MARKET OVERVIEW

The global couplings market is a unique segment of the larger mechanical components sector, encompassing the engineering, production, and distribution of couplings designed to couple two shafts end-to-end in order to provide power transmission. Although one might look at the product and say the idea is simple, the engineering principles behind it and the range of applications in sectors such as manufacturing, marine, aerospace, and energy make defining the market more complex. In the years ahead, this industry will experience changes driven by precision demand, custom configuration, and application-specific innovation. Couplings will remain essential components in machinery where torque transmission, vibration absorption, and alignment compensation are required.

These devices will not function as independent units but as part of complex mechanical systems that require high reliability and performance. From gear and grid to fluid and disc types, producers will create couplings specific to meet performance and structural demands, determined by particular working conditions such as speed, torque range, or environmental exposure. In contrast to most traditional mechanical elements, couplings have found themselves to accept a broad range of operating anomalies. These could encompass shaft misalignment, thermal expansion, or sudden load change.

In this context, the global couplings market will be differentiated not just by the physical product but by the manner in which manufacturers incorporate advanced materials and predictive design technologies to make their products more resilient. With industries progressing toward automated and digitally controlled machinery, couplings will have to be designed to interface with smart systems, causing design to become even more sophisticated. The global couplings market will also not be confined to traditional industrial equipment. The ubiquitous use of couplings in highly specialized applications like subsea turbines, heavy-lift cranes, or precision robots will transform their form and functionality. These applications require higher-order engineering beyond torque transmission to encompass characteristics such as corrosion resistance, thermal stability, and zero backlash under dynamic loads.

Suppliers will be compelled ever more to include technical consulting and application-specific customization as part of their value proposition. The global couplings market will also expand its boundaries by going for strategic partnerships and takeovers, whereby the key players will seek to broaden their portfolios by acquiring niche experts. These actions will lead to further segmentation, with companies that specialize in a particular coupling type or industry application coexisting alongside full-range providers. With growing digitalization across production operations, predictive maintenance functions will become integrated in coupling systems. This move will further impact the way these products are designed, traced, and maintained.

Standardization will still be there, but it will accompany a rising niche of customized solutions, particularly where safety cannot be traded off against operational efficiency. Validation of design by simulation and fatigue calculation will become increasingly part of product development since end-users need components to perform higher than typical standards. In describing the future nature of the global couplings market, it is evident that technical requirements and application-based complexity will determine not only how these goods are made but how they are viewed as mission-critical parts in a more automated and performance-conscious industrial world.

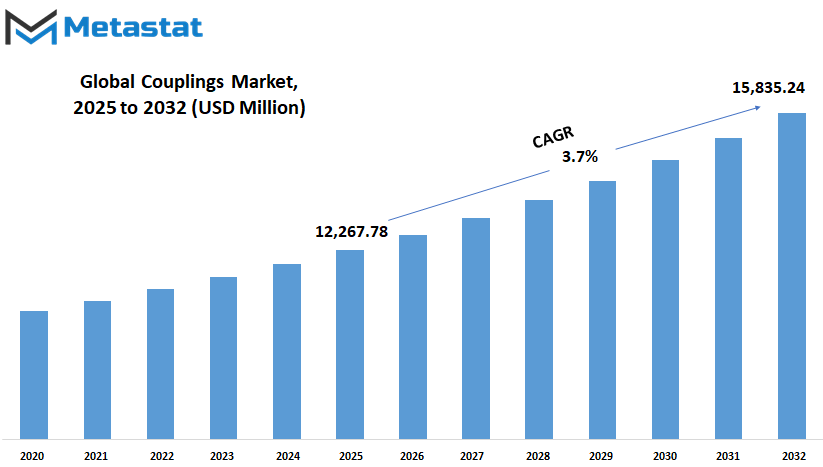

Global couplings market is estimated to reach $15,835.24 Million by 2032; growing at a CAGR of 3.7% from 2025 to 2032.

GROWTH FACTORS

The global couplings market is expected to see a noticeable shift in the years ahead as industries lean more toward smarter, faster, and more efficient systems. One of the main reasons behind this change is the growing demand from industrial automation and the increasing use of heavy machinery. These industries require equipment that can handle high levels of stress and motion without breaking down, making couplings a necessary part of many mechanical systems. As machines become more advanced, the need for reliable connection points between rotating parts also rises. Couplings serve this purpose by transferring torque while allowing for slight misalignments between parts, which is especially important in modern automated systems.

