MARKET OVERVIEW

Europe Aliphatic Isocyanates market and its industry form a very important segment of the chemical sector, figured by its uses in the production of high-performance polymers. These compounds have major uses in different end-use industries like automotive, construction, and textiles because of their good properties of durability, resistance to UV radiation, and flexibility. The market for aliphatic isocyanates in Europe is most likely to move forward, as these industries keep evolving and the demand for better materials is never supposed to go down.

Aliphatic isocyanates, mainly hexamethylene diisocyanate (HDI) and isophorone diisocyanate (IPDI), play a vital role in the production of polyurethane coatings, adhesives, sealants, and elastomers. Such an application becomes critical because of the desire for products that exhibit very good performance even in hard service. For example, in the automotive industry, aliphatic isocyanates will play a very important role in the preparation of coatings that offer brilliant gloss and good protection from environmental degradation to the auto. Similarly, in construction, these compounds will help in devising materials that guarantee durability and structural integrity.

Technological innovation and research continue as a benefit for the Europe Aliphatic Isocyanates market. With growing industries seeking sustainable and efficient solutions, there are higher chances that there will be a rise in the development and adoption of eco-friendly products in the marketplace. These undertakings strive to improve the performance and environmental footprint of aliphatic isocyanates, taking into account the ever more stringent regulatory standards and the increasing importance of sustainability.

Therefore, the strategic movements between the key players are going to define the future of the Europe Aliphatic Isocyanates market. Companies will look forward to mergers, acquisitions, and partnerships to increase their product portfolio and market share. This will enable innovation from the point of view of creating advanced materials that can serve the industry's changing needs.

The dynamics of the regional market are going to change, and they will be greatly influenced by changing consumer behavior, preference, and economic conditions. This will also call for aliphatic isocyanate manufacturers to focus on cleaner and greener products in order to match consumer and businesses' preferences. Further economic factors are the fluctuations in raw material prices and beneficial trade policies, which call for companies to develop resilient strategies to remain ahead of the cutthroat competition in the market.

Regulatory requirements will fill the market environment in Europe. As manufacturers continue emphasizing best practices and innovative solutions, alignment with environmental and safety standards is expected to rank as the highest of priorities. Such requirements are likely to stimulate the development of new formulations and processes which achieve more effective safety and sustainability for aliphatic isocyanates.

It will be influenced by new technological developments, strategic industry movements, changes in regulations, and shifting consumer preferences, which might, in turn, further influence the demand scenario of the Europe Aliphatic Isocyanates market. Innovation and growth in the application industries requiring high-performance materials, such as automotive and construction, will be the key driving forces. The ability of companies to turn and change with these dynamics and innovate will set their positioning in this competitive landscape to maintain relevance and attain success. With active current developments, the future of the Europe Aliphatic Isocyanates market seems to be determined later, with an even better quality product and sustainable for many purposes.

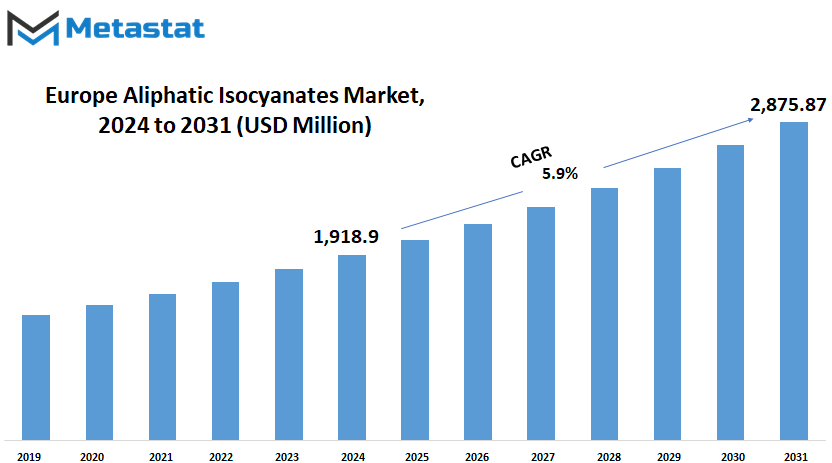

Europe Aliphatic Isocyanates market is estimated to reach $2,875.8 Million by 2031; growing at a CAGR of 5.9% from 2024 to 2031.

GROWTH FACTORS

Growth in the European Aliphatic Isocyanates market will be fostered by some of the major factors that play a dominant role in controlling the market environment and dictating the course of the market. Despite these drivers, there are some factors that might hinder this growth. Nevertheless, within these challenges lie some excellent opportunities that can drive the market growth in the near future.

