MARKET OVERVIEW

The market for Global Crane Rail is a part and parcel division under the purview of heavy machinery and construction industries. This market consists of the manufacturing, distribution, and maintenance of rails specifically built for cranes used in a very wide industrial base. Based on integrated use in an array of industries, cranes using these specialized rails extend to performing heavy lifting and materials movement that is required to be precise in shipping, manufacturing, and construction, among others.

The crane rail systems provide the maintenance of a stable and strong track for the movement of the cranes. These systems hold a very important part in working with heavy loads for high work efficiency and operational safety. Major developments in the Global Crane Rail market are being spurred by technological advancements in the sector and growing demand for efficient solutions in material handling. Advancements in materials and designs of the available rails are likely to further enhance their durability and performance, which can make crane rail systems even more durable under rugged conditions in industrial environments.

With the growth in industries and the number of infrastructure projects taking place, there will also be a rise in the demand for stable and reliable crane rail systems. The Global Crane Rail market will have a central role in what will happen in the future, since, day by day, cranes will be able to be used in a more effective and safer manner. The future improvements will probably focus on better quality and lifespan of crane rails, addressing issues with wear and tear, and increasing load capacity.

Apart from technological advancement, it will be the regulators' standards pressed on the market to ensure safety and, simultaneously, keep the environment conducive. The manufacturers of production will run under stringent regulations that compel constant innovation and quality of developed crane rail systems. The other major trend in the manufacture of crane rails would be towards the use of sustainable material and practices with worldwide focus on reducing the environment load.

The competitive landscape for the players operating in the global crane rail market would have efforts in line towards betterment of the product line and creation of a higher footfall in the target market. The organizations would invest in R&D for innovative products matching the growing needs from the customer's end. The strategic partnerships and collaborations will be necessary for growth and innovation.

Emerging markets will thus translate to new opportunities for growth as industrialization and infrastructure development hastens in such regions. Crane rail system demand is high within countries massively investing in construction and manufacturing projects. This trend will further help the Global Crane Rail market expand, developing a window for manufacturers to tap other markets and diversify their customer base.

The prospects for the Global Crane Rail market in the coming period will be inflenced by technological innovation, regulation influnces, and market dynamics. Crane rail systems have long been an integral part of any manufacturing process, and as industries evolve to demand more heightened solutions for efficient material handling, innovation in the crane rail market is always one step ahead. Resultantly, the market follows the changes in line with demand dynamics and applications from a diverse customer base, while consistently upholding safety and contribution towards sustainable growth.

Conclusion The Global Crane Rail market would witness substantial transformation facilitated by improvements in technology, government regulations that are coming up, and the increased demand for crane rail systems that are effective and reliable. The future market would, without any doubt, and without a shred of controversy, revolve around continuous innovation and adaptation that would guarantee it a space in any of the varying industrial operations that need cranes for heavy lifting and proper material mobilization. As the market evolves, it will play a critical role by supporting the growth and development of several businesses across the globe.

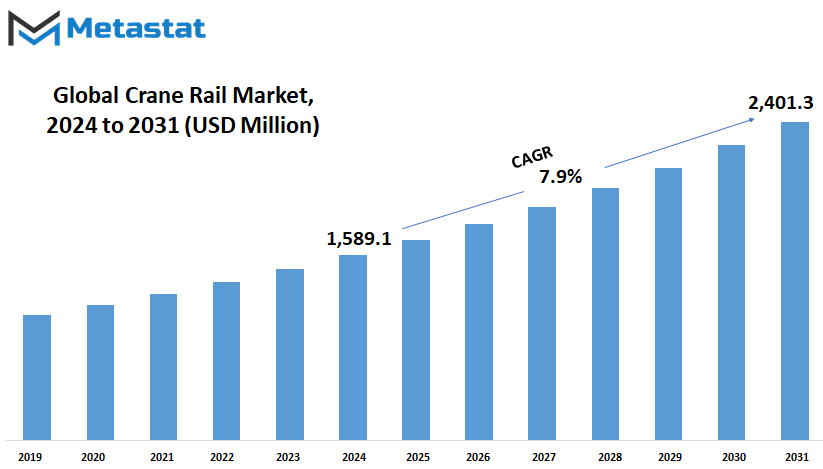

Global Crane Rail market is estimated to reach $2,401.3 Million by 2031; growing at a CAGR of 7.9% from 2024 to 2031.

