MARKET OVERVIEW

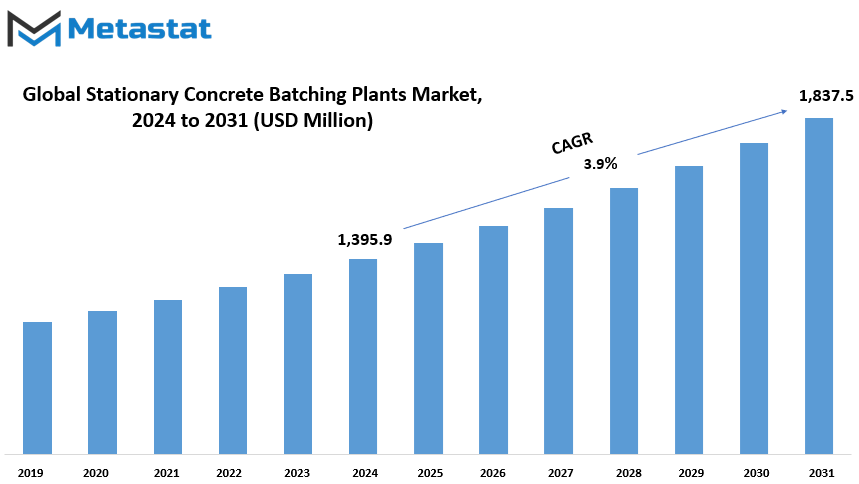

Global Stationary Concrete Batching Plants market is estimated to reach $1,837.5 Million by 2031; growing at a CAGR of 3.9% from 2024 to 2031.

Stationary concrete batching plants represent very important construction industry apparatus intended to deliver consistent quality for a wide range of building projects. Such fixed constructions, therefore, play a very critical role in construction material provision to meet specific needs across all structures, be it residential buildings, commercial facilities, or large infrastructure developments. In combining such material components as cement, aggregates, water, and additives in the right portions, these plants ensure consistency and reliability in the type of concrete delivered.

One of the main benefits that stationary concrete batching plants possess is that they can handle large-scale operations. The fact that these plants are based in one location means that they are designed to have high-end machinery and systems for proper mixing of large quantities of concrete. This makes it ideal for projects that require continuous and consistent flow of concrete over an extended period. Their fixed nature also allows for tighter control of the production process, which makes sure that every lot leaves the plant to strict standards of quality.

These plants function in a systematic process. Raw materials such as cement and aggregates are placed in their appropriate areas or silos, hence being prevented from contaminants and being available whenever required. Precise measuring and weighing systems then determine the exact quantities required for each batch. These materials are then mixed with water and any necessary additives in specialized mixers. This process ensures the final product has the required strength, durability, and workability for its intended use.

Stationary concrete batching plants, aside from their production capabilities, are also environmentally friendly. Part of the design includes techniques on how to manage dust and waste, therefore reducing pollution, thus helping the process adhere to environmental regulations. These plants make a great choice for modern construction demands that consider more than just good quality, such as also taking care of the environment.

This type of batching plant is mostly selected because it is known for the durability and the long run with efficiency. They are built to handle rigorous demands and operate consistently under varying conditions. This reliability is a critical factor for construction projects that cannot afford delays caused by inconsistent or low-quality concrete. Producing concrete on-site or near project locations can save time and cut transportation costs while further contributing to their efficiency.

In summary, stationary concrete batching plants have proven indispensable in the construction industry. They are to be leaned upon for reliable high-quality production. Stronger design, accurate operation, and environmentally concerned features make these a cornerstone in achieving successful construction outcomes.

GROWTH FACTORS

The construction industry has experienced significant changes, with growing demands for infrastructure, especially in developing regions. The demand for strong infrastructure, such as roads, bridges, and buildings, has increased in developing countries. This has created an increase in the demand for efficient solutions, which means concrete batching plants have become an essential part of the construction process. They help to streamline concrete production and ensure consistency and quality in large-scale projects. Their role in solving the increasing infrastructure requirement cannot be rivaled and solidifies their position in the market.

Technological advancements have further catalyzed the adoption of batching plants. Innovations have led to more efficient, automated systems that not only increase productivity but also focus on environmental sustainability. The features of these advancements focus on reducing energy consumption and minimizing waste, which corresponds with the industry's need to move towards greener construction methods. The environment-friendly batching plants are promising, as these respond to both the environmental aspects as well as operational efficiency. While technology is developing day after day, the chances for such automated and sustainable plants increasing are higher.