The growing demand from various industries is the major growth factor of the European Aliphatic Isocyanates market. Substances that find applications in a variety of industries, such as the automotive and construction sectors, are aliphatic isocyanates. These compounds have versatility that makes them quite vital for many manufacturing processes, hence their growing demand.

Another factor that strengthens the growth of the market is technological developments and innovations. Continuous research and development activities are carried out to increase the performance and properties of Aliphatic Isocyanates so that they can be used in a large number of applications. The continuous search for better performance keeps these compounds at the leading edge of technological change, thereby further accelerating demand for the market.

Again, stringent regulations and standards for environmental protection and safety also foster the growth of the market. The trend towards greening and sustainable solutions pushes industries to adopt aliphatic isocyanates that can reduce emissions and have less of an impact on the environment than other materials.

Though these are quite favoring factors, yet certain odds may still drastically slow down the European Aliphatic Isocyanates market. The key challenges to this will be in the form of economic fluctuations, regulatory complexities, and geopolitical tensions. Supply chain disruptions, costlier production, and above all, a less ambitious growth prospect ensue from such uncertainties in the market.

Furthermore, the market is not neutral to various exogenous shocks driven by natural disasters, pandemics, or geopolitical conflicts. These disturbances can result in failures in the supply chain, upsetting production capability and, hence, the market's stability.

Despite these, however, challenges exist that are indicative of promising opportunities likely to spur the market in the following years. Increasing investments in research and development and new areas of application in the pipeline are likely to offer generous opportunities to the players. At the same time, strategic collaborations, mergers, and acquisitions continue to stimulate market growth by diversifying product portfolios and increasing geographical presence.

Among the different driving forces behind the growth in the European aliphatic isocyanates market are increasing demand, changing technology, and new and developing regulations. Even though challenges exist, the opportunities are much more on the bright side, beating with a promising outlook for this market over the coming years.

MARKET SEGMENTATION

By Region

From the very domain of chemical compounds, speaking with an emphasis on solely aliphatic isocyanates, their significance lies in covering something much larger than just an ordinary scientific discovery. Aliphatic isocyanates, who by chemical structure have an isocyanate functional group, are all set to be one of the core materials emerging in different industries and applications.

The first and foremost application area where aliphatic isocyanates will flex their muscles is in coatings and adhesives. These compounds have some quite unique properties, making them highly sought after in the formulation of tough coatings and strong adhesives. During cross-linking employing polyols, the resulting polyurethane coatings exhibit high resistance to abrasion, chemicals, and weather. Indeed, aliphatic isocyanates help in producing adhesives of such great bonding strength that the adhesives are considered to hold together components, with the same strength of hold as the assembled component itself, in an assembly operation.

The automotive industry will also benefit greatly from the use of aliphatic isocyanates. Basically, as the desire is for materials strong but lighter in weight to be used in the construction of vehicles, the need for the manufacture of advanced composites and coatings will certainly call for such compounds. In the formulation of automotive coatings, these materials again come into play; they offer the automobile a most appealing look and help protect it from the elements, thus providing the finish with a long life.

In the field of industrial applications, aliphatic isocyanates will find broad use in elastomers and sealants. Elastomers prepared from such compounds show improved mechanical performance, making them particularly useful in applications where flexibility and resilience are required and where there may also be exposure to chemical attack. Especially, sealants formulated with aliphatic isocyanates adhere well to a wide range of substrates, reliably sealing them and protecting them from water and chemical penetration.

Given that industries around the world are struggling to comply with stringent regulatory requirements in addition to the growing concerns for the environment, interest in finding sustainable alternatives to traditional chemicals remains mounts. Therefore, aliphatic isocyanates, with their low volatility and reduced impact on the environment, will probably be used in the formulation of eco-friendly coatings, adhesives, and sealants. Their compatibility with waterborne formulations enhances their appeal, giving manufacturers the opportunity to cut emissions and enhance workplace safety.

The broad reach of aliphatic isocyanates across industries foreshadows a future where new solutions will match the changing needs of modern society. Coatings, adhesives, autobody, and industrial sealants are only a few areas where versatility and high performance will further drive developments and define the face of material science and technology.

By Applications

In the constantly changing scenario, the European aliphatic isocyanates market shows positive growth in most applications. In growing sectors like automotive, industrial, and construction, the demand for aliphatic isocyanates—compounds used in a variety of coatings, adhesives, sealants, and foams—is growing fast. The following paper takes a closer look at the various applications of aliphatic isocyanates in the European market and tries to highlight its importance and any future prospects.

