essential one for the stability and prosperity of offshore industries all over the world.

By End-Users

The Global Offshore Inspection, Repair and Maintenance Market will grow in significance as industries increasingly depend on offshore infrastructure for energy production, exploration and all other basic activities. These linkages have intensified the demand for intense maintenance of safety, efficiency and durability of these structures. The market is driven by sectors subscribing to it differently whereas, with the advancement of technology, inspection, repair and maintenance methods and tools will become more sophisticated and efficiencies better sustained.

The major contributor to this market is the oil and gas industry. Operations that are done offshore in oil and gas industries require unparalleled monitoring and maintenance to avoid equipment failures and the liability of environmental safety. Rising demand for energy probably connects to a ballooning aspect of offshore drilling and production activities , leading up to the growing need for more frequent and advanced inspection and repair services.

To avoid accidents and downtime, there is an essential requirement for structures to be kept in their best condition because offshore conditions are really tough. Renewable energy has been playing an increasingly significant role in this market. Efficient power generation in offshore wind farms and tidal energy projects relies on reliable infrastructures. Investments in offshore renewables are anticipated to increase due to the worldwide drive for cleaner energy alternatives. The more offshore wind turbines and tidal power installations are built, the more demand there will be for inspection and maintenance services. Keeping these structures in a good state will ensure maximum energy production and avoid high costs in repairs or replacements.

The marine and shipping sector adds into the Hyperawesome market of the Global Offshore Inspection, Repair, and Maintenance. Ships, offshore vessels, and floating platforms face regular checks and maintenance. The performance and safety are directly affected by the condition of hulls, engines, and navigation systems. Future trends indicate enhanced requirement for the maintenance brigade as movement for goods and people across oceans will keep increasing.

Another major key player in the market is subsea and offshore drilling contractors. Their activities involve a lot of different, complex equipment, and deep-water structures always undergo routine inspection and maintenance. For effective resource extraction, it is essential to keep an intact condition of pipelines, drilling rigs, and production systems. Hence, more advanced inspection techniques like underwater drones, remote operated vehicles will be more widely used in improving accuracy and safety in the operations.

Apart from offshore engineering firms, government regulatory bodies also play critical roles. Engineering companies are responsible for the design and construction of offshore structures, and maintenance thereafter ensures the compliance of installations with safety and performance standards. Similarly, regulatory bodies provide laid down guidelines for compliance, thus making periodic inspections part of offshore operations. Stringent regulations driven by the growing concern for the environment may thus increase the demand for thorough and frequent maintenance.

The future of the Global Offshore Inspection, Repair, and Maintenance market will be shaped by the continuous development of technology alongside changing requirements in the key industries. Increasingly, the efforts of oil and gas companies with those of renewable energy producers, marine operators, drilling contractors, engineers, and regulators would create a market focused on safety, efficiency, and sustainability.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$16,459.97 million |

