MARKET OVERVIEW

The Global Fiber Reinforced Polymer Rebar market and its industry are going to witness tremendous developments due to the infrastructure projects requiring stronger and longer-lasting construction materials worldwide. Traditionally, the steel reinforcement is facing issues like corrosion and maintenance costs, for which FRP rebar is gaining footing as an alternative.

This trend is not only redesigning the methodologies of engineering but also influencing material selection in construction, marine structures, and energy projects. With the sustainability and efficiency goals that industries pursue, the FRP rebar's role may grow beyond conventional uses, which means it has been a focus of extensive research and technological innovation. The reinforcement sector for structural purposes has been using materials that offer both strength and toughness for ages.

However, the disadvantages of steel in terms of susceptibility to moisture and chemical environments necessitate a more long-lasting substitute that does not reduce load-bearing strength. It is for this reason that composite materials have become an important replacement choice, with FRP rebar being an especially attractive alternative based on its resistance to corrosion and high tensile strength. Other sectors, such as transportation and defense, are currently considering its possible application in lieu of conventional rebar in crucial infrastructure.

The manufacturing processes for FRP rebar have been under investigation to make it better mechanically and to facilitate its introduction into existing frameworks of construction. Material scientists have been working to enhance bonding properties so that the interaction between the reinforcements and concrete mixtures occurs with minimal loss of structural stability.

As the construction industry increasingly employs advanced building techniques, the ability of FRP rebar to be used in conjunction with automated manufacturing and prefabrication techniques will likely play a key role in its extensive use in contemporary architectural projects. The implications of this trend are not merely about substitution for steel. The more extensive use of FRP rebar may alter supply chain dynamics, necessitating changes in production facilities and logistics networks. As new manufacturing bases arise to feed the increasing demand, localized production may reduce dependency on traditional reinforcement suppliers and rewrite market competitiveness.

The sustainable industries will lobby for regulatory changes to promote corrosion resistance and thereby result in revised building codes and construction standards. One of the critical aspects that will shape the industry is continuous material research focused on making FRP rebar more cost-effective without sacrificing structural benefits.

Advances in composite fiber technology and resin formulations will play a crucial role in ensuring that this material meets the requirements of high-stress applications. Additionally, the recyclability and reusability of FRP components are likely to be further explored to address environmental impact and long-term waste management. As technology continues to redefine construction methodologies, the integration of smart monitoring systems with FRP rebar could become a focus area.

The possibility of embedding sensors within these reinforcements to provide real-time structural health data may enhance safety measures and predictive maintenance strategies. With infrastructure projects increasingly prioritizing resilience and durability, such innovations will likely drive further interest in advanced composite materials.

The Global Fiber Reinforced Polymer Rebar market will continue evolving in response to shifting industry demands and technological breakthroughs. As it gains traction across various applications, its impact on construction, engineering, and material science will become more pronounced. The transition toward more durable and maintenance-free reinforcement solutions will redefine industry standards, shaping the future of structural development and sustainable construction practices.

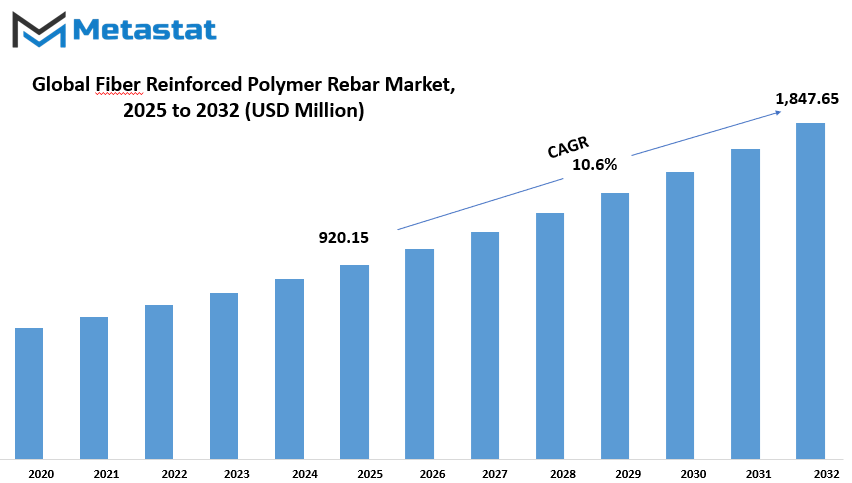

Global Fiber Reinforced Polymer Rebar market is estimated to reach $1,847.65 Million by 2032; growing at a CAGR of 10.6% from 2025 to 2032.

