MARKET OVERVIEW

The Global Spray Dryer market is a significant portion of the industrial drying sector. It makes a liquid or slurry material easy to turn to dry powder. The technique used here quickly helps evaporate all the liquid materials, allowing wide applications in many industries of food processing, manufacturing of drugs and chemicals, and more. However, the amount that has been spoken about regarding its operation and innovations leaves a vast expanse of a whole other world largely untouched.

Another area that is not so much spoken about is the regulatory and environmental implications associated with the industry. Governments around the world are continuously imposing stricter emission standards, and manufacturers are therefore compelled to innovate cleaner drying solutions. Sustainable practices within production facilities are no longer a choice but a necessity.

The energy-intensive nature of spray drying has also led to exploring alternative power sources, and more research is currently being done in renewable energy applications. Companies that do not meet the shifting environmental realities are likely to be hamstrung by operational problems in the short term. Another dimension often overlooked in mainstream analysis is the geopolitical determination of supply chains.

Important elements for spray drying processes, such as heat-resistant alloys and atomization technology, depend upon global trading networks. Disruptions in raw material availability or changes in trade policies can significantly impact equipment manufacturing costs and lead times. The reliance on specific regions for component production continues to raise concerns regarding supply stability, prompting businesses to diversify their sourcing strategies.

Technological convergence is gradually reshaping the industry. The integration of AI and ML to spray drying would be very embryonic yet is full of promising potential. Predictive maintenance and real-time optimization of process flows, including completely automated control, are projected to increase the effectiveness of this methodology while significantly decreasing downtime related to operations.

As Industry 4.0 models become a guiding force for productions, customised drying parameter tailoring depending upon the raw materials may eventually turn out to become a decisive choice. As automation becomes increasingly pervasive, the need for professionals qualified to manage intelligent systems will grow. Besides technology, changing consumer preferences are also affecting market dynamics.

Increasing demand for organic and clean-label food products has forced food manufacturers to rethink the ingredients and processing techniques used in their products. Spray drying, which was originally associated with mass production, is being modified to meet consumer demands for minimally processed foods. This trend is likely to open up new opportunities for equipment that can handle sensitive materials without compromising nutritional integrity.

A less explored area is the role of intellectual property in shaping competitive advantages. Patents related to nozzle design, drying chamber configurations, and airflow mechanisms continue to define market leadership. Companies investing in research and development often secure a stronghold by introducing proprietary technologies that improve efficiency or enhance product quality.

As innovation accelerates, legal battles over patented technologies may become more frequent, influencing the industry's trajectory. Looking forward, the future of the Global Spray Dryer market will be shaped by a combination of environmental factors, geopolitical changes, technological developments, and consumer-driven requirements.

The confluence of these factors is going to determine not only the production methods but also the strategic decisions of companies operating in this space. Those who can foresee and adapt to these under-researched influences will be best placed to navigate the complexities that lie ahead.

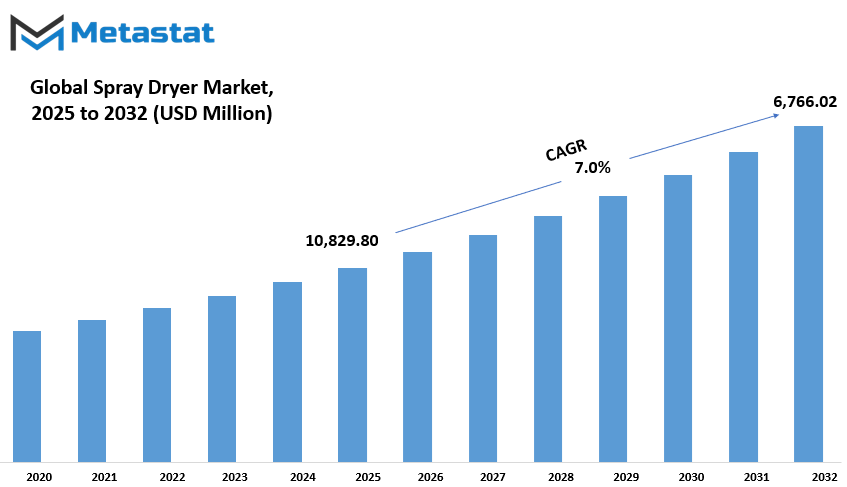

Global Spray Dryer market is estimated to reach $10,829.80 Million by 2032; growing at a CAGR of 7.0% from 2025 to 2032.