One of the major industries that is developing demand for aliphatic isocyanates is automotive coatings. In this case, coatings are paramount in enhancing the durability and outlook of automobiles by protecting them from corrosion and other environmental causes. This segment is bound to register an improved demand for aliphatic isocyanates with improving technology related to automobiles and increased consumer demand for better and more durable finishes.

Another key industrial area where aliphatic isocyanates represent an important application in the region is in industrial coatings. Apart from the protection against wear, chemicals, and weathering offered by the coating of machinery and equipment, infrastructure, and aerospace components, the coating with high-performance characteristics bestowed helps drive industries toward better performance and longevity of their assets.

Another important European market segment for aliphatic isocyanates lies in adhesives and sealants, which are applied to a wide range of industries, from construction and electronics to packaging. Given that the development of green and high-performance adhesives is highly regulated, it is foreseen that the demand for aliphatic isocyanates will surge in the coming years as primary raw materials.

Other key fields of application for aliphatic isocyanates in Europe are flexible and rigid foams. The uses in these foams can include furniture, bedding, insulation, and packaging, all of which need light, suitable, and durable solutions. Owing to the growing trend of energy efficiency and sustainability, it is expected that the demand for eco-friendly foams with aliphatic isocyanates will surge ahead.

Besides, plastic and wood coatings, textile coatings, and UV-resistant coatings are some other small, high-potential markets of aliphatic isocyanates in Europe. These coatings find applications in various end-user industries like furniture, fashion, and construction, providing better protection and aesthetic value to them.

The European market for aliphatic isocyanates is developing robust growth in a wide range of industries, from coatings in cars to industrial applications, adhesives and sealants, flexible and rigid foams, plastic and wood coatings, textile coatings, and UV-resistant coatings. With continuous developments in technology and immense focus on sustainability, it may be definitely predicted that soon, the demand for aliphatic isocyanates will surge ahead, leading to more innovations and capacity extensions.

By End User

The European aliphatic isocyanates market has been fragmented to a great extent with respect to the end users. The major segments in this varied scene are the automotive sector, healthcare sector, building & construction industry, furniture industry, and others.

In the automotive industry, a number of aliphatic isocyanates are applied. They contribute to producing the quality coatings, adhesives, and sealants used in vehicle manufacturing. With increasing advancement in the automotive industry, there will be further demand for new materials that will help improve performance and durability. On its part, aliphatic isocyanates will meet these new challenges by providing the auto parts with long life and reliability.

Another critical domain is healthcare. These compounds find application in the manufacture of medical appliances, gadgets, equipment, and pharmaceutical packaging materials. With increasing innovation and safety orientation in healthcare, demand for advanced materials having improved biocompatibility and chemistry resistance will increase, in which aliphatic isocyanates will share and pave the way for development in the healthcare sector.

Another key end-user of aliphatic isocyanates is the building and construction industry. These chemicals are at the heart of the formulation of high-performance coating, adhesives, and sealants in use within the architect industry. With increasing emphasis on sustainable construction and care for the environment, there will be a growing demand for eco-friendly materials that offer durability and resilience. Aliphatic isocyanates have an excellent position to support these sustainability objectives in terms of provision for green buildings and infrastructure.

Moreover, the furniture segment represents a major potential market for aliphatic isocyanates, which find use in very diverse applications, ranging from wood coatings and upholstery adhesives to sealants. Together with this trend of consumer preference for stylish designs with added durability, manufacturers will look for innovative materials that will merge the aesthetic appeal with functionality. Aliphatic isocyanates provide the versatility and performance characteristics that will be required to meet those design needs and drive innovation in furniture.

Other applications include aerospace, electronics, marine, and industrial coatings. With the improving technology in most industries, high demand is expected for high-performance materials such as aliphatic isocyanates.

In summary, the European aliphatic isocyanate market overview indicates a host of very diverse end-user segments that remain to be served by specific needs, which on their own are opportunities for growth. As industries continue to evolve and innovate further, aliphatic isocyanates will be some of the integral drivers of progress in the light of emerging needs—be they consumerist or of any other sectors of businesses.

By Technologies

The Europe Aliphatic Isocyanates market, when segregated on the basis of technologies, becomes categorized into segments that are key in altering the market dynamics. These include Monomers, Trimers, Biurets, Polyisocyanates, and Prepolymers.

Monomers are the basic blocks used in the synthesis of different polymeric materials. The versatility and reactivity justify their position at the center of producing such things as coatings, adhesives, and sealants. With improvements in chemical engineering, new monomers possessing novel properties are constantly being created that surely will expand the realms of their use.

