Global Aerospace Materials Testing Services Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

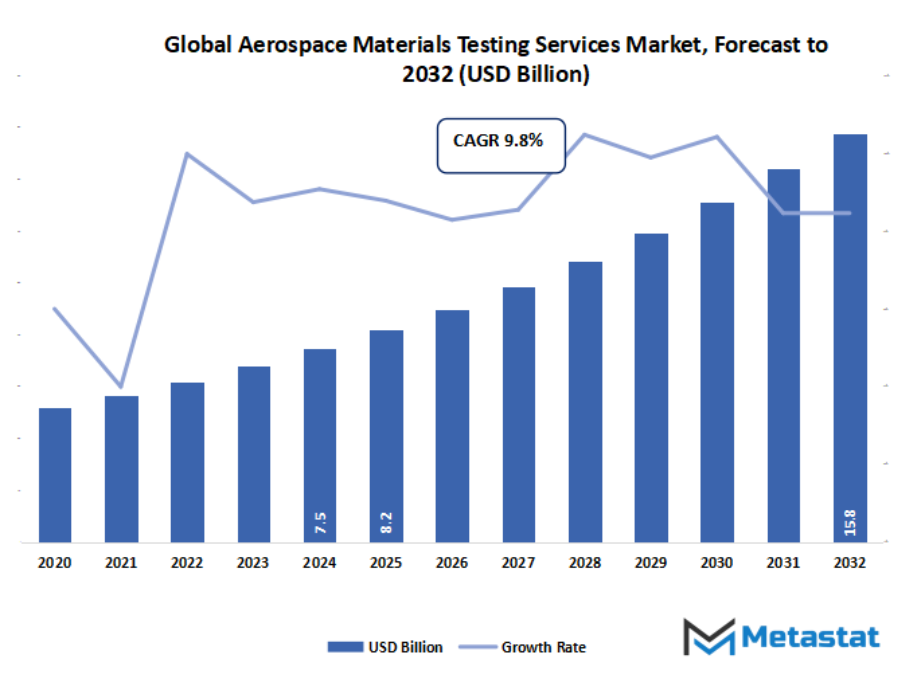

- The global aerospace materials testing services market valued at approximately USD 8.2 Billion in 2025, growing at a CAGR of around 9.8% through 2032, with potential to exceed USD 15.8 Billion.

- Metals (Aluminum, Titanium, Nickel, Steel, Others) account for a market share of 55.9% in 2024, driving innovation and expanding applications through intense research.

- Key trends driving growth: Rising regulatory and safety demands for materials used in modern aerospace platforms., Increasing global aircraft production and MRO (maintenance, repair & overhaul) activity driving testing needs.

- Opportunities include: Growing opportunity for digital material-testing platforms incorporating AI, robotics and remote inspection for aerospace & space sectors.

- Key insight: The market is set to grow exponentially in value over the next decade, highlighting significant growth opportunities.

Market Background & Overview

The global aerospace materials testing services market will keep forming an industry that demands absolute precision, long-time period reliability, and a deep information of the way advanced substances behave under severe situations. As aircraft designs move in the direction of lighter structures and an increasing number of complicated composites, the need for trying out will stretch beyond routine tests into areas where conventional strategies will now not be sufficient, with the intention to push service carriers into exploring new ways of decoding material behaviour, with the rising aerospace applications chasing more fuel performance and safety benchmarks.

What lies past the same old scope is the developing want to explore how next-generation substances will face up to environmental stresses that thus far have not been absolutely investigated. Testing within the destiny will now not be restrained to confirming mechanical power or resistance to fatigue, however it'll be directed toward the observe of lengthy-length exposure, microstructure alteration, and they have an effect on fluctuating atmospheric situations in the course of lengthy missions. As space journey increases, which means that trying out corporations will want to find out how substances act far from Earth, wherein radiation and thermal amplitude may additionally reshape expectancies of durability.

Market Segmentation Analysis

The global aerospace materials testing services market is mainly classified based on Type, Application, Service Type.

By Type is further segmented into:

- Metals (Aluminum, Titanium, Nickel, Steel, Others)

The global aerospace materials testing services market will advance further as metal-based structures move toward lighter, stronger, and safer designs. A growing demand for next-generation alloys will be responsible for a broader scope of verification methods studying durability, aging patterns, and stress behaviour that support future aircraft programs with higher performance expectations.

