MARKET OVERVIEW

The global hydrodynamic couplings market are at a crossroads where engineering technology and operational effectiveness will reshape its use in various industries. The market shall no longer just be limited to its conventional role in heavy machinery but shall find an increasing role in sectors that require optimized power transmission and accurate power control. The future will see an age where these couplings are designed with new materials and adaptive designs to endure greater stress environments with minimal energy loss.

Manufacturers are seeking to carry answers beyond conventional fluid dynamics, incorporating sensors and virtual controls for predictive overall performance monitoring. These technologies will redefine how corporations view such couplings, remodeling them from mechanical gadgets into smart structures with the capacity to self-regulate. This development will permit key operations in transport, energy technology, and production, where downtime is a waste and efficiency are of the essence. The awareness can be on designs that could provide robustness at variable load conditions, promoting seamless operation even at the toughest business configurations.

Sustainability is another area that will characterize the future. As industries across the world focus on energy saving and less emissions, hydrodynamic couplings will also be redesigned to provide optimal efficiency with minimal wastage. This will not only cater to operational requirements but also integrate with environmental regulations, ensuring they become part of industries' green transition across the globe. With the use of recyclable materials and fluid substitutes, producers will make such couplings sustainable components that integrate into sustainable development objectives.

Outside the conventional fields of heavy engineering and mining, the market will discover opportunities in high-tech infrastructure development, automated production lines, and ship propulsion systems. These uses will require couplings that will provide unparalleled reliability with support for automation and digital integration. The combination of mechanical hardness and technological smarts will become the basis of innovation in this field.

In addition, the competitive environment will change to collaborate between software professionals and mechanical engineers to develop couplings that would share real-time performance information. This interlinking would provide predictive maintenance, minimizing unscheduled downtimes and maximizing the lifetime of machines. Companies implementing such technology might gain operational excellence, emphasizing the strategic significance of these merchandise.

In the years to come, the global hydrodynamic couplings marketplace will no longer simplest keep pace with industry traits; it will forge ahead of them with new standards for precision, protection, and efficiency. Its awareness on sustainability, digitalization, and modern engineering could be what drives it, making it an irreplaceable pressure in figuring out the future of business power transmission.

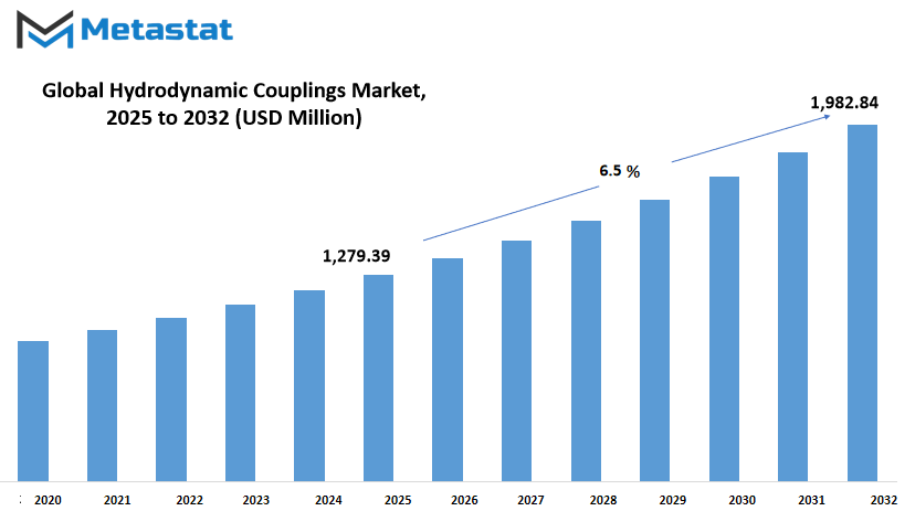

Global hydrodynamic couplings market is estimated to reach $1,982.84 Million by 2032; growing at a CAGR of 6.5% from 2025 to 2032.

GROWTH FACTORS

The global hydrodynamic couplings market is attracting interest as industries increasingly look for improved methods of power transmission with efficiency. Hydrodynamic couplings are critical in offering easy torque switch, minimizing mechanical pressure, and safeguarding structures in opposition to surprising overloading. With growing business automation and heavy-obligation packages, their call for has turned out to be more imperative. An increasing number of businesses rely upon hydrodynamic couplings to attain operational balance, especially in industries where solid electricity shipping is vital for productivity and safety.

One of the number one motives for the growing demand is their potential to enhance the performance of business gadgets. Hydrodynamic couplings are widespread in operations where reliability and frictionless strength transmission are very vital. Mining, cement plants, and marine industries have been very keen on using hydrodynamic couplings due to their provision of overload protection, which assists in protecting equipment from serious damage. This feature renders them a convenient option for applications dealing with large-scale, high-power procedures, guaranteeing low downtime and extended equipment lifespan.

