MARKET OVERVIEW

The global injection molding market will be at the center of a technological revolution that will restructure manufacturing norms in various industries. This sector will not be limited to traditional uses; rather, it will shift towards sophisticated approaches that emphasize efficiency, sustainability, and quality. Outside the limits of its uses today, injection molding will become an energetic player in healthcare, automotive, electronics, and aerospace fields, where complexity and accuracy cannot be compromised. As production systems evolve, the focus will be on high-performance polymers and material formulations designed to serve more stringent environmental and functional requirements.

The global injection molding market, in the future, will not just fulfill the demand for mass production but also facilitate customized production on an unprecedented scale. With automation playing a more significant role in industrial processes, injection molding will be perfectly complemented by smart technologies so that there are less human intervention and greater control over operations. Manufacturers will tend to go for predictive analysis and real-time monitoring so that consistency improves and wastage is reduced. This will lead to processes that are not only quicker but also greener, making sure that the use of material is taken to its optimal stage.

Environmental stewardship will also push innovation in the sector. Conventional manufacturing is usually attacked for its environmental effect, but injection molding will see advancements in biodegradable polymer and recoverable parts. The focus will be on designing systems with lower carbon footprints that produce compliant products for global standards. All this will provide opportunity for industries that previously shied away from using injection molding because of sustainability issues.

The power of consumer-led markets will continue to define production strategies. Companies will consciousness on agility with a view to respond to transferring requirements, and injection molding will provide the flexibility to modify with out sacrificing on best or speed. This flexibility will make the procedure a ought to-have for industries with a focal point on brief product development and compressed time-to-marketplace windows. Furthermore, hybrid and additive production techniques will aid injection molding, allowing manufacturers to combine the benefits of conventional molding with the accuracy of cutting-edge production practices.

Global partnerships will also take center level, with groups changing resources, understanding, and technologies to craft included networks that optimize production across the globe. This networked framework will allow globalized satisfactory, with products meeting worldwide requirements without the inefficiencies or delays. Additionally, the hard work pressure worried within the global injection molding market will should exchange, traumatic specialized competencies in digital operations, robotics, and modern cloth sciences.

Eventually, the arena will evolve right into a clever, sustainable, and customer-orientated industry. The future does not hold just continuation of existing practices but an era in which injection molding is identified with state-of-the-art technology and environmental stewardship. The global injection molding market will surpass traditional horizons, creating a future where industrial advancement is married to the dictates of sustainability and innovation.

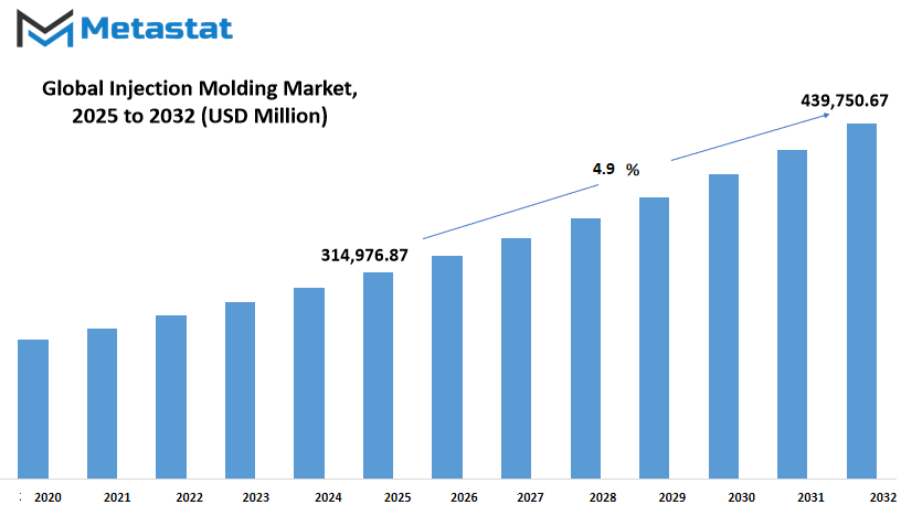

Global injection molding market is estimated to reach $439,750.67 Million by 2032; growing at a CAGR of 4.9% from 2025 to 2032.

