Global Industrial Gas Springs Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global industrial gas springs market has evolved into a niche area of the mechanical parts market, influenced by decades of engineering development and the relentless quest for motion control efficiency. Its history dates back to the mid-20th century when industries wanted smoother and safer means of controlling force and motion in machines. Early models were rudimentary, dependent on coiled springs, but these were not precise nor durable. The availability of nitrogen-filled cylinders changed this situation, and it was the initial significant step toward what eventually characterized the gas spring industry.

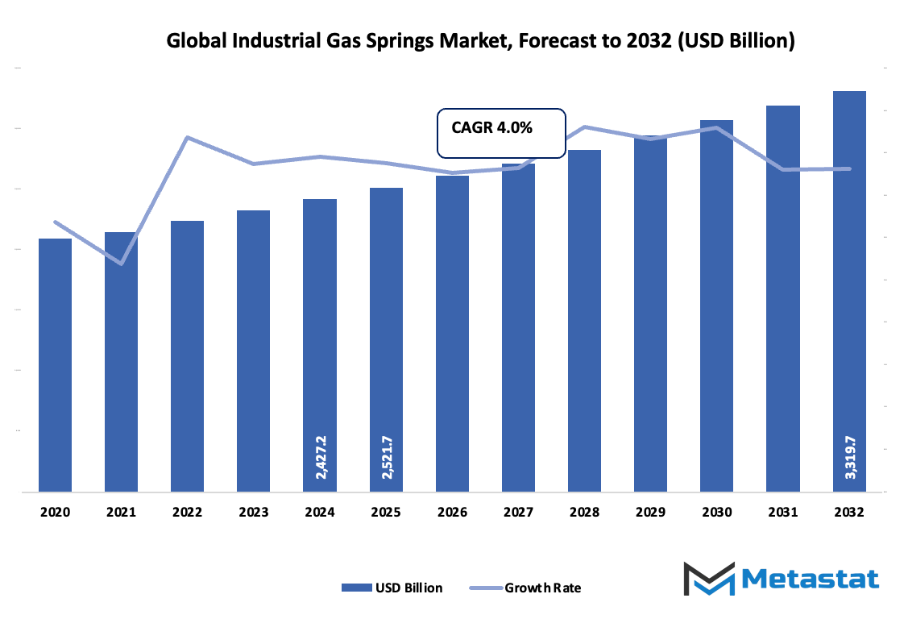

- Global industrial gas springs market worth about USD 2521.7 Billion in 2025 and growing at a CAGR of about 4.0% from 2032, with the possibility to grow beyond USD 3319.7 Billion.

- Lift Industrial Gas Spring holds almost 29.7% market share, pushing innovation and increasing usage through vigorous research.

- Major trends propelling growth: Increased use of automation and ergonomics in industrial equipment., Increased usage of gas springs in automotive, healthcare, and aerospace industries.

- Opportunities are: Widening applications and usage of stainless steel and corrosion-resistant gas springs in marine and medical applications.

- Key insight: The market is set to grow exponentially in value over the next decade, highlighting significant growth opportunities.

- In its early years, the market catered mainly to automotive manufacturers who needed reliable solutions for hoods, trunks, and seat adjustments.

As the concept proved its value, other sectors such as aerospace, medical equipment, and heavy machinery began adopting gas springs for their controlled and maintenance-free performance. The 1980s and 1990s saw explosive industrial automation, requiring more sophisticated control systems and introducing a new era of specialized gas spring design. Businesses turned their attention to variable damping systems, miniature housings, and corrosion-proof materials, a departure from standard mechanical assist components. With time, improvements in materials science and sealing technologies reshaped expectations. Stainless steel versions and progressive gas springs have set new lifespans for products operated in severe or high-load conditions. With globalization, Asian and Eastern European manufacturing centers became vital players, shaping pricing and production strategies. Concurrently, digital modeling and computer-aided design allowed quicker prototyping and testing, reducing development time significantly. Consumer and industrial needs have also changed.

Contemporary customers increasingly look for solutions that increase safety, minimize noise, and optimize energy efficiency in assembly processes. Environmental regulations and recycling consciousness have led manufacturers to implement cleaner production strategies and design gas springs which are easily disassembled or to be refurbished. As automation grows and spreads across industries, the global industrial gas springs market will keep evolving—driven not only by mechanical development but by the increasing need for intelligent, green, and people-oriented engineering solutions far greater than their original function.

Market Segments

The global industrial gas springs market is mainly classified based on Type, Application

By Type is further segmented into:

- Lift Industrial Gas Spring: Lift Industrial Gas Spring will find a vital place in lifting heavy equipment and machinery. Its primary purpose is to render controlled lifting and lowering operations, enhancing safety and convenience. With broad usage across automotive hoods, cabinets, and industrial machinery, this type will be on the rise in demand.