- Composites

Global aerospace materials testing services are going to gain momentum due to the increasing use of composite materials on wings, fuselage components, and thermal-resistant parts. Growing uses of carbon-fiber systems will power new testing methods focused on long-term reliability, structural consistency, and resistance to extreme environments that will enable future aircraft to achieve even greater efficiency and lower operational loads.

By Application the market is divided into:

- Military Aviation

The global aerospace materials testing services market will keep increasing as army fleets undertake advanced materials designed for speed, stealth, and resilience. Improved trying out standards will help aircraft working under excessive situations of thermal, mechanical, and aerodynamic strain, making sure stronger assignment readiness and the development of next-era defense structures with prolonged provider life.

- Civil Aviation

Commercial aircraft applications are shifting in the direction of designs which might be more secure, lighter, and extra fuel-efficient, which in turn will improve the global aerospace materials testing services market. Increased air travel globally will sell wider validation of more recent substances that permit quieter cabins and improvement in structural balance for long-time period reliability, shaping the future for sustainable and passenger-pleasant aviation.

By Service Type the market is further divided into:

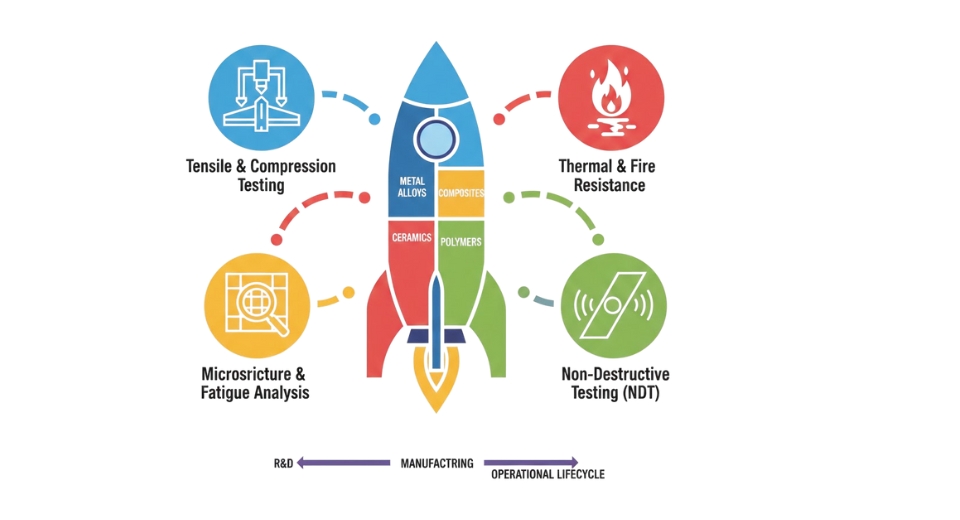

- Mechanical Testing

global aerospace materials testing services market will development as mechanical assessments assist to decide how future aerospace materials behave beneath dynamic stress, fatigue, and vibration. Demand for pristine structural standard performance will push for brand spanking new techniques that diploma evolving load patterns, in the end assisting aircraft tasks with better patience expectancies and development in operational protection.

- Non-Destructive Testing (NDT)

The international aerospace material finding out services marketplace is anticipated to develop notably because the Non-Destructive Testing strategies attain adulthood for identifying hidden flaws without dismantling the components. Future plane production will closely rely upon superior scanning, imaging, and detection structures that steady material integrity and decrease operational dangers across increasingly more complex aerospace structures.

- Environmental, Climatic, Thermal and Fire Testing

global aerospace materials testing services market will accelerate as aircraft materials face broader evaluations against heat fluctuations, fire exposure, and extreme climates. Expanding aerospace routes and higher performance demands shall need new testing practices that ensure stability, safety, and functionality in diversified global conditions.

- Chemical, Corrosion, Microstructural and Metallographic

The global aerospace materials testing services market will continue to develop as the need for chemical and microstructural checks becomes imperative for ascertaining degradation patterns, corrosion risks, and internal structural shifts. Deeper validation of destiny fabric structures may be required to maintain lengthy carrier cycles, improve safety against harsh elements, and enhance long-time period aircraft sturdiness.