GROWTH FACTORS

As awareness of corrosion-resistant material in construction is increasingly spreading across industries, the Global Fiber Reinforced Polymer (FRP) Rebar market is witnessing growth trends. The sector has experienced growth due to the need for long-lasting infrastructure solutions, which can sustain extreme environmental conditions. The widely used steel rebar tends to rust and corrode with time, thereby bringing about expensive maintenance and repair activities. On the other hand, FRP rebar is lightweight and corrosion resistant; so it is desirable in various construction projects. The other factor which is resulting in increased usage of FRP rebar is its durability in marine, bridge, and road construction.

Materials that resist water and chemicals for up to fifty years will be crucial for structures exposed to these conditions, such as coastal bridges and underwater tunnels. FRP rebar, due to its rust and chemical damage resistance, also increases the service life of such projects while cutting down on maintenance costs in the long run. As the demands for infrastructure are growing, demand for durable, low-maintenance materials is also expected to make the demand for FRP rebar grow. However, several challenges may act as a slow poison for FRP rebar to gain complete acceptance. Primarily, its higher price compared to a conventional steel rebar is one of the major drawbacks.

Though the cost can be justified by reduced maintenance and longer lifespan in the long term, many developers and contractors do not like it as the budget becomes a constraint for them. Also, lack of knowledge and untied standard codes for FRP rebar usage are a source of uncertainty for the market. It is unknown by most construction professionals, and its properties and applications are not well-known, so they do not want to give up conventional materials.

Lack of clear regulation and industry-wide standards makes the application of FRP rebar uneven in different regions; otherwise, some opportunities hold promising potential for future growth in the FRP rebar market. Governments and private investors are focusing increasingly on sustainable construction materials that do not lose strength over time; FRP rebar is definitely one of these. Increasingly, environmental concerns will create a need for sustainable alternatives, and this aspect will also continue to increase its demand.

Developments in this area are under way to enhance the cost effectiveness of FRP rebar for more applications. With continuous developments and an increased focus on the use of long-lasting construction materials, the market for FRP rebar will continue to grow in the coming years.

MARKET SEGMENTATION

By Product Type

The Global Fiber Reinforced Polymer (FRP) Rebar market is growing with a moderate pace as there has been an increasing demand in construction and infrastructure projects. Traditionally, the standard reinforcement material has been steel, however, problems like corrosion and high maintenance costs have led FRP rebar to emerge as a very strong alternative. Among the many features associated with this kind of reinforcement, including strength and durability, resistance to environmental influences, and lightweight, it stands out as being very attractive for engineers and builders all over the world. One of the primary reasons for this market is the need for more material lifespans as well as less maintenance.

Unlike steel, FRP rebar does not corrode and eventually weaken with time, thus significantly lowering the chances for structural deterioration. This makes it especially useful where moisture and chemical are present-such as regions by the seaside and industrial operations. It can also be ported easily thus saving on time to install this product, lowering labor costs while installation time also is reduced significantly. The variety of product contained in this market falls into the following three products. A huge percentage includes GFRP Rebar: valued at US$632.35 million.

This type is widely used due to its balance between cost and performance, hence its popularity in bridges, highways, and marine structures. The Carbon Fiber Reinforced Polymer (CFRP) Rebar, although more expensive, provides more strength and stiffness, hence a better application where high load-carrying capacity is required. Aramid Fiber Reinforced Polymer (AFRP) Rebar has a unique flexibility and strength. It is helpful in seismic-prone regions, where structures have to be resistant to recurring vibrations.

There are various factors that are leading to the market's growth. Increase investment in infrastructure projects, particularly in developing nations, is fostering demand for advanced materials. Long-term usage benefits of FRP rebar, both by the government and private sectors, are causing a shift in construction.