- Lockable Industrial Gas Spring: Lockable Industrial Gas Spring will provide adjustable and flexible positioning options. It enables users to lock the spring at any position they want, providing greater control and stability. This feature will make it appropriate for fixed-positioning applications like adjustable hospital beds and ergonomic chairs.

- Swivel Chair Industrial Gas Spring: Swivel Chair Industrial Gas Spring will continue to be essential in industrial and office seating systems. It facilitates smooth adjustment of seat height, offering comfort and ergonomic support. As more modernization takes place in workplaces and people increasingly seek comfort, the segment will continue steady market contribution.

- Gas Traction Springs: Gas Traction Springs will be used in controlled motion devices. They assist in pulling or counterbalancing motions, with smooth operation in machinery requiring uniform tension. Their demand in automobile and industrial fields will grow further in response to dependability and longevity.

- Damper: Damper shall act as a motion control component that performs shock and vibration absorption. It shall be an important component in ensuring mechanical stability and enhancing product life. Precision- and safety-oriented industries shall keep depending on dampers for controlled motion performance.

- Others: Other forms of Industrial Gas Springs will consist of specialized designs made for unique industrial applications. These can include custom-made systems for unique machinery or specific niches. Ongoing innovation and adjustment will be behind the creation of these varied gas spring solutions.

By Application the market is divided into:

- Automotive: Automotive will be among the largest end-use applications for the global industrial gas springs market. These parts will be utilized in the hoods, trunks, and seats of vehicles to ensure smooth movement and safety. Increased automotive production activities will also fuel segment growth further.

- Aerospace: Aerospace will find application for Industrial Gas Springs in accurate control of motion and support for lightweight components. Safety and performance requirements of aircraft systems will drive the demand for durable and reliable gas springs. Their performance under harsh conditions will enhance market uptake.

- Medical: Medical devices will demand Industrial Gas Springs for adjustable hospital beds, adjustable equipment, and support systems. Their easy movement and adjustability will increase convenience and operational productivity in hospitals. Increasing healthcare infrastructure will further boost the use of the product.

- Others: Other uses will be for industrial equipment, furniture, and special engineering applications. The flexibility and effectiveness of gas springs will continue to ensure acceptance in specialty solutions. Widening industrial growth globally will maintain this segment stable and increasing.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2521.7 Billion |

|

Market Size by 2032 |

$3319.7 Billion |

|

Growth Rate from 2025 to 2032 |

4.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

By Region:

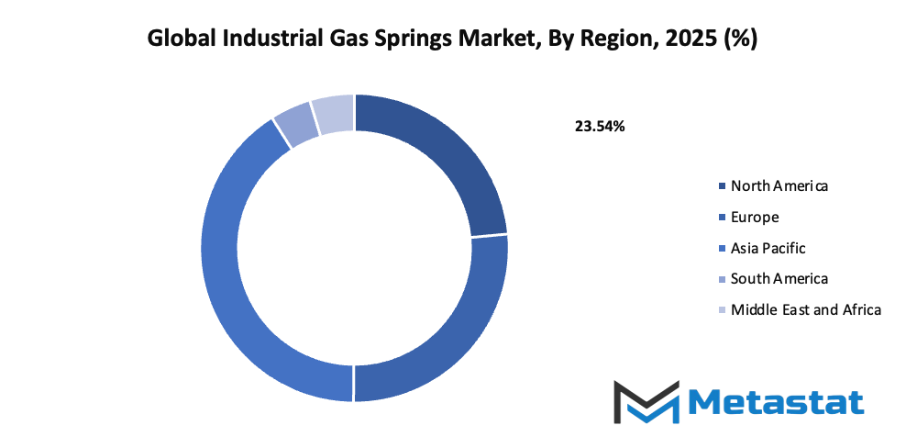

- Based on geography, the global industrial gas springs market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Rising adoption of automation and ergonomic solutions in industrial machinery: The global industrial gas springs market is growing due to increased automation and the demand for ergonomic equipment in manufacturing and production units. Industrial setups are focusing on reducing manual effort and improving efficiency, which has led to higher use of gas springs in machinery that assists with lifting, positioning, and adjusting heavy components safely and smoothly.

- Growing demand for gas springs in automotive, medical, and aerospace sectors: The global industrial gas springs market is expanding as industries such as automotive, medical, and aerospace continue to use gas springs for various applications. In the automotive sector, gas springs are used in vehicle hoods, tailgates, and seats, while in the medical and aerospace fields, they enhance precision, safety, and comfort in operations and equipment design.