GROWTH FACTORS

Spray dryers offer growth opportunities in the global market because of increasing demand in food and pharmaceutical industries for powdered products. Preserve quality and shelf life, which is the most crucial element of preserving different products of spray drying technology, is a very critical process in the two above-mentioned sectors. With the improvement in technology, manufacturers can now process heat-sensitive materials efficiently, which was once a major problem.

The developments have ensured higher quality of products without losing efficacy in active ingredients, especially for pharmaceuticals and food additives. However, a few factors slow down the market growth. High energy consumption characterizes spray drying. This method is energy intensive as it needs to consume massive amounts of heat, making operation expensive.

For instance, where markets are highly sensitive to price, such as cost-sensitive, it becomes difficult. These costs are deterring many firms from embracing spray drying, thereby making it not very viable for smaller manufacturers. Environmental issues are also now pressing concerns. Emissions associated with spray drying have increased regulatory concerns, forcing the industries to find more environmentally friendly alternatives.

Technology must, therefore, advance and reduce the adverse effects on the environment while preserving efficiency. Although there are setbacks, this sector offers opportunities in abundance. Environmental sustainability issues drive the production of energy-efficient spray drying technologies. Companies are exploring research and development to develop such technologies that ensure lower energy intake and emission output, making it an ecofriendly process.

Improvements in spray drying could thus open its wider applications in all industries involving chemical and nutraceutical sectors which require precise high techniques for drying. Moreover, the demand for high-quality powdered products is expected to continue rising, further fueling market growth. With increasing awareness about food safety and pharmaceutical efficacy, manufacturers are focusing on producing superior products with extended shelf life.

This trend will likely encourage further improvements in spray drying techniques, ensuring that products retain their essential properties while meeting industry regulations. Overall, while high costs and environmental concerns are hurdles, advancements in energy-efficient technologies and the growing demand for powdered products are anticipated to push the spray dryer market forward. As industries continue to seek innovative and sustainable drying solutions, the market is likely to exhibit steady growth during the next couple of years.

MARKET SEGMENTATION

By Type

Demand across various industries boosts the Global Spray Dryer market. Spray drying is the procedure of rapidly evaporation of moisture from a substance in liquid form to dry powder form. Thus, this spray drying method finds extensive applications within the food, pharmaceutical, and chemical industries in which the consistency and quality of the product matters. Advancements in technology are also what have made it possible for expansion in the market, which ensures efficiency and lesser energy consumption; thus, it is widely chosen by most manufacturers. The key driver for growth in the market is the rising need for processed and convenience foods.

The rise in demand for products that last longer and do not take much space is prompting consumers to ask for spray drying products like milk powder, coffee, and flavoring agents. This technology is also crucial in the pharmaceutical industry; it is used in manufacturing medicinal drugs with accurate dosages and stable formulations.

The chemical industry finds the use of spray drying in making catalysts and detergents of especial compounds. The Global Spray Dryer market has been divided into different types: Rotary Atomizer Spray Dryers with a value of $3,037.59 million, Nozzle Atomizer Spray Dryers, Fluidized Spray Dryers, and Closed Loop Spray Dryers. Each type has its own advantages, depending on the application.

Rotary atomizer spray dryers are widely used because they can handle large volumes of liquid and produce uniform particle sizes. Nozzle atomizer spray dryers provide better control over droplet size and distribution, making them ideal for heat-sensitive products. Fluidized spray dryers are enhanced to dry efficiently with increased heat transfer. Closed-loop spray dryers are also preferred in solvent-based materials as it will be safe and environment-friendly in processing.

Some factors that will influence growth in the market are advancements in technologies, increased investment in research and development, and quality and safety products are stringently followed. The companies continuously strive to update the performance of spray dryers by bringing energy-efficient designs and automation features to the equipment. This is primarily reducing cost but adds consistency and quality to the produced product.

This, however, leaves a challenge, mainly high costs in initial investments and maintenance expenses. However, rising demand by the emerging economies and innovations of techniques in spray drying are factors expected to alleviate such challenges. Further growth for the Global Spray Dryer market is expected since more industries are opening up with improved drying technology, thus making more opportunities open to manufacturers and suppliers around the globe.

By Application

The global spray dryer market is classified based on various applications. One of the main application segments is encapsulation, in which spray drying technology encapsulates active ingredients in a protective coating. This process stabilizes sensitive compounds, prolongs their shelf life, and controls their release. Encapsulation is commonly implemented in the pharmaceutical, food, and agricultural industries, where precise control of the release of ingredients is crucial. For instance, in the pharma industry, encapsulation can be considered quite important to maintain the medicines without environmental factors effects until they get consumed.

