MARKET OVERVIEW

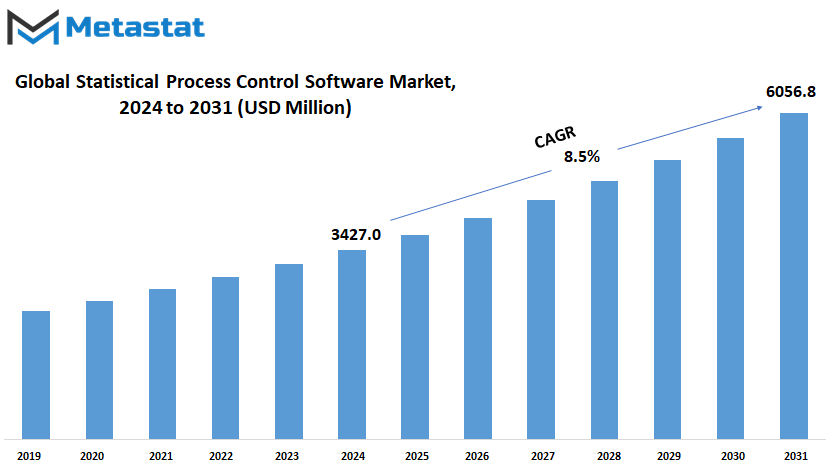

Global Statistical Process Control Software market is estimated to reach $6056.8 Million by 2031; growing at a CAGR of 8.5% from 2024 to 2031.

The Global Statistical Process Control Software market is an essential part of the modern industrial and manufacturing process, giving businesses the means to achieve the highest quality efficiency in their production processes. The market works mainly by providing a specific software to monitor, control, and optimize various dimensions of manufacturing and production lines. This market addresses a major requirement of industries that require precision and reliability in products while ensuring product consistency and safety through advanced data analytics, statistical models, and real-time monitoring.

In simple words, the market is the solution through software that helps companies collect, analyze, and respond to production data in real time. In doing this, it makes it easy for organizations to manage quality in their products closely since problems are identified and fixed before they mature into faults or inefficiency. Software markets that come in vary from the production of motor vehicles and electronic equipment up to pharmaceutical and food. The needs and requirements, therefore, on these businesses call for sound process control systems. These options are flexible and accommodative to various producers of all scales, from multinational firms to smaller companies seeking to improve their productivity.

The Global Statistical Process Control Software market is on the verge of tremendous growth as more sectors require products to be quality-made and free from defects. With the advent of Industry 4.0, the market too will transform, as many companies introduce artificial intelligence, machine learning, and IoT-enabled sensors to speed and accurately gather data to analyze, and the high production environment demands increasingly sophisticated statistical process control solutions. The Global Statistical Process Control Software market will therefore still see innovations with the advent of software tools that may be easily integrated into a smart factory and connected production ecosystem.

The key feature of this market is getting actionable insights from large chunks of data. The growth in industries adopting data-driven practices makes statistical process control software capable of transforming raw information into patterns, trends, and forecasts that aid in making better decisions on the production floor. This ability will remain central to the market as companies come to recognize the importance of using data for both quality control and strategic planning. There may be features such as control charts, data visualization, process capability analysis, and predictive analytics that all help in empowering operators as well as quality managers through information so that changes can be done immediately in real time.

Increasing requirements for regulatory compliance along with quality requirements across geographically dispersed markets will increasingly mandate the use of this software to ensure the standards of compliance. Avoidance of recalls, regulatory penalties, or reputational damage under the requirement of an international standard and customer expectation will drive companies toward the usage of statistical process control software. The focus of this compliance and customer satisfaction will make the Global Statistical Process Control Software market an indispensable aspect of industrial success in navigating a world where quality cannot be compromised.

The Global Statistical Process Control Software market is going to transform in the coming years with respect to technological development. In a way, the future of production is also going to be molded and shaped because of such culture building based on continuous improvement. More and more use of such software by manufacturers worldwide would make this market a basic foundation for innovation, quality assurance, and operational excellence in varied industrial landscapes.