Challenges and Opportunities

- High maintenance and replacement costs compared to traditional mechanical springs: A major challenge for the global industrial gas springs market is the higher cost of maintenance and replacement compared to mechanical alternatives. Gas springs require careful handling and regular servicing to prevent leakage or performance loss, which can increase long-term expenses and reduce the appeal for cost-sensitive industries.

- Limited suitability under extreme temperature or pressure conditions: The global industrial gas springs market faces performance limitations when used in extreme environments. Variations in temperature or pressure can affect gas spring functionality, leading to reduced reliability. This restricts their use in applications exposed to high heat, freezing conditions, or intense operational pressure, limiting overall market reach.

Opportunities

- Increasing use of stainless steel and corrosion-resistant gas springs in marine and medical applications: An important opportunity for the global industrial gas springs market lies in the growing preference for stainless steel and corrosion-resistant materials. These types of gas springs are well-suited for marine and medical uses, offering durability, hygiene, and resistance to moisture and chemicals, which helps extend service life and ensure consistent performance.

Competitive Landscape & Strategic Insights

The global industrial gas springs market will continue to experience significant transformation as technology, innovation, and market demands reshape how companies operate. The competitive landscape & strategic insights indicate that the sector is not only defined by established international manufacturers but also by the growing strength of regional producers entering the market. This combination of global expertise and local innovation is creating a highly dynamic environment where adaptability and forward-thinking strategies are becoming essential for success.

Prominent players such as Stabilus, Bansbach Easylift, SUSPA GmbH, HAHN Gasfedern GmbH, Ace Controls Inc., Camloc Motion Control, Special Springs s.r.l., Monroe Engineering Products, Gemini Gas Springs Inc., FIBRO, AVM Industries, Tecapres, Dictator Technik GmbH, JET Springs, DADCO Inc., Changzhou JuTeng Gas Spring Co., Ltd, and Vapsint S.R.L. are shaping the direction of the market through continuous product improvements, mergers, and collaborations. Each of these organizations focuses on developing high-performance products with enhanced durability, precision, and efficiency to meet the changing requirements of industrial applications.

In the future, automation, sustainability, and digital integration will define how competition unfolds. Manufacturers will increasingly rely on smart technologies to optimize design and production, enabling faster customization and better product tracking. The demand for gas springs that are lighter, more durable, and environmentally friendly will push companies to invest in research and development. This shift will likely result in products that not only reduce maintenance needs but also improve energy efficiency across various industrial systems.

Globalization will continue to open opportunities for cross-border partnerships, allowing regional firms to expand their influence while leveraging the technological expertise of established leaders. As more industries adopt automated equipment, robotics, and advanced machinery, the need for reliable gas spring solutions will grow. Companies that can balance quality, cost, and innovation will secure a strong position in this evolving market.

Strategic insights suggest that future competitiveness will depend on how effectively organizations use digital tools for predictive maintenance and product optimization. Artificial intelligence, data analytics, and connected systems will allow manufacturers to anticipate client needs and deliver tailored solutions with greater accuracy. This proactive approach will redefine customer relationships, emphasizing service, responsiveness, and long-term reliability over simple product supply.

Market size is forecast to rise from USD 2521.7 Billion in 2025 to over USD 3319.7 Billion by 2032. Industrial Gas Springs will maintain dominance but face growing competition from emerging formats.

As industries move toward smarter and more efficient production models, the global industrial gas springs market will continue to expand and diversify. Companies that stay committed to innovation, sustainability, and strategic collaboration will not only maintain their presence but also set new standards for performance and quality in the years ahead.

Report Coverage

This research report categorizes the global industrial gas springs market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global industrial gas springs market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global industrial gas springs market.

Industrial Gas Springs Market Key Segments:

By Type

- Lift Industrial Gas Spring

- Lockable Industrial Gas Spring

- Swivel Chair Industrial Gas Spring

- Gas Traction Springs

- Damper

- Others

By Application

- Automotive

- Aerospace

- Medical

- Others

Key Global Industrial Gas Springs Industry Players

- Stabilus

- Bansbach Easylift

- SUSPA GmbH

- HAHN Gasfedern GmbH

- Ace Controls Inc.

- Camloc Motion Control

- Special Springs s.r.l.

- Monroe Engineering Products

- Gemini Gas Springs Inc

- FIBRO

- AVM Industries

- Tecapres

- Dictator Technik GmbH

- JET Springs

- DADCO, Inc.

- Changzhou JuTeng Gas Spring Co., Ltd

- Vapsint S.R.L

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252