Despite these, there are challenges facing the market. One significant hurdle is the high initial cost associated with setting up batching plants. These costs, added to the continuous maintenance requirements, are deterrents, especially for smaller construction firms. Many batching plants are not flexible due to their stationary nature. The systems are not easily relocated, and hence, they may create problems for smaller or short term projects. These factors will restrain the market growth of the regions where project scales vary widely.

Despite these challenges, the focus of the industry on sustainability is a notable opportunity. Increasingly, the demand for eco-friendly construction materials and practices presents new opportunities for batching plant manufacturers. Plants designed with sustainability at their core, with technologies that reduce emissions and incorporate recycled materials, are well-positioned to capitalize on this trend. Such innovations can appeal to environmentally conscious developers and align with global efforts to reduce the carbon footprint of construction activities.

The demand for eco-friendly batching plants in the coming years will likely grow because of the market for efficient and sustainable solutions in construction. The high costs significant challenges. Still, the potential for innovation and the push for greener alternatives open a very lucrative opportunity for the market to thrive.

MARKET SEGMENTATION

Type

Concrete batching plants play a very crucial role in construction projects as they provide the necessary service of mixing concrete efficiently and consistently. They come in different types depending on the specific functions and capabilities. Thus, it makes it easier to understand and decide which one is most appropriate for a given task.

There is Ready Mix Concrete Batching Plants, which are commonly applied in the delivery of premixed concrete to construction sites. This saves time and ensures quality, because the concrete is produced at a central location, transported to the site, and prepared in transit mixers. The mixing is not carried out at the site, which is beneficial in massive or time-sensitive projects.

The most common type is Central Mix Concrete Batching Plants. This is where all the mixing takes place in the plant, and then concrete is delivered to site. This can provide greater control over the mix consistency and quality. This plant is best used for applications requiring precision and uniformity since it allows operators to monitor the mix very closely during production.

Wet Concrete Batching Plants are another type of design that adds water and other constituents directly at the plant. It produces a ready-to-pour mixture. This type of plant is preferred when the project demands fresh, immediately usable concrete. By incorporating all the ingredients, including water, before delivery, these plants ensure the maintenance of the intended properties of the mixture throughout transportation.

On the other hand, there are Dry Concrete Batching Plants. Dry concrete batching plants measure and blend the dry ingredients, including cement, sand, and aggregates. Water is added at the construction site during mixing. This type of plant has higher flexibility for projects that may have to be adjusted on-site or if traveling long distances may compromise the mix itself.

Each type of concrete batching plant serves specific construction needs, always taking into account factors of scale, location, and intended quality. Contractors can, therefore choose the right plant for their activity and thus streamline their operations to obtain reliable high-quality results.

By Capacity

The market for stationary concrete batching plants is divided based on capacity into small and large, with further specific differences being applied in terms of output per hour. Small-capacity plants, encompassing up to an output of 30 cubic meters per hour, are the major part of the market. The market for this kind of segment was USD 294.8 million in 2019, and this itself contributed 26.1% of the market share. This was during the period when its importance was highlighted in the industry. It was a vital option for such projects that required moderate concrete production capabilities.

The next segment is expected to grow steadily in the coming years. It is forecasted that the small-capacity segment will reach a market valuation of USD 386.1 million by 2026. The growth in this segment corresponds to a CAGR of 3.4% from 2020 to 2026. This steady growth represents the ongoing demand for batching plants in this category, as the needs of infrastructure development and construction projects are constantly requiring compact and efficient solutions.

The large-capacity segment, which is batching plants with an output of more than 60 cubic meters per hour, caters to bigger projects. This segment is mainly applied in areas where large amounts of concrete production are required in any construction, like large buildings, bridges, and infrastructure. The demand for this segment indicates growing interest in high-capacity equipment, especially in efficiency, catering to the demands of heavy construction.

This growth dynamic indicates different needs within the construction industry. Smaller capacity plants are still preferred because they offer an all-round flexibility for smaller-scale projects or site-specific requirements, while larger capacity plants still dominate in massive operations. The demand for these plants-whether large or small capacitate-is still expected to remain strong with further globalization of urbanization and construction activities.