GROWTH FACTORS

The global statistical process control (SPC) software market is on an encouraging growth path. One of the primary reasons is increasing demand across a range of industries. SPC software, by means of statistics, monitors and controls processes in companies for the purposes of quality and efficiency improvement. Demand in quality management has been consistent through the years with companies getting aware that reliable product quality and waste elimination can provide them with profits and ensure greater customer satisfaction. Thus, with a trend that continues to involve automation, and data-based decision, SPC software is being at the middle of those processes, improving efficiency in a process with less likely expensive mistakes.

A vital contributor to such growth, is the phenomenon of smart manufacturing and technologies under the rubric of Industry 4.0. Many modern businesses are incorporating the more advanced technologies such as IoT, AI, and machine learning to upscale their production activities. However, with the adoption of these technologies, they bring with them SPC software that helps in monitoring these processes in real time with necessary adjustments in the scenario. In addition, increased regulation requirements especially for pharmaceutical firms and automobile manufacturing companies have encouraged them to include SPC software as part of quality control process to achieve severe standards in their production.

However, some restrictions could limit the Global Statistical Process Control Software market to maximum potential. The expensive nature of the implementation of the software might discourage small and medium enterprises. This could be a challenge for small-scale businesses, which may not have the resources to put into such systems. Smaller businesses operate on more stringent budgets, making it difficult to justify the cost of SPC software. Some companies may also be hesitant to switch from older quality control methods to more contemporary digital solutions. Change is always difficult for many organizations, especially if employees require extra training to use the software effectively.

Despite these challenges, the future of the Global Statistical Process Control Software market seems bright, with full growth opportunities. The more that industries come to realize the benefits of data-driven process control, the higher the demand for SPC software is likely to be. Also, with ongoing technology improvements, it may be easier and less expensive to access software, opening it up to smaller businesses. In the future, SPC software could become a standard tool for quality management by companies of all sizes. The growth potential in emerging economies remains strong, as industries are rapidly growing and willing to implement advanced quality control measures to compete in the global arena. Thus, this market of Global Statistical Process Control Software is expected to grow steadily with the support of both the prevailing trends and the increased focus on efficient, high-quality production across various sectors.

MARKET SEGMENTATION

By Deployment Mode

The Global Statistical Process Control Software market will flourish with growing organizational demand for efficient, data-driven solutions to improve the quality and reduce variability in the process. SPC software used in businesses enables the ability to monitor and control their production processes in real-time with the help of statistics. This software provides business with insights into whether it operates as expected or else changes are required to meet product quality. It will extend the market because the more industries will realize the benefit of having such software, the more it will expand from the manufacturing sector to the health care sector.

Deployment Options for Companies could be either on-premise and cloud-based SPC software that have their advantages. Businesses that focus on data security and control like to be on-premise where software is installed and maintained in the company’s own infrastructure. Organisations handling sensitive information or those in highly regulated industries usually opt for on-premise deployment so they can control their environment where the software is installed. This kind of deployment requires heavy upfront investment on infrastructure, maintenance, and upgrades. However, such a deployment could provide a better fit in terms of tailoring a solution for some business requirements. Companies whose businesses demand constant access to data and are not relying on remote servers can still go for on-premise deployment.

With the change in technology, the interest in cloud-based SPC software has increased. This is because companies can easily access their software and data from any place in the world as long as it has an internet connection, making them flexible and scalable for modern businesses. Updates are done faster and have less pressure on internal IT departments because the provider maintains and improves the software. This means that in cloud-based SPC software, all these data sharing analyses can be made fast and informative for large-scale operations with geographically scattered units or remote office sites. This also means that this aspect will see more cloud solution innovation in the realm of the software industry from its SPC features perspective.

In the future, this Global Statistical Process Control Software market is going to get highly integrated into artificial intelligence and machine learning so that there will be predictive capacities in improvement and more automation for analysis. The improvements on the SPC software make it better to give insight, and based on insights, companies are able to predict when they will get quality issues. Due to such data-driven strategies gaining traction among industries, demand is most likely to increase with respect to both on-premise and cloud-based SPC software. More likely, cloud adoption will be faster with more organizations finding the adaptability and cost-effectiveness that the system offers.

