Global Electric Welding Machine Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global electric welding machine market has progressed from being a specialty production industry to playing the leading role in supporting contemporary manufacturing and construction. Its industry was founded in the first half of the twentieth century, when increased demands for stronger and more secure methods of metal joining led engineers to replace rivets and bolts. The development of the electric arc welding process in the 1900s opened the door, with manufacturers being able to produce stronger welds in less time and material. With shipbuilding, railroads, and heavy machinery manufacturing evolving, electric welding machines became standard equipment and no longer experimental devices.

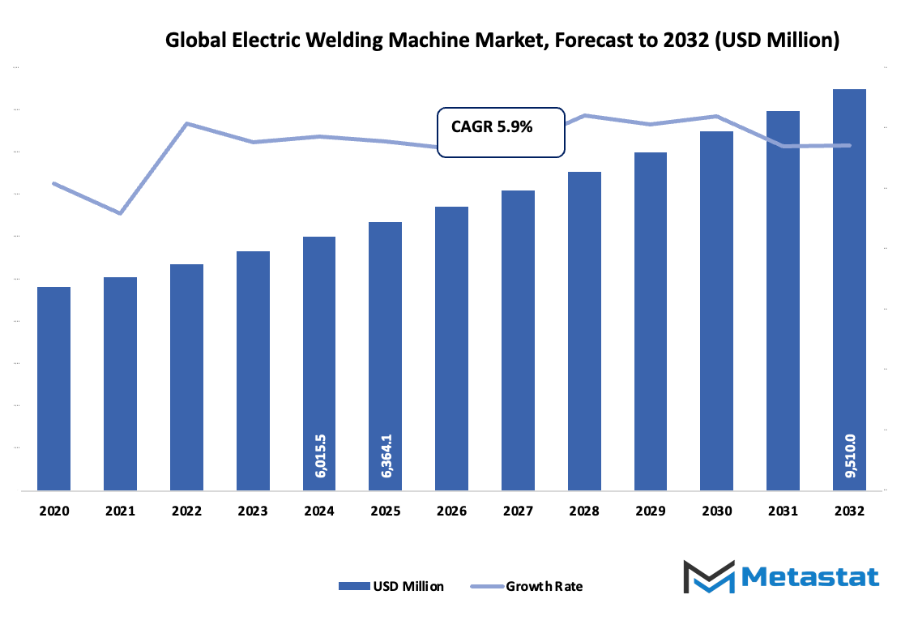

- Gobal electric welding machine market of around USD 6364.1 million in the year 2025, at a compound annual growth rate of around 5.9% till 2032 and has the potential to reach more than USD 9510.0 million.

- Arc Welding Machines represent almost 52.1% of the market share, promoting advancement and increasing application through rigorous research.

- Major trends fueling growth: Increased industrialization and infrastructure growth, Increased demand from vehicle and construction industries

- Opportunities are: Adoption of automated and robotic welding solutions for higher productivity and precision

- Key insight: The market is going to grow exponentially in terms of value in the next decade, representing enormous opportunity for growth.

The post-war era experienced seminal moments that kept transforming the market. During World War II, there was tremendous demand as nations required quick, durable welding solutions for defense vehicles and ships. During the post-war boom, growth in car manufacturing and road building made the machine more firmly established in workshops globally. In the 1970s and 1980s, inverter technology started to revolutionize the design of welding power sources, with them being more transportable, economical in energy usage, and simpler to move around. This revolution would eventually leave room for portable and on-the-job uses which were previously the preserve of gigantic factory installations.

Consumer needs have also shaped the course of the global electric welding machine market. It was controlled by bulk industries, but it will be serving small and medium enterprises as well as independent fabricators more and more for economic, accurate, and convenient equipment. The do-it-yourself movement and small metal-working shop revolution are impacting companies to simplify their machines and minimize their space requirements without compromising power. Technological innovations have been a continuous driving force for change. Robotic welding systems, electronic controls, and robotics will soon convert production floors. The machines will not only be welding but will also be watching in real time for signs of arc stability, energy consumption, and seam quality and will do so more efficiently and with less waste. Safety and energy-use regulatory models will be innovation drivers, encouraging the creation of lower-emission equipment and safer electrical components.

From its early days as an industrial innovator to its current complex state, the global electric welding machine market is at a crossroads of tradition and technology, ready to be tapped into new sectors and evolving expectations.

Market Segments

The global electric welding machine market is mainly classified based on Product Type, Technology, Application.

By Product Type is further segmented into:

- Arc Welding Machines: Arc welding machines will continue leading the global electric welding machine market due to high adaptability and affordability. The upcoming models will have a smart monitoring system for checking welding quality and minimizing defects. Simple-to-automate arc machines will be the favorite of the market for mass production, infrastructure, automotive, and heavy equipment manufacturing.

