MARKET OVERVIEW

The Global Stainless-Steel Electropolishing Service Market will continue to shape the future of surface finishing technologies across different industries. This will open up new avenues in applications and decision-making that are not previously imaginable. It will begin to point deeper integration with customized engineering solutions, digital fabrication processes, and high-precision manufacturing standards, beyond clear applications of medical, food processing, and semiconductor applications in the market.

The true potential of the Global Stainless-Steel Electropolishing Service Market will unfold only when material science converges with digital automation. The more advanced materials become, and the better performance requirements of these materials defined, the more micro-level, exact specs will be required for Stainless-Steel finishing. This service will help redefine how metals are used, especially in vacuum chambers, clean rooms, and specialized transport systems. It's going to become part of an extended strategy for functionality improvement, contamination reduction, maintenance, and energy consumption.

Market boundaries, too, will begin to shift as electropolishing finds a more solid place in the sustainability practices of enterprises. Already, Stainless-Steel is being touted for its recycling benefit, but with this process, it will go even further since companies will be striving to optimize lifecycle performance. Electropolishing makes materials more corrosion-resistant and lasts, but then the future would bring further reduction of the use of nature-harmful coatings and solvents in cleaning. The transition to clean manufacturing would have electropolishing in the line of technologies aligned to net-zero goals.

The future advancements in the Global Stainless-Steel Electropolishing Service Market are also set to take shape through digital twin technologies and real-time monitoring. Simulated modeling of electropolishing will be able to give companies an insight into the outcome before physical implementation to reduce waste and shorten production cycles.

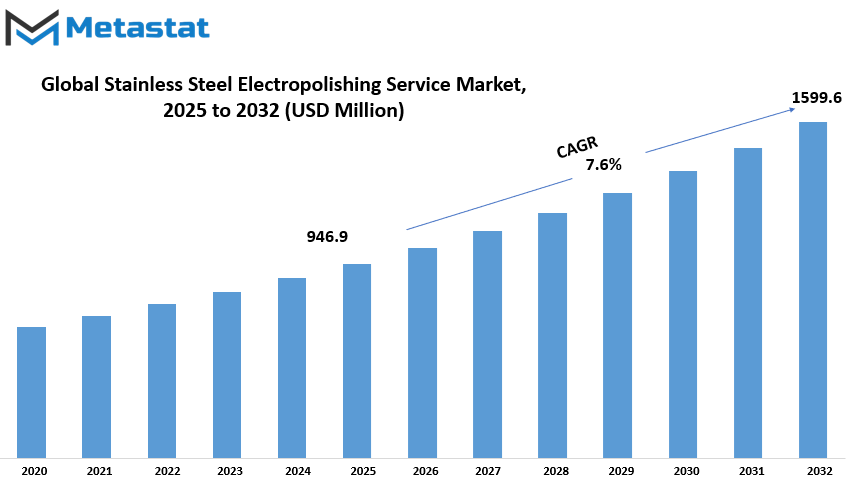

Global Stainless-Steel Electropolishing Service market is estimated to reach $1599.6 Million by 2032; growing at a CAGR of 7.6% from 2025 to 2032.

GROWTH FACTORS

The Global Stainless-Steel Electropolishing Service Market will continue to shape the future of surface finishing technologies across different industries. This will open up new avenues in applications and decision-making that are not previously imaginable. It will begin to point deeper integration with customized engineering solutions, digital fabrication processes, and high-precision manufacturing standards, beyond clear applications of medical, food processing, and semiconductor applications in the market.

The true potential of the Global Stainless-Steel Electropolishing Service Market will unfold only when material science converges with digital automation. The more advanced materials become, and the better performance requirements of these materials defined, the more micro-level, exact specs will be required for Stainless-Steel finishing. This service will help redefine how metals are used, especially in vacuum chambers, clean rooms, and specialized transport systems. It's going to become part of an extended strategy for functionality improvement, contamination reduction, maintenance, and energy consumption.

Market boundaries, too, will begin to shift as electropolishing finds a more solid place in the sustainability practices of enterprises. Already, Stainless-Steel is being touted for its recycling benefit, but with this process, it will go even further since companies will be striving to optimize lifecycle performance. Electropolishing makes materials more corrosion-resistant and lasts, but then the future would bring further reduction of the use of nature-harmful coatings and solvents in cleaning. The transition to clean manufacturing would have electropolishing in the line of technologies aligned to net-zero goals.

The future advancements in the Global Stainless-Steel Electropolishing Service Market are also set to take shape through digital twins technologies and real-time monitoring. Simulated modeling of electropolishing will be able to give companies an insight into the outcome before physical implementation to reduce waste and shorten production cycles.