- Others

The global aerospace materials testing services market will increase as new checking out categories emerge, supporting futuristic aerospace designs, alternative fuels, and superior manufacturing methods. The broader enlargement of services helps the detection of unexpected material challenges, better performance standards, and the improvement of revolutionary plane ideas for destiny generations.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$8.2Billion |

|

Market Size by 2032 |

$15.8Billion |

|

Growth Rate from 2025 to 2032 |

9.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

By Region:

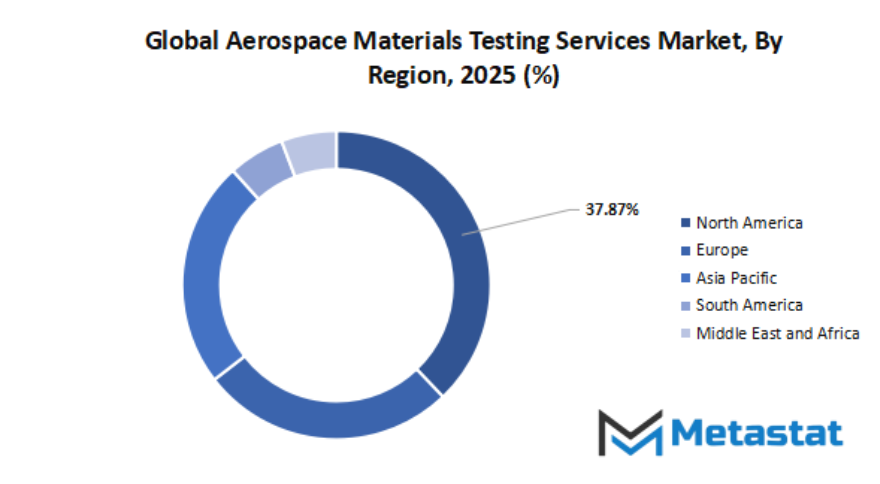

- Based on geography, the global aerospace materials testing services market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Market Dynamics

Growth Drivers:

Increasing regulatory and safety requirements for materials used in contemporary aerospace platforms.

global aerospace materials testing services market will move forward as more stringent rules dictate how every advanced airframe material is inspected and approved. Constant pressure to raise safety standards will push test methods to grow in accuracy, helping manufacturers avoid flaws that could affect flight performance in the future.

Increasing global aircraft production and MRO activity are driving the needs for testing.

global aerospace materials testing services market: The demand is expected to rise with an increase in commercial and defense aircraft entering production lines, creating a steady demand for inspections that confirm their long-term strength and reliability. Increasing MRO work will also require extensive verification, hence testing services are essential for supporting fleets expected to operate for longer cycles.

Restraints & Challenges:

High cost of specialized test laboratories and accreditation, which limits service accessibility.

The global aerospace materials testing services market will be hindered by the fact that advanced testing setups, requiring pricey tools, skilled teams, and recognized accreditation, raise the entry barrier for many service providers. This will lead to less availability in smaller regions and slower adoption for new aerospace programs seeking cost-efficient verification routes.

Long lead times and capacity constraints for qualified materials-testing infrastructure.

There will be delays in the global aerospace materials testing services market, as few certified facilities process an increasing amount of work, producing waiting times that will affect a project's timeline. Expanding the capacity to test will require huge investment, and this gap will challenge manufacturers who plan faster development cycles for next-generation aerospace structures.

Opportunities:

Growing possibility for digital cloth-checking out platforms incorporating AI, robotics, and far off inspection in the aerospace and space sectors.

This, in flip, will open up new boom paths for the global aerospace materials testing services market, as virtual structures will further assist faster, purifier, and extra consistent opinions. AI-supported inspections, robot managing, and remote monitoring will help test centers manage extra quantity, permitting aerospace and area developers to behave quicker even as lowering human blunders in complicated verification responsibilities.

Competitive Landscape & Strategic Insights

The global aerospace materials testing services market features a wide variety of corporations assisting requirements for protection, overall performance, and reliability across the aviation enterprise. The zone grows now not due to any single dominant pressure, however via the work of lengthy-hooked up global leaders and smaller nearby experts who continue to bolster their presence. This combination allows the market to move forward in a balanced way, with experience, innovation, and practical solutions for testing, aimed at meeting manufacturers', suppliers', and regulatory bodies' needs.

