MARKET OVERVIEW

The Global Transportation Composites Market caters to the demand for lightweight and high-strength solutions for different transportation modes in the automotive segment. This market majorly focuses on engineered composite materials specifically designed for performance, durability, and efficiency in automotive, aerospace, rail, and marine applications. Usually, these materials have reinforced fibers embedded in a matrix and thus enable the manufacturer to reduce overall weight while maintaining structural integrity.

Demand will certainly arise for materials to bear extremes of condition without loss of efficiency as transportation technologies continue to mature. The Global Transportation Composites market would respond to such needs by providing fully customized solutions that dovetail with mobility trends towards sustainability and better fuel performance. Further advances on composites, especially those having carbon fiber, glass fiber, and thermosetting resins, shall be in line with the stringent-specific application requirements on high-end stresses-whether in high-speed rail cars or next-generation aircraft structures.

It is expected that transport systems across the globe will incline toward achieving performance efficiency and durability as they are setting standards for regulation and forcing industries to push for further ways on alternatives from conventional metal-based components. In this scenario, the Global Transportation Composites market will attain situational relevance. For example, through their innovative materials, such will indirectly increase the emission reduction by reducing the weight of vehicles. It means that vehicles can consume less energy, thus complementing general long-term sustainability goals across transport networks. Material manufacturers are working closely with engineering teams to ensure the optimum composite layouts for every application with respect to performance and regulatory requirements.

In addition, this market will propagate modular manufacturing whereby components are designed for rapid assembly and reliability for the long term. Within the Global Transportation Composites market then it will be possible to customize material properties at the molecular level so designers can engineer parts to satisfy demanding specifications. There will be huge benefit from this flexibility especially in aerospace and defense where performance parameters must be met with no tolerance for deviations. The relationship of the design requirements to the compounding capabilities will dictate subsequent development to create more uniformity and reproducibility in materials.

Repairability and lifecycle cost efficiency will increasingly determine market directions. More and more, stakeholders in the Global Transportation Composites market will be interested in materials that offer performance, but at the same time, be easy to maintain and offer potential for recycling. These innovative prongs will promote the much anticipated next-generation materials in thermoplastic composites as well as smart material systems, both of which will have allow structural components to be reused, reshaped, or monitored throughout their operational life.

Digital technology will be further transformative in design and simulation processes for this market. Manufacturers will be able to use virtual testing environments to predict the behavior of materials under different operational conditions and reduce the need for physical prototype testing. Shorter product development times will be combined with improved cost efficiencies. The Global Transportation Composites market will then be able to offer the latest precision-engineered materials not only to ensure conformity with present demands but also to anticipate the changes that future transportation will require.

The Global Transportation Composites market will remain instrumental in creating better-performing vehicles through improved material efficiency. This market will continue to innovate advanced materials for contemporary transport systems. Ultimately, such innovations will contribute towards safety as well as lighter, better, and improved efficiencies in transportation globally.

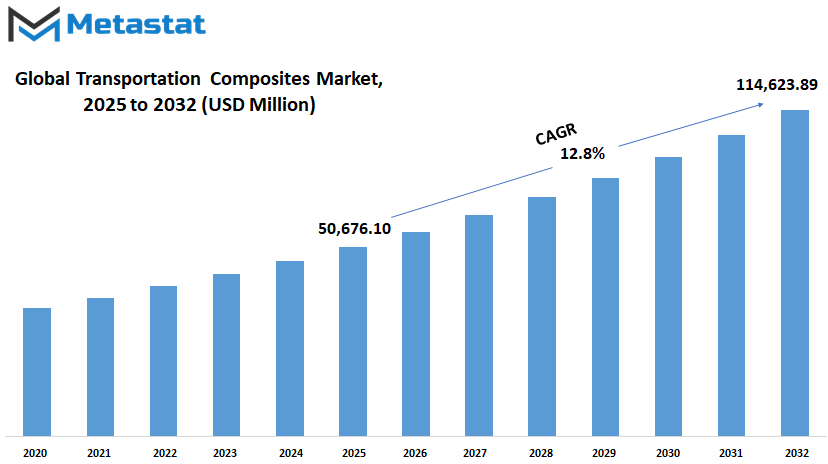

Global Transportation Composites market is estimated to reach $114,623.89 Million by 2032; growing at a CAGR of 12.8% from 2025 to 2032.

