Aug 21, 2025

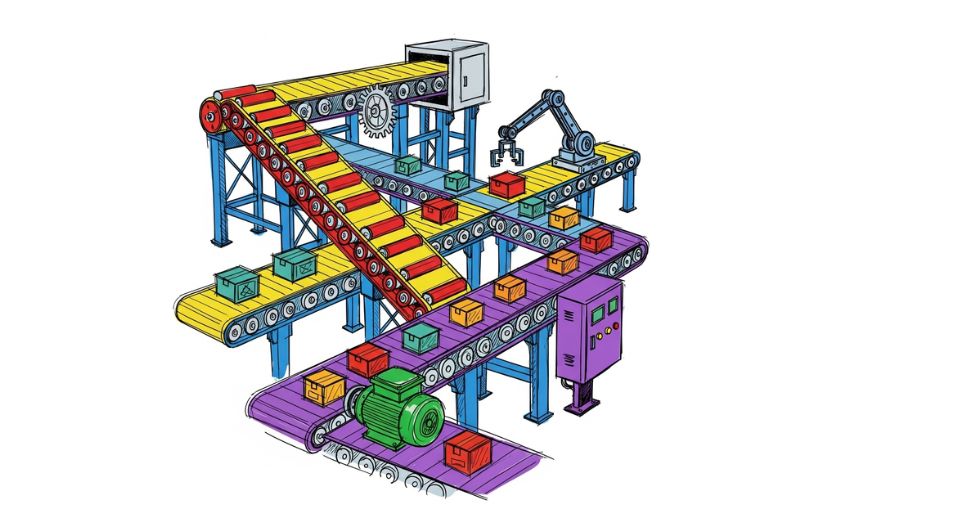

The just-released research study of conveyor systems market by Metastat Insight has opened new windows into how businesses nowadays are positioning themselves to meet evolving requirements of production and logistics. Not being a static account of numbers, the report illuminates trends across industries where automation and productivity are continually being optimized. It is within this environment that conveyor systems, previously viewed as mere utilitarian mechanical tools, have evolved into strategic resources influencing operational streams within factories, warehouses, and distribution centers across the globe.

Global Conveyor Systems market is estimated to reach $11,042.61 million in 2025 with a CAGR of 6.0% from 2025 to 2032.

What is interesting about the worldwide conveyor systems market is not just the penetration of these systems, but the manner by which they transform themselves to suit every industry they penetrate. In food processing, handling and cleanliness are the top priorities, and conveyors are engineered to transport delicate products while upholding rigorous standards. The automobile industry, on the other hand, depends on conveyors for the orderly flow of parts through several stages of assembly, promising time and accuracy never to be compromised. It's their flexibility that continues to extend their applicability and, by extension, increases their reach into various industries.

Now that industries become increasingly integrated, conveyors are no longer measured against the kind of functionality that they can just transport things from one point to another. They are measured based on how they integrate with larger operation systems, either through interoperability with robots, compatibility with digital monitoring, or energy savings in support of larger sustainability initiatives. This evolution is a change in mind-set where conveyors exist as part of a larger ecosystem rather than in isolation. The conveyor systems market is a reflection of this cultural shift amongst industry players, and the publication by Metastat Insight highlights the manner in which stakeholders are adjusting expectations to suit.

There is also a clear emphasis on customization in this environment. Businesses are calling for solutions adapted to their specific flow of goods instead of off-the-shelf configurations. A warehouse might need extensive, interconnected belts taking up large space, whereas a packaging factory might need small, modular conveyors that enable fast reconfigurations. These varied needs compel manufacturers to move away from standard solutions and instead engineer equipment that caters to the minute specifics of each process. This increasing desire for customization, while not recent, has become increasingly important as industries seek to optimize productivity without ballooning operational loads.

The global conveyor systems market is also shaped by how companies rethink the life cycle of equipment. Longevity and long-term upkeep are increasingly important issues as companies analyze the cost of ownership. More than just the initial installation, considerations of spare parts, technical support, and future expandability are tantamount in making decisions. This focus on longevity hints at the fact that conveyors are increasingly viewed as long-term partners in industrial growth rather than temporary solutions. The implications are substantial for manufacturers who now must balance cutting-edge design with rugged reliability.

Interestingly, the conversation surrounding conveyors has also shifted towards their interaction with people. As automation minimizes the dependency on human work for recurring or taxing activities, conveyors remain ingrained in industries where machines and people work together. Ergonomic designs, safety systems, and easy-to-use control panels guarantee that the existence of conveyors becomes an additive factor rather than a source of disruption in the daily routine of employees. This human-machine interaction still shapes the way conveyor systems are embraced by industries to the extent that design decisions reflecting beyond mere technical performance become paramount.

It is also important to observe how regional differences shape perceptions of conveyor systems. Industrial environments vary widely from one geography to another, bringing with them different expectations for conveyors. The mature industrial markets require advanced, digitally connected systems, whereas the emerging markets tend to seek robust and simpler-to-maintain solutions. The fact that conveyor producers are able to adapt to these varied conditions speaks volumes about the versatility of the technology as well as the need to understand contexts on the ground.

The conveyor systems market , as it is reflected in the most recent release from Metastat Insight, shows how once such an industry would have been conceived in entirely mechanical terms, it has now been filled with agendas of technology, sustainability, customization, and human contact. This many-sided image reflects why conveyors are no longer merely static constructions in factory environments but active participants in designing industrial strategy.

In drawing together these threads, it becomes clear that the global conveyor systems market is more than an assortment of equipment and installations. It reflects the broader ambitions of industries seeking smoother flows, more sustainable practices, and reliable long-term infrastructure. The report presented by Metastat Insight is a useful insight into how this market is being transformed, not just by the requirements of today but also by the expectation of future requirements that will continue to redefine the place of conveyors within today's industry.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479