Sep 04, 2025

A thorough analysis of industry trends just released by Metastat Insight puts the global commercial vehicle air filter market in a new perspective, balancing strategic insight and visionary thinking. The story starts with a recognition of the subtle but powerful trends driving demand and performance requirements across fleets globally. In contrast with formulaic commentary, this language betrays matured understanding and insight developed after fourteen years of tracking supply, design innovation, and regulatory regimes impacting filtration products specialized for heavy-duty use.

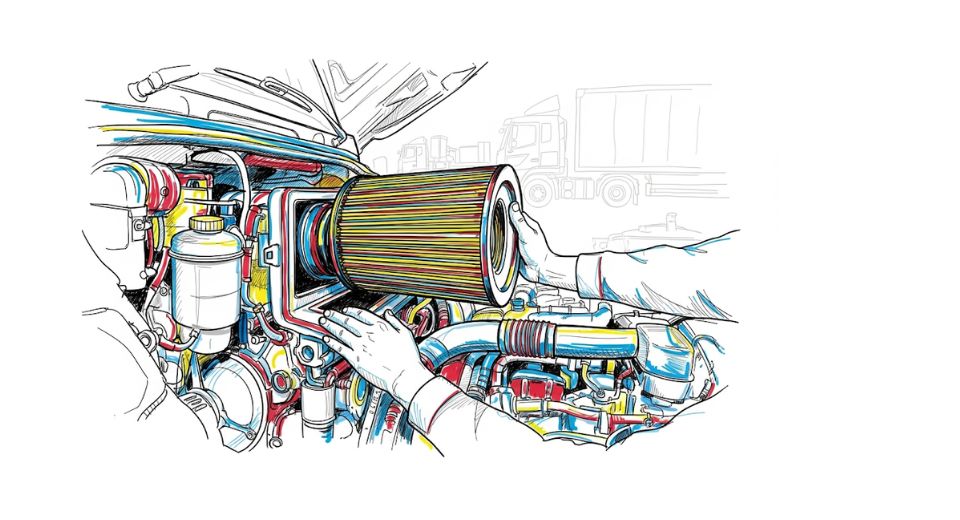

In commercial transport industries, filtration technology is a breath of precision that guarantees engines perform with repeatable power while filtering particulates carried from city life, dusty roads, and varying fuel qualities. With the passage of time, there have been innovations in air filters that demonstrate material science progress, manufacturing efficiencies, and design modifications favourable to harsh operating conditions. Today, filters are being viewed less as passive elements and more as facilitators of engine longevity, operational reliability, and maintenance cycle optimization. Purpose-oriented innovations such as multi-layer media, backed housings, and quick-change elements became standard features in offerings to the market, allowing operators to reduce downtime and achieve performance specifications under high load.

Confident uptake of improved filters is complementary to heightened attention to vehicle emissions, sustainability targets, and life-cycle cost savings. Extended-service-life filtration cuts down on waste creation, spurs resource efficiency, and facilitates compliance with stricter exhaust regulations, especially in markets tightening particulate matter limits. Maintenance personnel enjoy easy replacement routines and less service interruption, resulting in efficient workshop workflows and maximized resource use.

In addition to health and regulatory factors, fuel economy performance has also emerged as an issue. Cleaner intake air maintains engine efficiency, minimizing energy losses and lowering consumption. That correlation is evident when filtration performance avoids abrasive wear, keeps airflow integrity intact, and protects turbocharging systems from contamination. Contemporary air filters commonly employ features such as pleat-spacing optimization and pulse-clean designs, all leading to continued performance under severe operating cycles.

Material innovation dominates filter performance. Synthetic fiber advances, nanostructured media, and composite frame developments provide improved dust-holding capacity with minimal impact on airflow. These advances also minimize total filter mass and area, fitting within vehicle design trends toward lightweighting to free up payload gains and minimize fuel consumption. Production methods that combine molded end caps, adhesive bonding, and embossed support structures produce filters that withstand vibration, water, and mechanical stress.

Manufacturing agility and supply-chain resilience also influenced the discussion within the Metastat Insight presentation. Major manufacturers have localized manufacturing more and more, implemented lean strategies, and pursued near-sourcing tactics to mitigate material shortages. Automation investment, quality management, and modular component platforms allow for quicker customer order and customization response. Small and midsize filter manufacturers in response implemented partnerships, contract fabrication, or niche-market specialization and developed a variegated supplier base.

Commercial transport fleets, rental outlets, and logistics providers reacted to these upgrades by matching procurement specifications with ROI-based criteria. Filters with longer service life and lower maintenance labour contribute to lower total operating cost, which rings extremely well in low-cost transport niches. OEMs and aftermarket suppliers competed on differentiation through performance claims, validation testing, and service such as replacement reminders or electronic filter tracking through fleet telematics.

Developing trends added further thrust. Growth in electrified systems and hybrid powertrains transfers stress to cabin air and HVAC filtration requirements, although diesel and gasoline powertrains continue strong in heavy-duty vehicles. Filtration monitoring sensor integration provides predictive maintenance opportunities, warning of clogging levels or deteriorating performance. Chip- or tagging-enabled smart filters allow traceability, authenticity verification, and inventory tracking a feature for which large fleets with spare-part logistics worries will be grateful.

Regional dynamics also played their part. Markets with difficult terrain, high dust exposure, or severe temperature fluctuations required robust filtration solutions frequently reinforced with moisture-resistant seals, high-temperature adhesives, and media designed to repel fine particulate. Conversely, markets with strict emissions regulations emphasized finer filtration, compliance verification, and compatibility with exhaust after-treatment systems, such as diesel particulate filters or selective catalytic reduction units. That spectrum of requirements drove innovation throughout application segments ranging from on-road heavy-haul trucks to off-highway construction equipment.

Dialogue among filter manufacturers and end users became more critical. Joint testing, field testing under conditions of actual use, and laboratory-confirmed endurance testing became part of product development cycles. Technical services groups offered advice on filter choice, installation best practices, and interchangeability mapping, minimizing misapplication risks and enhancing customer satisfaction.

The discussion eventually comes back to an enlightened view presented by Metastat Insight, illuminating the global commercial vehicle air filter market with insightful remarks and strategic observations that surpass shallow talk. The discussion highlights how filtration technology accommodates regulatory changes, operational requirements, and changing maintenance philosophies in commercial transport. Performance, cost-effectiveness, supply responsiveness, and intelligent integration are common themes across markets and vehicle types. The seasoned perspective has been shaped by years of direct experience with filtration issues, manufacturer development, and fleet feedback loops. The narrative comes full circle as it started, repeating the in-depth market description originally presented by Metastat Insight but with fresh tone, human insight, and depth of knowledge gained from years in the trenches.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479