GROWTH FACTORS

The global crane rail market is foreseen to behold growth of great magnitude in the years to come, with several triggers lined up across the market. This would accrue out of industrialization and rapid infrastructure expansion, which has accelerated the demand for crane rail systems across various industries, from manufacturing to logistics and construction. These systems were attaining remarkable significance in the handing over of materials and traveling of equipment that support operational efficiency and productivity across industries.

Advancing crane technologies and automation place additional force behind this growth trajectory. In fact, state-of-the-art crane systems require more reliable and efficient rail networks in today's industry. These developments increase operational capabilities while making a valuable contribution to overall safety and precision in the process of handling.

Despite these optimistic trends, the challenges to market growth do prevail. The high upfront costs for installing and maintaining crane rail systems remain major constraints, especially large-scale projects or specialized applications. These costs often become a turn-off, hence slowing down the rate of acceptance in the market.

Another critical challenge is that there is a limited amount of skilled labor and expertise available for the installation and maintenance of crane rail systems. The shortage of competent personnel can result in project delays, poor installation quality, and hence negatively affect general performance and reliability.

Opportunities are likely to crop up in this global crane rail market. Notably, an opportunity includes expansion into emerging markets and sectors, such as renewable energy, aerospace, and shipbuilding. These industries are increasingly making use of state-of-the-art crane technologies to support their uniquely complex operational needs, opening new avenues for market growth and diversification.

Despite the cost and expertise of the workforce, the outlook for the global crane rail market is still exciting. The sustained industrialization and infrastructure development in most parts of the world are reportedly, coupled with technology innovations in crane systems, going to raise significant demand for cost-effective, efficient, and reliable rail solutions in the coming years. Besides, new applications being explored in emerging sectors are likely to present gainful opportunities to industry participants. It becomes imperative for stakeholders in the crane rail market to deal with such dynamics in a very strategic way in order to seize growth opportunities and serve the diversified industry demand effectively.

MARKET SEGMENTATION

By Type

This crane rail market is the most dynamic for any type of crane machinery, be it gantry cranes, overhead cranes, AS/RS systems, portal cranes, stacker or reclaimer cranes, stadium roofs, or rail-mounted tower cranes. The very important industries where the importance of such segments was realized are manufacturing, logistics, construction, and entertainment.

Gantry cranes are among the most versatile types of cranes used at ports, shipyards, and building sites owing to the strength in their operation. Overhead cranes will remain cardinal in any industrially based organization or company for quick, easy, and safe processes of lifting and moving material around. AS/RS systems are automated devices more and more applied in warehouses for storing and retrieving goods, which raises performance. Portal cranes, featuring great lifting capacity, form a strong need in container terminals and shipyards with the purpose of loading and unloading cargo.

Stacker or reclaimer cranes thus play a very important role in the handling industries of bulk material, like mining and generation of power. Stadium roofs, which use innovative crane rail systems, make possible the smooth operation of the retractable roofs in sports venues so that events continue uninterrupted by weather conditions. Rail-mounted tower cranes are flexible and strong in high-rise construction projects and make it easier to lift construction materials to heights safely and efficiently.

The prospects of this market look quite promising over the next few years, since industries are continuing to spend on building up infrastructure, automation, and high-end technologies. On the other hand, increasing urbanization, industrialization, and expansion of logistics and transportation networks across the world support its growth. In addition, stringent safety regulations imposed by authorities and the need to achieve operational efficiency have been fueling the demand for sophisticated crane rail systems across all applications.