Both segments contribute to the overall market growth, each fulfilling the different roles in solving construction issues. The industry's development over the forecast period will be influenced by technological advancement, efficiency enhancement, and sustainability considerations, hence ensuring that stationary concrete batching plants remain a cornerstone in modern construction processes.

By Distribution Channel

Products today can only distribute themselves in the market; without an effective distribution, businesses find ways not to reach their target audience efficiently. In terms of distribution channel, the market is subcategorized into direct sales, authorized dealers and distributors, online sales, and e-commerce. Each of these has different aims that make up a mixed-up system, which satisfies different types of consumers and business approaches.

This segmentation enables companies to choose the best ways of delivering their products, thus considering convenience, reach, and cost efficiency. Direct sales involve companies that communicate directly with customers without intermediaries. This often fosters stronger relationships with consumers since direct communication, personalized service, and instant feedback can be provided. Companies using this method tend to be customer need-based, as they would like to know what the customers need and thus adapt their offerings to fit those needs. It is simple and effective to ensure control over the customer experience and also that brand values and standards are not compromised.

The dealers and distributors act as middlemen, helping businesses to reach wider markets by using an existing network. Their involvement streamlines the process of getting products into the hands of customers, particularly in areas where logistical challenges might arise. Sales through online have greatly increased, and this is a cheap way to reach a large audience.

The channel has also enabled shoppers to browse and order commodities from the comfort of their homes. Businesses selling online invest in hassle-free websites, secure ways of payment, and efficient delivery methods. By doing this, they attract such tech-friendly customers who aim to make their transactions hassle-free. E-commerce platforms constitute a section of online sales, facilitating business entry into global markets. This has allowed small and large enterprises alike to present their products to millions of potential customers. E-commerce platforms have transformed the way consumers shop by offering user reviews, product comparisons, and targeted advertising.

By understanding and using these distribution channels, businesses can strategically position their products to meet consumer demands while optimizing their operations for better efficiency and growth. Each channel has its unique advantages, which contribute to a holistic system that supports diverse customer needs.

By End-User

It also forms a significant part of the global market for large-scale infrastructure development. The plants are essentially integrated parts of any industry that requires an uninterrupted supply of concrete to facilitate any project. Stationary batching plants produce concrete very efficiently, but their location is usually stationary as well, catering for those projects that require high volumes. Their importance is in offering uniform quality and fulfilling various construction needs. They are, by design, appropriate for use without the need for mobility; thus, they are preferred for massive projects.

The demands of stationary concrete batching plants are driven by their appeal to different types of end-users. Construction companies, for example, depend on these plants to ensure that concrete is always available when it needs to be delivered to locations like highways and bridges, and residential complexes. Such readiness at the time of delivery helps construction firms complete projects without being delayed and provides constant quality output from their end. Similarly, concrete manufacturers benefit from the technical efficiency from stationary batching plants by producing concrete in bulk while upholding quality.

Another factor for participation in this market is through government and public sectors, especially regarding infrastructure development and urban planning. Big works, such as railways, dams, and airports, require a reliable supply of concrete, making them more suitable for stationary batching plants because they last for so long, producing large quantities, so these projects are completed promptly.

Stationary concrete batching plants are not without their challenges, but the benefits far outweigh these. They are usually cheaper in the long run compared to mobile plants, especially for longer projects where one doesn't have to move it. They have been designed with efficiency and precision to be able to produce constant concrete mixes, which make them a corner stone of the construction industry, especially in highly urbanized regions with growing needs for infrastructure.

In conclusion, the global stationary concrete batching plants market caters to a wide variety of customers such as construction companies, concrete manufacturers, and the government and public sector. Due to the increasing demand for reliable and high-quality concrete production, these plants are very important in the construction and infrastructure development environment. Their ability to assure precision and consistency continues to make them a valuable investment for large projects worldwide.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,395.9 Million |