GROWTH FACTORS

The Global Transportation Composites Market is anticipated to grow steadily and this will be influenced by several strong factors. The increasing demand for lightweight and fuel-efficient vehicles is one of the important reasons for such growth. As the industries are tending toward de-emission and performance improvement, composite-materials are practical solutions; as being very strong and, at the same time, light in weight, both are suitable for transportation. Moreover, with governments pushing forward for sustainable practices and green methods of transportation, manufacturers seem to be moved towards adopting these materials into their designs and productions.

Another strong reason for growth is an increasing requirement for durability in materials that resist bad environmental conditions without regular replacement. For areas including aerospace, automotive, and railways, composites can prolong the life of the components and minimize total maintenance costs. This is both a money-saving process and an improvement in safety. Advances in technology in production techniques have also made it easier for the large-scale production of these materials so as to meet the mounting demand efficiently.

There are certain restraints to the growth of the Global Transportation Composites market. One of the restraints is high production costs. Though composite materials state savings over a long time, initial costs are simply too steep for some small manufacturers or companies with tighter budgets. Further, the absence of standardized regulations and testing procedures in some regions may cause a hindrance to a company's capability for market expansion and to bring new products rapidly into the marketplace.

Another issue is that there is a limited pool of trained technicians familiar with using these advanced materials. Not every production facility is equipped or trained to work with composites, and to work with these new materials requires investment in training and time needed to adapt. This could put off some companies from embracing composite technologies immediately.

Despite these issues, the future of the Global Transportation Composites market looks good. Increased awareness and improved production techniques will bring these materials within reach of more companies over time. Increasingly, electric vehicles, smart transportation systems, and high-speed rail networks will increasingly fuel demand. Developing regions are likely to present significant growth opportunities as they roll out new transport infrastructure. Innovation will continue, and global interest in efficient and eco-friendly solutions will push the market forward steadily. Continued research and international cooperation may offer solutions to current challenges and open even more doors for future growth.

MARKET SEGMENTATION

By Resin

There are bound to be some interesting changes in the Global Transportation Composites market, especially when one considers the materials to create stronger and more efficient transportation systems. With the rapidly growing demand for lighter and more durable cars, the materials utilized in their manufacture are changing. One of the more noticeable trends in this market is the use of thermosets and thermoplastic resins. These materials are increasingly being integrated into the design-build processes of the vehicle, affecting their performance, maintenance, and longevity.

Thermoset resins are widely used on the market due mainly to their excellent heat-resistance properties and the ability to maintain a specific shape when cured. Therefore, thermoset resins are great materials for high-thermal parts of vehicles or those parts which have to maintain the shape under pressure. This type of a resin provides a reliable structure where the parts will never get remolded. In the future, advancements in thermoset technology can result in even lighter and stronger components, thereby helping vehicles consume less fuel and create fewer emissions.

Thermoplastics, on the other hand, are heating up due to their flexibility and ability for reshaping. Therefore, they offer reusability and straightforward recyclability over thermosets. Thermoplastics are likely to be embraced more as the world gears itself towards sustainability and waste reduction. Thermoplastics are easier to repair, thus faster processing. For manufacturers, this means less time, resources, and more savings. Alongside the environmentally friendly options considered by manufacturers without compromising on quality and safety, their role in the Global Transportation Composites market will continue to grow.