By Weight Carrying Capacity

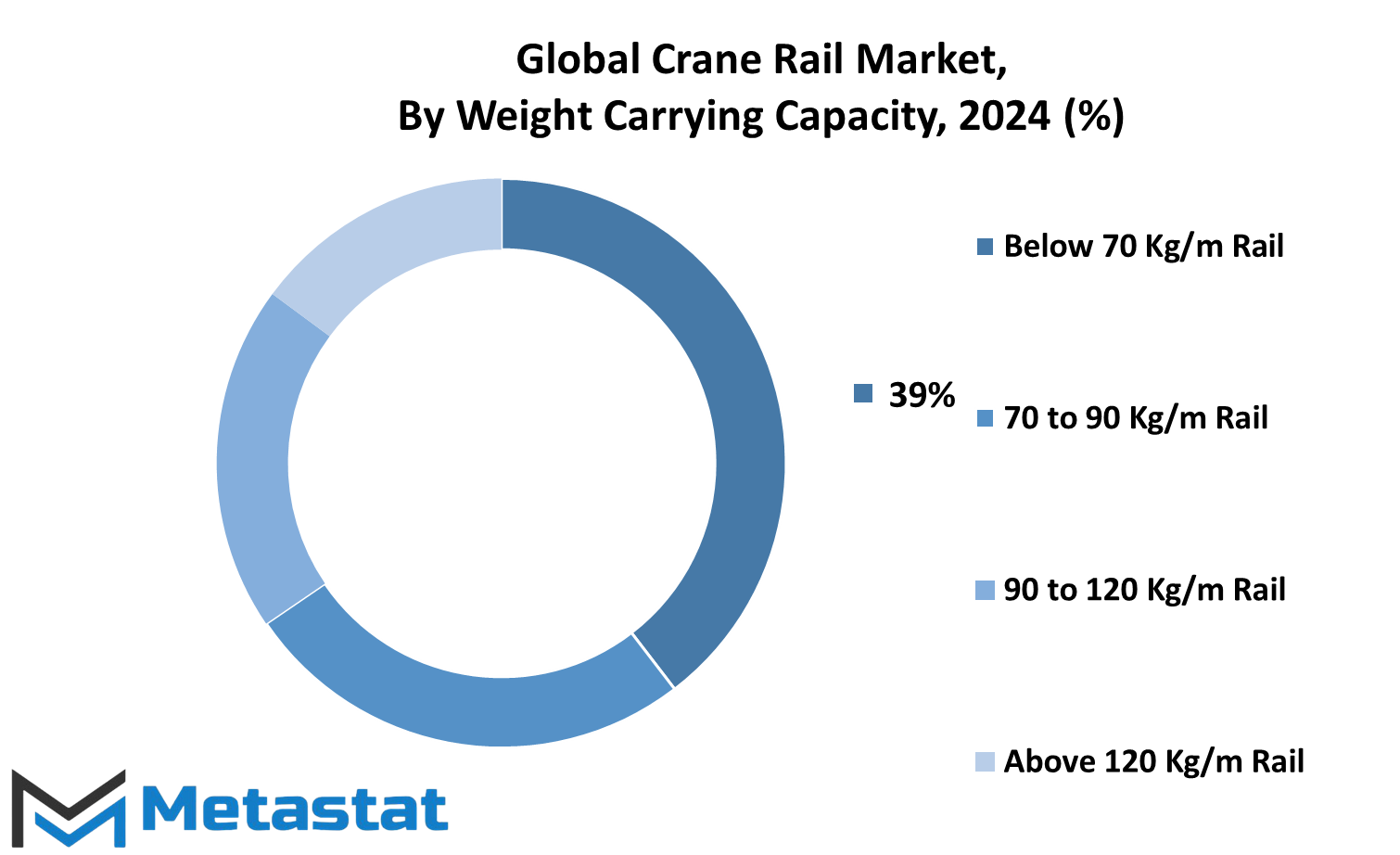

By weight-carrying capacity, the crane rail market caters to those rails that would support the smooth operation of cranes in many industries. These rails are classified by their weight-carrying capacity into below 70 Kg/m, 70 to 90 Kg/m, 90 to 120 Kg/m, and above 120 Kg/m. All these types meet special needs regarding various load requirements and working conditions under which cranes are used in several industries worldwide.

Most of the rail segments used in applications are of a weight-carrying capacity of less than 70 Kg/m. Such rails are normally applied in light-duty situations where the weight to be carried is modest. These rails can provide adequate support to smaller cranes handling lighter material or components normally found in small-scale manufacturing and warehousing industries.

Moving up in weight capacity, the 70 to 90 Kg/m category caters to a broader reach of industrial needs. Cranes that travel on these rails are able to move larger loads and typical in medium to heavy-duty manufacturing environments. These rails are more solid and stable; their durability and stability are very important in ensuring that cranes moving heavier materials or larger components perform reliably.

Furthermore, the 90 to 120 Kg/m rails make up a significant share of the market, serving industries operating robust crane systems that can handle high loads moving precisely and efficiently. These rails are used in heavy industrial settings such as steel mills, shipyards, and large-scale manufacturing plants.