While trimers are higher forms of monomers that self-assemble into stable structures possessing different properties, often improved mechanical and better chemical resistance, which could find applications in specialized uses such as automotive coatings and aerospace materials. Novel processes of trimerization are being investigated, offering tailored solutions to meet specific needs of industries as research evolves in this direction.

Another facet of the Europe Aliphatic Isocyanates market is biurets, with their characteristic cyclic structure. These products, with their peculiar chemical properties, meet processes where high thermal stability and resistance to environmental factors are required. Biuret-based formulations would bring an eco-friendly aspect as industries move toward sustainability and compliance with environmental regulations.

Acting as cross-linkers in polyurethane formulations, polyisocyanates span a very broad chemical space. Their potential for strong covalent bond formation enables the creation of very resistant coatings, foams, and elastomers. With ongoing research efforts into new polyisocyanate chemistries, further high-performance and more environmentally friendly materials should find their way into the market.

Prepolymers formed by reaction of polyisocyanates with polyols are one of the base intermediates for polyurethane materials production. The possibility of obtaining prepolymer reactivity and viscosity proper to be used in casting, molding, or spraying methods allows such use. Thus, while producers look at reworking their production lines, which saves them money and eliminates waste, demand for made-to-measure prepolymers will increase.

The segmentation of the Europe Aliphatic Isocyanates market into monomers, trimers, biurets, polyisocyanates, and prepolymers reflects the differing technological basket that seems to be fuelling its growth. As research and development come up with newer frontiers in material science, these technologies are going to turn vital in a big way in deciding the future course of the industry.

COMPETITIVE PLAYERS

The demand for aliphatic isocyanates will rise phenomenally in Europe within the next few years due to the increasing usage of high-performance materials in various industries. Aliphatic isocyanates are one of the raw materials demanded for the production of polyurethanes. Such materials have very good resistance against UV rays, mechanical properties, and durability and hence are applied in many industries related to automakers, building, and electronic devices.

The key players operating in the European market include BASF SE, Evonik Industries AG, Tosoh Corporation, Covestro AG, Vencorex, Perstorp Holding AB, Wanhua Chemical Group Co. Ltd., Mitsui Chemicals, Inc., Lanxess AG, and Dow Inc. Companies are on the innovation front, constantly investing in research and development to improve product performance and sustainability. They are expanding their production capacities to meet growing demand from various end-use industries.

For instance, BASF SE has been involved in the development of eco-friendly aliphatic isocyanates, which reduce VOC emissions. This has thus stuck to the strict Europe environmental regulations and players in the market are forced to Abide by them. Evonik Industries AG, on the other hand, has been striving on how to make its production process effective so that in turn, it can provide cost-effective solutions to its customers.

The second major application of aliphatic isocyanates in high volumes, which is consistent in the European region, is the automotive coatings and adhesives used for parts in the interior and exterior components of autos. Due to shifting toward electrical vehicles, there will be increased demand for light, yet powerful materials; hence, this will further push the aliphatic isocyanates market. Growing construction activities through urbanization and infrastructure development, coupled with greater demand for coatings and sealants that perform better, have also boosted the demand for aliphatic isocyanates.

Technology and sustenance are the future backdrops on which the market for aliphatic isocyanates in Europe will grow. Companies are looking at bio-based raw materials to make more environmentally friendly isocyanates by reducing their carbon footprint. Nanotechnology will further help in enhancing the properties of aliphatic isocyanates, making them versatile and more efficient.

The competitive landscape of the European aliphatic isocyanates market, no doubt, would continue to remain active, with players angling to hold their respective positions in the market via strategic collaborations, mergers, and acquisitions. For instance, Covestro AG had been very active in collaboration with other chemical companies regarding the development of new applications and expansion of its product portfolio.

The European aliphatic isocyanates market holds bright prospects in terms of growth and innovative potential. The unending efforts by the major players toward betterment in product performance, sustainability, and cost efficiency will keep on reshaping the trajectory of the aliphatic isocyanates market. Aliphatic isocyanates are going to continue playing a very significant role in contributing to Europe's need for advanced materials as industries evolve and new applications materialize.