Looking further ahead, thermoset and thermoplastic resin use is very likely to increase with improved technologies and advanced methods adopted by the transportation industry. Each resin has its own strengths, so the selection will depend on the needs of each vehicle or part. As industries are seeking ways to reduce cost, weight, and increase performance, these resins are going to play a greater role in the future of transportation materials. The Global Transportation Composites market will surely be in for some changes as these materials open entirely new avenues of design and wiser manufacturing.

By Manufacturing Process

The Global Transportation Composites marketplace is indeed on a burgeoning journey ahead, expected to keep surging as industries move towards light-weight and longer-lasting alternative materials for what's and where it can improve performance as well as reduce impacts on environment. Wrights are coming forward with much smarter ways of introducing cleaner transportation options into our lives, and therefore composites are becoming increasingly relevant in how vehicles are designed and built. Manufacturers are now focusing on optimized methods that ensure shorten the waste processes and promote sustainability. A shift from how materials are chosen and used within the commercial to personal transportation.

The market segments may be classified based on the type of processing into Compression Molding, Injection Molding, Resin Transfer Molding, and others. Each has its role in the process of how these methods are applied and which is focused depending on what the product is, strength requirements, and amount of output. For example, the number of times Compression Molding or most application is selected is because it has the ability to mass produce yet still conform to standards concerning quality consistency of parts. A prime example is in the case where the application calls for parts that would have to tough yet endure heavy loads without extra weight.

Injection Molding, as well, will see continued development ground owing to its high versatility. It houses capabilities for more sophisticated shapes and precise designs, ideal for parts that come in small sizes or must mate with high internal accuracy. This process shall continue to enjoy future growth as vehicle designs become more complex and technology-driven.

Resin Transfer Molding may not necessarily be the first choice for speedy production, but it is undoubtedly an avenue to be explored for the production of complex parts with robust fiber structures. This procedure shall also realize its expansion as the industry seeks performance improvements without compromising on quality. In fact, this will succor the drive to further automation, which is increasingly important in larger manufacturing environments.

Further, hybrid or newer such molding methods are being developed so that these will have a lot bigger role to play in the future because research has introduced new materials and technologies into the picture. The theme is about finding processes that could be cheap and significantly more adaptable to the evolving design and environmental goal requirements.

Trends point toward a future wherein the Global Transportation Composites market gets engineered by innovations, where every manufacturing process ends up being more developed to the better demand for fuel efficiency, safety of vehicles, and emission reductions. These cover a bit, but because of material science advances, composites will continue to push transportation into the future they will surely have again improved means of forming and applying those composites.

By Fiber

Because of advancements in material technologies as well as increasing demands for more lightweight, stronger, and sustainable solutions in transportation components, the Global Transportation Composites market is anticipated to and will likely grow steadily over the years. Some of the attributions to this market's future would be the different types of fiber in composite materials that various related industries would seek for better performance with reduced environmental impact. Now more than ever, selecting what type of fiber would be used is becoming a critical factor.

Glass fiber is widely consumed as it provides a good overall performance to cost ratio. It is strong and durable, and therefore will always have applications in various sectors of transportation and engineering. However, its weight coupled with a lack of recyclability could someday be motivating factors toward alternative materials. In future, transport systems, having the same objective of reducing consumption of fuel and emission of carbon, can also induce industries to explore lighter materials satisfying the safety and regulatory standards.

Carbon fiber is also gaining a lot of attention for its invaluable strength to weight ratio. It has historically been muy expensive, but with more research and advancement in production methods, its cost is anticipated to fall in the long term. The resulting cost-friendly option would make possible the wider application of carbon fiber in vehicles, aircraft, and next-generation public transit systems. Enhancing fuel efficiency and working towards electric mobility would then make carbon fiber a bracingly integrated part of transport design evolution.

They would also step into this domain. They probably might not be as strong as synthetic fibers, yet they definitely offer a greener alternative. It is possible that as environmental issues become all the more pressing, these fibers would find a home in those limited applications where moderate strength is acceptable but sustainability inclined really high on priority. For example, such natural fibers could serve as materials in inside panels or some noncritical structural parts, thus bringing reduction of the environmental footprint with function not getting compromised.

