MARKET OVERVIEW

Global Biphenyltetracarboxylic Dianhydride is of paramount significance to the polymer industry and holds a very important place for the future development of materials engineering. This compound, resulting from the condensation reaction of biphenyltetracarboxylic dianhydride with different diamines, is the building block of high-performance polymers. Its applications range from the aerospace and automobile industries to the electronic and healthcare sectors.

The BPDA-based polymers have good thermal stability and high mechanical strength in the production of aircraft and spacecraft parts light in weight but strong in mechanical structure. These polymers have made an immense contribution toward the development of aerospace technology; they can endure high temperatures while remaining resistant to environmental agents. It is also a fact that resistance to extreme conditions ensures safety and reliability for vital systems in aerospace.

In the automotive industry, BPDA-based polymers play their part very well in improving fuel efficiency and reducing emissions. BPDA-based polymers can be incorporated into various auto parts to develop light materials without loss of fuel economy; rather, it enhances with reduced emission. Additionally, BPDA-based polymers have good thermal stability, which makes them very suitable for use in engine component parts usually subjected to high temperatures.

The special properties of BPDA-based polymers also help the electronic industry enormously. With the electronic device becoming smaller in size and more complex, demands for high-performance materials which could meet up to the stringent performance requirements increase exponentially. BPDA-based polymers, having excellent electrical insulation properties with good heat and chemical resistance, have been an ideal candidate for the manufacture of a great variety of electronic components, including printed circuit boards, connectors, and encapsulants.

Moreover, BPDA-based polymers find applications in healthcare sectors in a variety of medical applications, especially in surgical instruments, drug delivery systems, and implantable devices. These polymers offer bio-compatibility, sterilizability, and durability, making them appropriate for application in critical medial devices.

The future of BPDA and its derivatives in the polymer industry looks bright. Further research and development are focused on improving their properties and versatility, hence opening new vistas of applications. Starting from innovative polymer synthesis techniques to the discovery of novel formulations, BPDA is sure to be at the front line to continuously revolutionize the face of materials, driving innovation and thus shape the future of engineering and technology.

Global sales of biphenyltetracarboxylic dianhydride have been the keystone of the polymer industry due to its properties and versatility, making it one of the most exciting polymers ever developed in history, thereby propelling the creation of high-performance materials used in aerospace, automotive, electronics, and health industries. BPDA and its derivatives will just continue to drive that trend into the future as technology pushes forward and demands evolve.

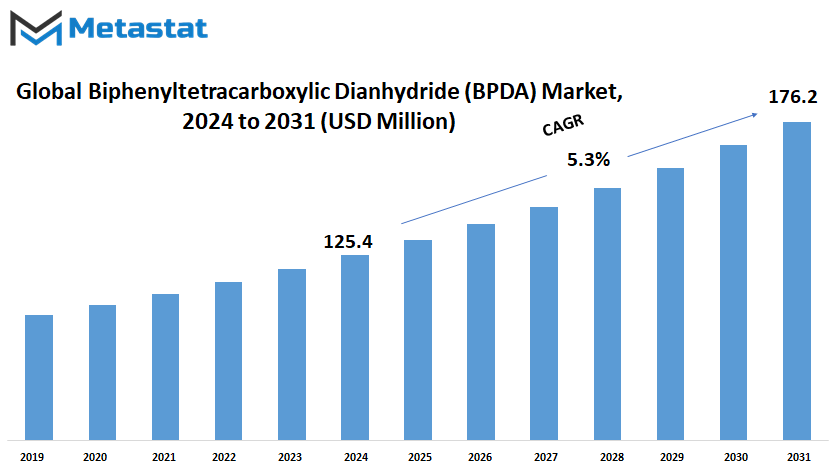

Global Biphenyltetracarboxylic Dianhydride (BPDA) market is estimated to reach $176.2 Million by 2031; growing at a CAGR of 5.3% from 2024 to 2031.

GROWTH FACTORS

The global demand for BPDA is highly boosted by the increasing demand for lightweight, high-strength materials in various industries, such as aerospace and automotive. In addition, increasing applications of BPDA in the electronic and semiconductor industries due to its excellent thermal stability and excellent electrical insulation are further supporting market growth.

However, market growth is easily damped by several challenges, the key ones being fluctuations in raw material prices—especially those used in the making of BPDA. Environmental regulations and public controversies related to chemicals that might be used in polymer production will further hinder any growth trajectory.

Looking ahead, the entering into new sectors like renewable energy and medical devices is likely to create lucrative opportunities for players in the BPDA market in the coming years. This would be driven by its high heat resistance and excellent chemical stability, making it an excellent material for a myriad of new innovations in those sectors.

