Nov 19, 2025

The global once-through steam generator (OTSG) market, which has been propelled by Metastat Insight through a new industry view, is positioned at the crossroads of new energy expectations and the continuous demand for cleaner industrial systems that are efficient in space, The productions in many areas are trying hard to meet the requirements of being reliable, thermally efficient, and eco-friendly at the same time. The situation created by these requirements is such that more interest is shown to the equipment that offers steady output, lesser footprint, and improved control of the process. The increasing focus on thermal optimization has characterized the market as an important facilitator for the plants that want to increase their steam production without the need for massive changes in the infrastructure.

Current Landscape and Industry Needs

Today's industrial plants are faced with operational margins that are becoming tighter, the waste reduction pressures, and the rising energy stewardship expectations. The traditional systems for steam generation which are characterized by their larger sizes and lengthy start-up times have caused all these demands to be very hard to bear. The vast majority of the plants require systems that not only are easily integrated with compact installations but also support continuous processing and provide a consistent output even when the load conditions vary. The once-through steam generator designs are therefore responding to the practical need of being flexible, reliable, and cleaner thermal support against this backdrop. These generators are the perfect solution for industries that are upgrading their old equipment or are venturing into areas with limited space and high supervision that require smarter choices.

Function and Value Proposition

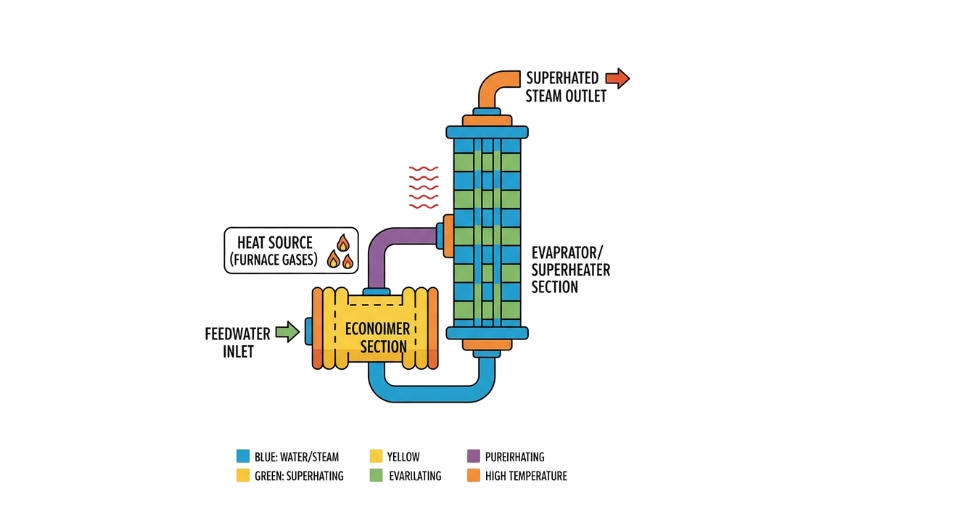

An OTG system is capable of producing steam through the circulation of water around coils, which eliminates the necessity of a large drum. This results in quick response times and easier load change transitions. The design encourages consistent operation, gives better control over steam quality and reduces the complexity of structures. Heavy oil processing, enhanced oil recovery, advanced manufacturing, or high-purity environments are the industries which can benefit the most from this method. The space-saving nature of the system makes it easier to install in places with limited space while the continuous flow design leads to less downtime, which is a common issue with traditional boiler setups. Additionally, the technology enables more efficient fuel consumption and better thermal consistency, thus assisting companies in perfecting their production processes. In the wake of increasing focus on the environment and emissions, the design is seen as a good alternative to traditional large-drum systems.

Evolution of Technology and Growing Adoption

Initial traction for once-through steam generation stemmed from sectors aiming to simplify steam supply while maintaining output stability. Over time, design refinements—ranging from improved metallurgy to smarter control algorithms—have strengthened confidence in these systems. Operators gained access to safer start-up sequences, more accurate monitoring tools, and configurations capable of supporting diverse fuel strategies. Each improvement expanded relevance across industrial ecosystems, moving the technology from niche adoption to broader acceptance. Recent advancements have also created smoother compatibility with digital operations, allowing automated adjustments that maintain consistent steam characteristics even during challenging production cycles. Gradual enhancement of reliability, maintainability, and efficiency continues to widen the market’s footprint.

Regional and Global Movements

Adoption levels differ across the world, shaped by industrial maturity, regulatory environments, and the composition of local energy systems. Areas with established heavy-industry clusters and advanced processing facilities show sustained interest due to ongoing infrastructure updates and the integration of cleaner-burning systems. Regions undertaking industrial expansion, especially in sectors requiring precise thermal management, reflect accelerating momentum as plants invest in equipment that aligns with tighter environmental frameworks. Emerging markets with new industrial corridors increasingly explore otg solutions due to their space-saving design and capacity to support growth without extensive retrofitting. The global pattern suggests expanding acceptance wherever modernization, efficiency targets, and land-use limitations intersect.

Barriers and Openings in the Market

Despite strong potential, adoption faces hurdles. Installation costs can challenge organizations managing constrained budgets, and certain applications demand specialized configurations or additional training for operators. Regulatory interpretation varies across geographies, occasionally introducing procedural delays for new projects. Competitive pressure from traditional steam systems also persists, particularly in facilities resistant to replacing existing infrastructure. Even so, opportunities remain considerable. Continued improvements in material durability, automation, and emissions-aligned operation reinforce the value of otg systems. Integration with emerging industrial technologies, expansions in process-intensive manufacturing, and demand for modular equipment create avenues for broader deployment. Collaboration between equipment providers and end-users further refines operational models, enhancing confidence and supporting long-term growth.

Growing Importance in Today’s Industrial Environment

Global pressures surrounding reduced emissions, optimized land use, and modernization of aging industrial assets highlight the significance of this market at this moment. Energy-dependent industries strive for solutions that align with cleaner production pathways, smoother load transitions, and operational transparency. The otg format supports these goals by offering a practical balance of efficiency, adaptability, and reduced spatial requirements. As industries shift toward more sustainable frameworks and digital supervisory systems, once-through design characteristics align naturally with larger transformation strategies. This creates a strong foundation for continued relevance in sectors seeking dependable thermal solutions that support environmental and economic considerations simultaneously.

The global once-through steam generator (otsg) market, presented through the lens of Metastat Insight, stands poised to influence how future facilities approach steam generation. With rising attention on cleaner processes, adaptive equipment, and streamlined energy use, the market underscores an industrial movement toward solutions built for both current pressures and long-term transformation.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479