Another factor pushing this market forward is the expansion of power transmission systems in both automotive and manufacturing sectors. Modern vehicles and production lines rely on precise motion control, and couplings play a key role in ensuring smooth and accurate power flow. As electric vehicles and smarter factories become more common, the demand for advanced couplings that can operate efficiently under various conditions is likely to grow. These changes aren’t just happening in one place they’re part of a broader global trend that favors efficiency, performance, and long-term durability.

Still, there are a few hurdles the market might face. One of them is the high upkeep required for couplings in rough working conditions. Dust, heat, and moisture can all wear down parts over time, leading to increased maintenance needs and unexpected downtime. This can be a problem, especially for companies trying to keep costs low while maintaining performance. In addition, there are other motion control options, like direct drives, that don’t always require couplings. These alternatives might not replace couplings altogether, but they could limit the growth of the global couplings market in specific applications.

Even with these challenges, the future looks promising. Ongoing advancements in coupling design such as models that are lighter, produce higher torque, and need little to no maintenance are opening up new possibilities. These innovations will likely attract attention from industries wanting to boost efficiency and lower operating costs. The growing interest in such smart solutions suggests that the global couplings market will continue to evolve with changing industrial needs. As technology keeps moving forward, couplings that offer better performance with fewer complications will become even more important, making way for steady and lasting growth.

MARKET SEGMENTATION

By Type

The global couplings market is expected to grow steadily in the coming years due to increasing demand from a wide range of industries. These couplings are essential components used to connect two shafts together at their ends, enabling the transfer of power while accommodating misalignment or movement. As technology progresses and automation becomes more widespread, the role of couplings will continue to expand. These parts are not just mechanical connectors; they play a vital role in ensuring that machines run smoothly, with fewer breakdowns and less maintenance. This growing dependence on efficient machinery will help drive the global couplings market forward.

By type, the global couplings market is further divided into elastomeric, metallic, and mechanical categories. Elastomeric couplings are popular for their flexibility and ability to dampen vibrations. They help protect other machine parts from wear and tear, extending equipment life. These are especially useful in applications where slight misalignment is common. Metallic couplings, on the other hand, are used when strength and durability are more important. They can withstand high temperatures and are well-suited for heavy-duty environments. Mechanical couplings are designed with moving parts like gears or discs and are ideal for precise alignment needs. Each type serves a different purpose and will see rising demand based on the specific needs of industries ranging from automotive to energy.

As more industries move toward automation and digital monitoring, there will be a growing focus on smarter, more adaptable machinery. This shift will likely lead to the development of advanced couplings that are capable of self-monitoring and performance feedback. In the future, couplings may be equipped with sensors that track alignment, vibration, and wear in real time. This will help reduce downtime and improve efficiency by allowing maintenance teams to act before problems occur. As industries continue to move toward predictive maintenance models, the demand for intelligent couplings will grow.

Overall, the global couplings market will keep changing to meet the needs of a fast-paced world where efficiency and reliability are more important than ever. As industries push for better output and lower operational costs, couplings will remain a key part of this progress. Manufacturers who invest in innovation and quality are likely to lead the global couplings market in the coming years. Whether it's through more durable materials or smarter design, the future of couplings will be shaped by the need for better performance and longer-lasting equipment.

By Application

The global couplings market will continue to grow as more industries aim for efficiency, stability, and smooth performance across their mechanical systems. As machines become more advanced and precise, the need for reliable couplings that connect rotating parts and transmit torque becomes more important. These components help reduce misalignment, improve performance, and support heavy-duty applications without frequent maintenance. Businesses are beginning to realize the long-term benefits of high-quality couplings, and this awareness is expected to shape the future demand.

In sectors like power generation, couplings play a critical role by keeping equipment running smoothly, even in tough environments. As power plants shift toward renewable sources and cleaner energy production, the equipment they use will also need to adapt. Couplings will be part of this change, helping to link parts of advanced turbines and generators in a way that reduces stress and wear. In metal and mining, where operations are often intense and heavy, couplings must handle high torque and vibrations. New materials and designs will likely make future couplings lighter but stronger, making them more suited to demanding work without causing downtime.

The papermaking industry is also changing. With growing demand for faster and cleaner production methods, couplings will need to support newer machines that operate at higher speeds. In automotive, the focus is shifting toward electric vehicles and automation. These changes require couplings that work silently and reliably over time. Advanced coupling designs may soon be built to handle more power with less noise and better energy efficiency, helping car makers meet stricter environmental standards.

Healthcare and aerospace & defense are also key areas where couplings will play a bigger role. In hospitals and labs, machines need to run smoothly without interruptions. Even small errors can have big consequences. High-precision couplings will help keep these tools reliable. In aerospace and defense, equipment often works under extreme conditions. Couplings here must be lightweight but tough. New technology might lead to smarter couplings that adjust to pressure, load, or temperature changes on the fly.