- DC Welding Machine: DC welding machines will gain popularity in the global electric welding machine market as a result of improved arc stability and higher output welds. New models will be equipped with sophisticated digital controls and lighter weights to facilitate applications in high-end fabrication. Increasing trend towards optimal energy use will compel manufacturers to come up with greater innovation.

- AC Welding Machine: AC welding machines will continue to have their niche in the global electric welding machine market where there are straightforward welding and cost-containment requirements. Advances in the future will enhance power control, decrease heat dissipation and rising operating safety. Increased portability will make the machines even more beneficial in repair and building work.

- Other: Other product segments in the global electric welding machine market will consist of hybrid and specialized machines. Future machines will be robotics compatible, offer intelligent software, and offer increased productivity for sophisticated applications. Niche welding solutions will increase in those industries requiring customized welding processes and energy efficiency gains.

By Technology the market is divided into:

- Manual: Manual welding will remain in the global electric welding machine market where flexibility and detailed craftsmanship are required. Future manual systems will have superior arc control and energy efficiency with simplicity of operation. Hand-held manual welders will remain vital within repair shops, small fabrication shops, and specialty fabrication.

- Automatic: Automatic welding will take control of the global electric welding machine market as businesses pursue greater efficiency and accuracy. Next-generation systems will be equipped with artificial intelligence and robots for making consistent welds with minimal human involvement. Automated installations will enhance safety, save labor, and address increased demand for mass production.

- Semi-automatic: Semi-automated welding will continue to be vital in the global electric welding machine market where price and affordability are a priority, with modest automation. Future systems will have more power control, computerized interfaces, and monitoring data for quality control. These machines will focus on achieving a balance between cost and productivity and will suit medium-scale producers.

By Application the market is further divided into:

- Automobile Industry: The automobile industry will continue driving the global electric welding machine market with demand for precise, automated welding. Future machines will integrate AI-driven monitoring for lightweight materials like aluminum and advanced steel. Increased electric vehicle production will push innovation in fast, accurate, and cost-effective welding systems.

- Shipping Industry: The shipping industry will sustain demand in the global electric welding machine marketfor heavy-duty and corrosion-resistant welding. Future machines will feature automated seam tracking, improved underwater welding capabilities, and better efficiency for large-scale shipbuilding. Digital technology will help reduce errors and improve safety in challenging marine conditions.

- Equipment Manufacturing Industry: The equipment manufacturing industry will shape the global electric welding machine market by demanding durable, efficient systems. Future machines will include advanced thermal control, faster setup, and adaptive welding for diverse metals. Automation and smart quality checks will enhance large-scale production of industrial equipment and machinery.

- Other: Other applications in the global electric welding machine market will expand with growing infrastructure, renewable energy projects, and customized fabrication. Future machines will be designed for unique materials and innovative production methods. Industries needing specialized welding for energy, aerospace, or construction will create opportunities for advanced solutions.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$6364.1 Million |

|

Market Size by 2032 |

$9510 Million |

|

Growth Rate from 2025 to 2032 |

5.9% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

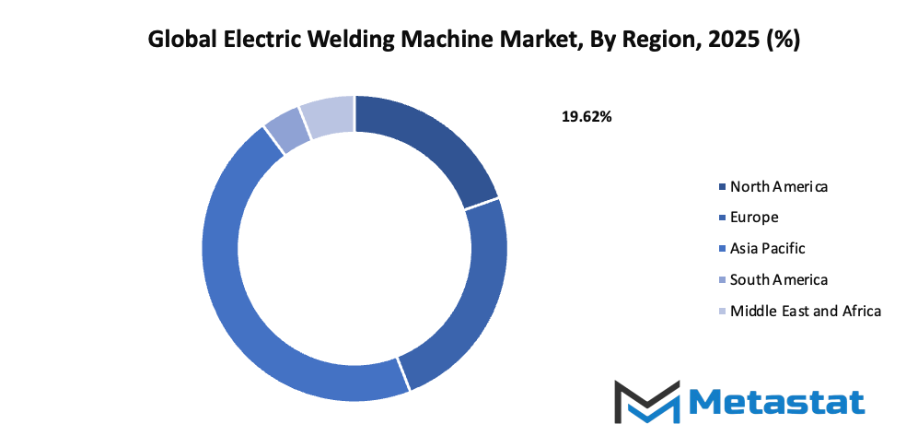

By Region:

- Based on geography, the global electric welding machine market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Growing industrialization and infrastructure development: Rapid industrial growth and large-scale infrastructure development across developing regions will drive demand for electric welding machines. Expanding construction activities, manufacturing facilities, and modernization of industrial plants will require reliable welding solutions. Growing focus on energy-efficient equipment will also encourage industries to invest in advanced electric welding machines.