The Global Statistical Process Control Software market is set to go ahead with evolving technologies and even deployment options. Organizations shall choose that which best caters to their needs be it security, flexibility or ease of use, hence both these options are also set up to support organizations in bringing in higher standards of quality, reducing the defects in output, as well as optimizing the work processes.

By Organization Size

The Global Statistical Process Control (SPC) Software market is bound to grow with the advent of better data handling and analysis. The demand for Statistical Process Control, where statistical methods can be employed for monitoring as well as control of business processes, is a necessity in present times. Companies use these tools to ensure uniformity while improving quality and error reduction in production. Through such tools, companies can be in a position to take well-informed decisions as based on real-time data that leads to the quality of operations and efficiency increase.

Based on the organization size, this market is fragmented. A company may find a reason to apply a particular product based on their size due to different types of applications for various kinds of business. SMEs are important for this market. For the year 2023, the value for SME alone was at 2099.3 USD million. Using the SPC software can come cheap to smaller companies where streamlining operations can compare favorably with the same efforts made by larger organizations. SMEs are ever increasing in their adoption of digital tools, and thereby improving their productivity without heft infrastructures. On monitoring quality, cutting the costs and making strategic choices, based on data from insights the SMEs through SPC software will easily level up with the heavy weights.

Large companies, therefore, need sophisticated processes and more comprehensive complete quality management solutions. Advanced analytics and process optimization are important to keep up their competitive edge in the market. Large companies may invest in tailored SPC solutions across departments and geographies that offer better consistency in quality. As automation and big data keep trending, large enterprises will certainly see a further rise in the adoption of SPC software for deeper insights, enabling predictive analytics to respond to problems before they create a production impact.

Advancement in AI and machine learning will only add more steam to the SPC Software market for the near future. These technologies can complement SPC software in a manner that gives predictive insight, so businesses can know where possible issues may arise so corrections are made on the spot. Thus, organizations can enjoy fewer defects, faster responses, and an improved working efficiency. It is bound to experience this because companies will tend towards Industry 4.0, more on the idea of connected devices, as well as digital transformation, which seeks to put more emphasis on data towards improvements in process.

By Application

The Global Statistical Process Control Software market is expected to grow considerably in the next few years by focusing on improving the overall manufacturing and quality control activities in the various sectors as organizations rely more on data-oriented decision-making to sustain against the competition. The critical tool here is the software for Statistical Process Control or SPC. The software also provides data with real-time tracking, analysis, and management, allowing production activity monitoring by the company to be as precise as possible. Relevant modifications are done there on the spot, a promise to be witnessed here numerous times in this article, due to the fact that several industries see improvements under its light not only regarding efficiency or operations but quality aspects as well.

Some important fields regarding the SPC application of software include good number of areas. Quality control will remain one of the applications, as this software lets businesses detect variations early enough to avoid costly production mistakes. The more companies care about product consistency and consumers’ satisfaction, the greater the importance of this feature. Process optimization is yet another vital application, through which the software helps business streamline production processes, thus yielding greater efficiency and cost-cutting. SPC software enables firms to be leaner, yet more efficient in how things get done, optimizing their workflow and waste level.

Another important segment for production monitoring is the process. Organizations can closely maintain a check on their manufacturing lines with this help that leads to less downtime. Real-time alerts and auto-collected data enable these firms to take immediate steps and hence minimize any halt that further maximizes total output from production. Moreover, the more regulatory standards grow, the more industries face higher demands for compliance. In 2023, the compliance management segment itself accounted for 378.5 million USD. That is to say that such a product plays an even more crucial role than is apparent. SPC software helps organizations comply with requirements and thus avoid fines or penalties while also being in good standing with customers and partners in terms of transparency and trust.

The "Others" category was another category in the market, and it had a value of 243.6 million USD in 2023, and it held a 7.71% market share. It also shows further applications where the SPC software is being utilized as a subsidiary in this area. In time, this category will become the home for new and growing requirements in a myriad of industries as the software is continuously developed and increased in usage.