Well-known companies like Aeroblaze Laboratory Inc, Applied Technical Services, LLC, Applus+ Laboratories, Clark Testing, Collins Aerospace, Composites Testing Lab, Dirats Laboratories, Inc., and Element Materials Technology play a constructive role by offering broad testing capabilities and reliable results. Their work underpins every step of the development of materials, enabling aircraft parts to progress with assurance from the design phase to reality. Such players have achieved their standing through continued quality and the ability to interface effectively with aerospace clients who rely on the accuracy of such tests to mitigate risks.

Along with them, other companies involved in the industry include Eurofins Scientific, EAG Laboratories, IMR Test Labs, Infinita Lab, Innovative Test Solutions, Inc. (ITS), Intertek Group plc, International Tin Association Ltd, Laboratory Testing Inc. (LTI), and Lucideon. Their specialized testing services assist clients in understanding various material behaviors under different stress, temperature variation, and long-term usage cycles. By providing lucid insights, these companies are helping aerospace manufacturers to enhance their products while keeping the safety aspect to the fore of each decision.

The market also involves professionals such as Mistras Group, Inc., National Technical Systems (NTS), NSL Analytical Services, Inc., SGS SA, T,C&A Lab (Alfa Chemistry), and TÜV SÜD. These companies support global programs and have close relations with certification bodies to ensure that the testing will result in conformance with international standards, and material use on an aircraft will function correctly throughout its lifetime. These organizations further enhance trust throughout the industry by providing unbiased and globally accepted evaluations.

Taken together, this mix of recognized names and increasing regional players forms a solid testing platform for the aerospace industry. Their paintings help groups meet new demanding situations, reply to superior aircraft designs, and ensures that first-rate may be relied upon. As generation in aerospace keeps evolving, those look at companies will maintain to play an integral function, making sure substances in new aircraft are secure, dependable, and organized for the trials of flight.

Forecast & Future Outlook

- Short-Term (1-2 Years): Recovery from COVID-19 disruptions with renewed testing demand as healthcare providers emphasize metabolic risk monitoring.

- Mid-Term (3-5 Years): Greater automation and multiplex assay adoption improve throughput and cost efficiency, increasing clinical adoption.

- Long-Term (6-10 Years): Potential integration into routine metabolic screening programs globally, supported by replacement of conventional tests with advanced biomarker panels.

Market size is forecast to rise from USD 8.2Billion in 2025 to over USD 15.8Billion by 2032. Aerospace Materials Testing Services will maintain dominance but face growing competition from emerging formats.

At the same time, the market is going to drive forward methods that can capture real-time data, enabling engineers to predict how materials might age, warp, or fracture long before failure becomes a risk. This shift will bring a more investigative approach where testing will be a continuous process rather than a step in production cycles. As new aerospace innovations enter development pipelines, the service providers will be challenged to build testing environments that replicate scenarios that do not yet exist but soon will.

Report Coverage

This research report categorizes the global aerospace materials testing services market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global aerospace materials testing services market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global aerospace materials testing services market.

Aerospace Materials Testing Services Market Key Segments:

By Type

- Metals (Aluminum, Titanium, Nickel, Steel, Others)

- Composites

By Application

- Military Aviation

- Civilian Aviation

By Service Type

- Mechanical Testing

- Non-Destructive Testing (NDT)

- Environmental, Climatic, Thermal and Fire Testing

- Chemical, Corrosion, Microstructural and Metallographic

- Others

Key Global Aerospace Materials Testing Services Industry Players

- Aeroblaze Laboratory Inc

- Applied Technical Services, LLC

- Applus+ Laboratories

- Clark Testing

- Collins Aerospace

- Composites Testing Lab

- Dirats Laboratories, Inc.

- Element Materials Technology

- Eurofins Scientific (EAG Laboratories)

- IMR Test Labs

- Infinita Lab

- Innovative Test Solutions, Inc. (ITS)

- Intertek Group plc

- International Tin Association Ltd

- Laboratory Testing Inc. (LTI)

- Lucideon

- Mistras Group, Inc.

- National Technical Systems (NTS)

- NSL Analytical Services, Inc.

- SGS SA

- T,C&A Lab (Alfa Chemistry)

- TÜV SÜD

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383