- Rising demand from automotive and construction sectors: The automotive and construction sectors will continue to boost the global electric welding machine market by requiring reliable and high-performance welding equipment. Increasing vehicle production, electric vehicle manufacturing, and infrastructure expansion will demand machines that offer better accuracy, strength, and cost efficiency, supporting long-term market growth.

Challenges and Opportunities

- High initial investment and maintenance costs: The cost of acquiring advanced electric welding machines and maintaining them can be high, creating a barrier for small and medium enterprises. Frequent upgrades, complex components, and specialized servicing will increase operational expenses, making it challenging for smaller businesses to adopt cutting-edge welding technologies.

- Skilled labour requirement for operating advanced welding machines: Operating modern electric welding machines requires highly trained personnel. Lack of skilled technicians can reduce productivity and limit adoption in some industries. Training programs and technical support will become essential to ensure proper use of advanced systems and maximize return on investment.

Opportunities

Adoption of automated and robotic welding solutions for enhanced productivity and precision:- Adoption of automated and robotic welding solutions for enhanced productivity and precision will transform the global electric welding machine market. These technologies will reduce errors, improve welding speed, and lower long-term costs. Industries will benefit from improved safety and consistent quality, making automation a major driver of future growth.

Competitive Landscape & Strategic Insights

The global electric welding machine market is set to experience significant growth as both international leaders and emerging regional competitors shape its future. The industry is a mix of well-established global companies and ambitious regional players that continue to drive innovation, enhance technology, and expand market reach. Important competitors in this market include Lincoln Electric Holdings, Inc., Miller Electric Mfg. LLC, Rajlaxmi Electricals Pvt Ltd., Fronius International GmbH, Panasonic Corporation, RD Weld Products Pvt. Ltd., Kemppi Oy, GCE India Pvt Ltd, Daihen Corporation, Electra Koko Tawa Weld Private Limited, Sai Arc India Private Limited, and Aotai Electric Co., Ltd. Each of these companies brings unique capabilities, advanced product offerings, and strategic approaches that influence market dynamics and customer preferences worldwide.

Soon, the Electric Welding Machine industry will benefit from technological advancements that make machines more efficient, precise, and adaptable to different industrial needs. Automation and digital integration are expected to redefine how welding machines operate, with smart systems that can monitor performance, optimize energy use, and improve safety standards. International industry leaders are likely to continue leading innovation through research and development, while regional competitors may focus on affordability, localized solutions, and rapid market penetration to capture specific segments. This combination will create a competitive environment where innovation and accessibility coexist, ultimately enhancing customer choices and driving overall market growth.

The expansion of industrial sectors in emerging economies will further influence the market, as demand for reliable and advanced welding solutions grows. Companies like Lincoln Electric Holdings, Inc. and Miller Electric Mfg. LLC will maintain strong global presence through technological superiority, whereas Rajlaxmi Electricals Pvt Ltd., RD Weld Products Pvt. Ltd., and Sai Arc India Private Limited will play a critical role in catering to regional demands with cost-effective and specialized solutions. This dual approach will shape the market landscape, creating opportunities for collaboration, partnerships, and knowledge exchange across borders.

Looking ahead, the global electric welding machine market will continue to evolve as innovation and competition drive progress. Companies like Fronius International GmbH, Panasonic Corporation, Kemppi Oy, GCE India Pvt Ltd, Daihen Corporation, Electra Koko Tawa Weld Private Limited, and Aotai Electric Co., Ltd., will expand capabilities by integrating intelligent features and energy-efficient technologies into welding machines. This trajectory indicates a future where the industry will offer machines that are not only faster and more precise but also environmentally responsible, adaptable to diverse industrial applications, and capable of meeting increasing global demand. In this way, both established leaders and emerging competitors will shape a market that balances technological advancement, sustainability, and accessibility, setting the stage for continuous growth and transformation.

Market size is forecast to rise from USD 6364.1 million in 2025 to over USD 9510 million by 2032. Electric Welding Machine will maintain dominance but face growing competition from emerging formats.

Report Coverage

This research report categorizes the global electric welding machine market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global electric welding machine market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global electric welding machine market.

Electric Welding Machine Market Key Segments:

By Product Type

- Arc Welding Machines

- DC Welding Machine

- AC Welding Machine

- Other

By Technology

- Manual

- Automatic

- Semi-automatic

By Application

- Automobile Industry

- Shipping Industry

- Equipment Manufacturing Industry

- Other

Key Global Electric Welding Machine Industry Players

- Lincoln Electric Holdings, Inc.

- Miller Electric Mfg. LLC

- Rajlaxmi Electricals Pvt Ltd.

- Fronius International GmbH

- Panasonic Corporation

- RD Weld Products Pvt. Ltd.

- Kemppi Oy

- GCE India Pvt Ltd

- Daihen Corporation

- Electra Koko Tawa Weld Private Limited

- Sai Arc India Private Limited

- Aotai Electric Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252