Other industries, from packaging to robotics, will continue to push for better performance. As machines get smarter and more connected, couplings will need to evolve too. The global couplings market will likely grow not just in size but also in how it serves different needs. Future couplings may even include sensors to track their condition and send data in real-time, reducing the risk of failure and boosting safety across sectors.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$12,267.78 million |

|

Market Size by 2032 |

$15,835.24 Million |

|

Growth Rate from 2025 to 2032 |

3.7% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global couplings market is steadily gaining attention as various industries continue to expand their operations and improve mechanical performance. Couplings are important in many systems because they help connect rotating shafts and transmit power effectively. As demand grows for efficient machinery and reduced maintenance costs, the use of couplings is likely to increase across different regions. Industries such as manufacturing, automotive, construction, and power generation will continue to rely on them, which will shape the future direction of this market.

Looking ahead, the global couplings market is expected to benefit from rising automation and a growing focus on energy efficiency. As machinery becomes smarter and more compact, the need for reliable, flexible, and high-performance couplings will grow. In factories where downtime is costly, couplings that can handle shock loads and misalignment without failure will become even more valuable. This shift will push manufacturers to develop more advanced materials and smarter designs that support predictive maintenance.

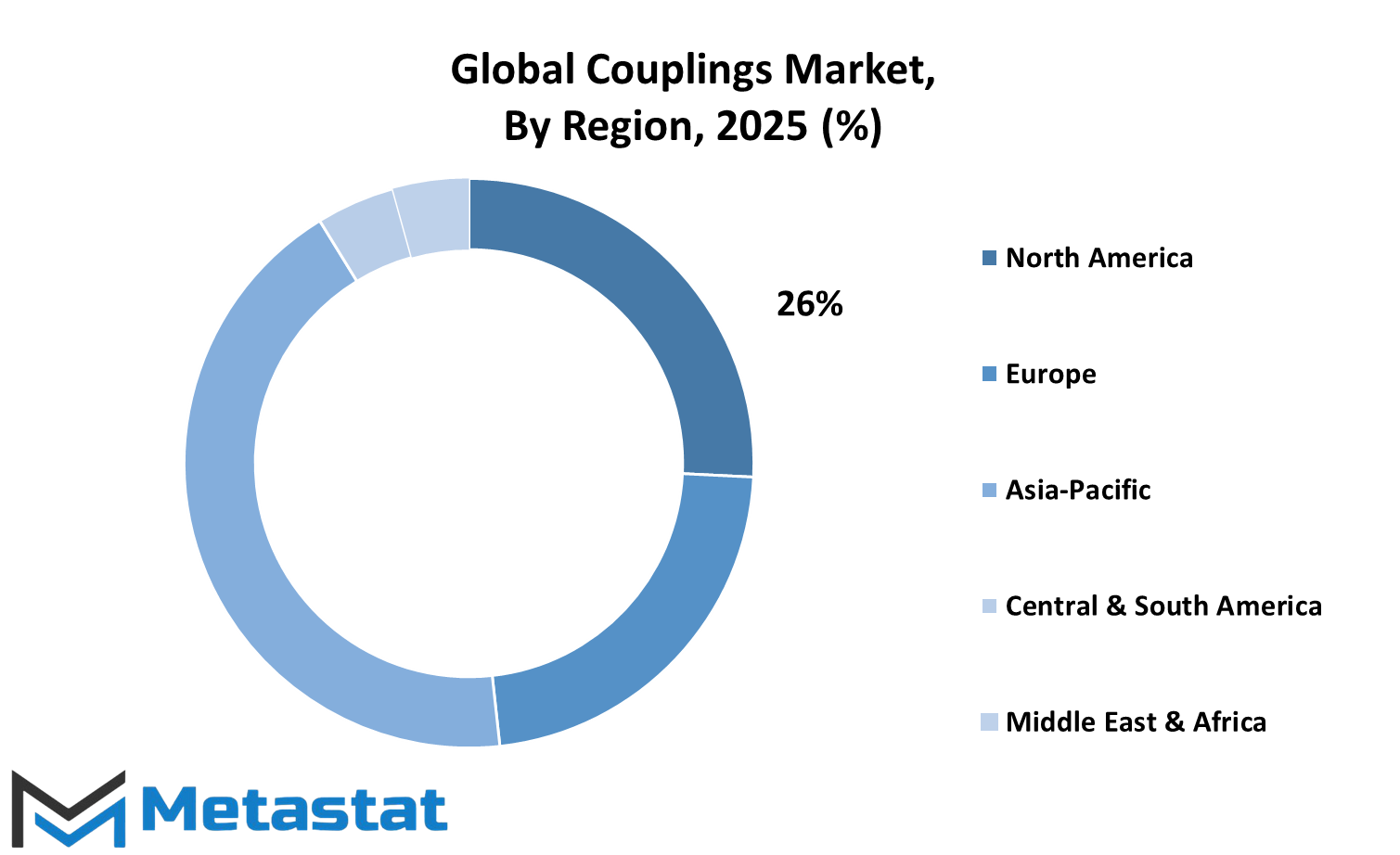

Geographically, the market is spread across North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. In North America, especially in the U.S. and Canada, strong industrial infrastructure and ongoing upgrades in the energy and transport sectors will drive steady demand. Europe, led by countries like Germany and the UK, is focusing on green energy and automated production, which will further increase the need for advanced coupling solutions.

Asia-Pacific, including fast-growing economies like China and India, will likely see the fastest growth in the global couplings market. This is due to rising investments in infrastructure, large-scale industrial projects, and the growing use of electric vehicles and renewable energy systems. Countries such as Japan and South Korea, with their focus on advanced technology and export-driven manufacturing, will also play a significant role.

In South America, Brazil and Argentina are expanding their industrial output, which will create more opportunities for couplings used in heavy machinery. The Middle East & Africa, particularly the GCC countries and South Africa, are increasing their investments in oil, gas, and power sectors. As these regions aim to modernize their infrastructure and reduce dependence on imports, local demand for durable and efficient couplings will rise.

Over time, the global couplings market will continue to grow, shaped by innovation and the need for better performance. As global industries aim to produce more with fewer resources, couplings will remain a vital part of that shift, helping machines run smoother and last longer.

COMPETITIVE PLAYERS