The future of the Global Statistical Process Control Software market will be more innovative with the software becoming intuitive and specifically tailored to meet specific industry requirements. Integration of artificial intelligence and machine learning might lead to smarter data analysis and predictive insights, thus making SPC software an indispensable asset for companies striving for continuous improvement. As businesses invest in digital solutions to remain agile and resilient, the demand for SPC software is going to grow, making it a backbone for quality assurance and operational excellence across industries.

By Industry Vertical

Growth in the respective industries has led to a marked increase in the global SPC software market. It can be deduced that quality control improvement, defect reduction, and process optimization are pillars of demand for SPC software, and the trend is significantly prominent within the manufacturing industry, as its usage will be rising drastically. The manufacturing segment was estimated to be worth $755.7 million alone in 2023. Considering the critical role such software plays in providing production quality monitoring and the immediate remediation of issues in such companies, this market area will substantially benefit from innovations and better data analysis constantly improved with the help of SPC software.

The automotive industry is one of the most important sectors for the global market of SPC software in 2023, at about $561.5 million. More and more automation within the automobile production lines lead to increasing demands for perfect quality in SPC software. These companies use software to produce each part for a car with absolute standardization in order to better ensure that the automobile functions safely and reliably. In an era when electric vehicles and autonomous technologies are in trend, demand for SPC software is bound to keep going upwards, where the question of quality would only get relevant in times where precision was the name of the game.

For aerospace and defense, the software plays the same amount of importance. With an estimate of $484.1 million for 2023, it is subjected to tough requirements of safety and regulation. Thus, a robust system of quality control has been in high demand. The development of innovation in space exploration, aircraft technology, and defense machinery will require high-quality products that SPC software must ensure. With such niche and sensitive products, focusing on quality also prevents mistakes that are cost-prohibitive and keeps safety and compliance intact within these markets.

The health and pharma industry with a market valuation of $388.8 million in 2023 also benefits hugely from using SPC software. High stakes and strict rules because of regulations heighten the focus on precision and safety, especially in pharmaceutical production. SPC software makes sure that drugs which pass the standards for being safe and effective are administered to the patients, hence less likely to make a mistake in production. Therefore, with the progress in health technology, especially regarding personalized medicine, the need for SPC tools is intensified to maintain uniform quality in patient-specific treatment.

Apart from these core industries, SPC software is still applied in the food and beverages, chemicals, electronics, semiconductors, and oil and gas industries. All of these industries have varying quality control requirements, and SPC software helps them achieve consistency while improving productivity. The global SPC software market seems to be on an expanding spree, looking forward because this is the future where competition will focus on bringing better data-driven decisions and innovation through the tool.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$3427.0 Million |