Furthermore, more stringent standards in environmental sustainability are compelling industries to opt for products that have a much smaller carbon footprint. Being manufactured using less energy and lasting longer than traditional reinforcement, FRP rebar is very much in sync with such changing standards. However, it still poses some challenges. Higher initial costs than that of steel and lesser awareness in some regions have been the reasons slowing down widespread acceptance.

However, ongoing research and technological advancements will likely address the concerns, thereby making FRP rebar an important player in the future of the construction industry. As more builders and engineers realize its benefits, demand is likely to keep increasing, and over time, further innovation and cost reductions are expected.

By Resin Type

Increasing demand for durable and corrosion-resistant construction materials is leading to the expansion of the global fiber reinforced polymer (FRP) rebar market. Steel rebars tend to rust and degrade over time, which could compromise the integrity of structures. In contrast, FRP rebars provide a lightweight yet strong alternative, making them highly desirable for infrastructure projects, especially in corrosive environments such as marine and industrial structures. In addition, their longer life cycle and less requirement for maintenance have naturally increased the popularity of these rebar types among engineers and construction firms.

FRP rebars are classified according to resin types, and the market is divided into Vinyl Ester Resin, Epoxy Resin, and Polyester Resin. Each type of resin has distinct properties that affect the performance and practicality in specific applications. Vinyl Ester Resin is known for high resistance to moisture and chemicals, which makes it suitable for application in structure that are exposed to harsh conditions. Epoxy Resin, however, boasts with excellent strength and adhesive qualities that ensure even the most challenging structural stability environments. Polyester Resin is the one that is much cheaper, having good durability for general construction and used in very general construction applications.

The demand is primarily from the construction industry with its focus toward sustainable and high-performance materials. Governments and private entities are focusing on projects related to long-term infrastructure, which includes bridges, highways, and tunnels. Simultaneously, as carbon footprints become less acceptable, more attention is now being paid toward FRP rebar, primarily because of environmentally friendly properties with respect to contributing to energy efficiency and minimizing constant repair requirements.

Regional market trends also affect the FRP rebar industry. North America and Europe are leading adopters because of stringent building codes and strong emphasis on sustainable development. However, rapidly developing regions in Asia and the Middle East, due to fast-paced urbanization, are looking at advanced construction materials. Further market growth can be expected because of the drive towards resilient, cost-effective solutions in these areas.

Technological development in manufacturing processes is also increasing the quality and reducing the costs of FRP rebars to be more commercially viable for an extensive range of industries. Ongoing research, new formulations, and improved techniques of production are likely to broaden their applications further, thus sustaining their position as a preferred rebar reinforcement in modern construction. With ongoing development and increasing awareness of their advantages, the market for FRP rebars will continue to increase in the near future.

By Size

The Global Fiber Reinforced Polymer (FRP) Rebar market is moving steadily as the industries are finding stronger and durable alternatives to conventional steel reinforcement. FRP rebar, having high strength with lightweight properties, is resistant to corrosion, gaining popularity in numerous construction projects globally. It will experience an increasing demand as it relates to infrastructural development and has a specific advantage in terms of regions prone to harsh weather and high moisture conditions. Being corrosion-resistant against chemicals, this is the best product for structures, such as bridges, tunnels, and marine applications, which often suffer from high corrosion risks.

The main driver in the market has been the cost savings over long periods. The initial cost is higher than the steel, but the durability does not incur extra maintenance costs down the line. Governments and private organizations are starting to invest more in projects where sustainable and robust materials are applied, which again increases demand. Advances in the manufacturing process improved the efficiency in production, so FRP rebar is also accessible to wider applications. The market is further divided by size into Less Than 10 mm Diameter, 10 mm to 20 mm Diameter, and More Than 20 mm Diameter.

The demand for different sizes depends on the type of construction projects and their specific requirements. Smaller diameters are often used in lightweight structures, while larger diameters provide the necessary strength for heavy-duty applications such as highways, railways, and high-rise buildings. Another reason behind the increased use of FRP rebar is that its size and composition can be tailored according to design. Regional trends about growth patterns show North America and Europe are in the lead in terms of market growth. Infrastructure, in both regions, has strict durability and sustainability standards.