At the upper end, rails above 120 Kg/m are designed for the most demanding industrial applications. Cranes using such rails can handle very heavy loads over long distances without risky loss in safety or efficiency. This would include very heavy machinery manufacturing, aero-space, and infrastructure developments.

The global crane rail market outlook is positive, with the drivers identified as industrial automation, infrastructure development projects, and increasing global trade activities. As industries continue to grow and modernize, demand related to crane rails with higher weight carrying capacity is likely to rise. To this end, the manufacturers will need to develop innovative rails of advanced strength, durability, and efficiency of operation so that they can conform with the changing demands of the applications from the industrial crane use in the international arena.

By Material

The Global Crane Rail market forms an exciting and dynamic part of today's world, into which many interlaced markets in this infrastructure sector flow. These various material markets, such as Steel and Aluminum, among others, perform contributory roles for the same.

Steel provides a strong base to crane rails with the requirement of durability and strength in heavy-duty applications. It finds a place in almost every industrial setup around the globe and forms a reliable structure in demanding environments. On the other hand, aluminum possesses some advantages regarding weight and corrosion resistance. With such properties, it becomes ideal for projects that require weight minimization and maximum life expectancy.

Finally, "Others" represents materials like composite materials or alloys that can provide focused benefits like better electrical conductivity or specialized environmental adaptations. A number of further developments in the Global Crane Rail market are foreseen in the future, driven by both technological advances and material development. More focus is expected on the further development of performance characteristics for present materials and the search for new materials that can offer improved performance characteristics. It will be part of the trend in sustainability, where materials that have low environmental impact will be broadly called for.

Furthermore, increasing investment in infrastructure globally and, particularly, in emerging economies—where rapid urbanization necessitates strong logistics and industrial capabilities—will be another factor behind market growth. Moreover, the path ahead for advanced manufacturing technologies, such as automation and digitalization, will lie in reshaping the industry landscape in terms of better production organization and improved product quality.

By Application

The crane rails market caters to different industries with varying applications. These industries range from the industrial and marine, through logistics and mining, to others. The industrial segment consumes crane rails on a large scale for moving heavy materials around factories and warehouses. This makes for smoother handling of raw materials and finished products, increasing the efficiency of various operational workflows.

In the marine sector, crane rails are core in cargo loading and offloading in harbors and shipyards. They make the transaction of containers and cargo easy from the ships to the storage yard or to any other means of transport, thus improving the efficiency of the ports. Logistics In transport centers, crane rails are very helpful in distribution centers where they allow quick movement of commodities from one means of transport to another like trucks to trains.

Further, the mining industry makes use of heavy crane rails for mineral and ore extraction and transport. In mining activities, they depict a system of motion for heavy equipment and material flows across rough landscapes and processing plants. Moreover, applications of crane rails also allow them to be used in other industries, from construction sites to energy facilities, while they help not only in installation but also in maintenance work of infrastructure and equipment.

The crane rail market is driven by technological development and growth in infrastructure across the globe. Innovations in material science and manufacturing processes will further enhance durability and efficiency of crane rails and cater to the changing industry demand. Growing investments in industrial and logistics automation will also drastically increase the demand for crane rail systems, as they are key to improving operational productivity and safety.

Furthermore, market dynamics will be influenced by environmental considerations and regulatory requirements that will make the development of sustainable crane rail solutions a necessity. As the world moves to achieve the sustainability goals, more emphasis on eco-friendly raw materials and energy efficiency designs is expected..

REGIONAL ANALYSIS

The global Crane Rail market has been divided into North America, Europe, Asia-Pacific, South America, and Middle East & Africa in this report. Especially, each individual region plays a significant role in the global market.

North America comprises the United States, Canada, and Mexico. It hosts a very developed industrial sector with huge infrastructure investments, established players, and technological advancements in the crane rail systems market.

It involves some of the major economies like the UK, Germany, France, Italy, and the Rest of Europe. The region has a strong manufacturing base and a rigorous regulatory environment that favors diffusion of cutting-edge crane rail technologies. Other drivers to the growth of the market include economic stability and many infrastructure projects.

Asia-Pacific comprises nations such as India, China, Japan, South Korea, and the Rest of Asia-Pacific. The rapid industrialization, urbanization, and infrastructural developments going on in emerging economies boost the demand for crane rail solutions. Market growth in this region is set to be fueled by the investments in smart city initiatives and logistics infrastructure.