MARKET SEGMENTATION

By Types

In the meantime, the global Stainless-Steel electropolishing service market has been going through an era of steady growth on account of demand generated by varied industries. Electropolishing service markets comprise various services for different purposes, enhancing surface quality, durability, and appearance of Stainless-Steel products. Among the important segments is Standard Electropolishing, presently worth $531.9 million. It is the prime technique used since it achieves a smooth and clean finish, lowers surface roughness, and minimizes corrosion. These advantages endorse its selection in applications where cleanliness and hygiene assume paramount importance, such as food processing, pharmaceuticals, and manufacture of medical equipment.

Micro-precision Electropolishing, apart from standard methods, is beginning to attract interest in an effort to achieve extremely fine surface finishes and highly controlled material removal. Such methods are typically selected for small or complex components within the electronics and aerospace industries, where even marginal imperfection can affect performance. Following is Passivation Electropolishing, advancing corrosion resistance in Stainless-Steel without altering its appearance. This method proves valuable in the case of components exposed to harsh environments, such as chemical processing and marine applications.

Another important segment is Electropolishing with Color Coding. This combines the benefits of normal electropolishing with a visual key for identifying parts or tools with color coding. It is extremely advantageous in industries requiring parts or tools to be identified rapidly during use or maintenance. This additionally benefits the efficiency of production and minimizes misplacements during handling or assembly.

Electropolishing for Welding is another niche service within this market. This service treats Stainless-Steel parts after the welding procedure in order to remove discoloration and the welding-induced oxidation from them. It ensures that the surfaces of the Stainless-Steel parts are returned to a clean, smooth condition and that the material increases corrosion and wear resistance. The welded joints then obtain the integrity of quality expected from the remainder of the component.

Such trends are putting pressures on parts in several industries, such as automotive, healthcare, construction, and electronics, for increasingly advanced Stainless-Steel components, which inevitably means higher demand for specific electropolishing services. Each service line provides a way to help manufacturers comply with stringent performance, hygiene, and safety standards. This market has great potential for growth in the future due to increased awareness and continuous technological advancements and is thus expected to swing towards more specific and efficient metal surface finishing solutions.

By Applications

Electropolishing Stainless-Steel enhances its use in the manufacturing and finishing processes. Electropolishing can be defined as a procedure to enhance the aesthetic properties and thus the life of Stainless-Steels through corrosion resistance. It encompasses the smoothing and cleaning of Stainless-Steel by the removal of a fine layer of disordered atoms on the top surface. Thus, it probably is due to these properties that many industries are now considering this method in their processing.

The market is segmented based on applications: Aerospace & Automotive, Recreational Marine, Medical & Pharmaceutical, Food & Beverage, and Household Appliance Manufacturers. In the aerospace and automotive sectors, electropolished parts that after polishing exhibit smooth unblemished surfaces are least likely to harbor contaminants. Such smoothness enhances the long-term reliability and performance of parts even under adversities.

In marine applications for recreation, unpolished Stainless-Steel is subject to corrosion due to saltwater exposure; thus, electropolishing provides protection against such detrimental corrosion damage. Afterwards, polishing gives appeal to boat manufacturers and owners concerned about design and aesthetics.

The requirement of cleanliness and hygiene is paramount for medical and pharmaceutical purposes. Therefore, electropolished surfaces allow ease in sterilization while reducing the harboring of bacteria. This proves to be advantageous for surgical instruments, implants, and manufacturing tools for medicine production. The smoother the surface, the less the chances of contamination, which in fact remains top priority in these fields.

Food and beverage industries also reap benefits of having equipment who's Stainless-Steel is easy to clean and resists corrosion. The surfaces of equipment that are electropolished help in minimizing bacterial build-up while prolonging their life span, both of which are crucial for safety and economically efficient production.

The manufacturers of household appliances are now looking at electropolishing for aesthetic improvement and reliability. A smoother surface, from the sink to washing machine drum, means fewer places for the dirt to settle in and better resistance to daily wear and tear.

