MARKET OVERVIEW

The global conveyor systems market are among the most vital pillars of industrial automation and material handling. Basically, the market is all about promoting efficiency in raw material, product, and goods transport across a wide range of industries. Unlike traditional handling processes dominated by human efforts, conveyor systems permit effortless, automated, and uniform movement of products, ensuring companies to save time and operation costs in the coming years. The kind of market such as this will be on an upswing not merely for its technical value but also for the manner in which it will revolutionize industrial processes across continents.

The global conveyor systems market requires more than a reflection on machinery. It is actually the intersection of mechanical design, automation technology, and logistics planning. Conveyor systems are in place to move objects along predetermined paths, whether within a factory, a warehouse, a distribution center, or even airports and mining operations. They range from basic belt conveyors transporting packaged goods to highly advanced automated systems used to sort, divert, and even read items in real time. As industries demand greater throughput and precision, the market will be a driving force to make sense of production and delivery lines.

The extent of this market extends beyond what might typically be imagined. Not only will massive industrial plants be dependent upon such systems, but retail distribution warehouses, online shop warehouses, and even farm structures in which harvests must be processed efficiently. Airports across the globe will continue utilizing conveyor technology to manage passengers' luggage, while ports and harbors will be relying upon it for containerized shipping cargo. Conveyors will remain a staple of movement of raw materials within heavy industry and mining. The conveyor systems market globally will therefore be an invisible but indispensable infrastructure that will support trade, logistics, and modern supply chains.

The other feature of this market is its adaptability. With diversification across industries, conveyor technology will also diversify. Customized designs, modularized buildings, and networking robotics and artificial intelligence will be the order of the day. For instance, future warehouses will not only use conveyors to move boxes from a point to another but will be connected with sensors, scanners, and data management systems that will optimize flow dynamically. The adaptability of such systems will allow them to serve small businesses with limited room as well as multi-national corporations working with humongous facilities.

In the coming years, the world conveyor systems industry will be viewed less as a collection of machines and more and more as a critical facilitator of industrial efficiency and logistical precision. It will be a mechanical engineering and digital technology industry that creates a platform for more speed, safety, and reliability in a variety of applications. This market, though often unnoticed in the day-to-day, will continue to shape the way goods are produced, warehoused, and distributed throughout the world to maintain industries in efficient and competitive order in a more connected world each and every day.

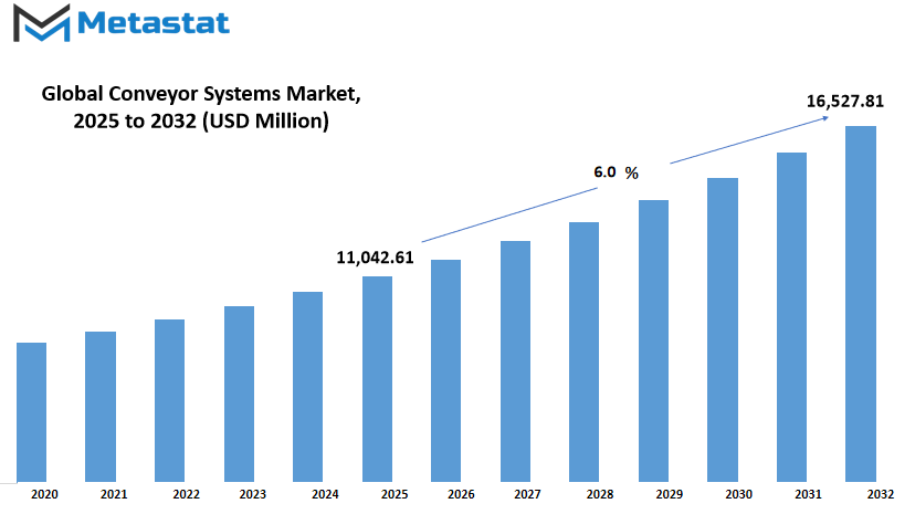

Global conveyor systems market is estimated to reach $16,527.81 Million by 2032; growing at a CAGR of 6.0% from 2025 to 2032.