The other fibers are being explored, each fiber having its particularities that really might suit closed applications. This ongoing innovation in this area makes the Global Transportation Composites market anything but a one-or-two-material market. Indeed, there will likely be a richly diverse mix, with each type of fiber chosen based on the needs of the vehicle, the performance goals, and the environmental targets.

Fiber selection in composites will be major for the transportation sector as it moves into a future that is all about energy efficiency, electrification, and sustainability. Such is the transition of the Global Transportation Composites market as it moves towards those materials that are strong and light, but that can also accommodate the manufacturing changes of the future and environmental expectations.

By Application

The future of the Global Transportation Composites Market is quite bright, with advancements in the material field coupled with the increased demand for efficient transportation being the main driving force around which components are developed and applied. Composites possess both lightweight and a high strength to weight ratio, finding increasing demand across nearly all market segments of the transportation industry. The significant demand is visible when studying these materials for interior, exterior, and other components of vehicles, where the balance of performance, safety, and design flexibility takes on ever-increasing importance.

In terms of interior applications, this is passenger comfort and safety, with a further emphasis on weight reduction. For this reason, manufacturers are looking for high-performance materials considering their most modern design needs. Composites give the best base in this context, as they considerably reduce the weight of interiors while maintaining their integrity. Lighter, more sustainable interior designs will contribute to better fuel economy and lower emissions. As vehicle designs become more innovative, so do those of electric and autonomous vehicles, with functional, adaptive interior materials becoming even more important in the future. Such advances will push the market for greater innovation in all aspects of comfort, including thermal management and sound insulation.

Composites are now being adopted on a growing scale in exterior applications due to the need for materials that can withstand harsh environmental conditions, resist corrosion, and allow aerodynamic configurations. These materials make it possible to design lighter vehicles that are not compromised in their safety and durability standards. The more stringent regulations on emissions and energy efficiency, the further companies will be pulled in these directions. It also allows the designer to form more intricate shapes, thus opening avenues for new function and aesthetics in vehicles. The move toward the collective shrinking of the environmental footprint of transport is also gathering heat, and so one will consider exterior composites as one of the areas that will be focused on in years to come.

Besides interior/exterior applications, there are also more applications growing for composites, such as structural components, one or two seating systems, and even small mechanical parts. These additional applications show the widening expanse within which these composite materials are to be used. As the transportation space aligns itself increasingly with smart, connected, and cleaner technologies, the significance of lightweight and durable materials would be even more critical. Those investing in new processes and materials would most likely set the pace for the changes within the Global Transportation Composites market, which would eventually lead the way to more and more efficient, but innovative, designs and performances of vehicles.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$50,676.10 million |