In the larger picture, demand for electropolishing services is increasing with the need of the industry for better performance, durable equipment, and improved hygiene. The continued pursuit of higher quality and durability by companies in various sectors will translate into higher use of Stainless-Steel electropolishing. Such a trend highlights the increasing role of the process in helping these products achieve standards and reliability in long-term use.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$946.9 million |

|

Market Size by 2032 |

$1599.6 Million |

|

Growth Rate from 2025 to 2032 |

7.6% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

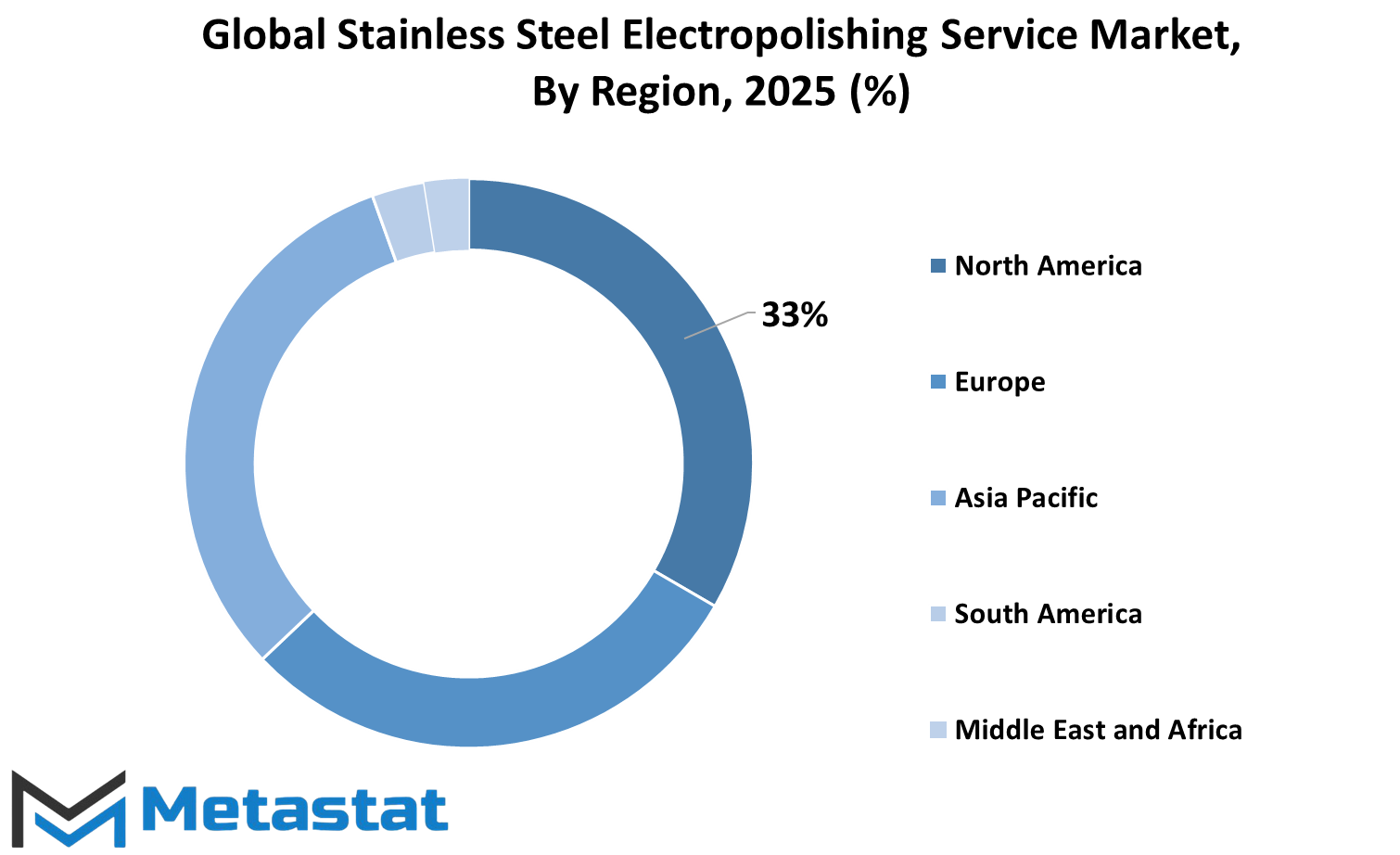

The global Stainless-Steel Electropolishing Service market is divided into key regions, which jointly help develop and grow the market. Geographically, this market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East and Africa. Under North America, the states are represented in U.S., Canada, and Mexico markets. Strong demand for this competitive market shown at this area is very much prompted hollow into well-established industries such as medical devices, food processing, and automotive manufacturing, which often require clean, smooth, and corrosion-resistant metal surfaces provided by electropolishing.

Europe is made of UK, Germany, France, Italy, and the Rest of Europe. This particular area has been advanced reasonably well, courtesy of technology and stringent laws, which promote the use of high-quality and hygienic and lifetime Stainless-Steel parts. Countries like Germany and the UK have always been manufacturing and health related, both these sectors using electropolished Stainless-Steel very much in needs within these safety and performance perspectives. Elsewise, Asia-Pacific is made of India, China, Japan, South Korea, and the Rest of Asia-Pasific, which has become one of the fastest-growing markets in electropolishing. This is because rapid industrialization is happening in China and India, and much investment goes into different industries such as electronics, pharmaceuticals, and construction-all needing electropolishing services.