GROWTH FACTORS

The global conveyor systems market is moving toward steady growth as industries continue to search for more efficient and reliable ways to manage their operations. Companies across different sectors want to improve productivity while reducing downtime, and this need creates a strong demand for advanced material handling solutions. One of the major factors supporting this growth is the rising use of automated systems in industries such as automotive repair and roadside assistance services. As these services expand, the need for dependable systems that can handle parts, equipment, and tools in a safer and faster manner becomes more important, giving the market a clear path of progress.

Another driver is the increasing investment in infrastructure projects and the regular upkeep of heavy machinery. Construction and large-scale industrial sites rely on smooth transportation of materials to keep work on schedule. Conveyor systems provide a dependable method of managing these tasks, helping businesses cut delays and lower labor strain. As more nations focus on modernizing their infrastructure, the market will continue to benefit from higher adoption rates, especially in regions that are still building the foundation for industrial growth.

Even with these positive signs, there are challenges that cannot be ignored. Safety remains a serious concern, as improper use of such systems can cause accidents or injuries. This issue can slow adoption in workplaces that lack trained staff or strong safety guidelines. In addition, the presence of other lifting and handling tools, some of which are cheaper or more portable, can reduce the preference for conveyor systems in certain settings. Companies weigh cost and flexibility carefully, and in some cases, alternatives are chosen, limiting market penetration.

Still, there are fresh opportunities on the horizon. The introduction of ergonomic and battery-powered designs is set to reshape expectations. These modern tools reduce physical strain on workers and provide more mobility, addressing both safety worries and performance goals. With industries placing greater attention on worker health and energy-efficient operations, such innovations could open up new areas of growth in the coming years.

Looking forward, the global conveyor systems market will remain shaped by both its strengths and its barriers. While demand from automotive services, infrastructure projects, and machinery upkeep continues to push it forward, overcoming safety risks and competing tools will decide the speed of its progress. The balance between these forces will define how successful the market becomes in a future driven by efficiency and technological change.

MARKET SEGMENTATION

By Type

The global conveyor systems market is expected to play an important role in shaping the future of industries that depend on faster, safer, and more efficient movement of goods. As manufacturing, retail, logistics, and distribution sectors continue to expand, the demand for advanced systems will grow at a steady pace. These systems are designed to make processes smoother and to reduce the amount of manual labor needed, which will not only save costs but also improve productivity. Looking ahead, the adoption of new technology will influence how these systems are built, managed, and improved, making them central to modern industrial growth.

By Type, the global conveyor systems market is further segmented into Belt, Roller, Pallet, Overhead, and Others. Each type will continue to find applications that match the unique needs of different industries. Belt conveyors, for example, will remain widely used in food, packaging, and general manufacturing because they are simple, reliable, and adaptable. Roller conveyors will be preferred for handling heavier items and will see rising use in distribution centers and warehouses where large volumes of products are moved daily. Pallet conveyors will become more important in industries that require safe handling of bulk goods, especially as companies push toward greater automation. Overhead conveyors will be used in environments where floor space is limited, while other customized systems will support specialized functions in niche markets. This segmentation shows that each category has its own place in future operations, and the choice will depend on the specific demands of the user.

What makes the global conveyor systems market so vital for the future is its link to automation and digital integration. Systems will increasingly include sensors, smart controls, and real-time monitoring to allow managers to track movement, predict maintenance needs, and reduce downtime. The use of artificial intelligence and machine learning will further improve efficiency by adjusting speeds, reducing energy use, and avoiding breakdowns. In addition, sustainability will guide the design of new systems, with a strong focus on reducing waste, recycling materials, and lowering energy consumption.

The growing demand for e-commerce, rapid urbanization, and the rise of global supply chains will ensure that these systems are not just tools but key solutions that will define how industries function. The global conveyor systems market will move beyond being seen only as equipment and will instead be viewed as an essential part of the infrastructure that supports the future of production, trade, and logistics.