Rapid urbanization and government efforts to increase infrastructure development within this region are quite popular, especially in Asia-Pacific, mainly in China and India. Emerging economies also begin to realize the benefits of using FRP rebar and eventually penetrate markets in various regions. Further innovation in fiber reinforcement is on the horizon with the constant advancement in technology. FRP rebar is expected to reach new heights of property improvements with advanced innovation.

Researchers are working on improving the fire resistance and load-bearing capacity of FRP rebar, making it fit for an ever more extended range of applications. With ongoing research into creating stronger and more adaptive materials, the market for FRP rebar is surely expected to progress and continue; it will provide future-long-term benefits for the construction industry.

By End-User

The Global Fiber Reinforced Polymer (FRP) Rebar market is expanding steadily due to increasing demand in various industries. This material is well known for its durability, corrosion resistance, and lightweight properties, making it a preferred choice over traditional steel reinforcement. As construction techniques advance and infrastructure projects continue around the world, FRP rebar adoption is likely to increase further.

This market has been categorized into construction, infrastructure, marine applications, and industrial applications by end-user. Fiber Reinforced Polymer Rebar in construction applications is utilized in residential, commercial, and institutional structures. They provide improved structural integrity and have longer lives than traditional materials. With the environment resistant to moisture, chemicals, and related or extreme weather conditions, this type of rebar is suited to harsh regions with extreme weather.

Builders and developers are opting for FRP rebar in increasing numbers because it reduces the maintenance cost of structures and enhances the sustainability of the structure in general. The infrastructure projects such as bridges, highways, and tunnels also embrace FRP rebar because of its resistance to harsh environmental conditions.

Unlike steel, which is prone to rust, FRP rebar retains its strength even in high-moisture environments. This also led to more usage of this material in major public works and by private investors who are considering long-term durability. FRP rebar also is lightweight which makes transportation easy and installation even easier, meaning that labor is reduced and so is the time for construction. Marine applications represent another significant segment in this market.

Since these structures are exposed to saltwater and high humidity, the traditional reinforcement materials used in them degrade rapidly. FRP rebar is a more reliable alternative for the long-term durability of docks, piers, seawalls, and other offshore structures. Its non-corrosive property makes it extremely valuable in coastal and underwater construction projects where maintenance can be costly and challenging.

FRP rebar is also beneficial for industrial applications, especially in chemical plants, wastewater treatment facilities, and manufacturing units. Such environments expose them to corrosive substances that would weaken the conventional materials over time. The use of FRP rebar maintains structural integrity and extends the lifespan of industrial facilities with less frequent repair and replacement.

The FRP rebar technology continuously develops its performance and cost-effectiveness through continued research and development. As the world seeks sustainable and resilient building solutions, the market for Fiber Reinforced Polymer Rebar will be on the rise as an efficient and durable alternative to the traditional reinforcement materials.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$920.15 million |

