Sep 04, 2025

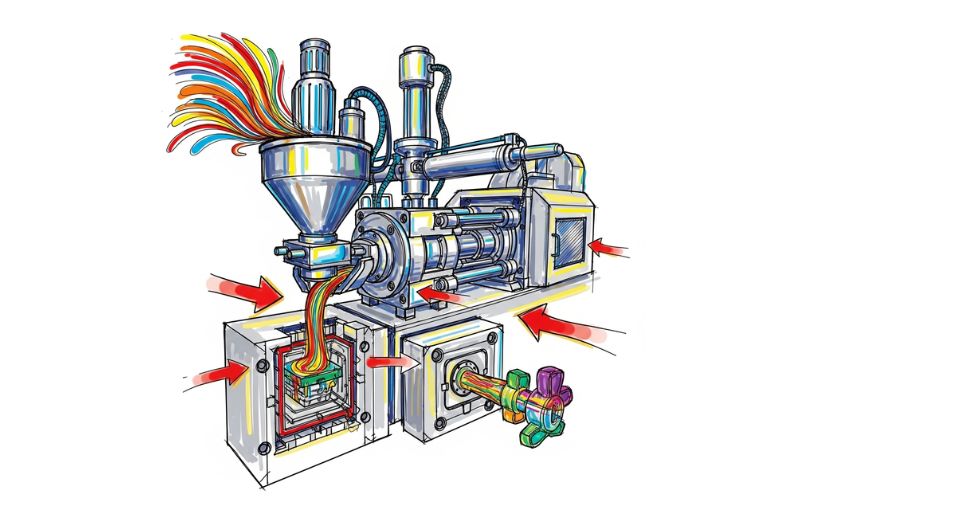

A recent presentation of the worldwide injection molding market report by Metastat Insight presents an enriched story of industrial dynamics to prompt reflection on evolving patterns in material transformation and manufacturing. A veteran's voice, which has been sculpted by close to a decade and half watching production landscapes, emerges to spin together observations that eschew superficiality. Growth patterns, if anticipated, are highlighted through optics that project supply-chain drivers, momentum of innovation, and rhythms of adoption instead of resorting to blanket labeling. Strategies and investments emerge naturally as aspects of new behaviours with companies instead of being found in the guise of key or driving reasons, but being manifested in form shifts in tooling complexity, polymer mixtures, and adaptability of design.

This introduction announces a shift from broad brushstrokes to richly textured observation that honours depth of field. Years of background in injection molding dynamics foster appreciation for shifts in machine technologies, where response time and accuracy intersect with materials responsive to calls for sustainability and form complexity.

The maturing in molding methods manifests through advances in cycle efficiency and temperature control, allowing parts once deemed out of reach. A geometry formerly needing sophisticated secondary operations now appear with tooling that uses real-time monitoring and adaptive control, minimizing waste and enhancing repeatability. Improvements in servo-hydraulic integration, although not described as "pivotal," have impact through real-time feedback loops that damp process variables, providing consistency from one production run to another. Changes in material usage underlie subtle but significant change. Polymer blends with bio-derived feedstocks or recycled material introduce shrinkage profile and melt flow variability to process conditions that test processors to redesign process conditions, but also create potential for circularity.

Special fillers add enhanced stiffness or heat resistance with minimal disruption to installed equipment footprints. Progressive changes in polymer supply, influenced by regulatory directions and sustainability priorities, cascade through purchasing choices, amplifying value chains towards resilience as opposed to mere cost or supply logic. Design breakthroughs come with additive-guided tooling, generative cavity geometries, conformal cooling, and internal lattice features. Such design advancements significantly reduce time-to-first sample and increase the ability to create lightweight or complex geometries directly off the mold. Moldmakers use simulation not just as a virtual test but as a means to filter tooling strategies flow analysis, warpage analysis, cooling optimization prior to cutting steel.

The payoff manifests in improved product performance and less iteration. That is a sign of maturity in how design and manufacturing meet on productivity, quality, and throughput. Real-time quality control integration naturally arises in facilities where sensor networks bridge cavity pressure, temperature, and flow to controls. Trends arise and aberrations get alerted prior to scrap piling up. That integration eliminates downstream inspection chokepoints and turns the focus towards inline verification. Smart alarms direct operators to interventions at mold-flow levels, with logging providing traceability of parts linked to cycles and cavities.

Patterns of demand shifts mirror larger trends in manufacturing: combination of small-lot customization with high-volume production. Molds with rapid cavity changeover and standardized plate interfaces provide flexibility while, simultaneously, sound multi-cavity designs continue to be critical for consistent high-volume production. That conflict is worked out on molding floor layouts, equipment choice, and inventory policy. That conflict determines capital deployment and operating procedures more than semiological constructs can convey.

Considerations of people skills arise as strategic investments. Technicians who are proficient in tool steel behaviour, process window control, and cycle trouble-shooting provide craftsmanship that software improvements cannot. That expertise maintains quality as process windows narrow and materials shift. Technical education and knowledge retention become unseen bulwarks against drift in accuracy over time. Geographic relocations of production also occur: markets formerly clustered in traditional centers now diversify as developing regions invest in infrastructure, worker skills, and supply-chain linkages. That dispersion insulates against disruption and ignites regional competitive strength. Equipment manufacturers and mold-providers monitor that dispersion, aligning support services as a result.

Logistics schedules and sourcing flexibility discover new patterns of alignment, not merely cost-effective but strategically balanced. Increased interest in near-zero waste goals pushes molders into closed-loop systems remanufactured runners, recycled sprues, melt-flow capture coupled with process control. That shift encourages environmental stewardship through proof of concept in production. Waste reduction is no longer slogan-driven but becomes everyday practicality, coupled with long-term resiliency. Throughout the manufacturing landscape, cooperation among molders, OEMs, and materials suppliers sows incremental gains. Coupled pilot runs with new grades, longer trials with thin-wall geometries, and co-engineering of additive-surface textures document partnership in action. That cooperation quietly shifts time-to-market, quality standard, and material performance expectations beyond marketing hype.

In summary, narrative based on the worldwide injection molding market report given by Metastat Insight reworded point of view here comes back at the end. A point of view informed by decades of industrial watching, where change occurs not only through broad themes but through process improvement, material realignment, design convergence, quality integration, workforce capability, geographic diversification, and sustainability focus. That finish resonance emphasizes steadiness in thinking evolution out of layered, people-driven change that indicates the mature beat of manufacturing.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479