By Load

The global conveyor systems market will continue to play an important role in supporting industries that rely on efficient movement of materials. As industries expand, the need for systems that can handle both heavy and light loads with speed and accuracy will grow. By load, the market is divided into bulk and unit, which shows the flexibility of these systems to serve different sectors. Bulk load conveyors are widely used in mining, agriculture, and energy industries where large quantities of raw materials need to be transported quickly. On the other hand, unit load conveyors are vital in sectors such as e-commerce, automotive, and food processing, where smaller items need to be moved, sorted, and packaged with precision.

Looking ahead, the global conveyor systems market will be influenced by automation, digital monitoring, and energy efficiency. Businesses are increasingly adopting smart conveyor systems that can connect with advanced software to track operations in real time. This shift will reduce downtime and improve productivity, as companies will be able to predict and prevent mechanical issues before they disrupt operations. Energy efficiency will also become a driving factor, as industries will prefer systems that consume less power while still maintaining high performance. In this way, conveyor systems will align with global efforts to reduce environmental impact.

The growth of online shopping will further expand the demand for unit load conveyors. With more consumers expecting faster deliveries, warehouses and distribution centers will rely on advanced conveyor systems to handle large volumes of individual packages daily. At the same time, bulk conveyors will not lose importance, as global demand for raw materials like coal, iron ore, and grains will continue. Both types will remain essential, but the unit load segment is expected to see faster adoption due to changes in consumer behavior and supply chain needs.

In the future, robotics and artificial intelligence will also support the global conveyor systems market. Systems will not only transport goods but also sort, measure, and manage them without human input. This will bring higher efficiency and reduce labor costs, which will be especially important in industries facing labor shortages. The future of this market will be shaped by its ability to balance speed, safety, and sustainability while adapting to different industries and loads. Whether bulk or unit, conveyor systems will continue to be at the center of industrial progress, providing the foundation for faster, cleaner, and more reliable operations worldwide.

By Location

The global conveyor systems market is becoming an important part of industrial progress, as more industries seek faster and more efficient ways to handle materials. In the future, this market will continue to grow because businesses will need systems that can move products safely, reduce manual labor, and improve overall productivity. Companies are looking for solutions that are reliable, energy-efficient, and capable of handling different types of goods. As technology continues to advance, these systems will not only carry items from one point to another but will also connect with digital tools that track and control operations with greater accuracy.

By location, the global conveyor systems market is further divided into in-floor, on-floor, and overhead systems. Each type will play a role in shaping how industries manage their processes. In-floor systems, for example, are built into the ground, which saves space and provides a cleaner layout. These are often used where safety and open floor design are important. On-floor systems will continue to be popular because of their flexibility and ease of installation. They can be adjusted or moved to fit new layouts, making them suitable for warehouses and factories that change their arrangements often. Overhead systems, on the other hand, make use of vertical space and free up ground areas for other activities. This design will become more valuable in the future as industries focus on maximizing every part of their working environment.

The global conveyor systems market will also be influenced by the growth of automation and artificial intelligence. These technologies will allow conveyors to operate with sensors that predict and prevent breakdowns, making the systems more dependable. Over time, this will lower costs for companies and help them meet customer demands more quickly. Another factor that will drive the market forward is sustainability. Businesses are expected to look for conveyor systems that use less energy and produce fewer emissions. Environmentally friendly designs will be a key selling point as industries face stricter rules and a growing need to show responsibility toward the planet.

Looking ahead, the global conveyor systems market will not just be about moving goods from place to place. It will become part of a larger network that supports smart factories and efficient supply chains. Whether in-floor, on-floor, or overhead, each system will continue to develop in ways that match the changing needs of businesses and the expectations of a future that demands speed, safety, and sustainability.

By Application

The global conveyor systems market will continue to expand as industries adopt more efficient methods of moving goods and materials. Businesses today focus heavily on speed, accuracy, and cost savings, and conveyor systems provide exactly that. As industries grow and competition rises, companies will look for ways to reduce delays and cut unnecessary labor costs, and conveyors will play a central role in that transformation. Their ability to handle large volumes and maintain consistency makes them a reliable choice for many sectors, and this reliability will keep demand strong in the years ahead.