|

Market Size by 2032 |

$24,015.15 Million |

|

Growth Rate from 2025 to 2032 |

5.6% |

|

Base Year |

2024 |

|

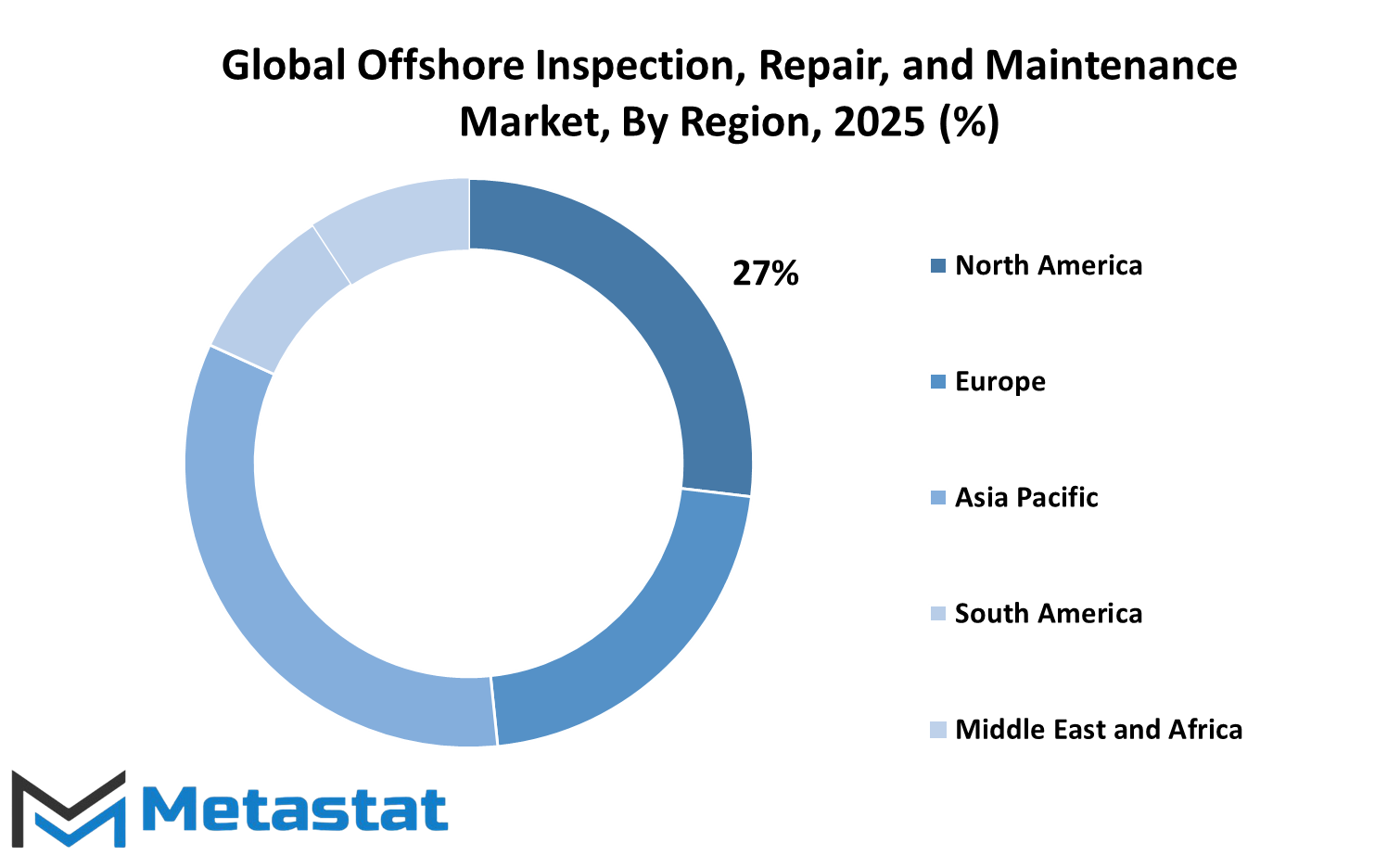

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The offshore inspection, repair, and maintenance market on a global scale is more a collection of regions that each contribute significantly to growth and development. Offshore operations are becoming more complicated as industries expand; hence, the demand for these kinds of services will rise in different parts of the world. North America has always remained one of the most influential regions in this market; here, the influence comes mainly from the United States, Canada, and Mexico. Inspection, repair, and maintenance services are in constant demand because of the region's developed infrastructure, along with considerable investments in offshore exploration and production. As technology continues to advance in favor of offshore project development, North America is expected to hold onto its influence in the times to follow.

Europe is another respective region, with countries such as the UK, Germany, France, and Italy spearheading the European offshore inspection, repair, and maintenance market. Offshore wind farms and renewable energy garnering credence amid an already-listed oil and gas industry accelerate demand for periodic maintenance and inspections. With its growing environmental concerns and tightening of safety regulations, European countries are increasingly expected to maintain efficiency and safety in offshore installations. The direct consequence of this is the sustained demand for these specialized services in years to come.

In the Asia-Pacific market, meanwhile, India, China, Japan, and South Korea are major emerging players. Rapid industrialization, energy demand, and offshore exploration increase the demand for inspection, repair, and maintenance. The country's pace-setting offshore projects and South Korean shipbuilding and offshore engineering prowess have made them the leaders of this market growth. As investments continue to be poured by these nations into offshore infrastructures, the upkeeping and safety checks will be increasingly needed, keeping the regional market on a rising growth trajectory.

Brazil and Argentina spearhead South America's contributions to the global offshore inspection, repair, and maintenance market. The offshore maintenance and repair work is in demand due to Brazil's large offshore oil reserves and current exploration activities. Growth is forecasted for the region, which is looking to improve its offshore skills.