|

Market Size by 2031 |

$6056.8 Million |

|

Growth Rate from 2024 to 2031 |

8.5% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

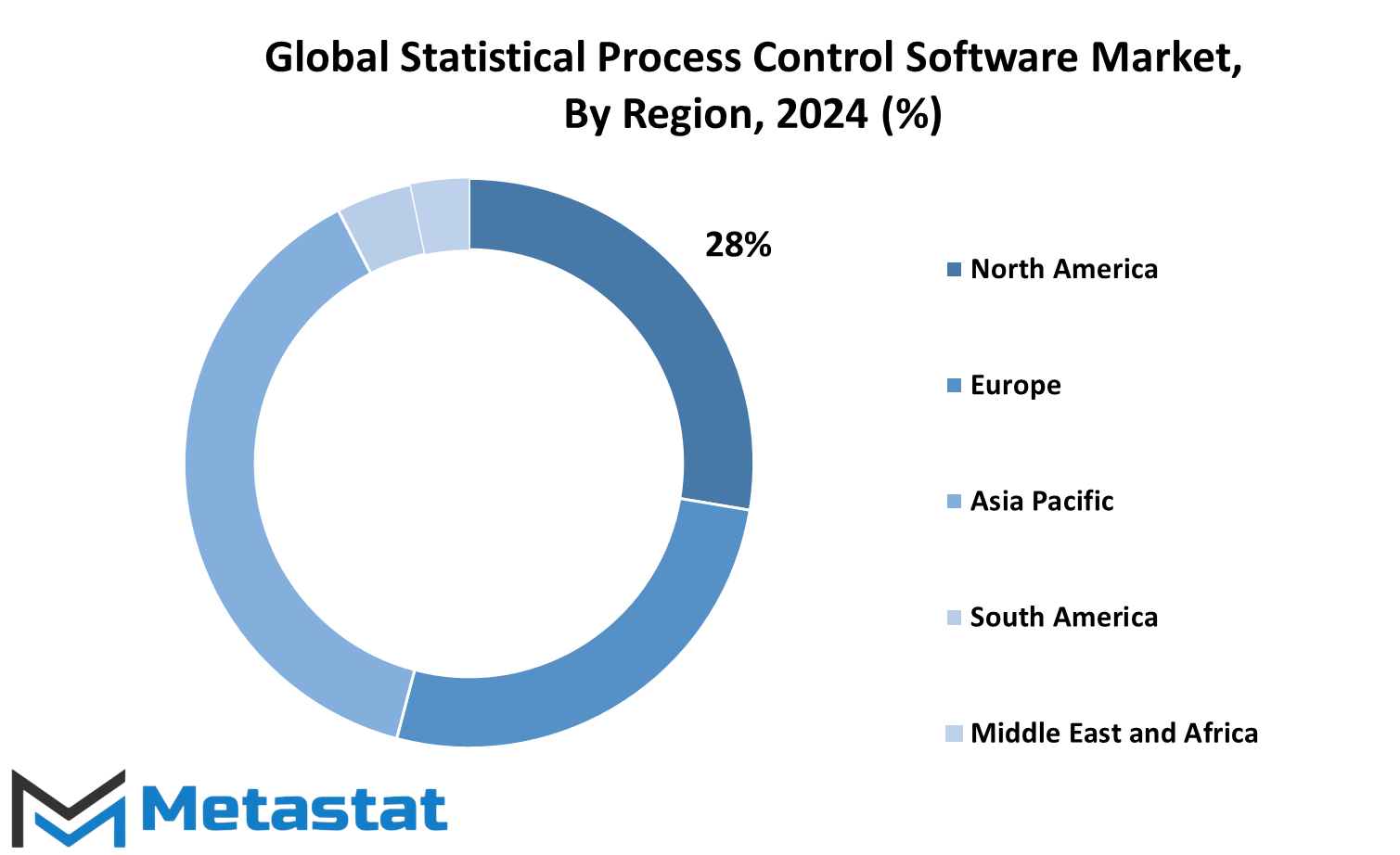

REGIONAL ANALYSIS

The global SPC software market is growing steadily with great potential in many different regions. The SPC market, which is known to increase the efficiency of manufacturing and quality control, will gain further adoption across the globe as companies move more to data-driven approaches. Nevertheless, regional dynamics do impact the adoption of the software. To get a closer view of the areas of opportunity and growth, the following highlights key regions.

It has major technology and high industrialization percentages in the United States, Canada, and Mexico. Thus, North America drives the market demand of SPC software. In this regard, industries seek to transform their industry into a digital economy using the SPC software for more effective production processes and subsequently quality products. This region will continue to hold the SPC application landscape, which will support automotive and its related industries, that may include healthcare and electronic machinery, as the places mainly need accuracy in all processing steps.

The other region is Europe, representing countries like UK, Germany, France, and Italy. Like others, Europe also shows this affection towards quality management along with manufacturing efficiency. Even German companies, known for making precision, spend heavily on SPC software; otherwise, they cannot maintain the existing performance in a global arena. This approach towards a quality-oriented market fits very well with added values from SPC software as they allow for real-time check-up and a faster reaction to deviation. The future prospect is good concerning SPC software throughout this market. Its primary regions, China, India, Japan, and South Korea are thriving economic blocs which should help hugely increase SPC software as an instrument within their geographical confines. Manufacturing hub: As various countries of Asia-Pacific start becoming manufacturing bases for orders in the region and beyond, it is promoting home industries to adopt the state-of-the-art SPC software that will improve the competitiveness and quality according to international standards. Hence, the Asian-Pacific market for SPC software will increase as the government encourages the markets and industries upgrade their present systems while looking forward to exporting the same to the rest of the world.