|

Market Size by 2031 |

$1,837.5 Million |

|

Growth Rate from 2024 to 2031 |

3.9% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

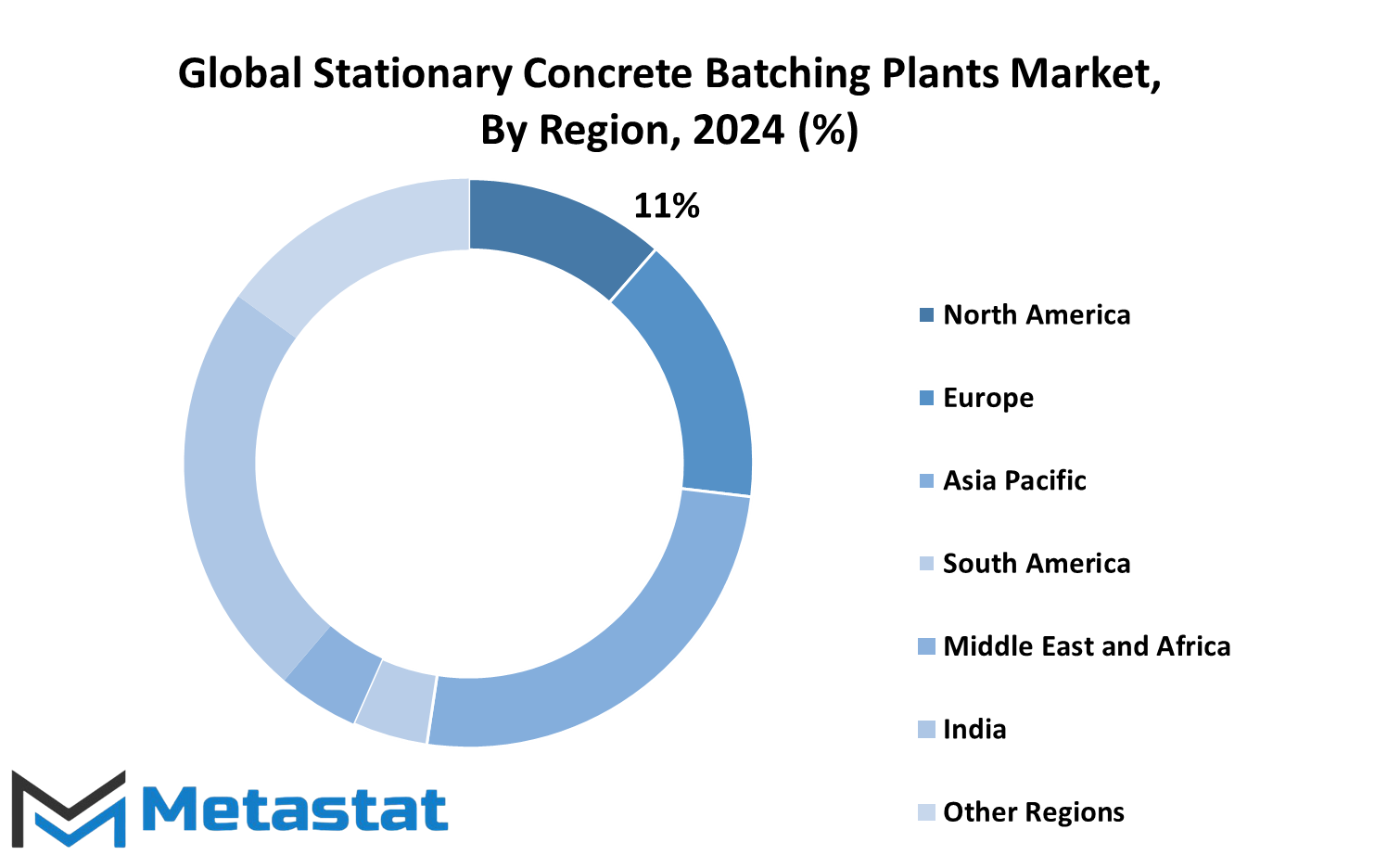

The global Stationary Concrete Batching Plants market is researched with respect to geographic regions such as North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. These regions further broken down in order to deliver a more accurate knowledge about the market scenario and activity in those regions.

North America has the United States, Canada, and Mexico as primary countries. These nations play a significant role in construction and infrastructure sectors and therefore are major contributors to the demand for stationary concrete batching plants. The region is rich in technological advancements and high investments in urban development, which are driving the growth of this market.

Europe is another key region, which includes the United Kingdom, Germany, France, and Italy. In addition to these major economies, the Rest of Europe contributes to the overall market landscape. Infrastructure modernization projects and sustainable construction practices are central to the demand for batching plants in this area.