Europe Aliphatic Isocyanates Market Key Segments:

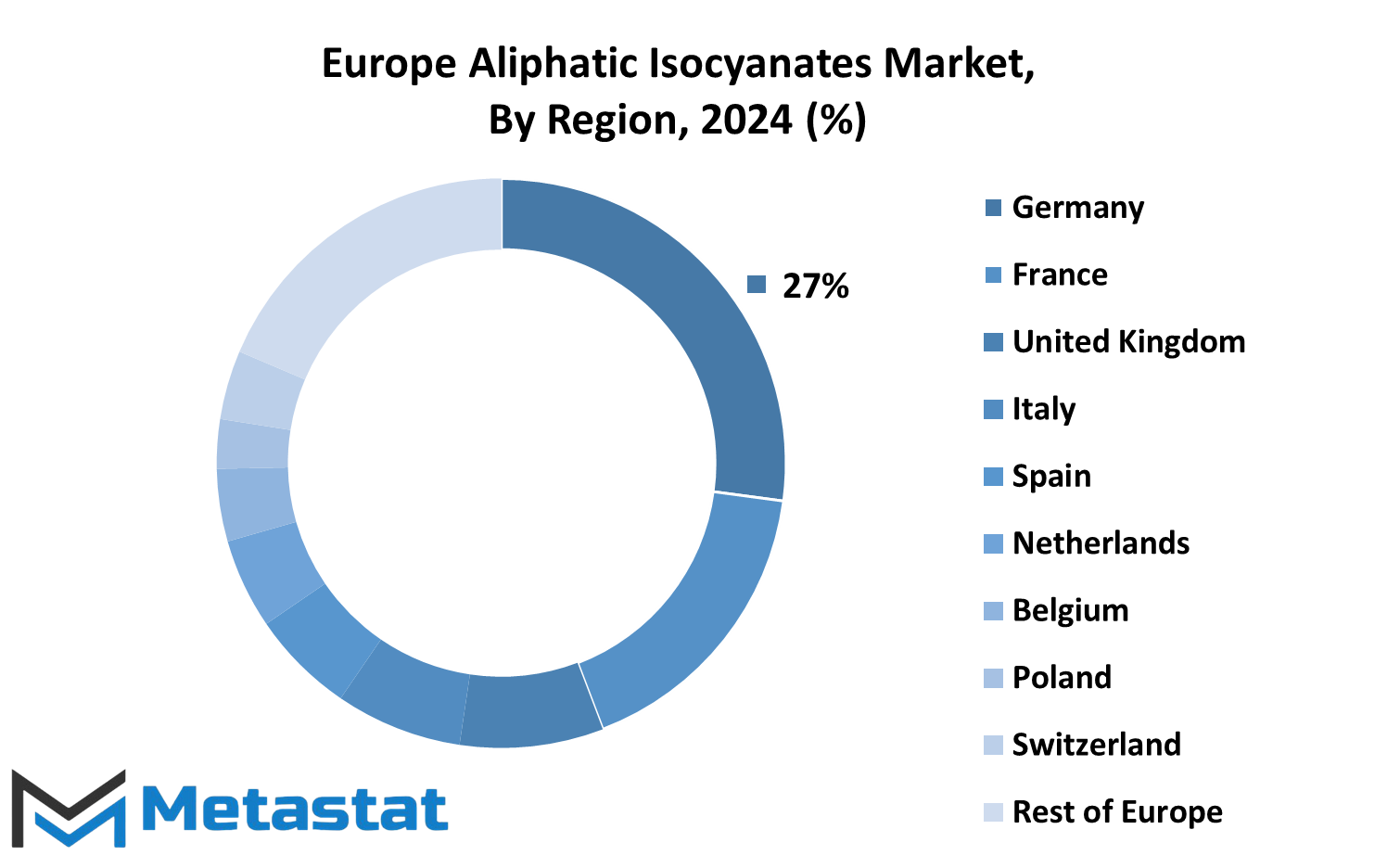

By Region

- Germany

- France

- United Kingdom

- Italy

- Spain

- Netherlands

- Belgium

- Poland

- Switzerland

- Rest of Europe

By Applications

- Automotive Coatings

- Industrial Coatings

- Adhesives and Sealants

- Flexible and Rigid Foams

- Plastic and Wood Coatings

- Textile Coatings and UV-resistant Coatings

- Protective and Weather-resistant Coatings

By End User

- Automotive

- Healthcare

- Building & Construction

- Furniture

- Others

By Technologies

- Monomers

- Trimers

- Biurets

- Polyisocyanates

- Prepolymers

Key Europe Aliphatic Isocyanates Industry Players

- BASF SE

- Evonik Industries AG

- Tosoh Corporation

- Covestro AG

- Vencorex

- Perstorp Holding AB

- Wanhua Chemical Group Co. Ltd.

- Mitsui Chemicals, Inc.

- Lanxess AG

- Dow Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383