An important application for spray dryers is in heat-sensitive material drying. This approach is especially used for materials, which would become degraded or otherwise lose their intended properties if placed under high-temperature conditions over a long term. Spray drying can evaporate water or solvents rapidly while conserving the integrity of the material. Compounds sensitive to temperature occur frequently in food production, for which maintaining the nutritional value and flavor character of the active ingredients is vital. Spray drying offers efficient technology for transforming liquids into powder without affecting the quality.

Other significant applications promoting growth in the global spray dryer market are the production of powder. This process is widely used in industries ranging from food and beverages to chemicals. Spray dryers convert liquid substances into fine powders, which can then be used in a variety of products. In the food industry, for instance, milk, coffee, and flavorings are often processed into powder form for convenience and longer shelf life. This is a huge advantage; in many sectors, spray drying is the method of choice because powders produced are of consistent quality and size.

Overall, the market for spray dryers is on the rise because various industries are continuously searching for efficient ways to process a large amount of materials. The production of encapsulation, drying of heat-sensitive materials, and powder production through spray dryers demonstrates the wide applications of this technology. It is expected that demand for high-quality powders and controlled-release stable products will continue to grow and expand the spray dryer market.

By Sales Channel

The Global Spray Dryer market is divided according to various sales channels through which these products reach the target markets. The said market is categorized into Direct Sales, Distributors, and Online Retail, as each of them has contributed to the market's shape and determinants in some way.

Direct Sales is a form of selling that is characterized by the direct interaction between manufacturers and customers. Large companies usually favor this method of selling since they have a good relationship with their customers and wish to control every step of the sales process. Companies selling directly to the consumer are able to offer personal services and establish long-term relationships.

This channel keeps a higher percentage of the sale price because no intermediary is involved. It also allows the company to inform customers accurately and provide technical support so that the right product is chosen for the need.

Distributors act as middlemen between manufacturers and end customers. They purchase the products in large quantities from manufacturers and sell them to retailers or end users. This is an important channel for the company since distributors normally have networks and experience in the local markets and therefore are in a position to reach more customers.

The distributor reduces the workload of manufacturers as far as customer relations are concerned and, therefore, the latter can concentrate on production. It also expands market reach in regions where the manufacturer does not have a direct presence or where logistics become difficult.

Online Retail is another prominent distribution channel that has expanded exponentially in the past years. The rising e-commerce portals have facilitated easy shopping for the consumers, who now can sit in their living rooms and place orders for different products.

The popularity of this channel is increasing among customers, who prefer this kind of easy and flexible buying. Manufacturers can leverage the online retail market by listing their products on the popular platforms or creating their own websites. Companies can reach customers all over the world since the geographical barriers are limited. Besides, online retail platforms provide companies with a wide range of marketing tools that can enhance visibility and attract more customers.

In conclusion, the Global Spray Dryer market is based on three sales channels: Direct Sales, Distributors, and Online Retail. Each channel has its own benefits, and together they contribute to the effective distribution of spray dryers worldwide. Direct sales offer personalized customer engagement, distributors expand market reach, and online retail provides convenience and access to a broader audience. These channels work together to ensure that spray dryers are readily available to a diverse customer base.

By End Users

The Spray Dryer market has been classified by different categories of end users. Some categories include the food and beverage industries, pharmaceuticals, chemicals, and ceramics. Spray drying is one of the most common industrial processes applied to convert liquids or slurries to dry powders in relatively rapid ways. Such a process proves to be helpful in retaining high quality and making their shelf lives longer for several products in all these industries.

Spray drying is one of the most important ways in the Food & Beverage Industry that is applied to make powdered ingredients such as milk powder, coffee, and spices. This allows companies to hold products for a long time, preserve their nutritional values, even their flavors. Also, powdered ingredients make transportation and storage easier and hence are integral to the industry.

The pharmaceutical sector also relies much on spray drying to produce powders of medicines. This technique assists in turning liquid drugs into fine, billowy powders that can easily be encapsulated or used in tablets, injections, or other pharmaceutical forms. Spray drying also assists in enhancing the stability of some drugs to remain active longer. Its high versatility in processing various pharmaceutical compounds makes it indispensable in the industry.

The use of spray dryers in the chemical industry applies to a range of applications. It can create specialty chemicals or produce fertilizers and detergents. It helps in the maintenance of chemicals' consistency but also allows for the production of materials with defined properties, including solubility and particle size. This is very essential in industries requiring precision and quality standards.

Spray drying is also used in the ceramics industry, mostly to prepare ceramic powders. This is applied to produce uniform-size and -shaped powders so that they can be applied in ceramics preparation, for instance, making of tiles and other tableware articles. The spray dried ceramic powder is able to possess the required characteristics for shaping and forming it into a final product with uniform quality.