It is directly driving the demands of the aerospace and automotive industries toward more lightweight materials with higher strengths. Fuel efficiency, performance, and safety have to be combined with reliability. BPDA is fast becoming the material for the fabrication of component parts in these industries due to its high thermal stability and electrical insulation properties.

Besides, the characteristics of BPDA have made it quite attractive in a variety of applications related to electronics and semiconductors, for which very high demands on precision and reliability were necessary. Its property of withstanding very high temperatures while maintaining electrical insulation makes this substance appropriate for integration within electronic components and circuitry.

Although quite promising, the prospects for growth will be hampered by raw material price fluctuations and regulatory pressure on the BPDA market. Increases in the prices of petroleum-based feedstocks that make up BPDA will bring down the overall efficiency of the manufacturing process. Besides, environmental regulations, such as those that reduce the use of some chemicals in polymer manufacturing processes, might remain a challenge for their compliance by industry players.

However, opportunities availed by the growing applications of BPDA in emerging sectors like renewable energy and medical devices are about to be explored by the market. The outstanding thermal resistance and chemical stability offered by BPDA make it applicable for these industries where performance and reliability are very crucial. All in all, with challenges ahead, the future outlook still holds up good for the BPDA market, driven by continuous innovation and extending possibilities for application.

MARKET SEGMENTATION

By Type

Global biphenyltetracarboxylic dianhydride (BPDA) is one of the niches that have shown a high growth rate in the recent past. The market is divided into several segments that can be expected to boost its expansion. Improving technological advancements and growing demand in various industries have brought speed in its growth.