|

Market Size by 2032 |

$114,623.89 Million |

|

Growth Rate from 2025 to 2032 |

12.8% |

|

Base Year |

2024 |

|

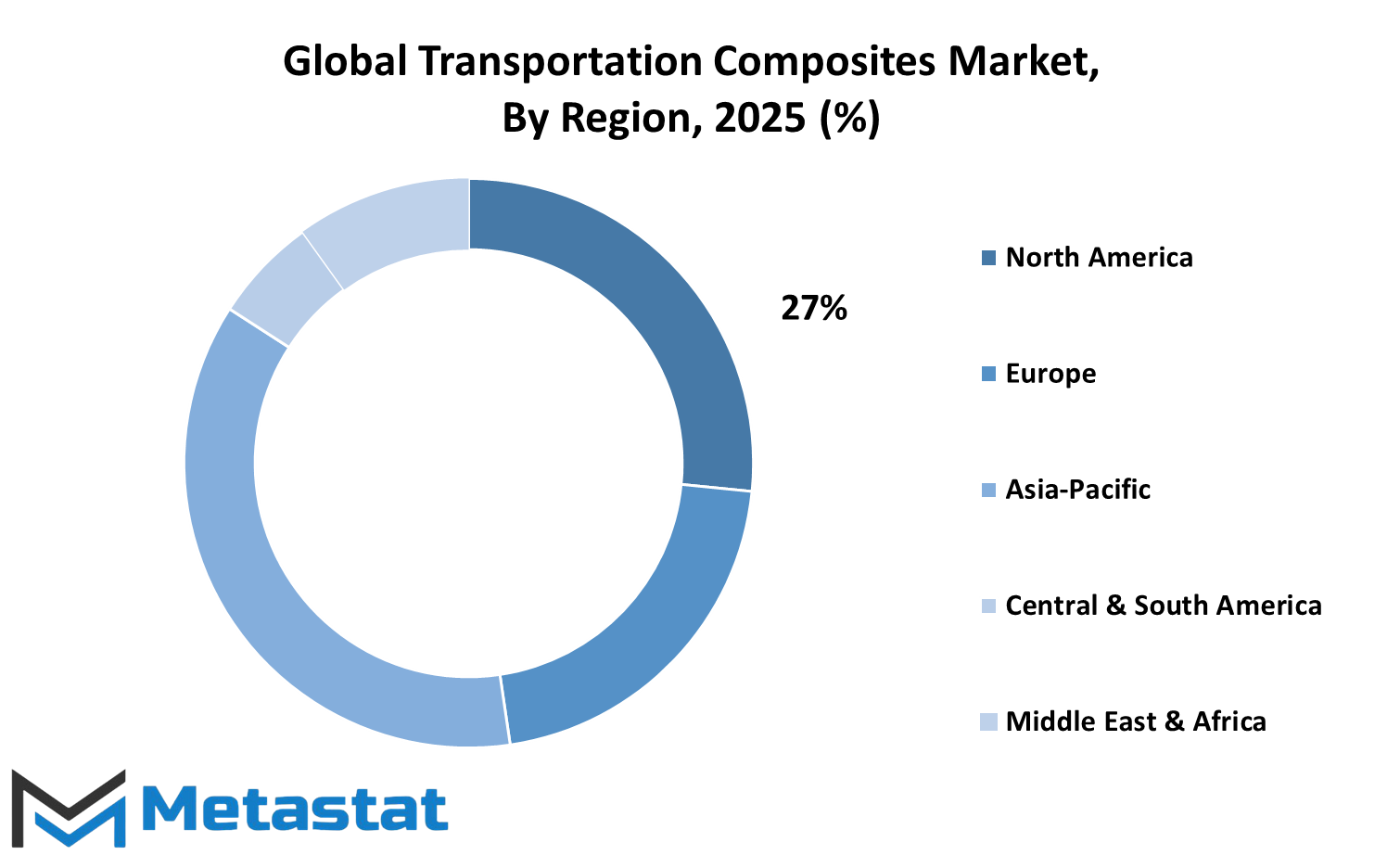

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The world is moving into a Transportation Composites domain fast, becoming one of its prominent components in the construction and maintenance of modern mobility. In the future, its expansion will largely depend on various regional demands all over the world. Each geographic region contributes uniquely to this market through its economy, industrial potential, and rising demand for transport. North America still has potential to keep the U.S., Mexico, and Canada busy because these nations are working to expand each other over sustainable modes of transport. Their focus will likely be somewhere between replacing heavier materials with lighter, more efficient alternatives and reducing energy use while improving performance in both public and private transportation systems.

Europe is another area of the world where the market will develop. Countries such as the UK, Germany, France, and Italy have gone very far with electric mobility and the development of high-speed rails. All these efforts are likely to encourage greater use of composite materials that offer flexibility, strength, and lightness. As European emulators require lower emissions and more robust and long-lasting transport infrastructure, composites will reach the hearts of manufacturers that want to comply with these rules. The whole continent is advancing at a considerable pace towards these mutually shared goals of better fuel economy and cleaner journeys.