|

Market Size by 2032 |

$1,847.65 Million |

|

Growth Rate from 2024 to 2031 |

10.6% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

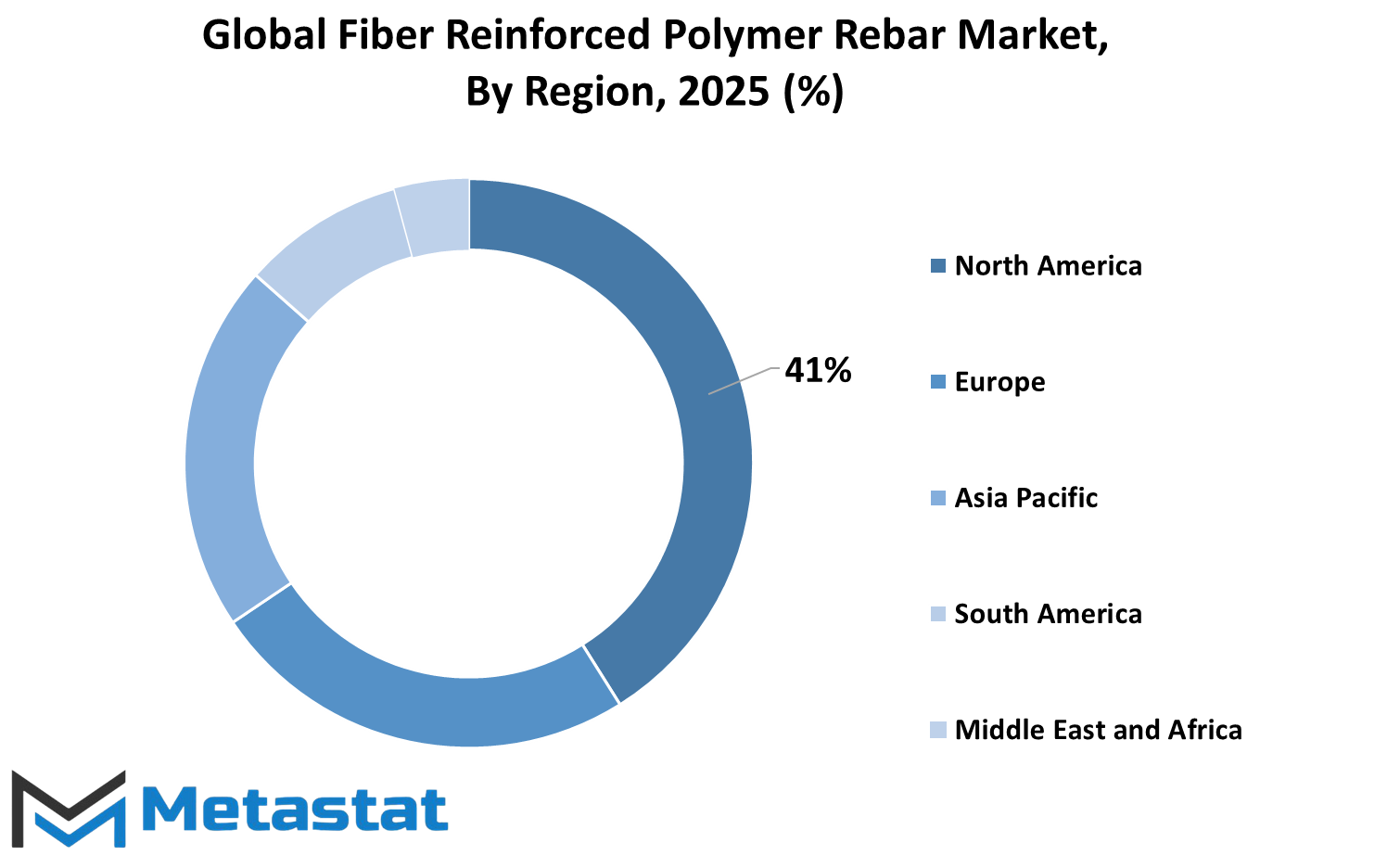

Global Fiber Reinforced Polymer Rebar Market, By Geography: The regions involved are North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Every region holds importance in this market's growth. They not only contribute to demand but also lead to further advancement in technology.

North America includes the U.S., Canada, and Mexico. In this region, Fiber Reinforced Polymer Rebar has been widely adopted based on the grounds of more large-scale infrastructure projects as well as durable construction materials. With relevant strict regulations encouraging sustainable building practices, strong demand is expected to continue. Innovation and research are strong in the U.S., thus new applications are driven across all sectors.

Europe consists of UK, Germany, France, Italy, and Rest of Europe. This region emphasizes sustainability and contemporary construction practices. Government policies aimed at supporting the green economy increased the demand for Fiber Reinforced Polymer Rebar in the country, mainly applied in the bridges and roads constructions. The technologies developed by both Germany and France are aimed towards the product developments.

Asia-Pacific can be divided into five segments: India, China, Japan, South Korea, and Rest of Asia-Pacific. Rapid urbanization and industrial development have created high demands for durable and corrosion-resistant construction materials in this region. China and India remain the major drivers behind the expansion of this market, given their large-scale infrastructure projects. Others, such as Japan and South Korea, also play a role by using advanced materials in their plans for infrastructure development.

In South America, the market consists of Brazil, Argentina, and the Rest of South America. Increased focus on enhancing public infrastructure and upgrading transport systems increases demand for Fiber Reinforced Polymer Rebar. Brazil continues to lead due to active construction processes and modernization efforts to rejuvenate its outdated infrastructure. In Argentina, awareness about durable construction materials is building, leading to increased demand for this material as well.