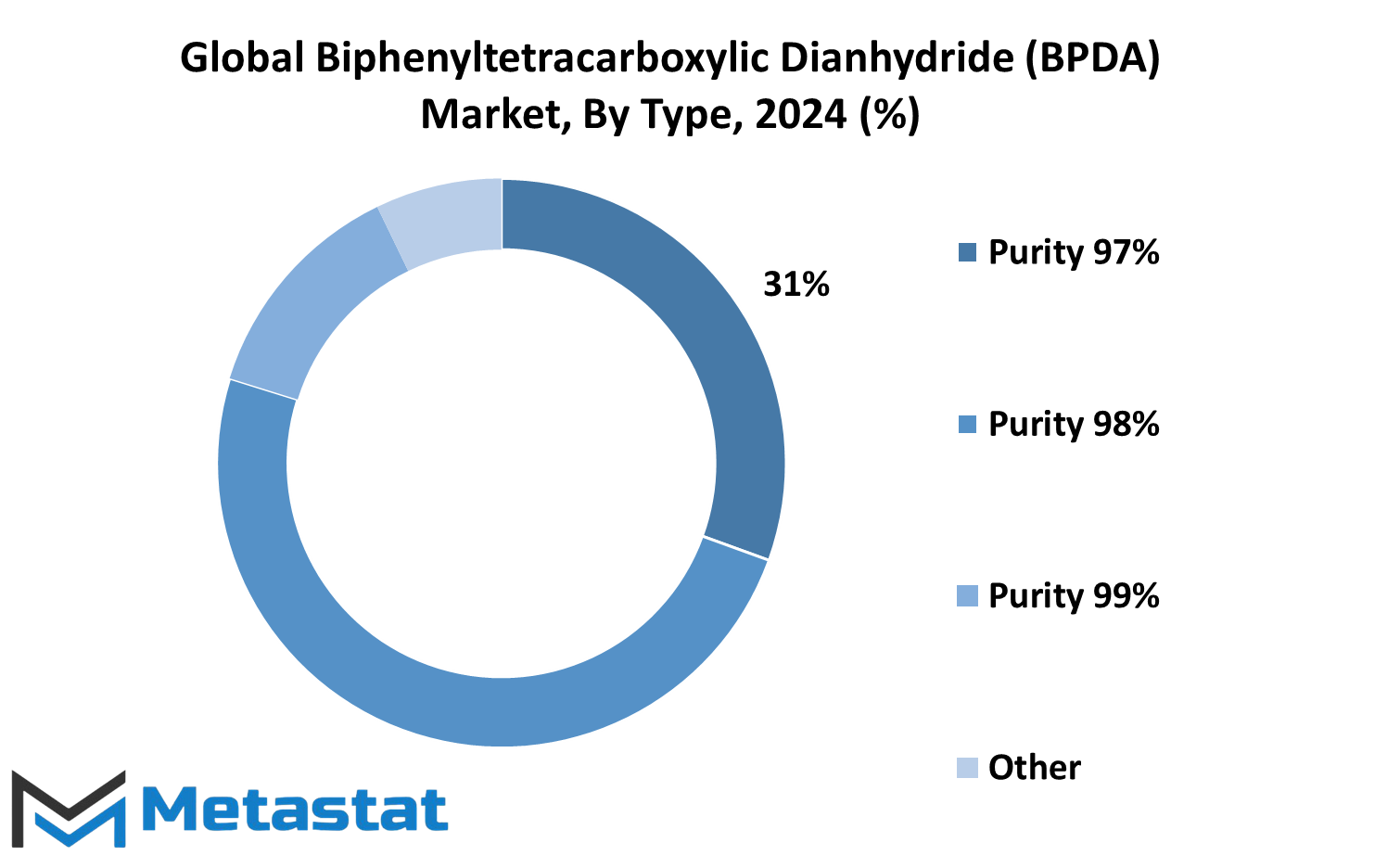

Another important characteristic that forms the BPDA market is segmentation based on purity levels. BPDA falls under multiple purity grades: 97%, 98%, 99%, and others. All of these grades have their own uses, serving different market demands.

The 97% purity grade for BPDA is applied in great diversity: from the production of engineering plastics, composites, and high-performance films to other applications. Its price combined with other excellent properties makes it very desirable for manufacturers who need more economical solutions without seriously degrading quality.

Moving up the scale of purity, the 98% purity grade will have improved performance characteristics that can be applied to more demanding industries such as electronics, aerospace, and automotive. It assuredly has better thermal stability, chemical resistance, and mechanical properties owing to the increased level of purity; hence, meeting the most stringent requirements of the modern-day manufacturing process.

This grade falls within the top range of BPDA quality, resulting in the highest purity and performance. Areas of application include specialized industries where precision and reliability are paramount: semiconductor manufacturing, advanced material research, and pharmaceutical synthesis. The ultra-pure quality ensures performance at the best level and consistency, hence driving innovation and pushing the envelope of technological possibilities.

Excluding the above-mentioned well-defined purity grades, the "Other" category comprises variations and customizations to suit specific end-user requirements. In this way, manufacturers are able to address niche markets and effectively solve unique challenges. This could mean modified purity levels, additives, or different processes to arrive at formulations customized to suit varied applications.

In the future, the BPDA market will further gain growth and diversification in demand by the evolving requirements of the industries and technological innovations. With the increasing adoption of digitalization, automation, and sustainable initiatives, the requirement for high-performance materials like BPDA will further increase. In addition, wave-of-the-future innovations with regard to process development and material science are bound to increase the range of applicability of BPDA, hence opening up new opportunities and eventually driving market expansion.

By Application

The global biphenyltetracarboxylic dianhydride market is expected to witness considerable growth over the next few years. BPDA represents an important chemical material with extensive applications across a variety of industries. Some of its key uses are very important for understanding the possible future trends of this market.

The most prominent application of BPDA is in the production of heat-resistant plastic film. With technology advancing at a fast rate, there is an increasing demand for materials that can bear high temperatures without affecting their integrity. BPDA-based plastic films can offer just this, thus becoming very important in industries such as packaging, automobiles, and aerospace.

Another critical area of application is in electronic circuits. With increasing complexity and miniaturization, the demands on good thermal stability and electrical insulation in materials used for electronics will increase, in which BPDA will play a central role for such an application in the manufacture of these circuits so that the performances realized in many electronic gadgets or equipment are reliable.

Color resistance inks also rely on BPDA for their formulation. Among other uses in printing, such inks are applicable in areas where it is necessary to have them resist fadingness or degradation. BPDA provides stability and durability for color resistance inks, ensuring vibrancy and quality in the printed matter.

Moreover, BPDA finds an important place in the medical and scientific industries. Everything from coating medical devices to scientific apparatus is accepted in the field of medicine because of their biocompatibility and resistance to chemicals.

The other uses of BPDA include adhesives, coatings, and specialty polymers. Hence, the versatility of BPDA makes it possible to be formulated into a large number of products within many industries, thereby ultimately driving demand and increasing market growth.

The future of the BPDA market looks bright, with further expansion buoyed by continuous technological innovations and diversification of applications. As industries continue innovating, thereby demanding materials that will have better performance characteristics than existing ones, it is likely that the role played by BPDA will be felt more. Manufacturers and other stakeholders in the BPDA market will have to keep pace with the evolving trends and make use of opportunities for growth and innovation.

Global biphenyltetracarboxylic dianhydride applies to a wide range of industries, such as heat-resistant plastic films, electronic circuits, color resist inks, medical and science applications, among many other uses. Thus, while the demand for high-performance materials is only growing, the future for the market of BPDA certainly looks promising..

REGIONAL ANALYSIS

The demand for global biphenyltetracarboxylic dianhydride is ever-changing with the changing market conditions today. BPDA finds major usage in those applications where high-performance material fabrication takes place, such as in the electronics, aerospace, and auto industries. Understanding geographical distribution provides an insight into the present and future trends in the BPDA market.