South America, including Brazil, Argentina, and the Rest of South America, represents a region with a developing industrial sector and, at the same time, with more investments in transport and logistics. The extension of harbour facilities and mining activities are pushing the demand for efficient crane rail systems.

After that, the Middle East & Africa region is segmented into GCC Countries, Egypt, South Africa, and Rest of Middle East & Africa. It is a region where there is a mix of developed and many developing economies, with infrastructure investments already underway, particularly in the construction and oil and gas industry sectors. This is likely to drive the demand for reliable solutions in crane rails to be used in this infrastructure work.

Each geographical region is known to have distinct opportunities and challenges for the Crane Rail market. The market dynamics at the regional level are premised on factors such as economic growth, industrial activities, infrastructure investments, and regulatory policies. It is, therefore, of utmost importance that stakeholders understand these regional nuances to strategize their entry into the regional market, expansion, and product development initiatives.

In this regard, the regional analysis of the global Crane Rail market underpins varying market conditions across North America, Europe, Asia Pacific, South America, and Middle East & Africa. The strategic assessment taken on these regions furnishes thick idea about market trends, competitive landscapes, and growth prospects that aid the stakeholders in making business decisions to leverage the opportunities emerging in the market.

COMPETITIVE PLAYERS

The global crane rail market is gaining immense momentum due to the increasing demand for efficient material handling systems across various industries. Growing infrastructure development and industrialization would necessitate reliable crane rail systems. Thus, major competitive players in this market drive its future with continuous innovation and ability to evolve according to the growing demands of their customers.

The prominent companies in crane rails include Ansteel and BaoTou Steel, known for their superior steel products that form the backbone of durable crane rails. Their insistence on advanced techniques of manufacturing and stringent quality control measures keeps them at the forefront. Likewise, EVRAZ and ArcelorMittal are recognized for their robust supply chains and a wide network of distribution.

SAIL and L.B. Foster have increased their production capacity manifold to meet the growing demand. The companies have engaged themselves in research and development to produce very many innovative products to suit their specific requirements of the industry. NSSMC and British Steel, with their decades of experience in steel making, still occupy a niche position in the market through their more reliable and high-performance crane rails.

Some of the major players in this industry include JSPL and Hebei Yongyang, attributed to their competitive pricing strategies and commitment towards green initiatives. Their efforts to reduce carbon footprints and deliver a better environment are very much in tune with the global 'green' movement. Gantrex and Bemo Rail are companies that essentially provide customized solutions to their clients to ensure that their unique requirements are met out for their diversified customer base.

Atlantic Track and Harmer Steel are known for their good customer service and after-sales support, a very important part of any business in establishing long-term relations with clients. Geographic presence in multiple regions is the key to serving a variety of diversified markets for Metinvest and Gantrail Group. North American Rail Products Inc. and Özkan Steel A.S. use their location advantage and state-of-the-art manufacturing facilities to provide solutions in the most efficient and timely manner for their clients.

HBIS Group Co. Ltd is well-supported by strong research capabilities, and innovation of products never stops. All these companies do not just work to cater to the market demand present in the current scenario but also strive to foresee future trends. They spend a lot on technology and innovation to ensure that their products evolve with the changing requirements of the industry.

The outlook for the global crane rail market looks very promising with such competitive players. Their commitment to quality, innovation, and customer satisfaction will surely drive the market to grow and adapt to new challenges and opportunities. As industries around the world strive to become more efficient and sustainable, demand for advanced crane rail systems will continue to rise, further driving the expansion of the market.

Crane Rail Market Key Segments:

By Type

- Gantry Cranes

- Overhead Cranes

- As/Rs Systems

- Portal Cranes

- Stacker Or Reclaimer Cranes

- Stadium Roofs

- Rail-Mounted Tower Cranes

By Weight Carrying Capacity

- Below 70 Kg/m Rail

- 70 to 90 Kg/m Rail

- 90 to 120 Kg/m Rail

- Above 120 Kg/m Rail

By Material

- Steel

- Aluminum

- Others

By Application

- Industrial Sector

- Marine Sector

- Logistic Sector

- Mining Sector

- Others

Key Global Crane Rail Industry Players

- Ansteel

- BaoTou Steel

- EVRAZ

- ArcelorMittal

- SAIL

- L.B. Foster

- NSSMC

- British Steel

- JSPL

- Hebei Yongyang

- Gantrex

- Bemo Rail

- Atlantic Trac

- Harmer Stee

- Metinvest

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383