The Middle East & Africa segment is further classified into GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa. The region has witnessed significant growth in the construction sector, primarily in the GCC countries, wherein large-scale infrastructure projects are highly in demand. The demand for Fiber Reinforced Polymer Rebar is increasing with developers seeking material that provides strength and resistance against harsh environmental conditions. In its efforts to support its infrastructure development and urban expansion, Egypt and South Africa are also adopting these materials.

With each region different in how it contributes, this will result in the Fiber Reinforced Polymer Rebar market globally being continuously on the rise with the construction industry changing and prioritizing sustainability and durability.

COMPETITIVE PLAYERS

The Global Fiber Reinforced Polymer (FRP) Rebar market is expected to grow gradually with the increasing adoption of advanced construction materials in various industries. FRP rebars are gaining popularity due to their strength, resistance to corrosion, and light weight, making them a good substitute for traditional steel reinforcement. The market is also driven by the increasing demand for long-lasting infrastructure, particularly in transportation and marine as well as industrial construction. Globally, the government has increased its spending on infrastructure projects, which favors the demand for advanced materials with improved structural strength while reducing the associated maintenance. One advantage FRP rebar offers is resistance to corrosion and chemical degradation.

Traditional steel reinforcement easily corrodes in regions with high moisture levels or chemicals, often leading to expensive repair jobs with reduced structural life. FRP rebar does not corrode, hence being highly recommended for use in bridges, tunnels, and other marine works. Furthermore, the lightness in weight makes movement and ease of assembling easy, hence saving labor costs as well as minimizing construction time. As sustainability becomes a priority in construction, FRP rebar also finds its place within the green agenda because it has a longer life and less negative impact on the environment. Despite its advantages, there are certain challenges that prevent the adoption of FRP rebar. The first is the higher cost of FRP materials compared to steel, which is a deterrent to some developers from adopting it.

Additionally, since steel has been the traditional reinforcement material for decades, FRP requires a change in design codes and construction practices. However, research is ongoing and technological advancements are overcoming these issues by making it more cost-effective and increasing the scope of applications. Many industry players are focusing on developing FRP rebar that meets standardized requirements, ensuring compatibility with existing construction methods.

The FRP rebar market is led by several key companies. Major manufacturers include Owens Corning, TUF-BAR, Armastek USA, Dextra Group, Pultron Composites, FiRep Inc., Schock Bauteile GmbH, Composite Group Chelyabinsk, Jiangsu Jiuding New Materials Co. Ltd, Reliance Industries Ltd, China Beihai Fiberglass Co. Ltd, Mateenbar Limited, Get FiBAR (Quad Composites), SFTec Inc., and GatorBar.

These companies are investing in research and development to enhance product quality, expand market reach, and strengthen their competitive positions. FRP rebar will be seen as a dominant force in building the future infrastructure, as it represents a path toward more sustainable and durable construction solutions. Advances in this technology, coupled with greater acceptance and recognition, make it likely to become a default option for reinforced concrete structures across the globe to make buildings more robust and less susceptible to degradation.

Fiber Reinforced Polymer Rebar Market Key Segments:

By Product Type

- Glass Fiber Reinforced Polymer (GFRP) Rebar

- Carbon Fiber Reinforced Polymer (CFRP) Rebar

- Aramid Fiber Reinforced Polymer (AFRP) Rebar

By Resin Type

- Vinyl Ester Resin

- Epoxy Resin

- Polyester Resin

By Size

- Less Than 10 mm Diameter

- 10 mm to 20 mm Diameter

- More Than 20 mm Diameter

By End-User

- Construction

- Infrastructure

- Marine applications

- Industrial applications

Key Global Fiber Reinforced Polymer Rebar Industry Players

- Owens Corning

- TUF-BAR

- Armastek USA

- Dextra Group

- Pultron Composites

- FiRep Inc.

- Schock Bauteile GmbH

- Composite Group Chelyabinsk

- Jiangsu Jiuding New Materials Co. Ltd

- Reliance Industries Ltd

- China Beihai Fiberglass Co. Ltd

- Mateenbar Limited

- Get FiBAR (Quad Composites)

- SFTec Inc.

- GatorBar

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252