Nov 22, 2025

The global aerospace materials testing services market presented by Metastat Insight sits at the center of a rapidly shifting landscape where safety demands, advanced engineering, and operational reliability intersect. Aviation stakeholders, defense programs, and space initiatives now face higher expectations for durability and performance, creating fresh attention toward verification methods that validate every structural element before any flight activity proceeds. Manufacturers, research facilities, and maintenance organizations increasingly turn toward specialized testing services that translate complex engineering expectations into clear, dependable outcomes. Growing focus on lightweight structures, new composite blends, and novel manufacturing routes has placed professional testing support in a position of heightened relevance.

Market Context

Aviation and space programs currently navigate pressure from material transitions, environmental considerations, and new production approaches. Emerging generations of engines, airframes, and propulsion concepts push traditional materials beyond earlier boundaries, increasing uncertainty for design teams and production units. Quality demands from regulatory systems and supply chains continue expanding, requiring proof of durability under extreme conditions, heavy loads, and prolonged operational cycles. Against this backdrop, the global aerospace materials testing services market brings structured validation, enabling manufacturers and operators to move forward without hesitation. Service providers deliver clarity during development and assurance during certification processes, supporting program timelines while reducing exposure to unforeseen performance issues.

How It Works / Why It’s Valuable

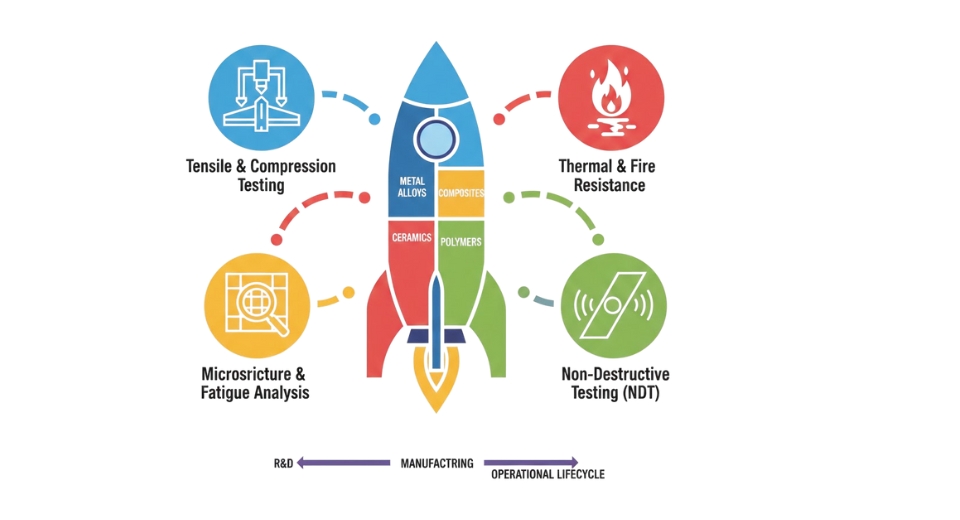

Material testing in aerospace settings focuses on characterizing behaviour under stress, heat, vibration, pressure, and corrosion. Laboratory environments replicate flight conditions, enabling engineers to observe responses long before components enter service. Advanced composite layers, high-temperature alloys, additive-manufactured parts, and protective coatings each require tailored assessment. Testing teams apply nondestructive techniques, structural evaluations, environmental simulations, and fatigue assessments to reveal performance boundaries with precision. This foundation strengthens design confidence, elevates safety margins, and enhances manufacturing consistency. Modern services provide not only measurement but interpretation, guiding material selection, production refinements, and maintenance strategies. Rapid turnarounds, specialized equipment, and multidisciplinary expertise allow programs to advance faster while maintaining unwavering attention to structural integrity.

Growth Story / Technological Evolution

Development within the global aerospace materials testing services market reflects steady enhancement rather than sudden transformation. Early attention focused on metals and conventional fabrication processes, but gradual diversification in aerospace material portfolios expanded testing complexity. Composite adoption introduced new behaviours requiring unfamiliar methods, leading to continuous refinement of analysis techniques. Additive manufacturing encouraged fresh testing standards to evaluate layer adhesion, structural uniformity, and long-term durability. Digital monitoring tools expanded visibility within laboratories, creating more reliable datasets and streamlined workflows. Environmental chambers, automation, and improved imaging technologies strengthened consistency and accuracy, lifting confidence across production stages. Collaboration between laboratories, aerospace manufacturers, and material developers nurtured testing protocols that now support a wider variety of applications across air, space, and defense platforms.

Regional or Global Trends

Strong activity for aerospace material testing concentrates within locations hosting dense clusters of aerospace manufacturing, space programs, and defense operations. These regions typically maintain extensive certification infrastructure, advanced engineering talent, and historical expertise in material development. Strong supplier networks and substantial investment in research programs reinforce demand for high-quality verification support. Emerging regions with rising aerospace ambitions show rapid interest in building local testing capability, often supported by partnerships with established laboratories. Expansion of commercial aviation, development of regional aerospace hubs, and growth in space-related initiatives contribute to broader adoption beyond traditional centers. Increased recognition of quality requirements encourages investment in advanced testing capacity across multiple continents.

Challenges and Opportunities

Operational costs, certification complexities, and rapid technological shifts create hurdles for service providers. New materials frequently demand unique procedures, creating pressure on laboratories to update methods, expand equipment portfolios, and maintain rigorous accreditation standards. Competitive landscapes encourage continuous improvement, while workforce training requires ongoing attention due to the specialized nature of testing. At the same time, significant opportunity arises from innovation in data analytics, automation, and simulation-supported evaluation. Deeper integration with digital manufacturing and predictive maintenance programs strengthens long-term relevance. Growing interest in sustainable material development fosters demand for specialized assessments that validate alternatives to traditional aerospace options. Collaboration with research organizations, production centers, and space initiatives offers pathways for broader service expansion.

Why It Matters Now

Global interest in safer flight operations, sustainable material choices, and advanced engineering drives new demand for dependable verification. Pressure on aerospace supply chains underscores the necessity of reliable testing partners capable of safeguarding production programs from unexpected delays or material inconsistencies. Increasing attention toward environmental performance encourages exploration of alternative materials, strengthening dependence on comprehensive validation. Expansion of commercial aviation, resurgence in space exploration, and continued modernization of defense programs raise expectations for accuracy and reliability across all testing efforts. As a result, the global aerospace materials testing services market presented by Metastat Insight holds stronger relevance than ever, reinforcing structural confidence and shaping the future of flight through disciplined verification and material assurance.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479