GROWTH FACTORS

The global injection molding market is experiencing steady expansion based on its capability to produce accurate, long-lasting, and cost-effective parts across industries. Increasing call for light-weight, long-lasting parts for vehicle and packaging makes use of is one of the most powerful drivers for this market. Car producers have become greater interested by decreasing weight to enhance gas efficiency, and plastics molded via injection are a very good answer with out sacrificing power. Similarly, the packaging area maintains to searching for substances which might be each durable and flexible, creating enormous possibilities for injection molding to thrive as manufacturers prioritize performance and fine in manufacturing.

Another principal driving force shaping the global injection molding market is the developing use of advanced plastic materials for cost-powerful production. These substances permit for progressed design flexibility and faster production cycles, permitting agencies to fulfill high-volume demands at the same time as maintaining prices below manipulate. This flexibility makes injection molding appealing in industries from client merchandise to electronics, wherein pace and precision are of the essence. When organizations goal to optimize tactics with out compromising product satisfactory, advanced polymers come into play ever more strongly.

In spite of these benefits, the global injection molding market has some challenges which cannot be overlooked. The biggest hurdle is the considerable initial investment necessary for injection molding machines and molds. Establishing a plant requires considerable capital, which can restrict entry for smaller firms or start-ups. Moreover, growing environmental pressures over plastic usage have caused extended guidelines, main to pressure on manufacturers to adopt green methods. Compliance with those guidelines frequently includes more price and adjustments in the method, which may be coins-straining for producers strolling skinny margins.

Yet, those troubles also deliver ability opportunities. The growing emphasis on sustainability has fueled bio-primarily based and recycled plastics innovation, providing a substitute for conventional resins. Not best does this trend respond to environmental issues but additionally makes the groups well-placed to deal with the growing call for inexperienced products from customers. In addition, the healthcare enterprise provides a strong increase area with injection molding having a crucial role to play in production clinical gadgets and elements where precision and reliability are important. As scientific requirements develop worldwide, the want for low-priced, best solutions will hold pushing the technology of injection molding forward.

The future of the global injection molding market is anticipated to peer a fashion towards greater progressive and sustainable manufacturing techniques within the years to come. Although issues concerning high prices of funding and pressures from policies continue to pose demanding situations, the cloth innovation possibilities and the increase in utility regions for industries such as the healthcare area will dictate the direction of this market's destiny. Companies that embody transformation and evolve with converting expectations may be in suitable stead to dominate an increasing number of aggressive markets.

MARKET SEGMENTATION

By Material

The global injection molding market is emerging as considered one of the largest production industries that has an vital position in production severa components utilized in car, packaging, electronics, healthcare, and diverse different fields. Such a procedure finds sizeable software due to its functionality of producing complicated shapes with high accuracy and low scrap, as a result being a cost-powerful and green method for mass production. As the call for durable and lightweight merchandise continues growing, injection molding will stay a key thing of the world's production sector.

The main force at the back of this enterprise is the large utility of plastic substances which have a monopoly within the enterprise with an expected cost of $299,058.62 million. Plastics have remarkable versatility, sturdiness, and occasional fees, making them ideal for use in applications starting from packaging to purchaser items to clinical gadgets. Their potential to be formed into specific bureaucracy without compromising on power and elasticity has earned them the top desire amongst maximum producers. Furthermore, non-stop innovation in recyclable and biodegradable plastics will hold to solidify their grip on this quarter.

Other than plastics, metals additionally command a extensive element inside the injection molding process. While plastics dominate the market owing to their affordability and layout versatility, metals are selected for programs annoying superior power, warmness resistance, and sturdiness. Industries inclusive of car, aerospace, and heavy equipment rely significantly on metallic injection molding to fabricate long lasting components that must adhere to stringent overall performance necessities. While not as overwhelming as plastics, the market for metal injection molding is likely to grow with improvements in technology and industry needs for highly accurate metal components of intricate geometries.

Other materials, such as ceramics and composites, also add to the growth of this market. These are specialty materials that service industries needing special properties like extreme resistance to heat, hardness, or insulation against electricity. Though they constitute a smaller segment of the entire market, their function in specialized applications provides consistent demand. As industries are in constant pursuit of creative ways to improve performance and efficiency, such materials will evolve new uses in the long run, adding richness to the global injection molding market.

In the future, the global injection molding market will continue to grow with manufacturing industries requiring affordable, high-quality production processes. The reign of plastics will be steadfast, but rising prominence of metals and other materials underscores the variety of possibilities in this arena. With better technology and environmentally friendly considerations taking center stage, the market will evolve with green materials and innovative manufacturing processes, making it relevant for years to come.

