Jun 02, 2025

The latest publication shared by Metastat Insight brings into focus the developments shaping the Global Gas Separation Membrane Market, offering a perspective grounded in industrial realities and technological progressions. Gas separation membranes, once considered a niche solution, have steadily woven themselves into the operational fabric of industries that prioritize selective gas processing. From refining applications to the handling of industrial gases and the treatment of natural resources, these membranes are increasingly preferred for their functionality, modular adaptability, and operational consistency. Their use reflects a broader shift toward cleaner, streamlined, and cost-sensitive methods for handling gas mixtures, particularly in sectors where precision separation holds value.

Manufacturers and industrial operators continue to evaluate options that allow them to control gas composition more accurately without incurring excessive infrastructure demands. Membrane systems present a unique balance, offering scalability and operational flexibility in settings that require continuous processing under variable conditions. This ability to function across different operational thresholds has led to their adoption in scenarios ranging from small processing units to larger industrial installations. The versatility of these membranes lies in their engineered material properties, allowing them to respond to distinct separation needs without extensive recalibration or structural modification.

As industries become more targeted in how they approach resource efficiency, the functionality of gas separation membranes has gained broader recognition. These systems are frequently employed in applications where traditional methods might demand greater maintenance or complex machinery. Instead of relying on elaborate setups, businesses increasingly seek solutions that reduce operational friction while maintaining reliability. Membrane-based technologies have responded to this call by allowing for continuous operation with minimal interruption, which is critical in environments that require steady output and low tolerance for downtime.

Material innovations have played a substantial role in the progression of this market. Engineers and scientists continue to explore new polymers and composite materials that enhance membrane selectivity, permeability, and resistance to harsh environments. These developments are not pursued in isolation; they are tightly connected to field observations and operational feedback. The dialogue between laboratory innovation and industry application has resulted in membranes that are not only more durable but also better tailored to specific separation tasks. This practical refinement helps operators maintain consistent product quality while managing long-term system performance.

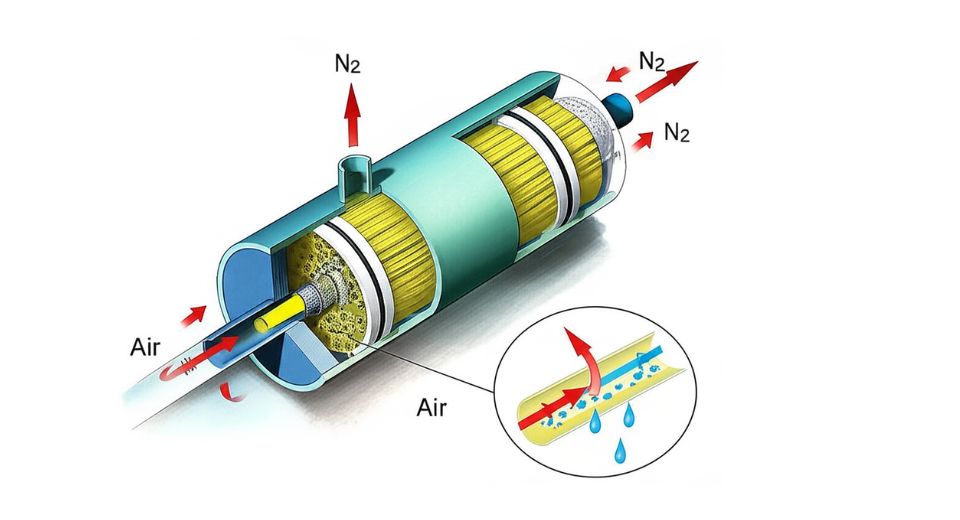

Gas compositions vary widely across industries, and so too must the response mechanisms embedded within the membrane systems. Customization is increasingly seen not just as an added feature but as a fundamental requirement. Providers in the Global Gas Separation Membrane Market are aligning their designs with the specific demands of different sectors, whether those relate to carbon dioxide removal, hydrogen recovery, or nitrogen production. The specificity of these applications calls for systems that are both technically sound and responsive to the process nuances of their intended deployment environments.

Operational scale is another area where membrane technology has demonstrated its adaptability. Whether it is a smaller setup focusing on pilot testing or a large-scale industrial operation seeking steady throughput, membranes offer solutions that are modular and easily integrable. This means that scaling up operations does not necessarily entail reworking existing infrastructure. Instead, systems can be augmented or duplicated as needed, streamlining growth strategies for companies that operate in energy, manufacturing, or environmental services. This type of structural efficiency not only supports expansion but also simplifies ongoing maintenance and troubleshooting.

Another feature that reinforces the presence of membranes in industrial environments is their relatively low requirement for auxiliary systems. Unlike some gas separation methods that depend on extensive ancillary equipment, membrane setups tend to operate within compact units. This minimizes the spatial footprint, which is especially valuable in facilities where space and layout constraints are common. Businesses benefit from this design characteristic not just in terms of installation but also in maintenance routines and operational visibility. Simplified systems allow teams to manage performance proactively, with fewer variables to monitor.

As new applications for gas separation continue to emerge, membrane technology is positioned to respond with tailored configurations. Industries engaged in biogas upgrading, synthetic gas purification, or petrochemical processing are exploring membrane integration as a way to fine-tune outputs while meeting stringent operational specifications. These tailored approaches are the result of steady collaboration between technology developers and process engineers, ensuring that solutions are grounded in practical use and not just laboratory theory. The outcome is a market defined by responsiveness and reliability, where membrane systems are increasingly central to operations that demand consistent separation outcomes.

Drawing from the Global Gas Separation Membrane Market Report presented by Metastat Insight, it becomes clear that this market reflects a pattern of steady refinement and targeted implementation. The role of gas separation membranes is no longer confined to a limited range of industries or applications. Instead, they are now recognized for their contribution to operational stability and processing accuracy across diverse industrial settings. As businesses continue to refine their approaches to gas management, membranes remain a trusted solution balancing efficiency, adaptability, and technical sophistication in a way that supports both current demands and future growth opportunities.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479