There is growing interest in SPC software from South America, with Brazil and Argentina being very interested. Improving processes and reducing waste are both in the best interests of South American industries, therefore creating a clear opportunity to offer SPC software solutions. The market here will develop gradually as local businesses seek efficiency and growth in their operations.

In the Middle East and Africa, growth in industries in the GCC countries, Egypt, and South Africa is supporting gradual adoption of SPC software. With diversification and industrialization of these economies, there is a huge demand for SPC software as a result of the constant requirement for quality products; hence, it aims at upgrading manufacturing standards and thus accelerating economic development.

Overall, the global Statistical Process Control Software market is estimated to grow in every geographic region, with different challenges and drivers shaping the development of SPC software utilization in various regions.

COMPETITIVE PLAYERS

The Global Statistical Process Control (SPC) Software market is growing due to industries searching for new ways to increase the quality of production along with their efficiency. Statistical Process Control Software plays an important role in monitoring and controlling processes in manufacturing for a consistent quality level without much variation. This kind of technology enables companies to measure, control, and optimize the manufacturing process in order to reduce waste and increase productivity, which can have a positive effect on profitability. With the increasing trend of data-driven manufacturing, SPC software is also providing applications for real-time monitoring, historical data analysis, and predictive insights. As the automation and smart manufacturing practices are gaining pace in all industries, in the following years, the demand for advanced SPC software is going to rise significantly.

The competition is very tight in the market, with the key players developing the advanced features according to specific industrial needs. Companies like SCR Soft Technologies (P) Ltd, Germanedge GmbH, ICONICS, Inc., Hexagon AB, and Net-Inspect, LLC are constantly innovating to provide unique functionalities and seamless integration into various manufacturing environments. The companies invest in cutting-edge technology and user-friendly designs to enhance the customer experience. For example, some SPC software solutions have customizable dashboards that can quickly identify trends and change processes in real time. Other major players include DataLyzer International Inc., Minitab, LLC, and Zontec, Inc., which specialize in making the SPC tools available to smaller-sized organizations by providing scalable packages to suit various business size.

The future of this industry is expected to transition to a more intuitive AI-driven SPC software within the near future. Solutions for this new generation would employ artificial intelligence to anticipate and prevent problems before their actual occurrence, thereby lessening downtime and maximizing production. As connectivity increases in the Industrial Internet of Things, machines will talk to SPC software that will adjust processes according to live data automatically. The change would be more significant in those industries, such as the automotive and aerospace industries or the electronics industry, in which precision and consistency play a more important role. The key companies, like Quality America Inc., Factory Systems, and QDA Solutions GmbH, are engaged in software development that harmoniously aligns with the technologies of IIoT and machine learning.

Partnerships and acquisitions will be drivers in the competitive dynamics of the market during its maturation. Larger firms such as Dassault Systèmes (DELMIAWorks) and Hexagon AB will continue to buy up smaller specialized companies in their portfolio and provide end-to-end solutions. This will help them capture a broader market share and provide clients with diverse and advanced features. In this dynamic market, companies that adapt to the emerging technologies and cater to the specific demands of each industry will continue to enjoy a competitive advantage, thereby further innovating in the Global Statistical Process Control Software market.

Statistical Process Control Software Market Key Segments:

By Deployment Mode

- On-Premise

- Cloud-Based

By Organization Size

- Small and Medium Enterprises (SMEs)

- Large Enterprises

By Application

- Quality Control

- Process Optimization

- Production Monitoring

- Compliance Management

- Others

By Industry Vertical

- Manufacturing

- Automotive

- Aerospace and Defense

- Healthcare and Pharmaceuticals

- Food and Beverages

- Chemicals

- Electronics and Semiconductors

- Oil and Gas

- Others

Key Global Statistical Process Control Software Industry Players

- SCR Soft Technologies (P) Ltd

- Germanedge GmbH

- ICONICS, Inc.

- Hexagon AB

- Net-Inspect, LLC

- DataLyzer International Inc.

- Minitab, LLC

- Zontec, Inc.

- QAD Redzone

- Marposs S.p.A.

- Ellistat

- Dassault Systèmes (DELMIAWorks)

- Zometric Smart Manufacturing Solutions

- Northwest Analytics, Inc.

- Quality America Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383