By Application

The global injection molding market is an essential section of the manufacturing industry, with a chief contribution to product layout that is utilized during each day life and industrial purposes. The injection molding technique permits the manufacturing of correct and difficult parts with performance and repeatability, making it one of the maximum universally used manufacturing techniques. Its versatility and low fee have made it a need in numerous industries, ranging from patron products to excessive-performance engineering items. As industry demands solutions that weigh between durability, design, and mass production, injection molding is a sure bet.

Of the top application sectors, packaging ranks highly because of high demand for light, tough, and inexpensive materials. Packaging applications for injection molding are specially fueled via growing demand for green and useful designs in meals, beverages, and personal care merchandise. The functionality to create personalized shapes with minimum cloth waste facilitates the packaging industry achieve both overall performance and ecological goals. This element may also revel in boom as corporations push for brand spanking new designs and packaging answers that respond to patron wishes for comfort and protection.

Another zone with a high contribution is the automotive and transportation industry, wherein injection molding is important for producing elements that want energy without needless weight added. As electric powered automobiles gain recognition and the sector transitions to gas efficiency, vehicle producers are transferring in the direction of the use of lightweight plastic additives made by this method. Internal components which includes dashboards, bumpers, and indoors trim are widely manufactured using injection molding, imparting accuracy and uniformity in mass production. Likewise, the constructing and creation enterprise relies upon upon this era for manufacturing fittings, panels, and piping structures which might be of high-quality durability and performance however facilitate fee control in massive-extent projects.

Other industries like medical, consumables and electronics, and miscellaneous packages additionally play an essential role in boosting marketplace increase. For the scientific zone, injection molding enables the manufacture of equipment and gadgets that require high precision, sterility, and adherence to stringent safety rules. For electronics, it allows the production of components with problematic info essential for customer merchandise and business device. Its versatility is such that it could meet specialized wishes without compromising on first-rate consistency. These various makes use of reflect why the injection molding enterprise will continue to grow as businesses recognition on performance, innovation, and performance of their production activities.

The growing call for in these segments of software is a sign of a strong destiny for the global injection molding market. As companies embrace higher techniques and assets to cater to sector-precise needs, this procedure shall remain on the center of manufacturing techniques globally. The fact that it allows integrating design accuracy, scalability, and affordability approach that injection molding shall no longer best keep its dominance however can even grow to be increasingly essential as companies goal for higher product first-rate and green operation.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$314,976.87 million |

|

Market Size by 2032 |

$439,750.67 Million |

|

Growth Rate from 2025 to 2032 |

4.9% |

|

Base Year |

2024 |

|

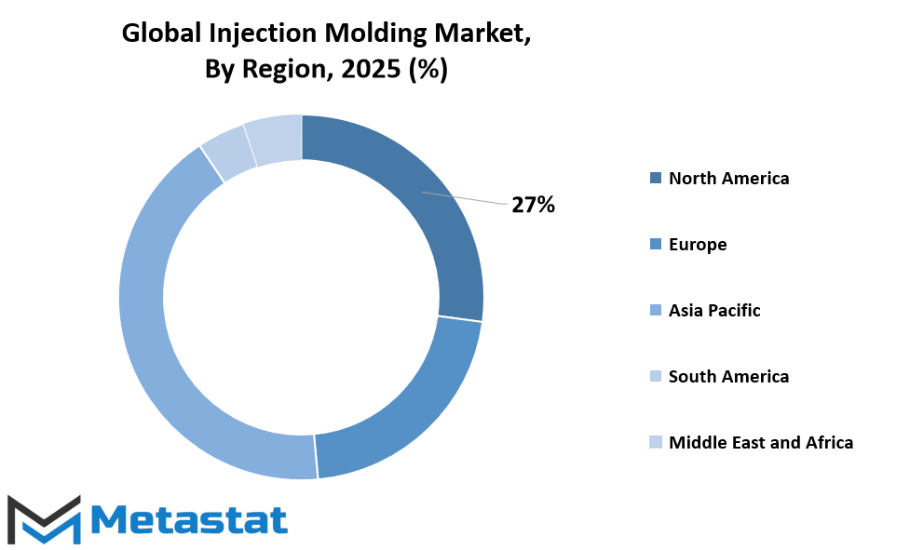

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global injection molding market is locally divided to symbolize regional business improvement and call for tendencies. North America is a major contributor on this market, with a strong base pushed by using leading-aspect manufacturing technology and robust call for in automobile, healthcare, and consumer goods industries. In the region, the USA takes the lead with its excessive-ability generating devices and cognizance on high-grade plastic elements. Canada and Mexico add consistently, fueled by industrialization and the provision of large vehicle and packaging companies.

