Jun 27, 2025

Metastat Insight publication on the Global Zero Liquid Discharge (ZLD) System Market provides an in-depth overview of an industry changing the face of contemporary industrial practices in water recovery and reuse. As concerns over environmentalism become increasingly popular in many industries, the notion of zero liquid discharge has progressed from being a theoretical concept to a practical imperative. This industry captures the interest of manufacturers seeking to reduce their wastewater volume and enhance long-term sustainability. ZLD plants, designed to remove liquid waste altogether, provide not just environmental compliance but potential operational reuse value, a combination which is increasingly sought after.

Global Zero Liquid Discharge (ZLD) System market is estimated to reach $8,443.86 million in 2025 with a CAGR of 8.0% from 2025 to 2032.

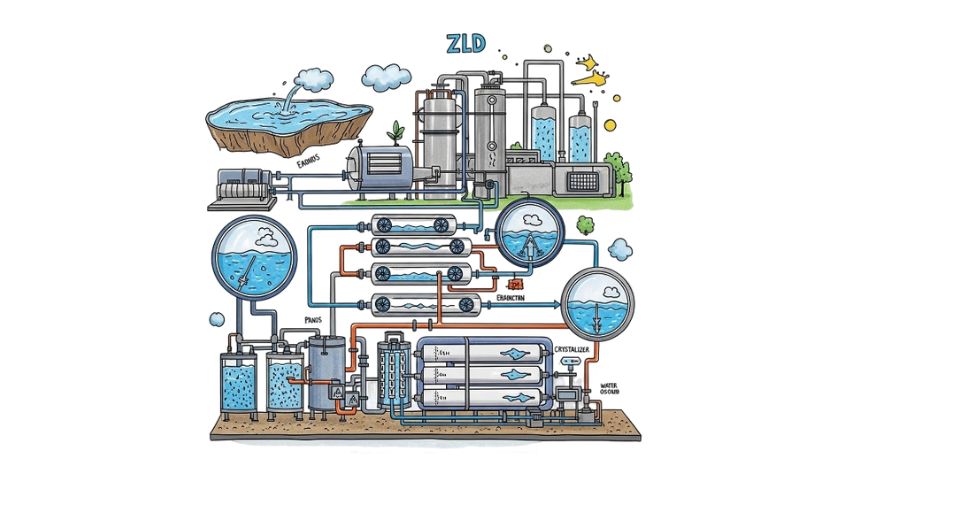

Of special interest in the conversation surrounding this industry is the range of technologies synergistically contributing within every ZLD solution. Various pieces of devices such as evaporator, crystallizer and pre-healing units work together to recycle precious resources and reduce disposal requirements. Instead of flowing to the wastes uninterrupted or partially, the ZLD systems loop liquid waste, giving industries a way to follow strict discharge rules keeping in mind the overall environmental objectives. Even though the size and use of such systems vary in industries, the original basis remains the same in every installation: recovering, recycle and reducing.

Depending on the industry, the character of industrial wastewater is quite different, ranging from chemical manufacturing to textiles, pharma to power generation. ZLD system vendors are then constantly innovating technologies to suit the nature and quantity of effluents unique to each process. This has created a multihued and competitive environment, where engineering flexibility and tailor-made solutions tend to be the deciding factors. Firms that develop and provide these systems typically stay in close touch with facility operators to develop processes that not only eliminate discharge but integrate perfectly into built-out infrastructure, a function that calls for both co-operation and innovation.

In addition to the machinery itself, a further area of interest is the impact these systems have on corporate conduct. Companies are increasingly seeing water not only as a cost of doing business, but as a strategic asset. Adopting ZLD technologies often represents a change in mindset - a one that sees water in the heart of both operational excellence and public responsibility. This change is a proof of internalization of environmental leadership not only for regulatory compliance or brand reputation, but also flexibility and longevity in resource-intensive operations.

Additionally, as the water scarcity situation in most areas intensifies, the importance of capable technologies in recovery of full water has increased. ZLD facilities are no longer confined to areas with stringent regulations; they are increasingly becoming part of overall water stewardship initiatives in areas where sustainable industrial practices are voluntarily pursued. In these instances, firms even utilize the performance of their ZLD systems as markers for corporate sustainability reporting or public disclosure. These plants thus leverage their impact beyond factory and treatment plant walls, into discussions regarding responsible growth and environmental stewardship.

Technologically, there is ongoing research aimed at making ZLD systems more efficient, cost-effective, and flexible. Innovation has increased the scalability of these systems so that smaller operations can contemplate adoption where previously it was only viable for large-scale industrial facilities. Developments in membrane technologies, hybrid systems, and energy recovery solutions continue to influence the incorporation and handling of these systems. With advances typically spurred by a mix of regulatory need and voluntary corporate objectives, the technologies in this area are a testament to a steadily more active approach to water management.

In addition, the function of digital monitoring and automation is increasingly significant in ZLD system operation. Real-time information enables operators to maximize performance, minimize system downtime, and plan for maintenance needs. This digital integration enhances efficiency as well as lowers the risk of system failure, which can be financially and environmentally costly. As these technologies become more accessible, they help make ZLD systems economically feasible for more companies and applications.

Full circle, then, the revelations contained in the Metastat Insight report on the Global Zero Liquid Discharge (ZLD) System Market present an industry meeting practical challenges head-on with a forward-looking perspective. Discussion of water treatment has moved from reactive to regenerative, and ZLD systems capture that shift. As businesses increasingly see the value in conserving water with precaution and care, this industry is notable for redefining how businesses deal with waste and resource recovery. Here, the Global Zero Liquid Discharge (ZLD) System Market, as reflected in the latest discoveries by Metastat Insight, is not only a technological path but a wider promise of sustainable industrial revolution.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479