On the other hand, South America consists of Brazil, Argentina, and the Rest of South America, showing a slower growth rate compared with the previously mentioned regions. Thus, growth under this region can be attributed to the development of oil-and-gas, food production, and manufacturing industries, where electropolished Stainless-Steel serves the required long-lasting quality and relatively clean surface finish. Finally, this region is the Gulf Middle East and Africa, which comprises of the GCC countries, Egypt, South Africa, and the Rest of the Middle East and Africa. The region is considered underdeveloped but demonstrates immense potential as increasing industries are demanding electropolishing in construction, energy, and water treatment sectors. Demand for electropolishing within these regions is expected to gradually thrive with the coming of new infrastructure initiatives and industrial operations.

Each of the above regions has its share in the global market. It depends on local industries and their economic growth, as well as their technological advancement. These regional differences are important for companies wishing to enter the Stainless-Steel electropolishing service market or invest in the market.

COMPETITIVE PLAYERS

The global stainless-steel electropolishing service market is slowly growing because industries are demanding cleaner, more accurate finishes on all their metal work pieces. Electropolishing is a technique through which Stainless-Steel is treated in such a way so as to dispose off a very minute layer of material on its surface and render it even smoother and shinier than before. This is done in order to reduce contamination and to improve the beneficial properties of components made from Stainless-Steel for a number of different applications. Today, electropolishing is an important procedure for cleanliness and quality standards ranging from medical devices to instrumentation for food processing.

With hygienic and strong components in mind, industries will keep on demanding more and more electropolishing services for Stainless-Steels. This electropolishing service is needed chiefly in those industries when a mere minute defect on the surface may jeopardize performance. In the medical industry, for example, Stainless-Steel tools and implants must be polished in such a smooth manner as to prevent themselves from harboring bacteria. The same applies to parts used for any work in the food and beverage industries, where surface finish will correlate with product safety and cleanliness. Electropolishing makes cleaning and maintenance easier for such parts, availing them for meeting stringent industry specifications.

Many industrial players are helping this market. Some pressure companies offering Stainless-Steel electropolishing services are Electro-Max, Inc., MPE Limited, Harrison Electropolishing L.P., AMF Technologies, Inc., and Astro Pak Corporation. Other organizations such as FZE Manufacturing Solutions LLC, Able Electropolishing Co., Inc., New England Electropolishing, Twin City Plating, Elkhorn Electropolish, Commercial Metal Polishing, and Elite Metal Finishing LLC are stimulating the industry by providing innovative technologies and excellent customer service. White Mountain Process, National Plating Company, Irving Polishing & Manufacturing, Inc., Commercial Electro Plating Inc., Celco Inc, and Southern Stainless Pty Ltd. also play a vital role in furnishing regions' industries with trusted electropolishing solutions.

The industries' adaptability to technology changes and consumer expectations will determine what the future looks like for this market. As customers continue to seek avenues for becoming more efficient and are demanding compliant quality production, electropolishing services will be one of those that fulfill such needs to an increasing extent. In turn, the continued demand for prescriptive solutions will require service providers to enhance their methods, invest in superior equipment, and customize solutions. All in all, the Stainless-Steel electropolishing service market will remain formidable, given a strong presence of industry players forging market needs in the areas of healthcare, food processing industry, manufacturing, etc.

Stainless-Steel Electropolishing Service Market Key Segments:

By Types

- Standard Electropolishing

- Micro-precision Electropolishing

- Passivation Electropolishing

- Electropolishing with Color Coding

- Electropolishing for Welding

By Applications

- Aerospace and Automotive

- Recreational Marine

- Medical and Pharmaceutical

- Food and Beverage

- Manufacturers of Household Appliances

Key Global Stainless-Steel Electropolishing Service Industry Players

- Electro-Max, Inc.

- MPE Limited

- Harrison Electropolishing L.P.

- AMF Technologies, Inc.

- Astro Pak Corporation

- FZE Manufacturing Solutions LLC

- Able Electropolishing Co., Inc

- New England Electropolishing

- Twin City Plating

- Elkhorn Electropolish

- Commercial Metal Polishing

- Elite Metal Finishing LLC

- White Mountain Process

- National Plating Company

- Irving Polishing & Manufacturing, Inc.

- Commercial Electro Plating Inc.

- Celco Inc

- Southern Stainless Pty Ltd

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252