Europe is some other vital area for injection molding, with international locations together with the United Kingdom, Germany, France, and Italy dominating its growth. The dominant presence of car multinationals and a quite advanced production base have contributed to Europe becoming a vital center of this technology. Germany, especially, is known for precision engineering that aids the need for injection-molded components in most industries. Some other regions in Europe also have constant demand, being sustained by packaging and medical uses.

Asia-Pacific region leads the injection molding market on account of its fast-growing industrial base and mounting plastic product consumption. China and India are major contributors due to their huge manufacturing bases and low-cost production capacities. Japan and South Korea contribute value with high-level technology and material and machine innovation, thus the region becomes a combination of cost-effectiveness and high-quality production. This blend of scale and innovation makes the Asia-Pacific region a leading driver of future growth in this market.

South America and Middle East & Africa contribute consistently, albeit at a smaller level than other markets. Brazil and Argentina dominate the South American market with demand throughout cars and client items. On the other hand, the Middle East & Africa marketplace, along with such international locations as the GCC nations, Egypt, and South Africa, is experiencing regular boom pushed via business interest and infrastructural projects. Although those regions are but to broaden concerning huge-scale production, their increasing financial operations portend shiny potentialities for injection molding inside the foreseeable destiny.

COMPETITIVE PLAYERS

The global injection molding market is molding the future of manufacturing by offering industries an affordable and effective way of making accurate and long-lasting parts. It is a critical process in industries like automotive, medical, packaging, and consumer products, as it enables high-volume production with consistent quality. Since companies are searching for means of satisfying increasing demand, injection molding is particularly noted for its capacity for minimizing waste, shortening production cycles, and producing products with high precision. As increasing uses across a range of industries are sought, the market will continue to interest companies and investors globally.

Advances in technology have further improved the attraction of injection molding. New machines and automation technologies have increased speed and accuracy, enabling companies to manage intricate designs and produce improved product consistency. The increasing application of advanced polymers and biodegradable materials is also contributing by reducing the weight and environmental impact of products. With industries increasingly striving for innovation, injection molding will be a critical technology in providing consistent solutions that fulfill high-performance and environmental demands.

A diverse range of firms is spearheading this market with their experience and innovation. Some of the major firms include C&J Industries, Engel Austria GmbH, All-Plastics, Biomerics, HTI Plastics, Husky Injection Molding Systems Ltd., The Rodon Group, EVCO Plastics, Majors Plastics, Inc., Proto Labs, Inc., Tessy Plastics, Currier Plastics, Inc., Berry Global Inc, H&K Müller GmbH & Co. KG, Hehnke GmbH & Co KG, TR Electronic, D&M Plastics, LLC., Silgan Holdings Inc., and Amcor PLC. They are not only broadening their product lines but also emphasizing sustainability and intelligent manufacturing strategies. By leveraging digital technologies and high-end automation, they are creating new standards for productivity and accuracy in the marketplace.

The growth of the global injection molding market will also be augmented by the increasing demand for light weight components, particularly for automotive and electronics, where both efficiency and durability are paramount. It will also see more healthcare applications as injection molding makes it possible to produce medical devices and components of remarkable precision. These, along with a worldwide emphasis on lowering production costs and streamlining supply chain efficiency, will create a rosy future for the injection molding business. With ever-improving materials, machine technology, and design capabilities, the market will be a vital component of manufacturing in the modern age.

Injection Molding Market Key Segments:

By Material

- Plastics

- Metal

- Others

By Application

- Packaging

- Consumables & Electronics

- Automotive & Transportation

- Building & Construction

- Medical

- Others

Key Global Injection Molding Industry Players

- C&J Industries

- Engel Austria GmbH

- All-Plastics

- Biomerics

- HTI Plastics

- Husky Injection Molding Systems Ltd.

- The Rodon Group

- EVCO Plastics

- Majors Plastics, Inc.

- Proto Labs, Inc.

- Tessy Plastics

- Currier Plastics, Inc.

- Berry Global Inc

- H&K Müller GmbH & Co. KG

- Hehnke GmbH & Co KG

- TR Electronic

- D&M Plastics, LLC.

- Silgan Holdings Inc.

- Amcor PLC

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383