By application, the global conveyor systems market is divided into food and beverages, pharmaceuticals, transport and logistics, manufacturing, automotive, and others. Each of these areas has specific needs that conveyors will continue to address. In food and beverages, companies will rely on conveyors to meet strict safety standards while keeping production lines moving quickly. In pharmaceuticals, the demand for precision and cleanliness will push conveyor makers to develop systems that ensure safe handling of sensitive products. Transport and logistics will remain one of the fastest-growing segments, with e-commerce driving the need for warehouses that can sort, pack, and ship orders with little room for error.

Manufacturing will continue to benefit from conveyors as companies automate production lines to maintain steady output and reduce human error. Automotive industries will also keep investing in conveyor systems as they build complex vehicles that require precise assembly at each stage. Other industries, ranging from mining to packaging, will add to the demand as they search for solutions that help them move products faster and safer. These sectors will continue shaping how conveyor technology develops, encouraging manufacturers to design systems that are smarter, more flexible, and energy-efficient.

Looking to the future, the global conveyor systems market will evolve with technology. Artificial intelligence, sensors, and automation will be increasingly built into conveyors to improve their performance. These upgrades will allow systems to detect faults early, adjust speed automatically, and even work with robotic arms to create a seamless flow of operations. Energy efficiency will also become a priority, with industries demanding systems that reduce power consumption without sacrificing output. As sustainability goals rise worldwide, conveyors that are built with eco-friendly materials and smarter energy use will find greater acceptance.

The global conveyor systems market will not just grow in size but in capability, shaping how industries operate in the future. It will continue to be a backbone of production and distribution, driving progress across multiple sectors.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$11,042.61 million |

|

Market Size by 2032 |

$16,527.81 Million |

|

Growth Rate from 2025 to 2032 |

6.0% |

|

Base Year |

2024 |

|

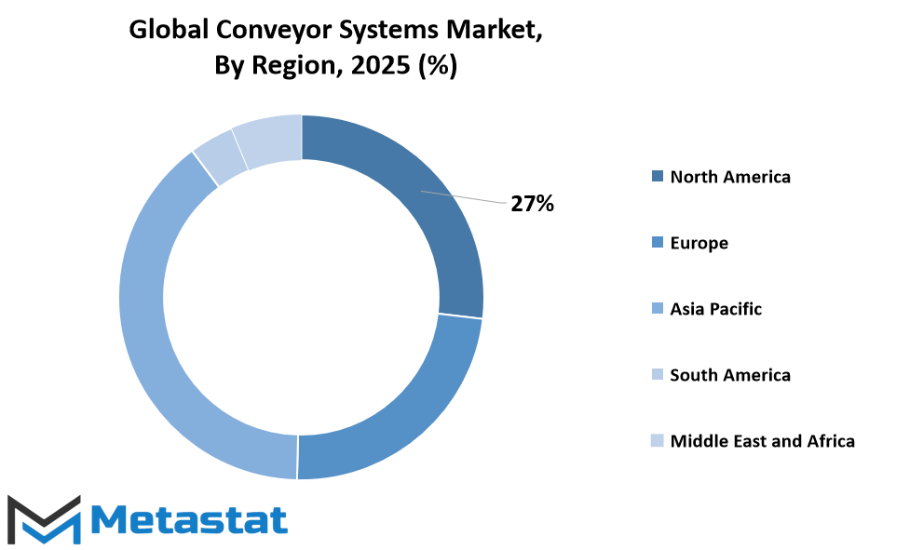

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global conveyor systems market is becoming an important part of modern industries, shaping the way goods are moved, handled, and delivered. As industries continue to expand and automation becomes more common, the demand for efficient conveyor solutions will keep growing. These systems will not only speed up processes but also reduce labor costs and improve workplace safety. Their role in industries such as manufacturing, logistics, and retail will continue to strengthen, making them a vital link in the global supply chain of the future.

When looking at the global conveyor systems market from a geographic perspective, each region carries its own influence. North America, with the U.S., Canada, and Mexico, will continue to focus on advanced technology, supporting industries that demand speed and precision. The U.S. in particular will remain a leader in adopting new automation systems, while Canada and Mexico will expand with manufacturing and distribution growth. Europe, divided into the UK, Germany, France, Italy, and the Rest of Europe, will remain a strong player with its highly developed industrial base. Germany will stay central to technological innovation, while other parts of Europe will see steady adoption of conveyor systems in various industries.