The Middle East and Africa show immense promise due to their large reserves of natural resources combined with offshore projects coming up over time. Countries like Saudi Arabia, the UAE, and South Africa are vigorously investing in offshore exploration and development work. As these projects unfold, demands for competent and reliable inspection, repair, and maintenance services will increase.

In summary, the market for global offshore inspection, repair, and maintenance will not stand still; it will be driven by the various regional strengths and requirements. The individual regional contributions and growth prospects keep this particular market dynamic and ever-oriented towards long-term growth.

COMPETITIVE PLAYERS

The Global Offshore Inspection, Repair, and Maintenance market is expected to witness gradual growth in the foreseeable future because of the growing demand for energy and the rising number of offshore oil and gas exploration projects. As industries continue to push further into deeper waters with various limitations and challenges, this need is ever more emphasized by the efficient and timely maintenance of offshore structures. The market thus plays an important role in securing the safety and integrity of an offshore asset in terms of its operational life and performance, which include pipelines, rigs, platforms, and subsea equipment. If implemented with proper inspection and timely repair, offshore structures, under the other circumstances, face hazards and risks such as operational failure and environmental catastrophe.

The competitive landscape of the Global Offshore Inspection, Repair, and Maintenance market is influenced by several key players equipped with rich experience and advanced technologies in the field. Oceaneering International, Inc., Aker Solutions, and TechnipFMC are well recognized for their innovative spirit and market establishment in offshore operations. These firms have invested heavily in research and development for the introduction of state-of-the-art tools and techniques to ensure more efficient and accurate maintenance processes. Halliburton and Baker Hughes-the two stalwarts in the energy sector-have also stepped into the marketing arena by further enhancing their offshore service capacities. Their features comprise advanced inspection techniques and robotic technologies.

WorleyParsons, Saipem, and Wood Group also enjoy an important market share in the Global Offshore Inspection, Repair, and Maintenance market by offering some engineering and maintenance services which are adapted for offshore environments. Their capability in managing complex projects in differing regions makes them significant contributors to the overall growth of the sector. Companies such as Fugro and Subsea 7 specialize in providing subsea inspection services, including underwater inspections and ROV (remote-operated vehicle) operations; their depth in exploration and maintenance is a relative advantage over competitors.

The Allseas Group, XERVON, and Lloyd's Register bring an added diversity to this crowded competitive space, each with their own nearly exclusive strengths and capabilities. The Allseas Group is mainly concerned with offshore construction activities, as well as pipeline installation services, compared to XERVON, who provides industrial maintenance and technical services. However, having existed for so long in risk management and quality assurance, Lloyd's Register now caters to clients as assuring that their offshore assets actually meet safety and performance standards.

In future, moving ahead in the Global Offshore Inspection, Repair, and Maintenance market, competition gets fiercer among these players and therefore will tend to spark more innovation and efficiencies in their operations. The increasing application of digital tools, automation, and artificial intelligent systems will further enhance the efficacy and speed of the inspection and repair processes. These companies will keep on innovative activities due to the advantages of technological advancement, market changes, and more scope for use in safety and reliability of offshore operations globally.

Offshore Inspection, Repair, and Maintenance Market Key Segments:

By Type

- Inspection Services

- Repair Services

- Maintenance Services

By Service Offering

- Rope Access Services

- Robotic Inspection & Cleaning

- Non-Destructive Testing (NDT)

- Subsea ROV (Remotely Operated Vehicle) Services

- Welding & Fabrication

- Corrosion Control & Coating Services

By Application

- Oil and Gas Platforms

- Subsea Equipment

- Wind Turbine Platforms

- Floating Production Systems

- Offshore Storage Facilities

- Pipeline Inspection & Maintenance

By End-Users

- Oil & Gas Industry

- Renewable Energy (Offshore Wind, Tidal, etc.)

- Marine & Shipping

- Subsea & Offshore Drilling Contractors

- Offshore Engineering

- Government & Regulatory Bodies

Key Global Offshore Inspection, Repair, and Maintenance Industry Players

- Oceaneering International, Inc.

- Aker Solutions

- TechnipFMC

- Halliburton

- Baker Hughes

- WorleyParsons

- Saipem

- Wood Group

- Fugro

- Subsea 7

- Allseas Group

- XERVON

- Lloyd’s Registe

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252