Notwithstanding their advantages, the market has some drawbacks. The operating and maintenance costs of hydrodynamic couplings are comparatively higher than other existing alternatives. This aspect can restrain their uptake, particularly by firms willing to reduce costs. Variable frequency drives are also increasingly becoming a substitute technology. These drives provide accurate speed control and energy efficiency, which make them attractive to companies wanting modern, cost-saving solutions. The trend towards such alternatives is threatening the increase of hydrodynamic couplings within the long time period.

Despite those challenges, there are substantial possibilities for future growth. The use of advanced materials in coupling designs will enhance durability and diminish put on, as a result making them value-powerful in the long time. Meanwhile, digital tracking device adoption is also poised to enhance overall performance through the instantaneous provision of operational conditions statistics. Preventive preservation and top-rated device tuning will become less difficult, and probabilities of unexpected breakdowns will lower. Through those developments, the global hydrodynamic couplings market can continue to be relevant and provide extra fee to industries within the destiny.

MARKET SEGMENTATION

By Type

The global hydrodynamic couplings market is slowly influencing the management of power transmission in industries, as companies look for solutions that enhance efficiency and ensure equipment protection. Couplings find large utility across industries together with mining, power generation, and production because of their potential to limit mechanical pressure and enhance the lifespan of coupled machinery. Improved commercial automation coupled with elevated requirements for smoother torque transmission will result in accelerated demand for hydrodynamic couplings throughout numerous regions.

The global hydrodynamic couplings market provides a variety of types, each tailored to meet operating requirements. One of the most prevalent types is constant-fill hydrodynamic couplings due to their simplicity and reliability. They consist of a constant oil filling, hence making them perfect in applications necessitating regular transmission of torque with minimal fluctuation. Conversely, variable-speed hydrodynamic couplings offer greater flexibility since they are capable of responding to changes in speed, providing greater control in operations where there is load and speed variation. These are the characteristics that make them ideal for energy-efficient industries as well as adaptable operations.

Delay-fill hydrodynamic couplings offer an additional degree of control by having a time delay prior to full torque transmission, which serves to prevent shock loads during startup. This feature makes them very valuable in heavy-duty applications like conveyors and crushers, where equipment requires soft start to prevent mechanical stress. Likewise, fill-controlled hydrodynamic couplings enable operators to change the quantity of working fluid in real time so that torque and speed can be precisely controlled. This model is widely used in current automated systems where accurate performance adjustment is very crucial for productivity.

As industries continue to pursue the optimization of performance and reduction of downtime, these various forms of hydrodynamic couplings will see increasing usage. Their capacity to provide smooth power transmission, guard motors from damage, and enhance operating efficiency renders them a vital element in industrial systems. As technology continues to advance the design and capabilities of these units, the market will continue to be a significant sector of the international power transmission business for the foreseeable future.

By Application

The global hydrodynamic couplings market is of significant use to industries with the need for efficient and smooth power transmission. They find extensive application as they lower mechanical stress, while also facilitating torque control, in operations. Hydrodynamic couplings are unlike stiff connections in that they provide for deformable movement among joined parts, thus avoiding shock conditions and wear on machinery. This feature makes them a solution of choice in applications where controlled speed and energy efficiency are critical to ensure constant performance.

One of the key uses of hydrodynamic couplings is in transmitting power. They find substantial utility in instances wherein power switch among components have to be smooth and constant. In heavy-responsibility operations, manufacturing, and mining industries, those couplings additionally make sure overload prevention and act as a cushion impact to guard the motor and driven system. This position proves specifically vital with the operation of large equipment that undergoes high versions in torque.

Additionally, Industrial device is based on those couplings for uninterrupted operation without mechanical failure-triggered interruptions. Machines which include conveyors, crushers, and mixers typically operate under stressful situations where overloading or abrupt breaks can result in steeply-priced downtime. Hydrodynamic couplings offer a secure, efficient means of controlling such hazards with the aid of presenting a easy begin and controlled acceleration. For conveyors that delivery heavy masses or crushers that handle bulky substances, flexibility lessens the danger of breakdowns and prolongs the lifespan of the equipment.

The global hydrodynamic couplings market also has excellent demand from industries that employ pumps, compressors, and fans. In such uses, ensuring constant speed and safeguarding against motor overload is paramount. Hydrodynamic couplings enable variable speed control, which is extremely beneficial for pumps operating on fluids at varying flow rates or fans used in systems with varying air volume demands. Through mechanical strain discount and shock absorption, these couplings make certain operation stability, that's crucial to overall performance and safety.