The segmentation of the global BPDA market is done based on geography, where North America remains one of the prominent regions. Growing aerospace and automobile sectors drive the demand for BPDA in North America. With growing technology and rising requirements for light, yet strong materials, BPDA finds extensive application in the manufacture of components such as composites, adhesives, and coatings.

It now shifts to the European market: another key arena for BPDA. Herein, with a strong emphasis on sustainability and environmental regulations, it opens up the way for the large-scale adoption of BPDA-based materials in an environmentally-friendly manner that outperforms existing alternatives. In this sense, European industries, especially carmakers and electricals, are gradually replacing BPDA to meet stringent requirements for efficiency and safety.

With the booming industrial sector, the Asia-Pacific region allows vast opportunities for the BPDA market. It is expected that countries like China, Japan, and South Korea will grow sectors like electronics, telecommunications, and transportation at a very fast pace. With these industries striving to be more innovative and competitive, demand for BPDA will just keep growing. Moreover, investments made in research and development in this region still accelerate the adoption of BPDA-based materials, thus fueling further market growth.

Latin America and the Middle East & Africa regions also contribute to the global BPDA market, although to a lesser extent. Despite being embattled with problems such as economic instability and political uncertainties, these regions are scattered with potential, especially in sectors like construction and infrastructure development. As the economies in these regions stabilize and industrialize, demand for BPDA will rise but not as rapidly as in other regions.

One can find growth in the global BPDA market undersea, driven by several factors. Comprehending geographical dispersion in this market would be very critical for stakeholders who want to exploit every opportunity while avoiding setbacks. Continued innovation and strategic investments in this regard will keep the BPDA market buoyant in its continuous satisfaction of diverse industries around the globe.

COMPETITIVE PLAYERS

There exist a number of key players within the Biphenyltetracarboxylic Dianhydride market who keep it growing and almost monopolize it with new technological innovation. Notable among the larger ones are Mitsubishi Chemical, Alfa Chemistry, Akron Polymer Systems, Ube Industries, Merck KGaA, Shangdong Helishi, Chemwill Asia Co., Ltd., Dayang chem, actions Hangzhou) Co., Ltd., Wuhan Fortuna Chemical Co., Ltd, Henan Tianfu Chemical Co., Ltd, and Jinan Finer Chemical Co., Ltd.

For the next few years, such industry giants would drive the BPDA market, under their competitive strategies and novel approaches. The companies would move with the technological changes and changing consumer demand through adaptation and finessing of their offerings. Strategic partnerships or mutual collaboration will be frequent as companies try to use each other's strengths and resources.

This could also mean that the future of the BPDA market could be oriented toward sustainability and eco-friendliness. With the increased awareness of the impact on the environment, there are persistent voices from consumers and regulatory bodies for greener options. Companies involved in BPDA production will likely put time and resources into research and development to come up with products that can answer these demands while adhering to high performance standards.

Above and beyond, globalization will have a strong role to play in changing the competitive landscape of the BPDA market. Companies will have to be prepared to face competition from domestic and international players as more and more markets continue to link up across the world. Resultant of this is the growing urge to get differentiated and grow in value proposition to come up above in the global marketplace.

Improvements in manufacturing processes and materials science will also be another big driver of innovation within the BPDA industry. Indeed, firms will further investigate new processes for production and materials that will improve product quality, lower costs, and improve the sustainability of their products. This relentless search for novelty will impose permanent pressure on firms to remain competitive within a fast-changing market.

Moreover, digital transformation is going to radicalize the way companies involved in BPDA work and relate to their customers. With innovations like artificial intelligence and big data analytics, firms will be better placed in understanding consumer preferences and emerging market trends. Such a data-driven approach would make it possible for companies to fine-tune their product offerings and corresponding marketing strategies in the best possible manner.

The Biphenyltetracarboxylic Dianhydride market is likely to grow and evolve over the next few years. Key participants would continue to fuel innovation, embrace sustainability, approach globalization, and leverage digital technologies to sustain competitive advantage in a changing market scenario.

Biphenyltetracarboxylic Dianhydride (BPDA) Market Key Segments:

By Type

- Purity 97%

- Purity98%

- Purity99%

- Other

By Application

- Heat-Resistant Plastic Film

- Electronic Circuits

- Color Resist Inks

- Medical and Science

- Other

Key Global Biphenyltetracarboxylic Dianhydride (BPDA) Industry Players

- Mitsubishi Chemical

- Alfa Chemistry

- Akron Polymer Systems

- Ube Industries

- Merck KGaA

- Shangdong Helishi

- Chemwill Asia Co., Ltd.

- Dayang chem (Hangzhou) Co., Ltd.

- Wuhan Fortuna Chemical Co.,Ltd

- Henan Tianfu Chemical Co.,Ltd

- Jinan Finer Chemical Co., Ltd

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252