The global couplings market is expected to undergo significant changes in the years to come as industries across the world continue to modernize their machinery and improve power transmission systems. As more sectors lean toward automation and advanced mechanical solutions, the need for reliable and efficient couplings becomes even more important. These mechanical devices, used to connect two shafts together at their ends to transmit power, play a key role in the operation of many machines. They help reduce wear and tear, prevent misalignment issues, and improve overall system efficiency. With industries such as manufacturing, energy, mining, and transportation increasingly relying on these systems, the demand for couplings is only expected to grow steadily.

Leading the way in this market are competitive players who continue to shape its direction. Companies like SKF, Bibby Turboflex, Siemens, Rexnord, and Altra Industrial Motion are not just focusing on product quality, but are also investing in new technology and research. These players are constantly working to create couplings that are lighter, stronger, and more adaptable to extreme working conditions. Others like Tsubakimoto Chain Co., Voith, and Regal Beloit Corporation are looking into ways to offer more energy-efficient designs, which align with global moves toward sustainable practices. This focus on innovation is likely to open up new applications for couplings and expand their use in places where they were not traditionally needed.

Future competition in the global couplings market will likely come down to who can offer the most versatile and cost-effective solutions. Companies such as Timken, Emerson Electric Co., KTR Systems, and Lovejoy are expected to keep upgrading their product lines to meet changing industry needs. Meanwhile, firms like John Crane, Industrial Clutch Parts Ltd., Vulkan Group, and Martin Sprocket & Gear, Inc. will continue to focus on reliability, especially for critical systems where failure is not an option. New developments from CENTA Power Transmission, Ruland Manufacturing Co., Inc., PT Coupling Co., Flender GmbH, and Radicon may also influence market trends by offering fresh ideas in product design or unique materials that enhance durability.

As industries become more connected and digital, couplings will be required to support smarter machines and faster operations. In this environment, companies that can combine mechanical strength with digital feedback systems will likely take the lead. The global couplings market, driven by competition and a need for constant improvement, will continue to evolve, offering better products and broader choices for all kinds of industries.

Couplings Market Key Segments:

By Type

- Elastomeric

- Metallic

- Mechanical

By Application

- Power Generation

- Metal & Mining

- Papermaking

- Automotive

- Healthcare

- Aerospace & Defense

- Other

Key Global Couplings Industry Players

- SKF

- Bibby Turboflex

- Siemens

- Rexnord

- Altra Industrial Motion

- Tsubakimoto Chain Co.

- Voith

- Regal Beloit Corporation

- Timken

- Emerson Electric Co.

- KTR Systems

- Lovejoy

- John Crane

- Industrial Clutch Parts Ltd.

- Vulkan Group

- Martin Sprocket & Gear, Inc.

- CENTA Power Transmission

- Ruland Manufacturing Co., Inc.

- PT Coupling Co.

- Flender GmbH

- Radicon

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383