As industries attention more on durability and power efficiency, the call for hydrodynamic couplings in these applications will remain high. With its ability to decrease wear and tear, beautify overall performance, and offer flexibility, those couplings become a sincere alternative in numerous heavy-responsibility and precision-based operations. With similarly technological improvements and the pressure for more automation, these couplings becomes even more crucial to resource business structures that call for continuous and dependable strength transmission.

By End User

The global hydrodynamic couplings market is getting more attention because of its critical application in enhancing the efficiency and reliability of industrial processes. They are commonly deployed to transfer torque between shafts in heavy machinery, providing smooth power transmission and shock absorption and vibration protection. They provide speed and torque control without mechanical contact, which is one of the reasons why they are most desired in industries seeking durability and accuracy. As industrial applications continue to look for solutions that minimize wear and tear while ensuring operating stability, hydrodynamic couplings will be a vital component of the equipment landscape.

When considering the global hydrodynamic couplings market by end-user, the mining sector accounts for a major percentage due to the heavy equipment used in material extraction and haulage. Hydrodynamic couplings used in mining machinery assist in controlling high torque requirements and abrupt loads, thus diminishing the load on equipment and prolonging operational life. Likewise, the cement sector also finds these couplings suitable for use in conveyors, mills, and crushers, where performance should be consistent under aggressive conditions. These industries are favored by these couplings owing to their capacity to take shocks and avoid overloading, reducing downtime and maintenance expenses.

The power generation segment is another prominent application area for hydrodynamic couplings, particularly in systems requiring controlled startup and smooth acceleration of heavy machinery. In thermal and hydropower plants, they provide stable operation under fluctuating loads. The oil and gas sector also accounts for significant market growth since couplings are employed in drill rigs, compressors, and pumps where reliability is a matter of utmost importance. Their application in avoiding mechanical breakdowns in high-hazard conditions makes them an essential part in these industries.

Other sectors like marine, petrochemical and chemical, automotive, and pulp and paper also contribute significantly to driving demand. Hydrodynamic couplings are utilized by marine ships in propulsion drives to provide smooth maneuvering and load management. In the petrochemical and chemical industry, they facilitate processes demanding accuracy and safety in harsh operating conditions. The automobile industry uses these couplings for heavy-duty motors and specialized device, even as the pulp and paper industry makes use of them to enhance productiveness in massive-scale processing machinery. All of those industries appreciate the consistency of hydrodynamic couplings in performance, strain reduction on machinery, and multiplied operational protection.

In total, the global hydrodynamic couplings market will keep expanding as industries invest in equipment that provides durability and operational versatility. Their use across various industries underscores their significance in the preservation of efficiency, reduction of equipment damage, and facilitation of the smooth operation of important processes. With continuous industrial growth and the increased demand for dependable torque transmission solutions, this market will be an integral component of the industrial machinery sector for years to come.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,279.39 million |

|

Market Size by 2032 |

$1,982.84 Million |

|

Growth Rate from 2025 to 2032 |

6.5% |

|

Base Year |

2024 |

|

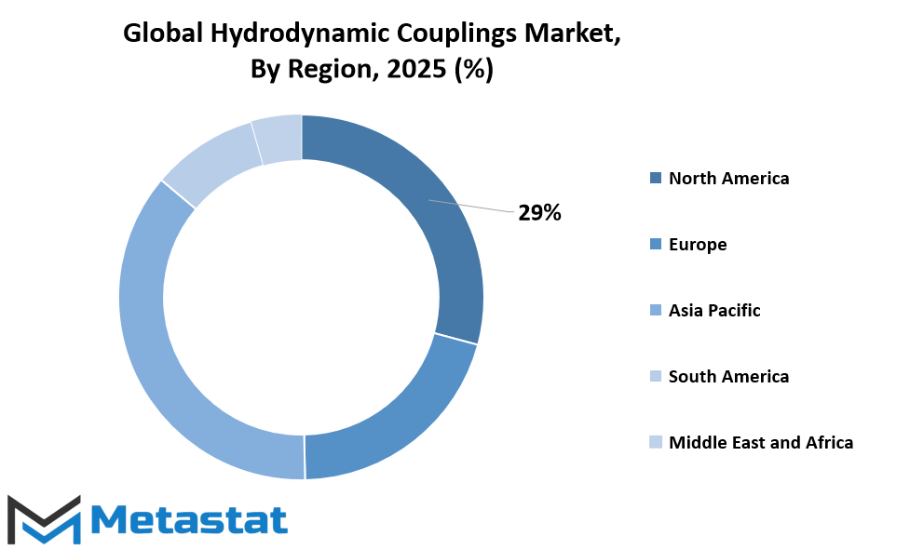

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global hydrodynamic couplings market is quite influenced by its global reach, and the demand patterns across key regions differ. Every region has its very own business necessities, generation degrees, and funding reasons, and these contribute to the general marketplace increase. Segmentation based totally on region makes it simpler for businesses to recognize where the finest adoption prices are happening and what forces are propelling the marketplace in diverse areas worldwide. Companies intending to develop the world over may also take these geographical segments into attention so that you can formulate specialized strategies.