The Asia-Pacific region will represent a significant market share since all countries, including India and China, Japan and South Korea, are fast developing on industrial and urban grounds. The Rest of Asia Pacific will also complement these first movers in adding the depth of the market. That said, investments made across residential and commercial infrastructures add to the region significantly and increase adoption in Stationary Concrete Batching Plants.

Another significant growing market in South America is Brazil and Argentina, followed by the rest of South America. All these areas support the expansion of the market. Activities such as transport network construction activities and residential projects boost the demand for this region.

Lastly, the Middle East & Africa encompasses countries ranging from those in the GCC, Egypt, to South Africa. The Rest of the Middle East & Africa also contributes to the market. This region experiences a rising number of infrastructure projects on account of urbanization and industrial development, thereby aiding the market for stationary concrete batching plants.

Every region has different drivers and challenges, which is why geographic segmentation is an important approach for understanding the general trends in the market. Analyzing these subdivisions will allow stakeholders to identify opportunities better and cater to specific demands in various parts of the world.

COMPETITIVE PLAYERS

Stationary concrete batching plants are fundamental in the construction industry and represent the main equipment that ensures the constant production of good-quality concrete. The mixing of raw materials, including cement, water, aggregates, and additives, results in the desired concrete mix for different projects. Fixed in a location, the stationary batching plant is not mobile like its counterpart and is usually found near a construction site or an area that constantly requires concrete production. Reliability and efficiency are the characteristics that make them the ideal choice for big projects, such as bridges, dams, highways, and tall buildings.

Stationary concrete batching plant manufacturers rely on innovation and state-of-the-art technology. In this field, the market leaders are professionals who adhere to quality norms. Companies like SANY Group, Liebherr Group, SCHWING Stetter GmbH, and MEKA have gained a prominent position in the market by continuously improving the design and functionality of their plants. Zoomlion Heavy Industry Science & Technology Co., Ltd., XCMG Group, and Atlas Industries are also well-known for their ability to meet different client requirements. ELKON Concrete Batching Plants, Nilkanth Engineering Works, and Teka Maschinenbau GmbH have also been a contribution to the industry in the form of durable and efficient solutions.

Moreover, Ammann Group, BHS-Sonthofen GmbH, Jianxin Machinery Co., Ltd., and Gamzen Plast Private Limited continue to shape the market. The companies work hard to innovate in mixing so that the concrete is at its best. Contributions do not end at just the manufacturing plants; these companies also offer complete support to their clients, be it installation, maintenance, or upgrade, for smooth functioning.

Not an overstatement that stationary concrete batching plants play a highly important role in construction sites, particularly regarding time, with the production of high quantities of concrete at minimal cost with these plants. Increasing infrastructure needs worldwide make the role played by these plants even more important. Companies manufacturing this industry are committed to meeting various environmental challenges as well as that related to energy efficiency, and therefore have an indispensable role to play in sustainable construction. As these companies continue to push forward and meet the challenges of the world, they strengthen themselves further as leaders in this active and vital industry.

Stationary Concrete Batching Plants Market Key Segments:

By Type

- Ready Mix Concrete Batching Plants

- Central Mix Concrete Batching Plants

- Wet Concrete Batching Plants

- Dry Concrete Batching Plants

By Capacity

- Small Capacity (Up to 30 Cubic Meters per Hour)

- Medium Capacity (30 to 60 Cubic Meters per Hour)

- Large Capacity (Above 60 Cubic Meters per Hour)

By Distribution Channel

- Direct Sales

- Authorized Dealers and Distributors

- Online Sales and E-Commerce

By End-User

- Construction Companies

- Concrete Manufacturers

- Government and Public Sector

Key Global Stationary Concrete Batching Plants Industry Players

- SANY Group

- Liebherr Group

- SCHWING Stetter GmbH

- MEKA

- Zoomlion Heavy Industry Science & Technology Co., Ltd.

- XCMG Group

- Atlas Industries

- ELKON Concrete Batching Plants

- Nilkanth Engineering Works

- Teka Maschinenbau GmbH

- Ammann Group

- BHS-Sonthofen GmbH

- Jianxin Machinery Co., Ltd.

- Gamzen Plast Private Limited

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383