In Asia Pacific, the market is expected to develop with a rapid pace. Countries like India, China, Japan, and South Korea are investing largely in their future A transportation system from electric vehicles to modern railway systems and taking steps toward creating next-generation public transport systems. This demand will thus grow the use of composites, which help in reducing weight, increasing lifespan, and lessening the cost of maintenance. It is the most potential area for future growth, driven by innovations and cost-effective production. Other parts of Asia-Pacific are starting to favor cheaper and better materials.

South America will gain slowly in demand but steadily. The example where this phenomenon shows well is in Brazil and Argentina, where these nations strive to improve their transport systems. As countries grow economically, the need for lightweight but durable materials will increase. Such Middle East and Africa are likely to see growth due to the expansion of infrastructure projects. Countries like those of the GCC, Egypt, and South Africa focus on diversifying their economies; modern transport will drive investment that will raise interest in composite materials with long-term value.

In every region, the global Transportation Composites market is likely to evolve through a mix of innovation, environmental policies, and varying consumer needs. As each of these areas moves forward, the demand for materials that are smarter, lighter, and more reliable will become a common priority.

COMPETITIVE PLAYERS

Transportation composites represent a gradual change in how the world conducts its vehicle and related structure manufacturing. The more industries that will prioritize weight reduction and increasing fuel efficiency will favor the steady growth of transportation composites. Besides imparting strength, these materials are durable without much added weight, especially useful for automotive, aerospace, and railway applications. The way this market is likely to evolve over time continues to be forced by the issues of environmental concern and changes in consumer demand. Thus, a greater push for using sustainable means of transportation will increase the demand for advanced composites.

Several key players have contributed to the market and are still doing so with innovation. Companies like Hexcel Corporation and Toray Industries, Inc. are developing high-performance composite solutions with a good mixture of strength and lightness. Teijin Limited and SGL Carbon SE are also focusing on new processes to improve production compatibility and reduce costs. With the growing popularity of electric vehicles, the need for light materials will become an increasing concern, pushing the companies like Mitsubishi Chemical Corporation and Solvay S.A. for the commercialization of new composite blends that conform to stringent safety-and-environmental regulations.

Yet another growing demand for better energy management is carving the future of Global Transportation Composites. Composites help improve the naturally energy efficiency of transportation equipment by means of weight reduction. Owens Corning and Plasan Carbon Composites are already looking at the materials that are both strong and engineered to conquer extreme weather and temperature, which are becoming quite critical in commercial and defense applications.

The growth of technology greatly influences the turn of these markets. Companies such as Huntsman Corporation and BASF SE are working on innovative bonding agents that facilitate the introduction of composites into conventional vehicle design. Concurrently, DuPont de Nemours, Inc. and 3M Company are investigating improvements to surface durability and long-term maintenance issues. The developments are indicative of a more versatile and durable generation of composites.

Thus, reliable light materials will remain paramount with the ever-increasing transportation demand across the globe. The Global Transportation Composites market will continue to flourish with the likes of Gurit Holding AG and Mitsubishi Rayon Co., Ltd. leading the charge for innovation. A brighter outlook for resilient and smarter solutions promoting sustainability and performance makes this market a prime candidate for close observation in the coming years.

Transportation Composites Market Key Segments:

By Resin

- Thermoset

- Thermoplastic

By Manufacturing Process

- Compression Molding

- Injection Molding

- Resin Transfer Molding

- Others

By Fiber

- Glass

- Carbon

- Natural

- Others

By Application

- Interior

- Exterior

- Others

Key Global Transportation Composites Industry Players

- Hexcel Corporation

- Toray Industries, Inc.

- Teijin Limited

- SGL Carbon SE

- Mitsubishi Chemical Corporation

- Gurit Holding AG

- Solvay S.A.

- Owens Corning

- Plasan Carbon Composites

- Huntsman Corporation

- BASF SE

- DuPont de Nemours, Inc.

- 3M Company

- Mitsubishi Rayon Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252