North America commands a massive percentage within the market courtesy of a strong manufacturing base and sophisticated technology integration. The region comprises the U.S., Canada, and Mexico, in which sectors like mining, electricity, and manufacturing preserve to depend on powerful power transmission systems. The United States reigns ideal inside the place way to its mega-scale infrastructures and ongoing industrial machinery modernization. Canada and Mexico add their share through their expanding manufacturing industry and investments in energy projects, with North America being a significant hub for hydrodynamic coupling demand.

Europe is also a major market, with major nations such as the UK, Germany, France, and Italy taking leadership. This area is concentrated on energy efficiency and sustainability, prompting the uptake of advanced coupling systems. Advanced engineering industries in Germany and industrial upgrading in the UK are key drivers of market growth in this area. France and Italy also feature significantly by making investments in upgraded manufacturing and power generation facilities. The remainder of Europe contributes to the demand as some nations attempt to increase industrial production while keeping in line with environmental regulations.

The Asia-Pacific has huge ability for increase, fueled by full-size industrialization across international locations like India, China, Japan, and South Korea. China dominates the location thru its widespread production zone, at the same time as India is experiencing a surge in strength and infrastructure projects. Japan and South Korea cognizance on technological advancements and automation, which will increase the usage of hydrodynamic couplings in new industries. The rest of Asia-Pacific additionally performs its part, with the smaller economies enhancing their industrial base to in shape global standards, riding this area to be a major motive force for the market's growth.

COMPETITIVE PLAYERS

The global hydrodynamic couplings market is drawing interest since businesses are always looking for trustworthy power transmission solutions that will provide smooth and efficient performance. Couplings are extremely common where controlled transmission of speed and torque is required in applications like mining, energy generation, maritime operations, and material handling systems. The technology utilizes fluid dynamics to permit secure transmission of power with reduced mechanical wear and shock absorption during operations. This renders hydrodynamic couplings a critical component in systems where durability and flexibility are required for fluctuating loads.

Demand for hydrodynamic couplings will continue to be on the rise as there will be a greater need for high-performance machinery in the power generation, steelmaking, and heavy industry manufacturing industries. The machinery in these sectors needs to be able to absorb sudden changes in torque without damaging motors or driven equipment. Through controlled acceleration and deceleration, these couplings enhance operational safety as well as increase the lifespan of vital components. This capacity to minimize mechanical stress and provide smooth power transmission makes them a viable option for firms that are looking to improve efficiency and minimize upkeep expenses.

Top players are driving innovation in this market. Major players in the global hydrodynamic couplings market are Voith GmbH & Co. KGaA, Siemens AG, Rexnord Corporation, Vulkan Group, KTR Systems GmbH, Fluidomat Limited, Transfluid S.p.A, Flender GmbH, TYMA CZ, s.r.o., Westcar S.r.l., and Kudosworld Transmission Equipment Co., Ltd. These companies specialize in providing advanced designs with enhanced energy efficiency, more torque capacity, and compact design. Most of them are investing in research to come up with products that can meet industries with specific needs, including industries with extreme operating conditions.

Prospects for the global hydrodynamic couplings market in the future are bright as industries around the globe proceed to upgrade their machinery and emphasize energy efficiency. Increasing industrial automation, along with demand for low-maintenance and high-performance transmission solutions, will tend to drive the use of these couplings. In addition, as global infrastructure development grows and industries like the mining and energy sectors experience growth, the demand for long-lasting and efficient coupling solutions will rise. With advances in technology and ongoing innovation by the main players, the market is set to be a significant sector of the power transmission business.

Hydrodynamic Couplings Market Key Segments:

By Type

- Constant-fill Hydrodynamic Couplings

- Variable-speed Hydrodynamic Couplings

- Delay-fill Hydrodynamic Couplings

- Fill-controlled Hydrodynamic Couplings

By Application

- Power Transmission

- Industrial Machinery

- Conveyors

- Crushers

- Mixers

- Pumps

- Compressors

- Fans

By End User

- Mining Industry

- Cement Industry

- Power Generation

- Oil and Gas Industry

- Marine Industry

- Chemical and Petrochemical Industry

- Automotive Sector

- Pulp and Paper Industry

Key Global Hydrodynamic Couplings Industry Players

- Voith GmbH & Co. KGaA

- Siemens AG

- Rexnord Corporation

- Vulkan Group

- KTR Systems GmbH

- Fluidomat Limited

- Transfluid S.p.A

- Flender GmbH

- Vulkan Group

- TYMA CZ, s.r.o.

- Westcar S.r.l.

- Kudosworld Transmission Equipment Co., Ltd

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252