Overall, the spray drying process is indispensable across multiple industries. The global market continues to grow as businesses seek more efficient ways to preserve, store, and transport materials in powdered form. As each sector finds new uses for spray drying, the demand for this technology will continue to rise, contributing to its widespread adoption across various fields.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$6,766.02 million |

|

Market Size by 2032 |

$10,829.80 Million |

|

Growth Rate from 2024 to 2031 |

7.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

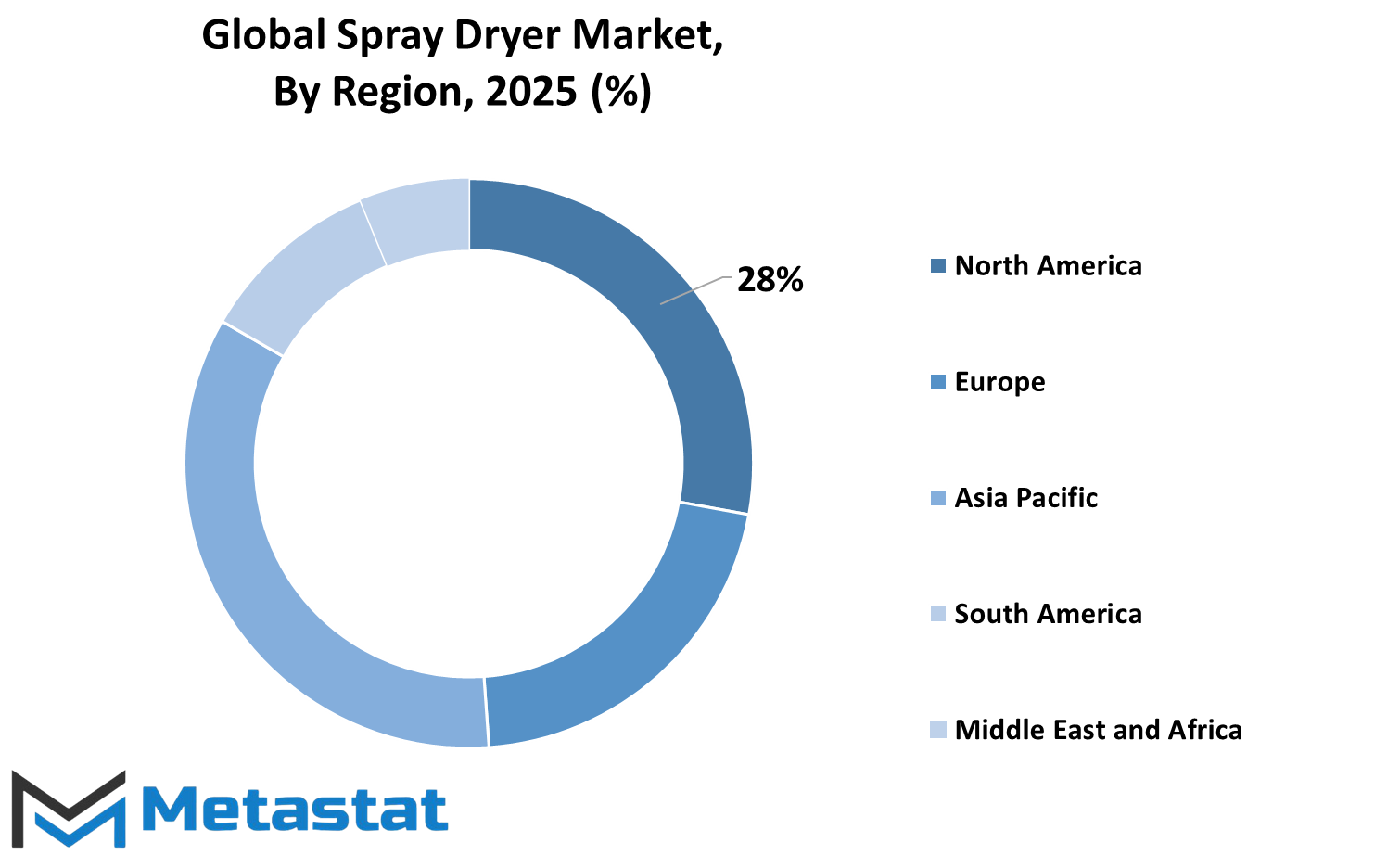

The global Spray Dryer market is segmented based on geography into several key regions: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. North America is further bifurcated into the United States, Canada, and Mexico. Europe is segmented into the United Kingdom, Germany, France, Italy, and other countries under the Rest of Europe category.