In the Asia-Pacific region, including India, China, Japan, South Korea, and the Rest of Asia-Pacific, rapid industrialization and the rise of e-commerce will fuel strong growth. China and India will be at the forefront due to their growing economies and large-scale manufacturing, while Japan and South Korea will drive adoption through advanced technology and robotics. This region will likely become the fastest-growing market, as both production and consumer demand continue to rise. South America, with Brazil, Argentina, and the Rest of South America, will show potential as infrastructure improves and industries such as food processing and mining expand. The Middle East & Africa, covering GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa, will also witness steady progress. Investments in logistics and growing trade activities will help drive the adoption of conveyor systems across this region.

COMPETITIVE PLAYERS

The global conveyor systems market will continue to play a major role in shaping how industries move goods efficiently, reliably, and at scale. With constant pressure on businesses to speed up operations and cut costs, companies are turning to more advanced and automated conveyor solutions. These systems are no longer limited to traditional manufacturing floors but are now essential in sectors such as e-commerce, food and beverage, retail, airports, and pharmaceuticals. The growing demand for faster deliveries, safe handling of products, and smoother operations will keep driving the adoption of smarter conveyor technologies across the world.

Looking ahead, the global conveyor systems market will be strongly influenced by the integration of digital tools, robotics, and artificial intelligence. Systems that can monitor performance, predict maintenance needs, and adapt to shifting production requirements will gain preference. Energy efficiency will also play a central role as companies look to reduce environmental impact while keeping operations cost-effective. This push toward sustainable and intelligent conveyor solutions will not only improve efficiency but will also redefine how industries manage supply chains in the future.

Competitive players will remain at the heart of this transformation. Key names such as Daifuku Co., Ltd., SSI Schaefer AG, Dematic Group, Vanderlande Industries, Honeywell Intelligrated, and Swisslog Holding AG have already set strong foundations in automation and innovation. Murata Machinery, Ltd., Interroll Group, BEUMER Group GmbH & Co. KG, TGW Logistics Group, and Fives Group will also continue to invest in advanced designs to stay ahead in the race. Alongside them, Hytrol Conveyor Company, Inc., FlexLink AB, Bastian Solutions, Inc., Mecalux, S.A., Shuttleworth, LLC, Kardex Group, and Dorner Mfg. Corp. are expected to strengthen their positions by offering customized solutions tailored to specific industry needs.

The future will likely bring even tighter competition among these players, with collaborations, acquisitions, and joint ventures shaping the landscape. Companies that can combine innovation with scalability will lead the way, especially as industries demand systems that can handle both heavy-duty operations and delicate product movement with equal precision. Smaller companies may find opportunities by focusing on niche solutions or regional markets, but larger players with global reach will continue to dominate the stage.

Overall, the global conveyor systems market will not only grow but also evolve into a more technology-driven and sustainability-focused industry. Competitive players will remain central to this journey, pushing boundaries and setting higher standards for what conveyor systems can achieve in the decades to come.

Conveyor Systems Market Key Segments:

By Type

- Belt

- Roller

- Pallet

- Overhead

- Others

By Load

- Bulk

- Unit

By Location

- In-floor

- On-floor

- Overhead

By Application

- Food & beverages

- Pharmaceuticals

- Transport & logistics

- Manufacturing

- Automotive

- Others

Key Global Conveyor Systems Industry Players

- Daifuku Co., Ltd.

- SSI Schaefer AG

- Dematic Group

- Vanderlande Industries

- Honeywell Intelligrated

- Swisslog Holding AG

- Murata Machinery, Ltd.

- Interroll Group

- BEUMER Group GmbH & Co. KG

- TGW Logistics Group

- Fives Group

- Hytrol Conveyor Company, Inc.

- FlexLink AB

- Bastian Solutions, Inc.

- Mecalux, S.A.

- Shuttleworth, LLC

- Kardex Group

- Dorner Mfg. Corp.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383