Asia-Pacific is further segmented into India, China, Japan, South Korea, and the rest in the Rest of Asia-Pacific. The South American market comprises Brazil, Argentina, and the rest in the Rest of South America. Finally, the Middle East & Africa region is split into GCC Countries, Egypt, South Africa, and the rest in the Rest of Middle East & Africa.

This segmentation allows businesses to analyze specific regions in more detail, helping them to understand market demand and growth potential in various parts of the world. North America, for example, will continue to be a significant player in the Spray Dryer market, with the United States, Canada, and Mexico contributing to overall market dynamics.

Europe, home to the UK, Germany, and France, will also witness growth in terms of technological innovation and industrial needs. Asia-Pacific, which is a rapidly growing region, is expected to face a boom in demand because of the industrializing sectors in China, India, Japan, and South Korea that will further spur the growth in the global market.

The South American Spray Dryer market, albeit smaller, shall still have significance, especially with countries like Brazil and Argentina well known for agriculture and industrial undertakings. The Middle East & Africa shall also witness moderate growth in terms of demand by the diverse GCC countries, Egypt, and South Africa, induced by industrial usage and the urge for better technologies in drying practices across various fields.

Companies may identify the different geographical segments by their business specific strategies to suit regional needs and focal challenges to exploit growth opportunities that arises in different markets. The regional analysis provides a comprehensive view of the Global Spray Dryer market, pointing out areas where demand growth will occur in the near future.

COMPETITIVE PLAYERS

The global market for spray dryer is growing very fast because, in all fields of industries, the spray drying technology is increasingly being applied for the effective conversion of liquid or slurry into dry powders. This technology particularly depends on such industries as food processing, pharmaceuticals, chemicals, and so on, on account of usage of powdered material. Demand is increasing for spray dryers because of the increasing need for drying methods that are more efficient, cost-effective, and capable of maintaining product quality while saving energy.

Key companies in the market include established names such as GEA Group, SPX Flow, and Buchi Labortechnik AG. These companies have significantly developed the spray drying technology in offering a range of solutions to cater to the various needs of their customers. GEA Group, for instance, is one of the world's leading suppliers of spray drying plants for food, pharmaceuticals, and chemical applications. The products from this company are known for being reliable, energy-efficient, and multifaceted.

Other equally influential players in the market are Dedert Corporation, Yamato Scientific Co., Ltd., and European Spraydry Technologies (EST) Ltd. They also play critical roles in developing spray dryers with a variety of capacities and other technological features customized to meet specific customer demands. Their equipment finds widespread application, including powdered milk production, coffee, and vitamins.

Companies like ACMEFIL Engineering Systems, Shandong Tianli Energy Co., Ltd. and New AVM Systech Pvt. Ltd. remain innovators of the field providing specific spray dryers for special industries. Like Shandong Tianli Energy Co., Ltd. specializes on solutions that result in energy efficiency for drying process while New AVM Systech Pvt. Ltd. develops customizable spray dryers for the pharmaceutical and food sectors.

Other key players in the global market for spray dryer are Labplant UK Ltd., Spray Drying Systems Inc., and Freund Corporation. These firms are dedicated to developing spray drying technologies, increasing product quality, and enhancing efficiency in general.

In response to the increased demand for quality spray dryers, these companies will likely drive the future of the industry. Their innovations in spray drying technology will improve industries' production processes, reduce energy consumption, and meet the rising demand for high-quality powdered products. Competition between these players is expected to spur further developments in spray dryer technology, which will offer businesses a more efficient and versatile solution around the world.

Spray Dryer Market Key Segments:

By Type

- Rotary Atomizer Spray Dryers

- Nozzle Atomizer Spray Dryers

- Fluidized Spray Dryers

- Closed Loop Spray Dryers

By Application

- Encapsulation

- Drying of Heat-Sensitive Materials

- Powder Production

By Sales Channel

- Direct Sales

- Distributors

- Online Retail

By End Users

- Food & Beverage Industry

- Pharmaceuticals

- Chemicals

- Ceramics

Key Global Spray Dryer Industry Players

- GEA Group

- SPX Flow

- Buchi Labortechnik AG

- Dedert Corporation

- Yamato Scientific Co., Ltd.

- European Spraydry Technologies (EST) Ltd

- ACMEFIL Engineering Systems

- Shandong Tianli Energy Co., Ltd.

- New AVM Systech Pvt. Ltd.

- Labplant UK Ltd.

- Spray Drying Systems Inc.

- Freund Corporation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252